Key Highlights:

- Tracking forklift hours is crucial for scheduling maintenance, preventing unexpected breakdowns.

- Regular maintenance can reduce forklift incidents, with 70% potentially preventable through better strategies.

- Monitoring usage allows for accurate cost management, impacting project budgets and timelines.

- Adhering to safety regulations is essential, as overutilized forklifts can lead to accidents.

- Analysing usage patterns helps optimise fleet management and reduce idle time, enhancing productivity.

- Consistent monitoring extends the lifespan of forklifts and aids in timely replacements.

- Methods for tracking hours include manual logs, operational metres, telematics systems, mobile apps, RFID, GPS monitoring, and fleet management software.

- Data analysis can identify utilisation patterns, predict maintenance needs, and assess performance metrics.

- Establishing a routine for tracking includes daily checks, weekly reviews, monthly maintenance meetings, and operator training.

- A feedback loop for operators enhances the tracking process and promotes continuous improvement.

Introduction

Tracking forklift hours is not just a routine task; it plays a vital role in enhancing project efficiency and safety within construction and manufacturing settings. By grasping the nuances of forklift hour tracking, organizations can create opportunities for improved maintenance scheduling, effective cost management, and adherence to safety regulations. Yet, a significant challenge persists: how can companies successfully implement and utilize these tracking methods to optimize performance and reduce risks? This article explores the essential practices and tools required to master forklift hours tracking, ensuring that operations are conducted smoothly and efficiently.

Understand the Importance of Tracking Forklift Hours

Tracking forklift hours is essential for several reasons:

-

Maintenance Scheduling: Regular tracking helps determine when maintenance is due, preventing unexpected breakdowns. For instance, if the forklift hours accumulate to 500, it may require a service check to ensure optimal performance. According to OSHA, 70% of forklift incidents could have been prevented with better safety strategies, underscoring the importance of proactive maintenance.

-

Cost Management: Monitoring usage allows project managers to allocate costs more accurately, ensuring that budgets reflect actual equipment usage. This leads to better financial decisions regarding equipment rental or purchase. Notably, the average recovery time for forklift injuries is 13 days, which can significantly impact project budgets and timelines.

-

Safety Compliance: Tracking forklift hours assists in ensuring adherence to safety regulations. Overutilized lifting vehicles may fail to meet safety standards, resulting in potential accidents. A single forklift has a 90% chance of being involved in a serious accident during its service life, highlighting the need for diligent forklift hours tracking.

-

Performance Optimization: Understanding usage patterns facilitates improved fleet management, ensuring that lifting vehicles are utilized efficiently and minimizing idle time. This optimization can significantly enhance overall project productivity.

-

Lifespan Extension: Consistent monitoring of usage aids in forecasting when a lifting machine is nearing the end of its effective life, allowing for timely replacements and reducing operational interruptions. Additionally, employee turnover can result from forklift accidents, leading to increased recruitment costs, making it crucial to maintain a safe operating environment.

![]()

Explore Methods and Tools for Tracking Hours

There are several methods and tools available for tracking forklift hours, each offering distinct advantages:

-

Manual Logs: Operators can maintain a manual logbook to document time after each shift. While straightforward, this method is susceptible to human error. Statistics show that manual logs can lead to inaccuracies, with up to 63% of companies acquiring new lifting equipment every 12-24 months due to inadequate management of existing tools.

-

Operational Meters: Most lift trucks come equipped with meters that automatically monitor operation. Regularly checking these meters provides precise information on forklift hours, ensuring fleet managers have a reliable basis for performance evaluation.

-

Advanced telematics systems enable real-time monitoring of forklift hours, including time spent, location, and performance metrics. As Brad Butler notes, "Knowledge is power, as they say, and equipment telemetry is the source of that knowledge." These systems can integrate with fleet management software, offering comprehensive insights that enhance decision-making and operational efficiency.

-

Mobile Applications: Various mobile applications designed for equipment monitoring allow operators to log forklift hours directly from their smartphones, streamlining the process and improving data collection accuracy.

-

RFID and GPS Monitoring: Implementing RFID tags or GPS systems provides accurate tracking of lift vehicle movements and operations, enhancing visibility and accountability. This technology ensures effective equipment utilization, thereby reducing idle times.

-

Fleet Management Software: Software solutions that consolidate data from multiple sources can simplify the monitoring process. For example, a case study on optimizing lift usage illustrates how establishing work rotations can reduce competition for vehicles, ultimately boosting productivity. These platforms offer analytics and reports that aid in decision-making regarding fleet management and resource allocation.

By leveraging these tools, organizations can significantly enhance their tracking capabilities, leading to improved productivity and reduced operational costs.

![]()

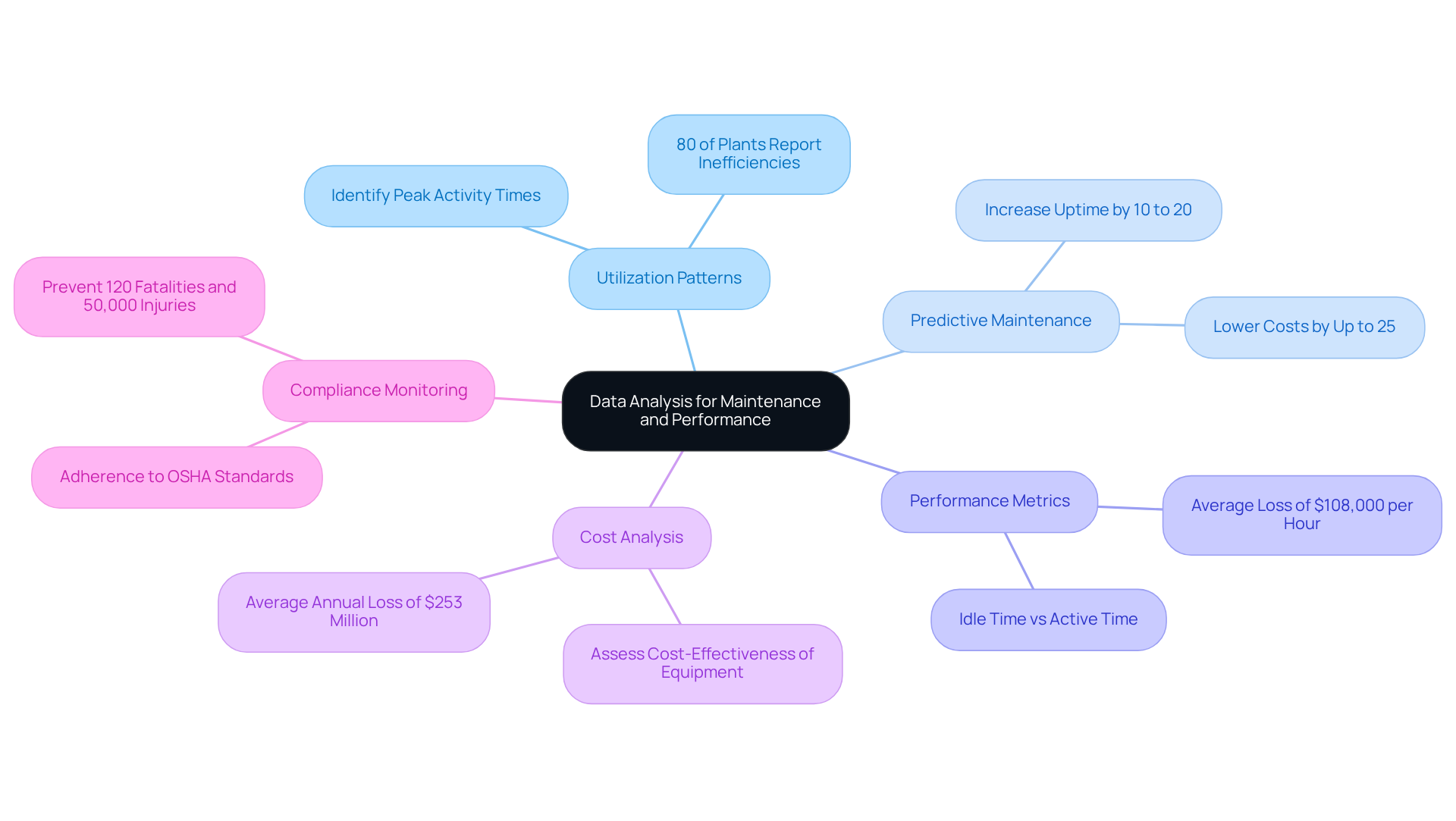

Analyze Tracked Data for Maintenance and Performance Insights

Optimizing performance through data analysis is essential by tracking forklift hours.

-

Identify Utilization Patterns: By reviewing forklift hours, managers can pinpoint peak activity times and adjust staffing or equipment allocation accordingly. This strategic adjustment is vital, especially since 80% of manufacturing plants report that aging equipment or machine breakdowns are leading causes of operational inefficiency.

-

Predictive Maintenance: Analyzing usage trends allows for predicting when maintenance is necessary, facilitating scheduled downtime instead of unexpected repairs. Predictive maintenance can lower costs by up to 25% and increase uptime by 10% to 20%, making it a crucial strategy for construction project managers.

-

Performance Metrics: Evaluating metrics such as idle time versus active time helps identify inefficiencies. For example, if a lifting device remains inactive for long periods, it may indicate a need for improved task distribution. Tracking these metrics is critical, as facilities lose an average of $108,000 each time period due to unplanned downtime, underscoring the importance of effective performance assessment.

-

Cost Analysis: The data can also be used to assess the cost-effectiveness of each lifting machine. Understanding which units underperform can inform decisions about whether to repair or replace equipment. Large manufacturing plants, on average, lose $253 million annually due to unplanned downtime, highlighting the financial implications of maintenance decisions.

-

Compliance Monitoring: It is essential to ensure that all lifting vehicles comply with safety regulations by reviewing maintenance records in relation to operational time. Adhering to OSHA's lockout tagout (LOTO) standards is crucial for safety, as it is estimated to prevent 120 fatalities and 50,000 injuries each year. This diligence not only helps avoid penalties but also enhances safety, fostering a safer working environment.

Establish a Routine for Regular Tracking and Review

Establishing a routine is essential to ensure effective tracking of forklift hours.

-

Daily Checks: Operators should implement a daily routine to record their time at the end of each shift. This practice can be integrated into a pre-shift checklist, promoting compliance and accuracy in tracking.

-

Weekly Reviews: It is important to schedule weekly reviews of the tracked data to identify trends and address any discrepancies. This process may involve comparing manual logs with time meter readings to ensure consistency.

-

Monthly Maintenance Meetings: Monthly maintenance meetings should be held to discuss maintenance needs based on the forklift hours tracked. This approach ensures that all team members are informed about equipment status and upcoming maintenance schedules.

-

Training Sessions: Regular training for operators on the importance of precise monitoring and effective use of monitoring tools is crucial. This fosters a culture of accountability and enhances overall operational efficiency.

-

Feedback Loop: Establishing a feedback loop allows operators to report issues or suggest improvements to the tracking process. This mechanism ensures continuous enhancement of the system, contributing to better tracking and maintenance practices.

![]()

Conclusion

Tracking forklift hours is essential for enhancing project efficiency and safety. By closely monitoring usage, organizations can ensure optimal maintenance, manage costs effectively, comply with safety regulations, and extend the lifespan of their equipment. The insights gained from tracking forklift hours not only improve operational efficiency but also contribute to a safer working environment.

This guide has highlighted the importance of tracking forklift hours through various lenses, including:

- Maintenance scheduling

- Cost management

- Safety compliance

- Performance optimization

- Lifespan extension

We have explored different methods and tools for tracking, from manual logs to advanced telematics systems, each offering unique advantages for data collection and analysis. Establishing a routine for regular tracking and review is crucial, as it fosters accountability and operational excellence.

Ultimately, effective tracking of forklift hours transcends mere compliance; it represents a strategic approach that can lead to significant improvements in productivity and safety. Organizations are encouraged to adopt these best practices and leverage technology to enhance their tracking capabilities. By prioritizing forklift hours monitoring, businesses can safeguard their operations and drive long-term success in their projects.

Frequently Asked Questions

Why is tracking forklift hours important?

Tracking forklift hours is important for maintenance scheduling, cost management, safety compliance, performance optimization, and extending the lifespan of the equipment.

How does tracking forklift hours help with maintenance scheduling?

Regular tracking helps determine when maintenance is due, preventing unexpected breakdowns. For example, a forklift may require a service check after accumulating 500 hours to ensure optimal performance.

What role does forklift hour tracking play in cost management?

Monitoring usage allows project managers to allocate costs accurately, ensuring budgets reflect actual equipment usage, which leads to better financial decisions regarding equipment rental or purchase.

How does tracking forklift hours contribute to safety compliance?

It helps ensure adherence to safety regulations by identifying overutilized lifting vehicles that may fail to meet safety standards, thus reducing the risk of accidents.

What is the likelihood of a forklift being involved in a serious accident?

A single forklift has a 90% chance of being involved in a serious accident during its service life, highlighting the importance of diligent tracking of forklift hours.

In what way does tracking forklift hours optimize performance?

Understanding usage patterns facilitates improved fleet management, ensuring that lifting vehicles are utilized efficiently and minimizing idle time, which can enhance overall project productivity.

How does consistent monitoring of forklift hours extend the lifespan of the equipment?

It aids in forecasting when a lifting machine is nearing the end of its effective life, allowing for timely replacements and reducing operational interruptions.

List of Sources

- Understand the Importance of Tracking Forklift Hours

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Tracking Forklift Hour Meter Readings - SIERA.AI (https://siera.ai/blog/tracking-forklift-hour-meter-readings)

- Tracking Equipment Hours in Construction (https://buildlogic.com.au/the-power-of-tracking-equipment-hours-in-construction)

- How data insights improve forklift fleet management decisions? (https://solidealonsiteservice.com/how-data-help-you-make-better-decisions-forklift-fleet-management)

- Benefits of Forklift Asset Management Systems (https://totalwarehouse.com/blogs/benefits-of-forklift-asset-management-systems)

- Explore Methods and Tools for Tracking Hours

- How data insights improve forklift fleet management decisions? (https://solidealonsiteservice.com/how-data-help-you-make-better-decisions-forklift-fleet-management)

- Revolutionize Your Warehouse With the Power of Forklift Telemetry (https://sstlift.com/blog/revolutionize-warehouse-forklift-telemetry)

- Data-Driven Decision Making: Leveraging Telematics for Fleet Optimization - MH Equipment (https://mhequipment.com/blog/data-driven-decision-making-leveraging-telematics-for-fleet-optimization)

- How to TRULY Calculate Forklift Utilization and Optimize Your Fleet (https://midcoforklift.com/blog/how-many-forklifts-do-i-need-right-sizing-forklift-fleet)

- Track your forklift utilization to make key MHE decisions (https://onetrack.ai/playbooks/forklift-fleet-utilization)

- Analyze Tracked Data for Maintenance and Performance Insights

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- 10 Maintenance Statistics that Drive Your KPI Selection (https://dynaway.com/blog/10-maintenance-statistics-that-drive-your-kpi-selection)

- 25 maintenance stats you need for 2026: Predictive maintenance data, AI trends, and more (https://stacker.com/stories/business-economy/25-maintenance-stats-you-need-2026-predictive-maintenance-data-ai-trends)

- Establish a Routine for Regular Tracking and Review

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- 7 Vital Equipment Service Metrics To Look Out For (https://fieldequip.com/equipment-servicing-and-maintenance-crucial-metrics-to-check)

- Maintenance Statistics: Predictive & Preventive, Labor & Costs (https://upkeep.com/learning/maintenance-statistics)

- 6 Surprising Stats About Tool Tracking | Link Labs | Blog (https://link-labs.com/blog/6-surprising-stats-about-tool-tracking)

- 7 Equipment Utilization Metrics You Should Be Tracking (https://gocodes.com/asset-tracking/equipment-utilization-metrics)