Key Highlights:

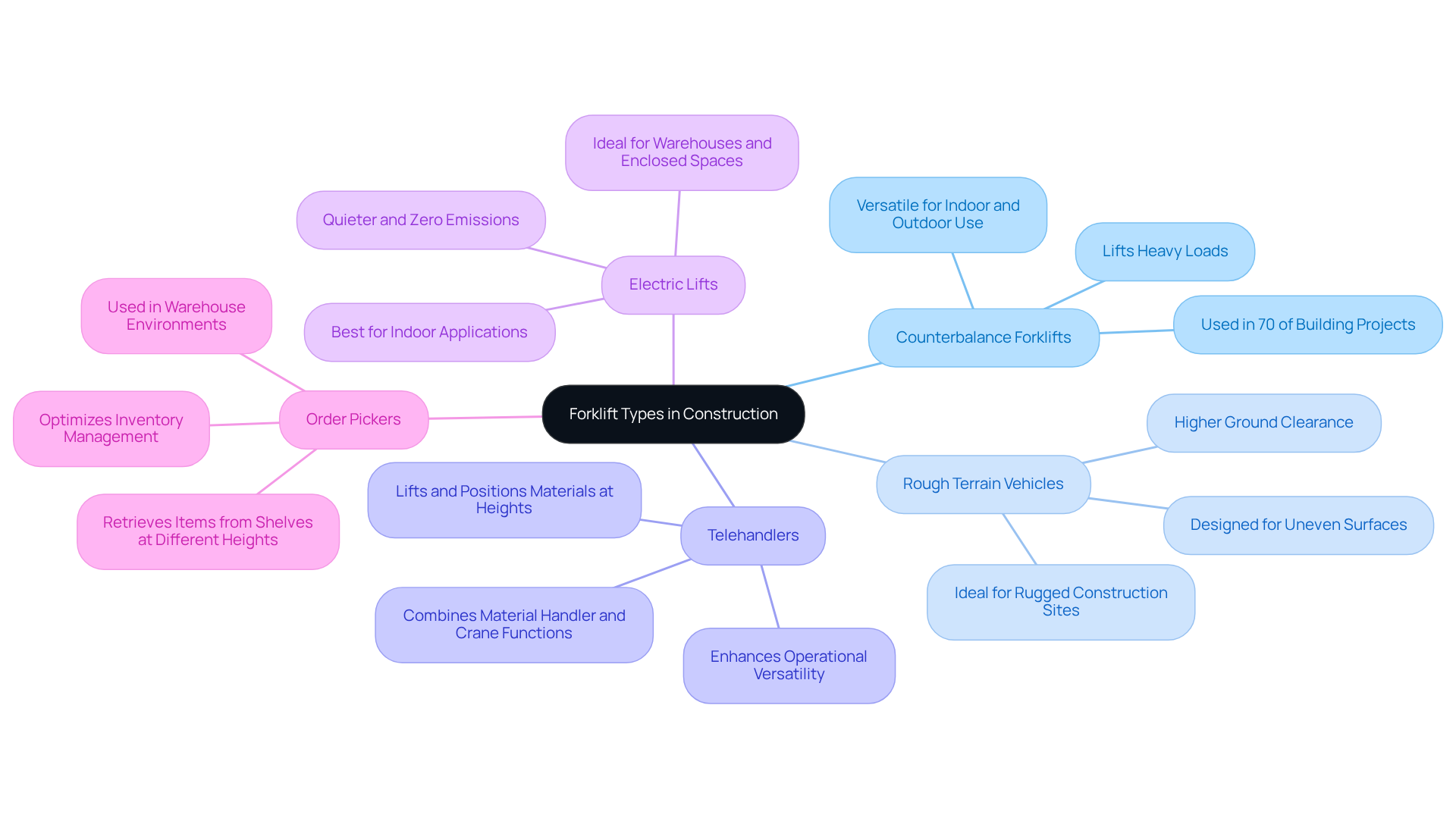

- Various types of forklifts are used in construction, including counterbalance, rough terrain vehicles, telehandlers, electric lifts, and order pickers, each serving specific operational needs.

- Counterbalance forklifts are the most widely used, accounting for approximately 70% of building projects due to their versatility.

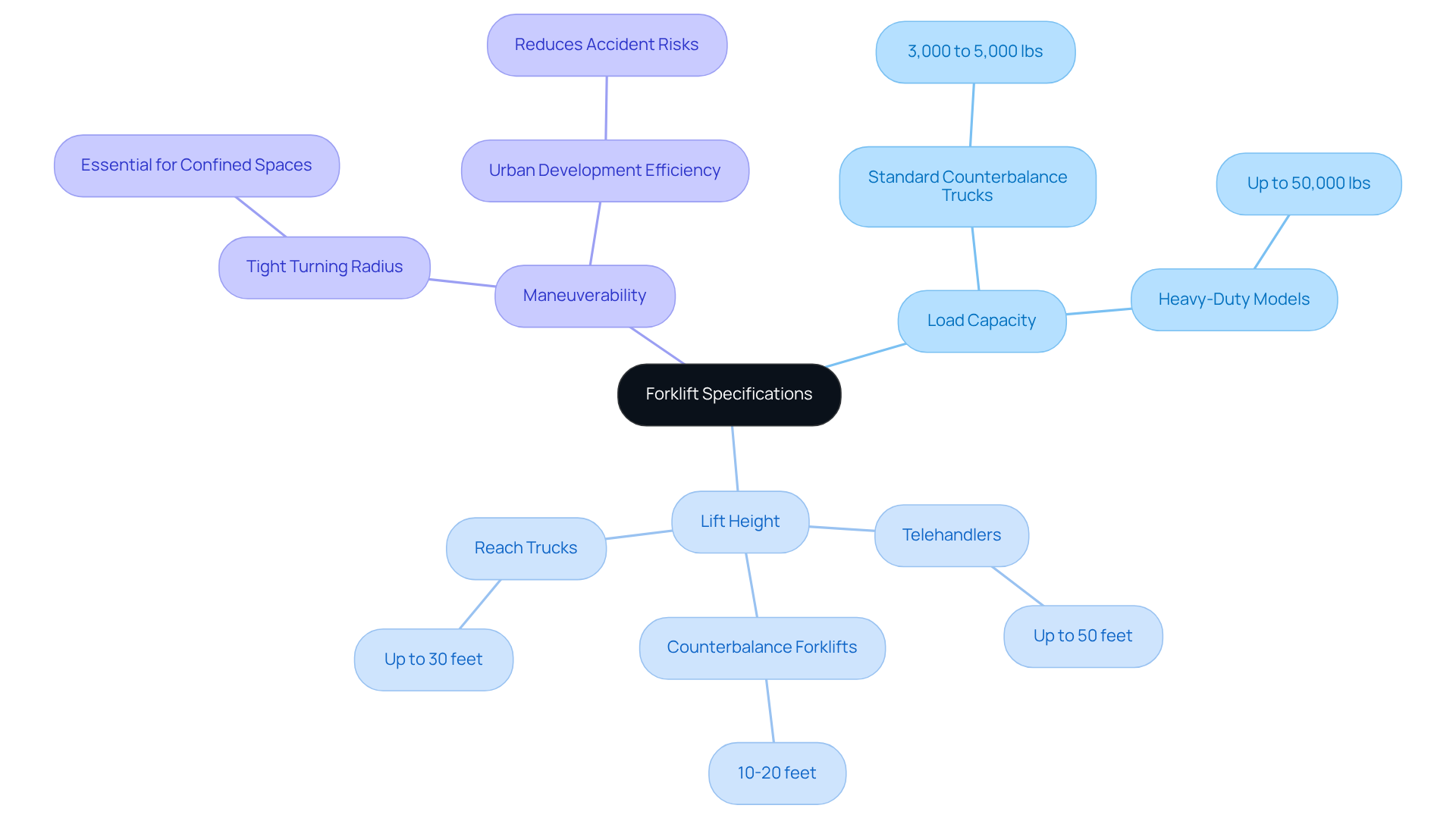

- Key specifications for selecting forklifts include load capacity (3,000 to 50,000 pounds), lift height (up to 50 feet for telehandlers), and manoeuvrability in tight spaces.

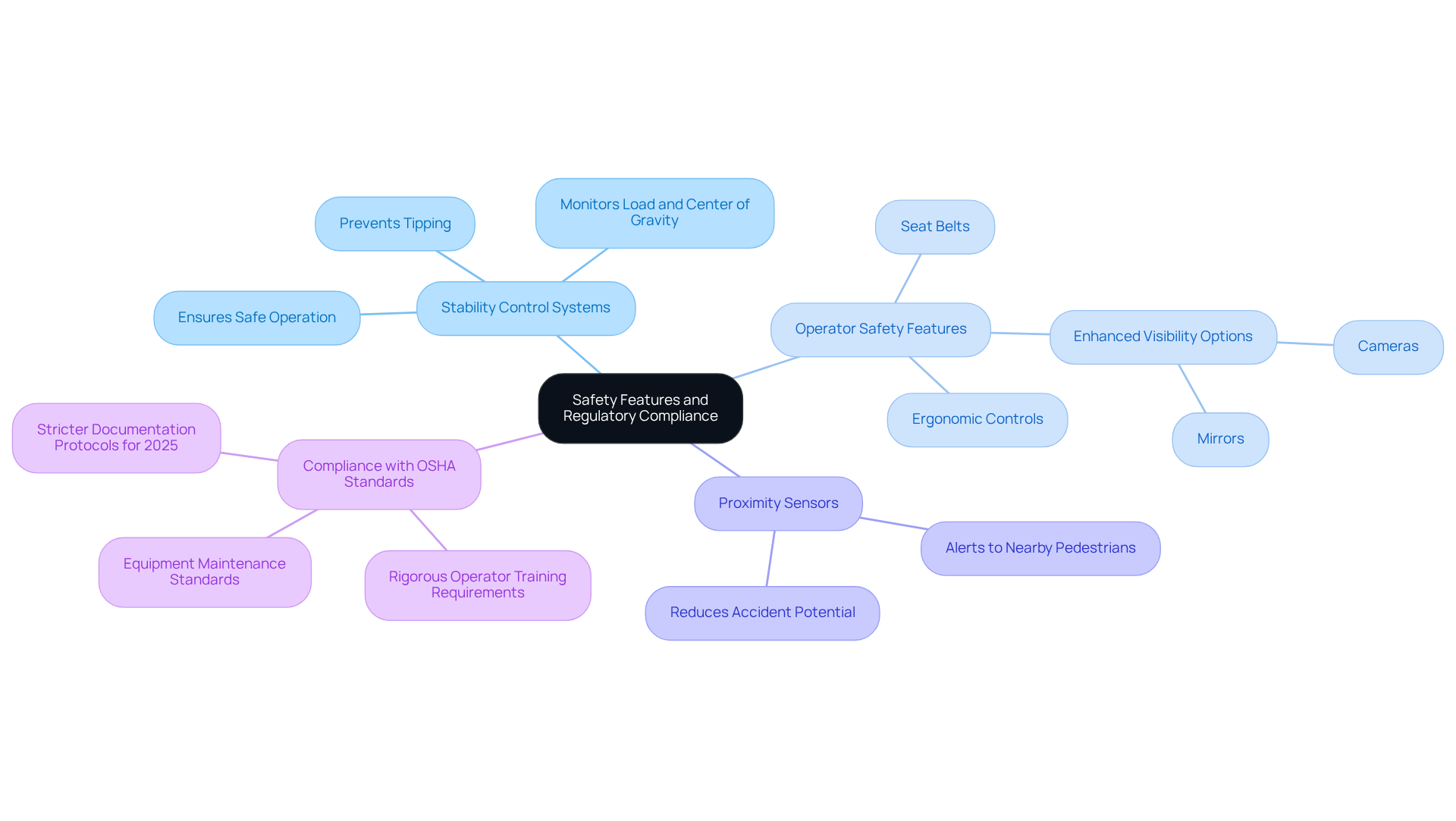

- Safety features are critical, such as stability control systems, operator safety features, proximity sensors, and compliance with OSHA standards to reduce accident risks.

- Forklift incidents account for about 11% of physical injuries in warehouses, highlighting the importance of safety measures.

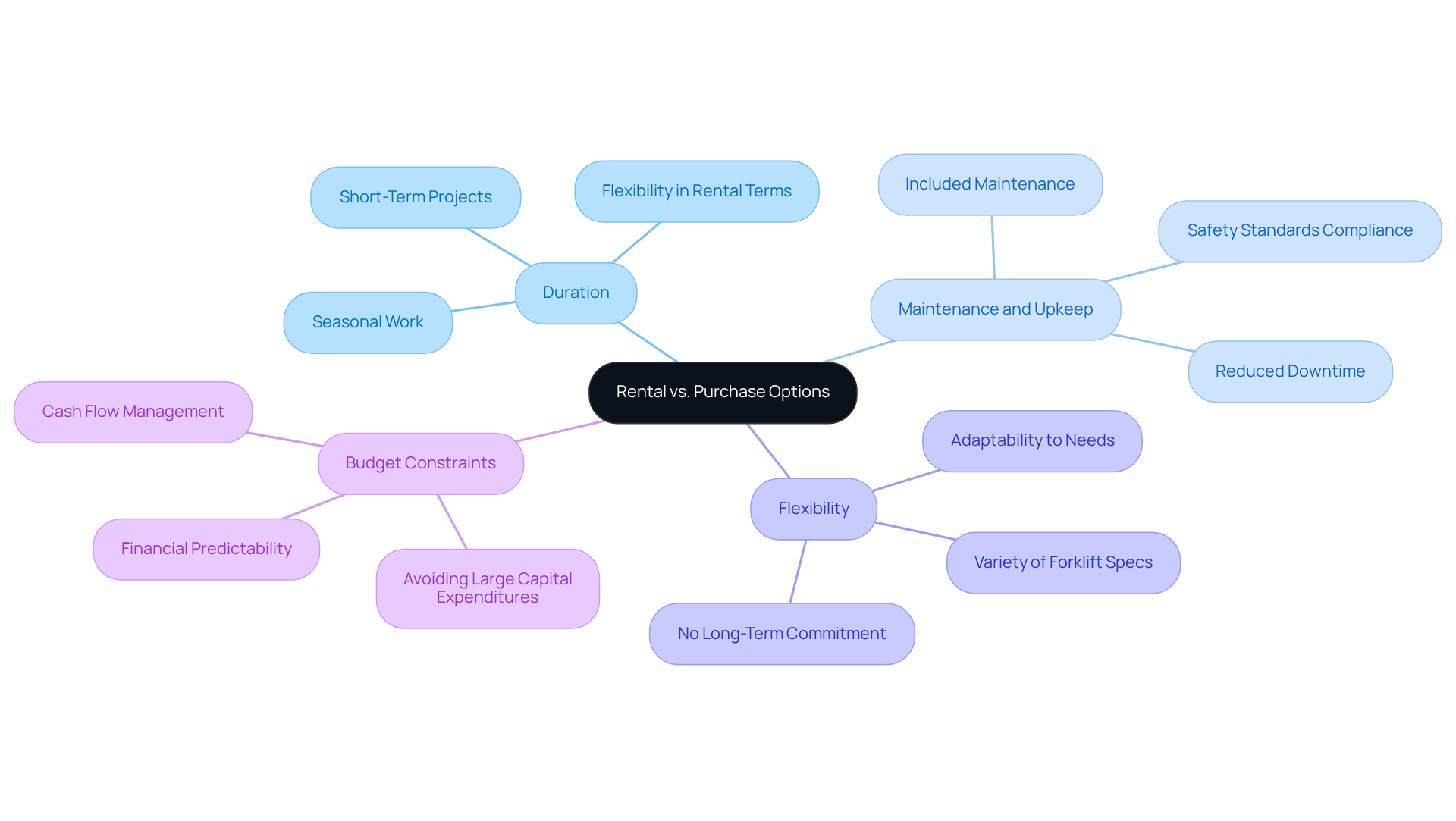

- When deciding between renting or purchasing forklifts, consider project duration, maintenance support, flexibility in equipment options, and budget constraints.

- Rental agreements can provide economic advantages for short-term projects, allowing for flexibility without long-term financial commitment.

Introduction

In the dynamic construction industry, selecting the right lifting equipment is crucial for a project's success. With various forklift types available, including versatile counterbalance forklifts and rugged rough terrain vehicles, construction managers must understand their specific applications to enhance productivity and safety.

However, with numerous options and specifications to consider - such as load capacity, lift height, and safety features - how can managers ensure they choose the right equipment for their unique project requirements?

This article explores essential insights and best practices for mastering forklift specifications, empowering construction professionals to navigate the complexities of equipment selection with confidence.

Understand Forklift Types and Their Applications in Construction

In the construction sector, various types of lifting equipment are utilized, each designed for specific tasks and settings. Understanding these types is crucial for selecting the right equipment to optimize productivity and safety. The most common forklift types include:

- Counterbalance Forklifts: These versatile machines are suitable for both indoor and outdoor use, capable of lifting heavy loads and transporting materials across flat surfaces. Approximately 70% of building projects employ counterbalance lift trucks due to their versatility and effectiveness.

- Rough Terrain Vehicles: Specifically designed for outdoor operations on uneven surfaces, these machines feature larger tires and higher ground clearance, making them ideal for rugged construction sites.

- Telehandlers: Merging the capabilities of a material handler and a crane, telehandlers are essential for lifting and positioning materials at considerable heights, thereby improving operational versatility on job sites.

- Electric Lifts: Best suited for indoor applications, electric lifts are quieter and produce zero emissions, making them perfect for warehouses and enclosed spaces where air quality is a concern.

- Order Pickers: Mainly utilized in warehouse environments, these machines allow operators to effectively retrieve items from shelves at different heights, optimizing inventory management.

By thoroughly grasping the particular uses of each type of lift, site managers can make informed decisions that significantly enhance both efficiency and safety at the work location.

Evaluate Key Specifications: Load Capacity, Height, and Maneuverability

When selecting a forklift for construction projects, it is essential to evaluate the forklift specs.

Load Capacity: This specification refers to the maximum weight a lifting machine can safely raise. It is crucial to choose a lift truck with a load capacity that exceeds the heaviest materials you plan to handle. For example, standard counterbalance lift trucks typically have capacities ranging from 3,000 to 5,000 pounds, while heavy-duty models can lift up to 50,000 pounds, catering to various construction tasks.

Lift Height: The maximum height a lifting truck can reach is another critical factor. Depending on your project requirements, you may need a forklift capable of lifting materials to significant heights. Telehandlers, for instance, can reach up to 50 feet, making them ideal for tasks that require elevated access to materials or equipment.

Maneuverability: In tight building sites, effective maneuverability is vital. Forklifts with a smaller turning radius can navigate confined spaces more efficiently, reducing the risk of accidents and enhancing overall operational efficiency. This is particularly important in urban development settings where space is limited.

By thoroughly assessing the forklift specs, project managers can ensure they select the appropriate lifting equipment tailored to their specific needs, ultimately enhancing efficiency and safety on the work site.

Prioritize Safety Features and Regulatory Compliance

Safety is paramount when selecting a lifting vehicle for construction projects. Key safety features to consider include:

- Stability Control Systems: These systems are vital for preventing tipping by continuously monitoring the vehicle's load and center of gravity, ensuring safe operation even in challenging conditions.

- Operator Safety Features: Essential components such as seat belts, ergonomic controls, and enhanced visibility options - like cameras and mirrors - are crucial for protecting operators and minimizing risks.

- Proximity Sensors: These sensors alert operators to nearby pedestrians or obstacles, significantly reducing the potential for accidents in busy work environments.

- Compliance with OSHA Standards: Ensuring that the forklift adheres to the latest OSHA regulations is imperative. These regulations include rigorous operator training requirements and equipment maintenance standards. The revised OSHA standards for 2025 highlight stricter documentation and training protocols, reinforcing the need for thorough protective measures. Forklift incidents account for approximately 11% of all physical injuries in warehouses and factories, underscoring the essential requirement for these protective features. Furthermore, lift trucks lead to around 7,500 injuries and nearly 100 deaths each year, emphasizing the significance of prioritizing safety in lift truck operations.

By prioritizing these safety features and ensuring compliance with regulations, construction managers can create a safer work environment and significantly reduce the risk of accidents.

Consider Rental vs. Purchase Options Based on Project Needs

When deciding whether to rent or purchase a forklift, several key factors warrant careful consideration:

-

Duration: Renting often proves to be the most economical choice for short-term projects, allowing companies to sidestep the significant initial costs associated with purchasing equipment. For example, businesses involved in seasonal work can rent forklifts during peak times, ensuring they only incur costs when the equipment is actively needed. As David Cox points out, "Rental agreements provide near-ultimate flexibility and customization that can be tailored to any individual business’ requirements."

-

Maintenance and Upkeep: A major advantage of renting is that maintenance and service support are typically included in rental agreements. This arrangement reduces downtime and unexpected repair expenses, which is vital for construction managers striving to keep projects on track. Regular maintenance ensures that the equipment remains in optimal condition, enhancing safety and efficiency on the job site. Industry insights reveal that "Rental companies maintain equipment in top condition, meeting the latest safety standards."

-

Flexibility: Renting provides unparalleled adaptability, enabling construction managers to choose from various forklift specs tailored to specific needs. This flexibility ensures that the appropriate equipment is available for diverse tasks, from heavy lifting to material handling, without the long-term commitment of ownership. As Amelia Woodley highlights, "The rental industry itself is intrinsically sustainable, promoting circularity through the practice of renting items instead of single-use purchases."

-

Budget Constraints: Renting can significantly aid in managing cash flow, particularly for projects with tight budgets. By avoiding large capital expenditures, businesses can redirect funds to other essential areas, such as labor or materials. This financial predictability is crucial for effective project management. Recent statistics indicate that rental penetration has reached 56.4%, underscoring a growing trend in the industry that supports the financial benefits of renting over purchasing.

In conclusion, by thoughtfully evaluating these factors and integrating insights from industry experts, construction managers can make informed decisions that align with their project requirements and financial limitations, ultimately leading to more efficient and cost-effective operations.

Conclusion

Understanding the details of forklift specifications is essential for construction managers who aim to enhance project efficiency and safety. By exploring the various types of forklifts, their load capacities, lift heights, and safety features, construction professionals can make informed decisions that align with their specific project needs. The insights shared in this article underscore the importance of selecting the right equipment to optimize operations on construction sites.

Key considerations include:

- The type of forklift suited for different tasks

- The critical specifications that impact performance

- The necessity of safety features

These elements highlight the comprehensive approach required when managing lifting equipment. Additionally, the discussion on rental versus purchase options provides valuable guidance for managing budgets and ensuring operational flexibility. Such insights are crucial for effectively navigating the complexities of construction projects.

Ultimately, prioritizing the right forklift specifications not only contributes to improved productivity but also fosters a safer work environment. As the construction industry evolves, staying informed about the latest standards and practices, including safety regulations and equipment rental trends, is imperative. Construction managers are encouraged to leverage these insights to make strategic decisions that enhance both operational efficiency and safety on their job sites.

Frequently Asked Questions

What are the main types of forklifts used in construction?

The main types of forklifts used in construction include Counterbalance Forklifts, Rough Terrain Vehicles, Telehandlers, Electric Lifts, and Order Pickers.

What are Counterbalance Forklifts and where are they used?

Counterbalance Forklifts are versatile machines suitable for both indoor and outdoor use. They can lift heavy loads and transport materials across flat surfaces and are used in approximately 70% of building projects.

What are Rough Terrain Vehicles designed for?

Rough Terrain Vehicles are specifically designed for outdoor operations on uneven surfaces. They feature larger tires and higher ground clearance, making them ideal for rugged construction sites.

What is the purpose of Telehandlers in construction?

Telehandlers combine the capabilities of a material handler and a crane, allowing for the lifting and positioning of materials at considerable heights, thus improving operational versatility on job sites.

When are Electric Lifts most suitable for use?

Electric Lifts are best suited for indoor applications as they are quieter and produce zero emissions, making them ideal for warehouses and enclosed spaces where air quality is a concern.

What role do Order Pickers play in construction or warehouse environments?

Order Pickers are mainly utilized in warehouse environments, allowing operators to effectively retrieve items from shelves at different heights, which optimizes inventory management.

Why is it important for site managers to understand the different types of lifts?

Understanding the particular uses of each type of lift enables site managers to make informed decisions that significantly enhance both efficiency and safety at the work location.

List of Sources

- Understand Forklift Types and Their Applications in Construction

- 119 Construction Quotes that Hit the Nail on the Head | BigRentz (https://bigrentz.com/blog/construction-quotes?srsltid=AfmBOormrlpRh08Rb79hCaFgoYGwp2sN0t73JcBooUIgMgEnCwwrelKD)

- Forklift Statistics and Facts (2026) (https://news.market.us/forklift-statistics)

- Different Types of Forklifts - ROYAL (https://ryforklift.com/blog/different-types-of-forklifts.html)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- Evaluate Key Specifications: Load Capacity, Height, and Maneuverability

- Forklift Statistics and Facts (2026) (https://news.market.us/forklift-statistics)

- US Forklift Market Size, Industry Trends & Share Report 2025 - 2030 (https://mordorintelligence.com/industry-reports/us-forklift-market)

- Understanding Lift Heights and Choosing the Right Forklift (https://forkliftselect.com/blogs/news/understanding-lift-heights-and-choosing-the-right-forklift)

- How High Can Your Forklift Go? (https://zonemfc.com/forklift-lifting-height)

- Navigating Forklift Capacity: Key Considerations for Operations (https://linde-mh.us/insights/articles/forklift-capacity)

- Prioritize Safety Features and Regulatory Compliance

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Warehouse Safety Statistics 2026: Injury Rates, Risks and Prevention Tips (https://blog.oshaonlinecenter.com/warehouse-safety-statistics)

- Consider Rental vs. Purchase Options Based on Project Needs

- Forklift Rental vs. Purchase: A Comparative Analysis (https://atlanticforkliftservices.com/forklift-rental-vs-purchase-a-comparative-analysis)

- 10 ‘food for thought’ quotes on equipment rental in 2024 (https://internationalrentalnews.com/news/words-of-wisdom-of-2024-so-far-10-quotes-providing-food-for-thought/8038427.article)

- The Benefits of Forklift Rentals for Short-Term and Long-Term Projects (https://programminginsider.com/the-benefits-of-forklift-rentals-for-short-term-and-long-term-projects)

- Top Reasons to Consider a Forklift on Rent for Your Business Needs (https://aaaforklifts.com/blogs/news/top-reasons-to-consider-a-forklift-on-rent-for-your-business-needs?srsltid=AfmBOoodONn6pBwFC6aMutBxwtgoPsbXP2gg1s9G_tYZWqzH6HpYry-b)