Key Highlights:

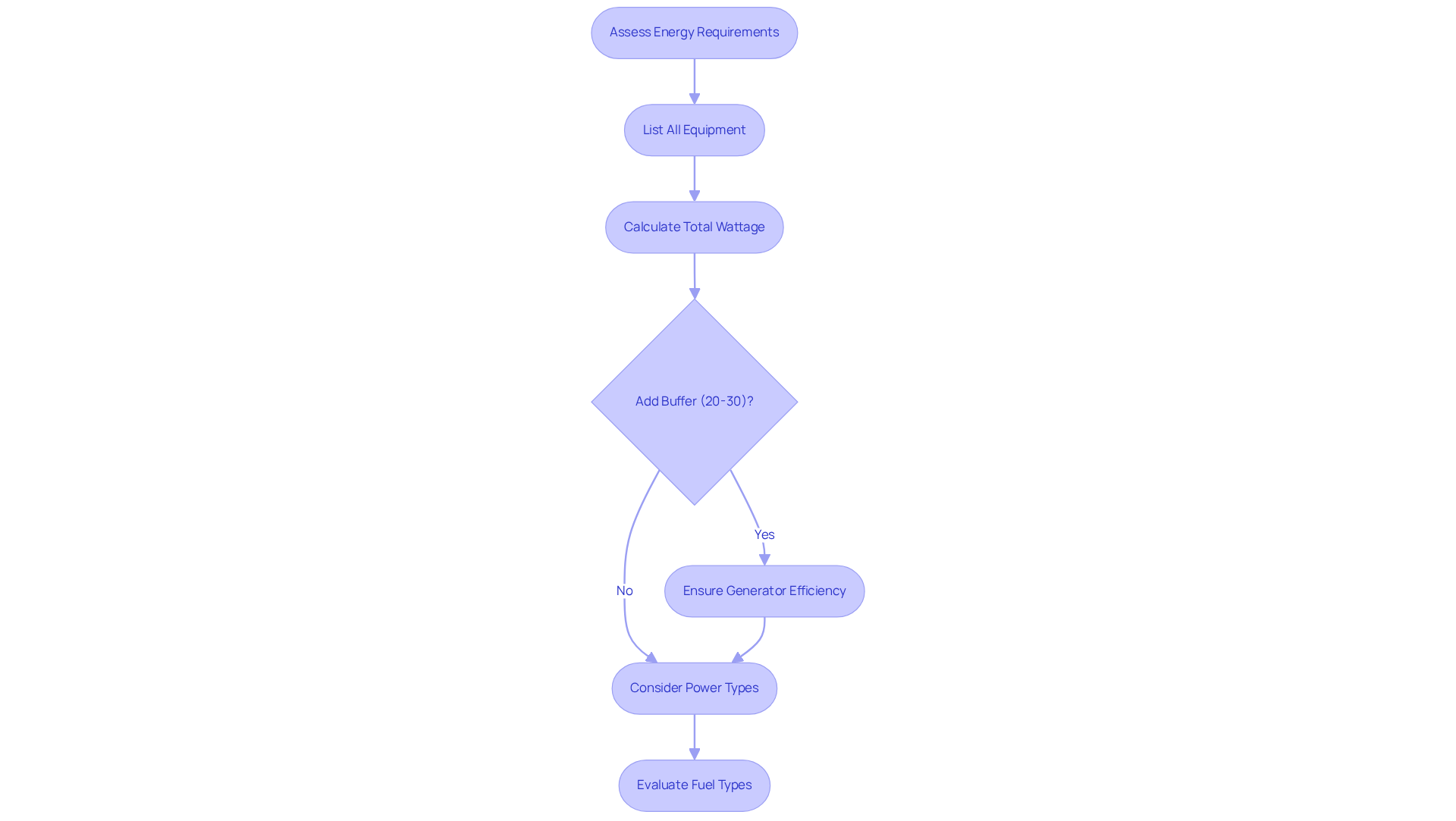

- Begin by listing all equipment and calculating total wattage to determine energy needs, including a buffer of 20-30% for surges.

- Understand the type of power required (single-phase vs. three-phase) for different tools and machinery.

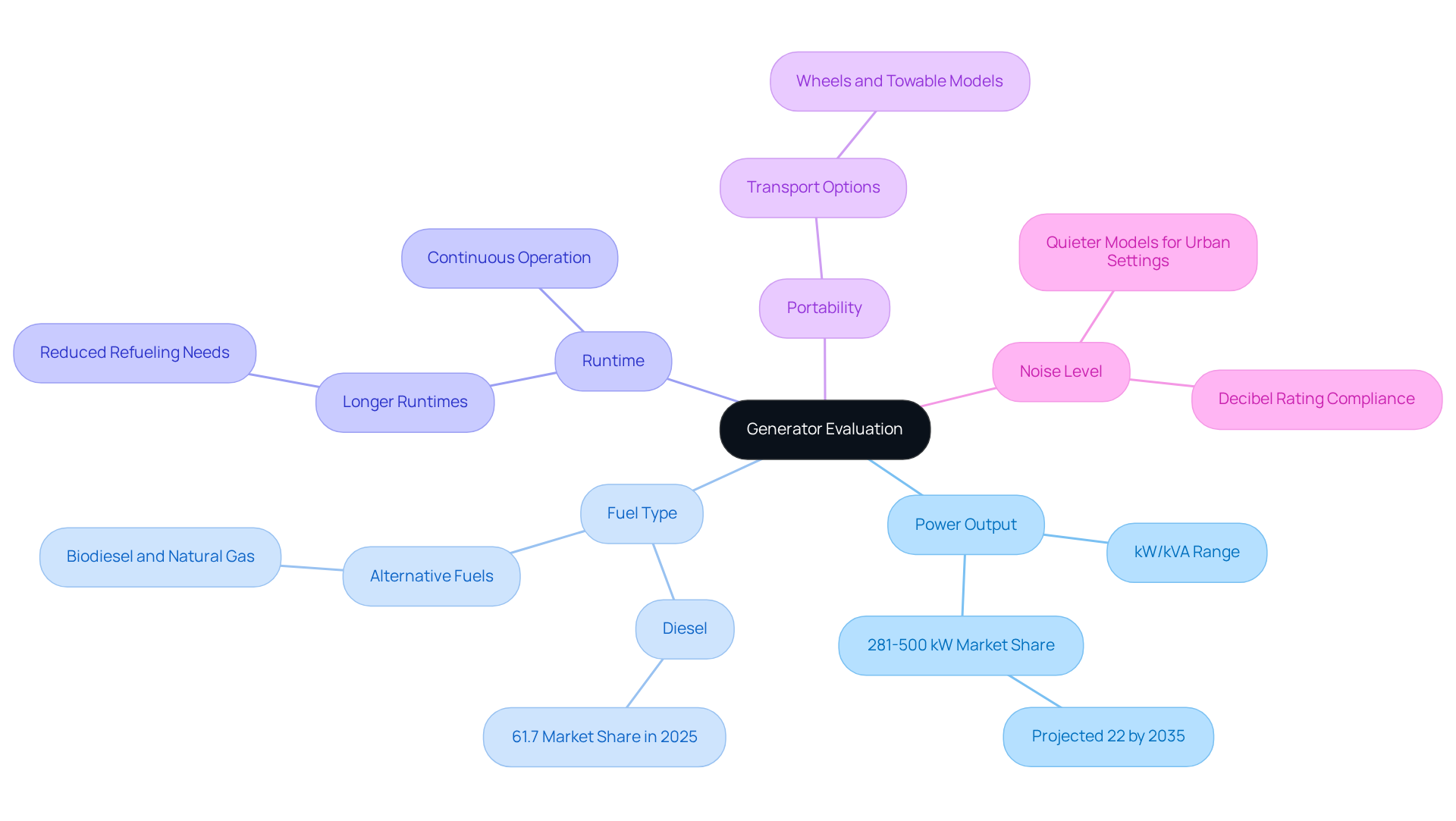

- Evaluate generator specifications such as power output, fuel type (preferably diesel), runtime, portability, and noise level for compliance.

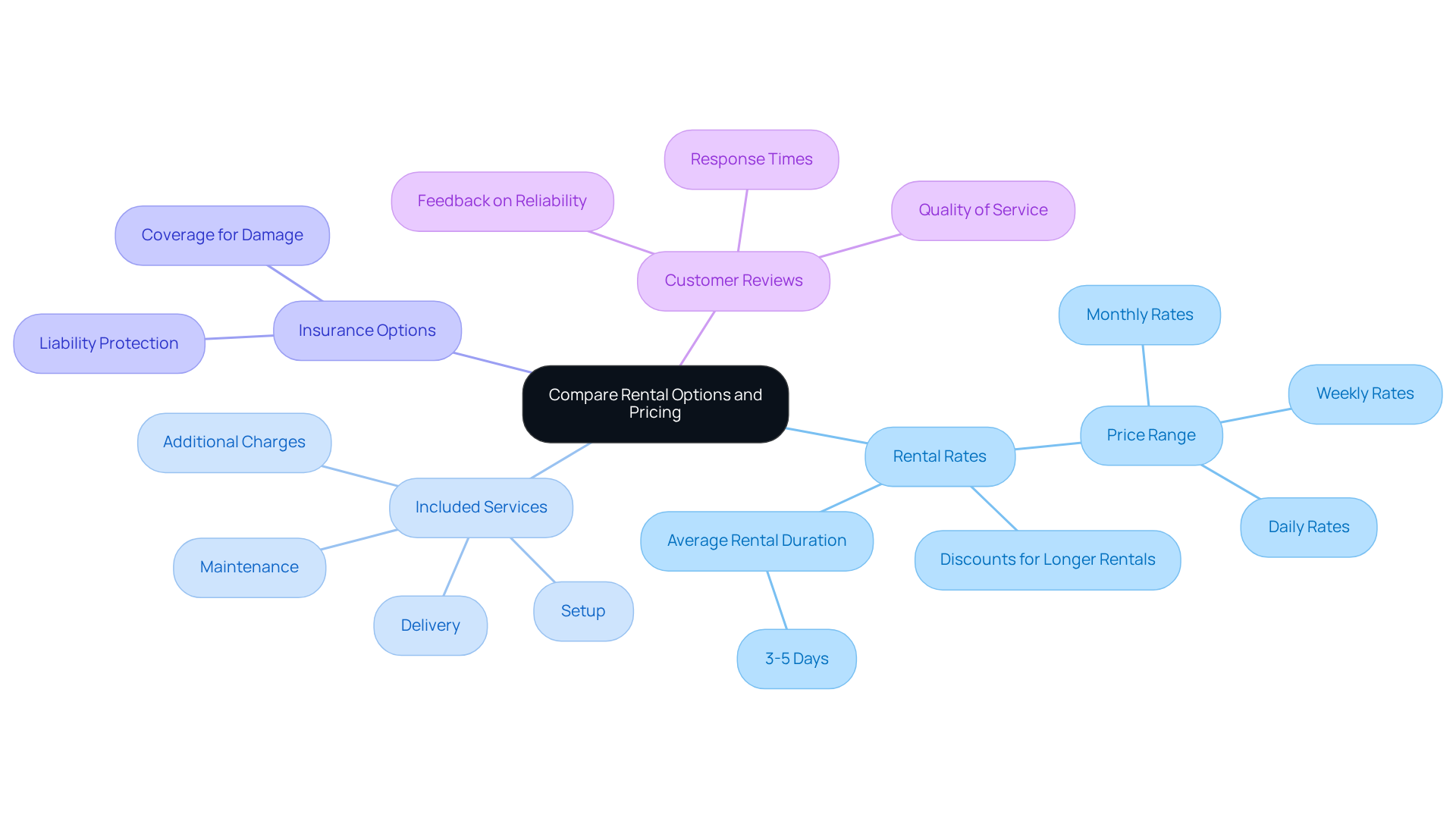

- Rental rates for industrial generators range from $50 to $300 per day, with discounts for longer leases; assess included services and insurance options.

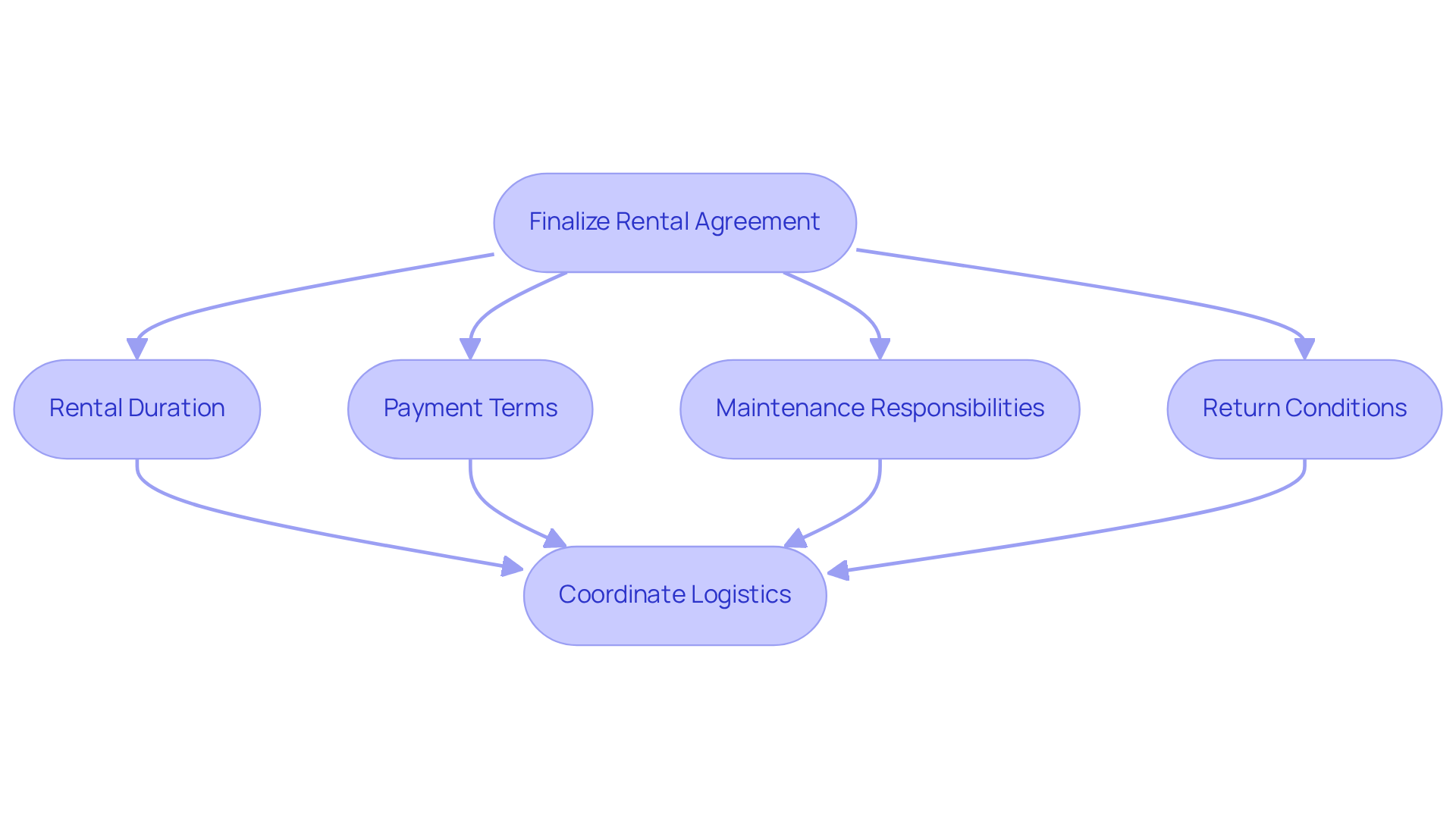

- Before finalising a rental agreement, clarify rental duration, payment terms, maintenance responsibilities, and return conditions to avoid unexpected issues.

Introduction

Understanding the complexities of industrial generator rental is crucial for the success of any construction project. Construction sites require dependable power sources to ensure operations run seamlessly. Therefore, assessing energy needs, evaluating generator specifications, and navigating rental agreements are essential skills for project managers.

With a multitude of options and variables to consider, how can you make the right choice without overspending or facing operational challenges? This guide outlines the key steps and considerations for mastering industrial generator rentals, empowering you to make informed decisions that boost productivity and efficiency on-site.

Understand Your Power Needs for the Project

Assessing Your Energy Requirements

To accurately determine your energy needs, begin by listing all equipment that will be utilized on-site, including tools, lighting, and HVAC systems. Calculate the total wattage by summing the wattage of each piece of equipment. For instance, if a concrete mixer requires 1,500 watts to start and 1,000 watts to operate, alongside other tools needing 2,000 watts, your total energy requirement would be 3,500 watts. It's prudent to add a buffer of 20-30% to accommodate any additional equipment or unexpected surges, ensuring the generator operates efficiently without risking overload. Consulting the owner's manual or a professional electrician can provide further guidance on precise calculations.

Understanding Power Types

Furthermore, consider the type of energy required: single-phase or three-phase. Most construction sites rely on three-phase power for heavy machinery, while smaller tools typically function on single-phase power. Understanding these distinctions is crucial for selecting the appropriate power source size and type for your project. For example, a central air conditioner with a 24,000 BTU rating requires 4,950 watts to start and 3,800 watts to run, underscoring the necessity for meticulous wattage calculations to prevent operational issues. Additionally, be aware that inadequate capacity for starting wattage can result in tripped breakers and equipment failure.

Ensuring Smooth Operations

By thoroughly evaluating your energy needs and considering the typical fuel types for machines - diesel, gas, or propane - you can ensure that your equipment meets both continuous and peak energy demands. This careful planning facilitates smooth operations on-site, minimizing disruptions and enhancing productivity. Don't hesitate to reach out to professionals for assistance in making these critical calculations.

Evaluate Generator Specifications and Features

When evaluating generators for construction projects, it’s crucial to focus on several key specifications that ensure you make an informed choice:

-

Power Output: Confirm that the generator's output, measured in kW or kVA, meets or exceeds your calculated power needs. The most commonly utilized power sources in construction activities typically range from 125 kVA to 750 kVA. Notably, the 281-500 kW category is projected to capture a 22% market share by 2035, effectively addressing mid-range energy requirements.

-

Fuel Type: Diesel power sources are often the preferred choice due to their efficiency and durability, accounting for approximately 61.7% of the market share in 2025. While alternatives like gasoline and propane exist, diesel remains dominant, particularly for heavy-duty applications. Additionally, the growing trend of eco-friendly building practices is leading to the adoption of power sources that utilize alternative fuels such as biodiesel and natural gas, which help reduce emissions and environmental impact.

-

Runtime: Evaluate the generator's runtime on a full tank. Longer runtimes reduce the need for frequent refueling, which is especially beneficial for large-scale projects where downtime can be costly. Generators designed for continuous operation are essential for maintaining productivity on-site.

-

Portability: Depending on your site layout, you may require a power source that is easy to transport. Look for models equipped with wheels or towable options, enhancing mobility and adaptability across various job sites.

-

Noise Level: Some projects may impose strict noise restrictions, making it vital to check the generator's decibel rating for compliance. Recent advancements in design have led to quieter models, which are increasingly favored in urban construction settings.

By thoroughly evaluating these specifications, you can select a generator that not only meets your energy needs but also aligns with your project requirements, ensuring operational efficiency and compliance with site regulations. Considering that power outages cost the United States an estimated USD 18 billion to USD 33 billion annually, the importance of reliable power sources in construction cannot be overstated.

Compare Rental Options and Pricing

Navigating the equipment leasing market effectively starts with a thorough investigation of local leasing firms, such as EZ Equipment Rental. Understanding their services is crucial. Here are key factors to consider:

-

Rental Rates: Get acquainted with daily, weekly, and monthly rates. The prices for industrial generator rental typically range from $50 to $300 per day, depending on size and capacity. Larger generators usually come with higher leasing costs, and the average rental duration is around 3-5 days. Many companies offer discounts for longer leasing periods, which can significantly reduce your overall expenses.

-

Included Services: Evaluate whether the lease covers essential services like delivery, setup, and maintenance. Some providers may charge extra for these services, so it’s vital to clarify what’s included in the leasing agreement. Remember, additional services such as delivery and installation can increase your total costs.

-

Insurance Options: Don’t forget to ask about insurance coverage for the generator during the rental period. This coverage protects you from liability in case of damage, providing peace of mind while using the equipment. Given the potential financial impact of extended power outages, having insurance is a critical consideration.

-

Customer Reviews: Look for feedback from previous clients about the reliability and quality of service offered by the company. Positive testimonials, especially those praising excellent service and quick response times, can provide valuable insights into the company’s reputation and customer satisfaction.

Additionally, keep in mind that July and August are peak months for industrial generator rental, which can affect availability and pricing. By carefully comparing these factors, you can make an informed decision that balances cost with quality of service, ensuring your construction projects are powered efficiently and effectively.

Finalize Your Rental Agreement and Logistics

Before finalizing your rental agreement, it’s essential to review several key elements that can significantly impact your experience:

- Rental Duration: Clearly specify the start and end dates of the rental period. Understand the conditions for extending the lease if necessary to avoid any surprises down the line.

- Payment Terms: Confirm the total leasing cost, including any deposits or additional fees. Ensure you are fully aware of the payment schedule to manage your budget effectively.

- Maintenance Responsibilities: Clarify who is responsible for maintenance and repairs during the rental period. Leasing industrial generator rental from a reputable firm like EZ Equipment Rental ensures you receive well-maintained power sources and forklifts. Their equipment undergoes regular maintenance, significantly reducing the risk of breakdowns during critical operations. Furthermore, their dedicated team provides comprehensive support, addressing any issues promptly to minimize downtime.

- Return Conditions: Understand the conditions for returning the device, including any cleaning or refueling requirements to avoid additional charges.

Once the agreement is finalized, coordinate logistics for delivery and setup. Provide the rental company with the site location and any specific access requirements. Effective logistics coordination is crucial to ensure that the industrial generator rental is operational when needed, which enhances project efficiency and reliability.

Conclusion

Mastering the process of industrial generator rental is crucial for the success of construction projects. By accurately assessing power needs and evaluating generator specifications, project managers can select the right equipment to keep operations running smoothly. This strategic approach not only enhances productivity but also mitigates the risks associated with power outages and equipment failures.

Key considerations include:

- Calculating total wattage requirements

- Understanding different power types

- Evaluating generator features such as fuel type, runtime, and noise levels

Furthermore, thoroughly comparing rental options and understanding costs are essential steps in finalizing agreements with clear terms. Each of these factors plays a vital role in selecting a reliable power source that aligns with project demands.

Investing time and effort into mastering industrial generator rental can lead to significant benefits, including cost savings, increased efficiency, and reduced downtime. As the construction industry evolves, prioritizing reliable power solutions remains a critical component of successful project management. Taking action now to implement these strategies will ensure that future construction projects are powered effectively, paving the way for seamless operations and enhanced outcomes.

Frequently Asked Questions

How do I determine my energy requirements for a project?

To determine your energy requirements, list all equipment that will be used on-site, including tools, lighting, and HVAC systems. Calculate the total wattage by summing the wattage of each piece of equipment. It’s advisable to add a buffer of 20-30% to accommodate any additional equipment or unexpected surges.

Why is it important to add a buffer to the total wattage calculation?

Adding a buffer of 20-30% ensures that the generator operates efficiently without risking overload. This helps accommodate any additional equipment or unexpected surges in power demand.

What types of power should I consider for my project?

You should consider whether you need single-phase or three-phase power. Most construction sites use three-phase power for heavy machinery, while smaller tools typically operate on single-phase power.

Can you give an example of wattage requirements for equipment?

For instance, a concrete mixer may require 1,500 watts to start and 1,000 watts to operate, while other tools might need 2,000 watts. This results in a total energy requirement of 3,500 watts.

What happens if I don't account for starting wattage?

Inadequate capacity for starting wattage can lead to tripped breakers and equipment failure, disrupting operations on-site.

How can I ensure smooth operations with my energy needs?

By thoroughly evaluating your energy needs and considering the typical fuel types for machines-diesel, gas, or propane-you can ensure that your equipment meets both continuous and peak energy demands, minimizing disruptions and enhancing productivity.

Should I consult a professional for energy calculations?

Yes, consulting the owner's manual or a professional electrician can provide further guidance on precise calculations and help ensure that your energy needs are accurately assessed.