Key Highlights:

- Choosing the right jackhammer involves assessing the type of work (light, medium, heavy-duty) and selecting appropriate electric, pneumatic, or hydraulic models.

- Heavier jackhammers deliver greater impact energy; a 90 lb tool is more effective for substantial demolition than a 60 lb model.

- Bit selection is crucial; chisel bits are best for concrete, while pointed bits work better for rock, enhancing efficiency.

- Portability is important; electric models are lighter and easier to manoeuvre, making them suitable for dynamic work environments.

- Reviewing rental agreements is essential to avoid unexpected fees and understand costs related to logistics, damage, and usage limits.

- Negotiating rental terms can lead to discounts, especially for long-term rentals or repeat customers.

- Daily inspections of jackhammers can prevent costly downtime due to machinery failure, which can be significant in construction.

- Regular lubrication and cleaning of jackhammers extend their lifespan and ensure optimal performance.

- Engaging with rental professionals for tailored advice and participating in training can enhance operational efficiency and project outcomes.

- Networking with industry peers can provide valuable insights and practical solutions for equipment usage and project management.

Introduction

Selecting the right jackhammer for your construction project is crucial, yet it can often feel overwhelming. With a myriad of equipment types, rental agreements, and maintenance requirements, project managers face a complex landscape that can significantly affect both budget and efficiency. To navigate this terrain successfully, it’s essential to employ effective strategies that streamline the rental process and maximize productivity. This article explores vital practices for selecting, renting, and maintaining jackhammers, equipping project managers with the knowledge needed to make informed decisions and enhance project execution.

Understanding the various types of jackhammers available is the first step in ensuring a successful project. Each type offers unique benefits tailored to specific tasks, from lightweight models ideal for smaller jobs to heavy-duty options designed for more demanding applications. By recognizing the strengths of each tool, project managers can select the right equipment that aligns with their project needs, ultimately leading to improved efficiency and reduced downtime.

Furthermore, establishing clear rental agreements is paramount. These agreements should outline not only the terms of use but also maintenance responsibilities and support options. By securing reliable rental partners, project managers can ensure that they have access to well-maintained equipment, minimizing the risk of unexpected breakdowns. This proactive approach not only saves time but also enhances overall project reliability.

In addition, incorporating testimonials from satisfied customers can significantly bolster confidence in the chosen equipment. Hearing firsthand accounts of reliability and performance can reassure project managers that they are making the right choice. Statistics showcasing the success rates of specific jackhammers in similar projects can further reinforce this trust, making the decision-making process smoother.

To wrap up, the key to successful jackhammer selection and rental lies in informed decision-making and strategic planning. By understanding the available options, establishing clear agreements, and leveraging customer insights, project managers can enhance their project execution. Don’t hesitate-take action today to ensure your next construction project is equipped with the right tools for success.

Select the Right Jackhammer for Your Project Needs

Choosing a jackhammer rental as the right tool for breaking concrete is crucial for your project's success. It requires a careful evaluation of your specific needs. Here are key considerations:

- Type of Work: Determine if your tasks are light, medium, or heavy-duty. Electric tools are perfect for smaller jobs, while pneumatic or hydraulic models excel in larger demolition tasks, ensuring both efficiency and effectiveness.

- Weight and Impact Energy: Heavier demolition tools provide greater impact energy, essential for breaking tough materials like concrete. For instance, a 90 lb power tool delivers significantly more force than a 60 lb version, making it more suitable for substantial demolition tasks. Notably, electric demolition hammers are robust enough for 90% of demolition tasks, which is why many contractors favor them.

- Bit Selection: Selecting the right bit type is vital for optimal performance. Chisel bits are ideal for concrete, while pointed bits are better for rock. This tailored approach enhances efficiency and minimizes downtime. A case study highlights the importance of using hammer bits specifically rated for breaking reinforced concrete to prevent premature wear, ensuring longevity and effectiveness.

- Portability: Evaluate the weight and transportability of the equipment, especially if frequent movement on-site is necessary. Electric models are generally lighter and easier to maneuver, providing a significant advantage in dynamic work environments. Take the Tomahawk 1500W Electric Jackhammer, for example; it offers professional performance suitable for contractors and serious DIYers, delivering 45 joules of impact energy and operating at 1400 BPM (blows per minute).

By considering these factors, managers can make informed decisions regarding jackhammer rental that align with their objectives, ultimately boosting productivity and ensuring successful outcomes. As Chris Mendez, a demolition foreman, points out, electric tools for breaking concrete are cleaner, quieter, and powerful enough for 90% of demolition jobs, making them a preferred choice for many contractors.

Understand Rental Terms to Control Costs

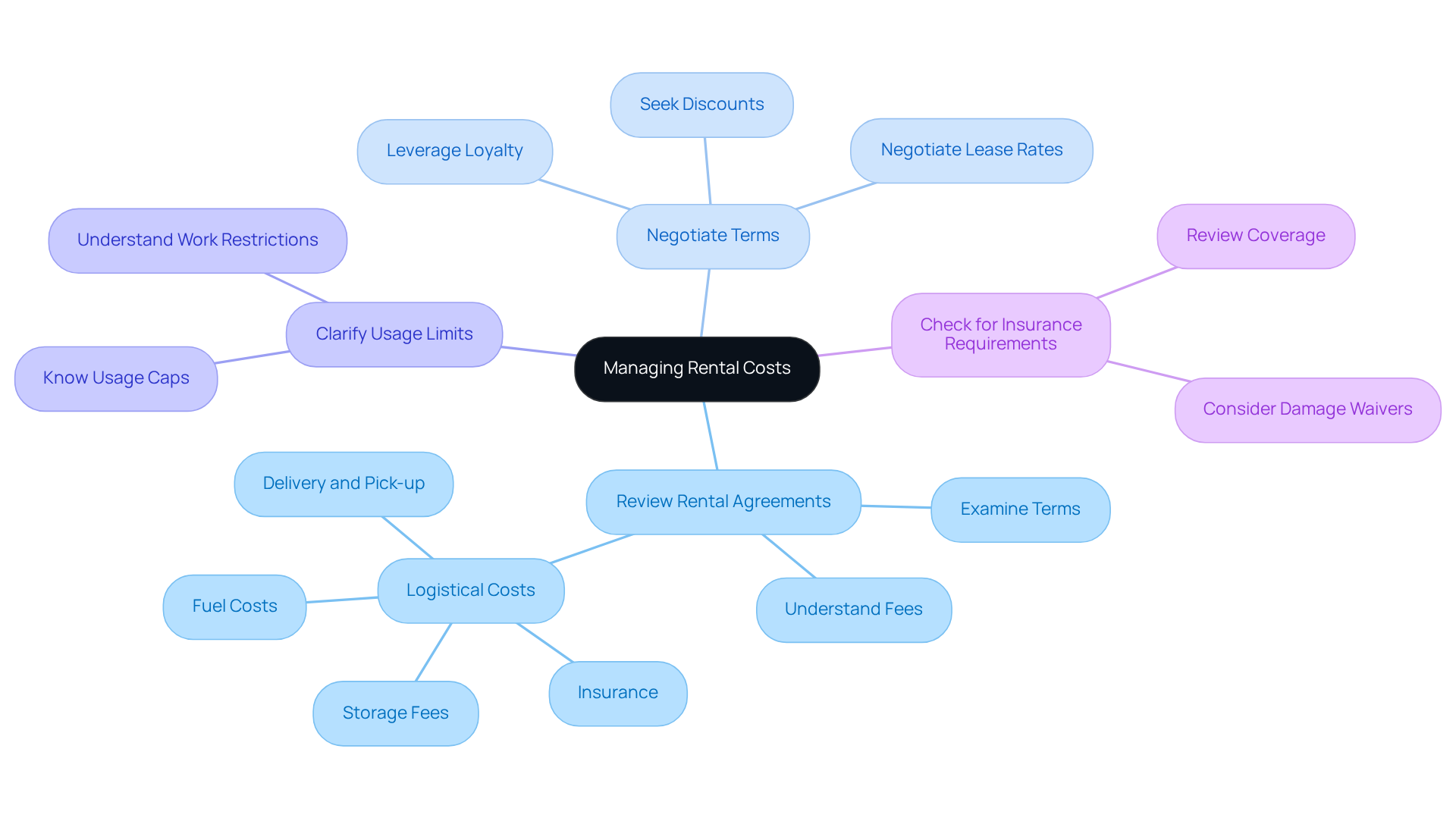

To effectively manage costs when renting jackhammers, project managers should implement several key strategies:

-

Review Rental Agreements: Start by thoroughly examining the rental contract. Understanding all terms, including rental duration, fees, and conditions regarding damage or loss, is crucial when it comes to jackhammer rental. Pay close attention to clauses that could lead to additional charges, as these can significantly impact overall costs. For example, knowing the logistical costs associated with jackhammer rental-such as delivery, pick-up, fuel, insurance, and storage-provides valuable context for budgeting.

-

Negotiate Terms: Leverage your position as a repeat customer to negotiate lease rates. Many rental companies are willing to offer discounts for long-term rentals or loyal clients, which can lead to substantial savings. As Mariela Merino wisely suggests, "Before signing your next lease for tools, come to the table informed and empowered."

-

Clarify Usage Limits: It's essential to understand any restrictions on usage, such as daily hour caps or limitations on the types of work permitted. This knowledge helps prevent unexpected overage fees and ensures adherence to leasing terms. Josh Nickell emphasizes the importance of planning and analytics in asset management to eliminate guesswork.

-

Check for Insurance Requirements: Be aware of any insurance coverage stipulations outlined in the lease agreement. Knowing these can help you avoid unforeseen expenses related to liability or damage. Additionally, consider including damage waiver clauses in leasing agreements to mitigate potential costs associated with equipment damage.

By mastering these leasing terms and being aware of common pitfalls, managers can maintain tighter control over their budgets. This proactive approach enables informed, financially sound decisions throughout their endeavors.

Maintain Equipment for Optimal Performance

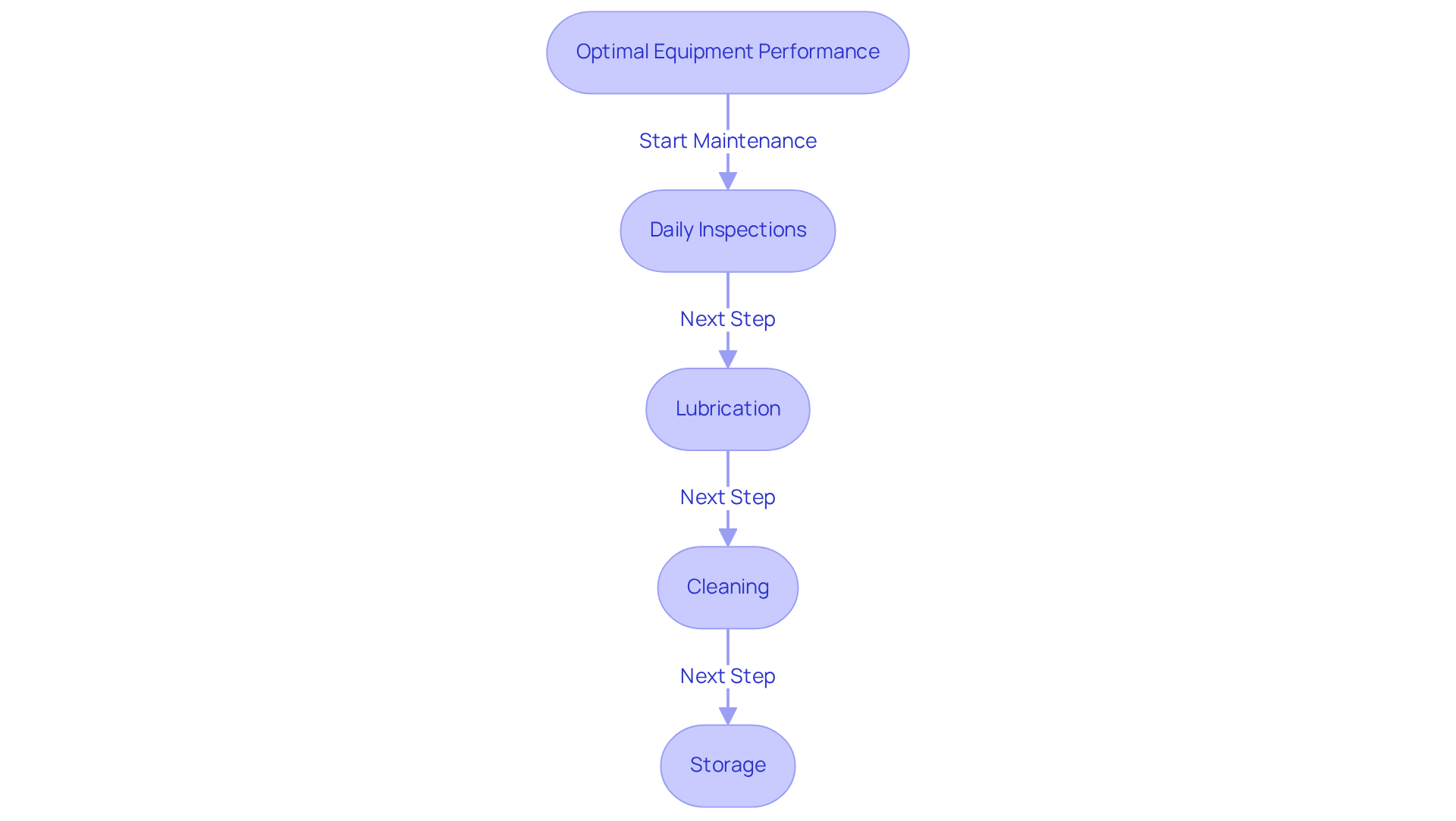

To ensure jackhammer rental units operate efficiently throughout the rental period, project managers must adopt essential maintenance practices that guarantee reliability and performance.

-

Daily Inspections: Conduct thorough inspections before each use to identify any visible damage or wear. Check the power cord, bits, and overall functionality to ensure safety and optimal performance. Routine checks can significantly reduce unexpected downtime, which costs companies up to $50 billion annually due to machinery failure. Aging machinery is nearly three times more likely to cause unplanned downtime, underscoring the critical nature of this maintenance practice.

-

Lubrication: Follow the manufacturer's guidelines for lubricating moving parts. Proper lubrication minimizes wear and tear, ensuring smooth operation and extending the equipment's lifespan. As industry experts emphasize, "Regular lubrication is key to maintaining the performance and longevity of the tool."

-

Cleaning: After each use, clean the tool to remove dust and debris. This practice prevents buildup that can hinder performance and prolongs the life of the equipment. A well-maintained demolition tool can operate effectively for years, provided it receives the necessary care.

-

Storage: Store the tool in a dry, secure location when not in use. Adequate storage protects it from environmental harm and reduces the risk of theft, ensuring that the tools remain in prime condition for upcoming tasks.

By implementing these maintenance methods, managers can optimize the lifespan and effectiveness of tools, including jackhammer rental, ultimately contributing to the success of their construction projects.

Utilize Expert Support for Informed Rental Decisions

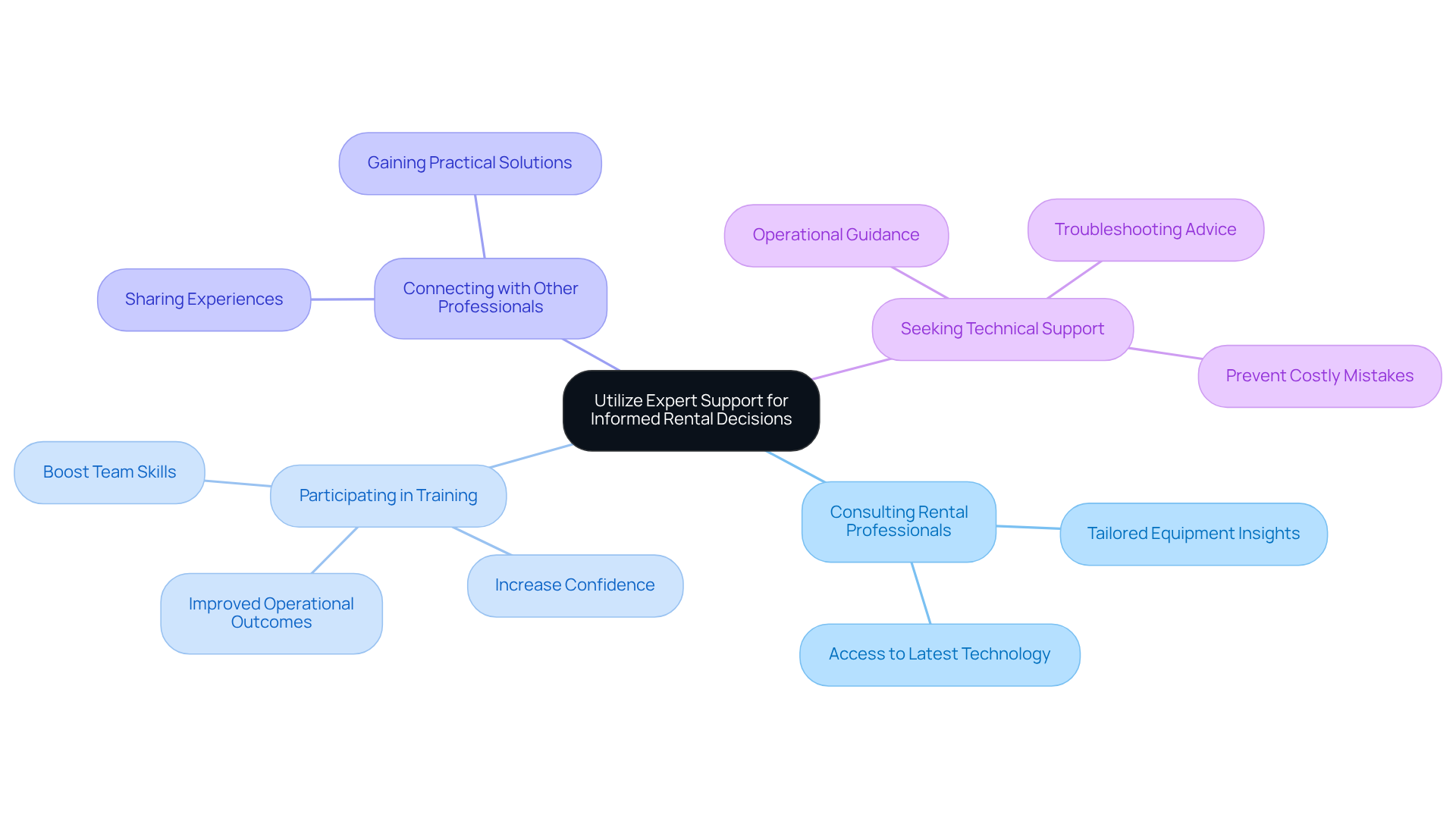

Project managers can significantly enhance their jackhammer rental experience by leveraging expert support in several impactful ways:

- Consulting Rental Professionals: Engage with knowledgeable staff at rental companies who can provide tailored insights into the most suitable equipment for your specific project needs. Their recommendations stem from extensive experience and familiarity with the latest technology in the field. Notably, the U.S. construction machinery leasing market is projected to reach USD 10,336.16 million by 2026, highlighting the growing demand for leasing services.

If uncertainties arise regarding the operation or maintenance of the jackhammer, don’t hesitate to seek technical support from the leasing company. They can offer valuable tips, troubleshooting advice, and operational guidance that can prevent costly mistakes. Expert Scott Hackett emphasizes the importance of utilizing technical support to enhance operational efficiency in asset management.

-

Participating in Training: Many rental firms provide training sessions focused on the safe and effective use of their tools. Taking advantage of these opportunities can significantly boost your team's skills and confidence, ensuring they are well-prepared to handle the equipment. Statistics indicate that a substantial percentage of managers who engage in training sessions report improved operational outcomes.

-

Connecting with Other Professionals: Engaging in industry forums or local construction groups allows managers to share experiences and gain insights from colleagues who have faced similar challenges. This networking can yield practical solutions that enhance task execution.

By utilizing expert support, project managers can make informed decisions that lead to successful project outcomes and optimal equipment utilization.

Conclusion

Choosing the right jackhammer rental is crucial for the success of your construction projects. By understanding your project's specific needs and selecting the appropriate equipment, you can significantly enhance productivity and ensure effective demolition work. This article underscores the importance of careful consideration in choosing the right tool, comprehending rental agreements, maintaining equipment, and leveraging expert support.

Evaluating the type of work and the required impact energy is essential. Negotiating favorable rental terms can lead to cost savings, while implementing a robust maintenance regimen keeps jackhammers operating at peak performance. Furthermore, engaging with rental professionals and participating in training can provide invaluable support, leading to informed decisions and successful project outcomes.

Ultimately, effective management of jackhammer rentals not only boosts the efficiency of individual projects but also fosters a culture of proactive planning and resourcefulness within the industry. By embracing these best practices, you equip yourself to navigate the complexities of equipment rental, ensuring that each project is completed successfully and within budget. Don't hesitate-reach out to your local rental provider today to explore your options and elevate your project outcomes.

Frequently Asked Questions

What should I consider when choosing a jackhammer for my project?

Key considerations include the type of work (light, medium, or heavy-duty), weight and impact energy of the tool, bit selection, and portability.

What type of jackhammer is best for different workloads?

Electric tools are ideal for smaller jobs, while pneumatic or hydraulic models are better suited for larger demolition tasks.

How does the weight of a jackhammer affect its performance?

Heavier demolition tools provide greater impact energy, which is essential for breaking tough materials like concrete. For example, a 90 lb tool delivers significantly more force than a 60 lb tool.

What type of bit should I use for breaking concrete?

Chisel bits are ideal for breaking concrete, while pointed bits are better for rock. Using the right bit type enhances efficiency and minimizes downtime.

Why is it important to use hammer bits rated for breaking reinforced concrete?

Using the appropriate hammer bits prevents premature wear and ensures the longevity and effectiveness of the jackhammer.

How important is the portability of a jackhammer?

Portability is important, especially for jobs requiring frequent movement on-site. Electric models are generally lighter and easier to maneuver.

Can you provide an example of a suitable electric jackhammer?

The Tomahawk 1500W Electric Jackhammer is an example that offers professional performance, delivering 45 joules of impact energy and operating at 1400 BPM.

What are the advantages of using electric jackhammers for demolition?

Electric jackhammers are cleaner, quieter, and powerful enough for 90% of demolition jobs, making them a preferred choice for many contractors.