Key Highlights:

- Forklift data plates, or nameplates, provide vital information about vehicle specifications and operational limits, essential for safety and compliance.

- Key details on data plates include truck model, serial number, weight specifications, load capacity, load centre, and fuel type.

- OSHA mandates that every forklift must have a durable data plate with legible information, positioned for easy visibility.

- Data plates must be updated to reflect any modifications affecting capacity or function, ensuring compliance with safety standards.

- Operating without data plates increases accident risks, legal consequences, insurance issues, and operational inefficiencies.

- In 2023, there were 67 fatalities related to lift truck accidents, highlighting the dangers of improper operation.

- If a data plate is missing or unreadable, operators should cease operations, contact the manufacturer for a replacement, document the issue, and review safety protocols.

Introduction

Understanding the critical role of forklift data plates is essential for ensuring safety in any operational setting. These vital tags provide necessary specifications about lift trucks and are mandated by OSHA to promote compliance and mitigate risks. When these data plates are missing or unreadable, the consequences can be severe, potentially leading to accidents, legal repercussions, and financial liabilities. This article explores the requirements, risks, and solutions related to OSHA forklift data plates, equipping operators with the knowledge needed to maintain safety and compliance in their workplaces.

Define Forklift Data Plates and Their Essential Information

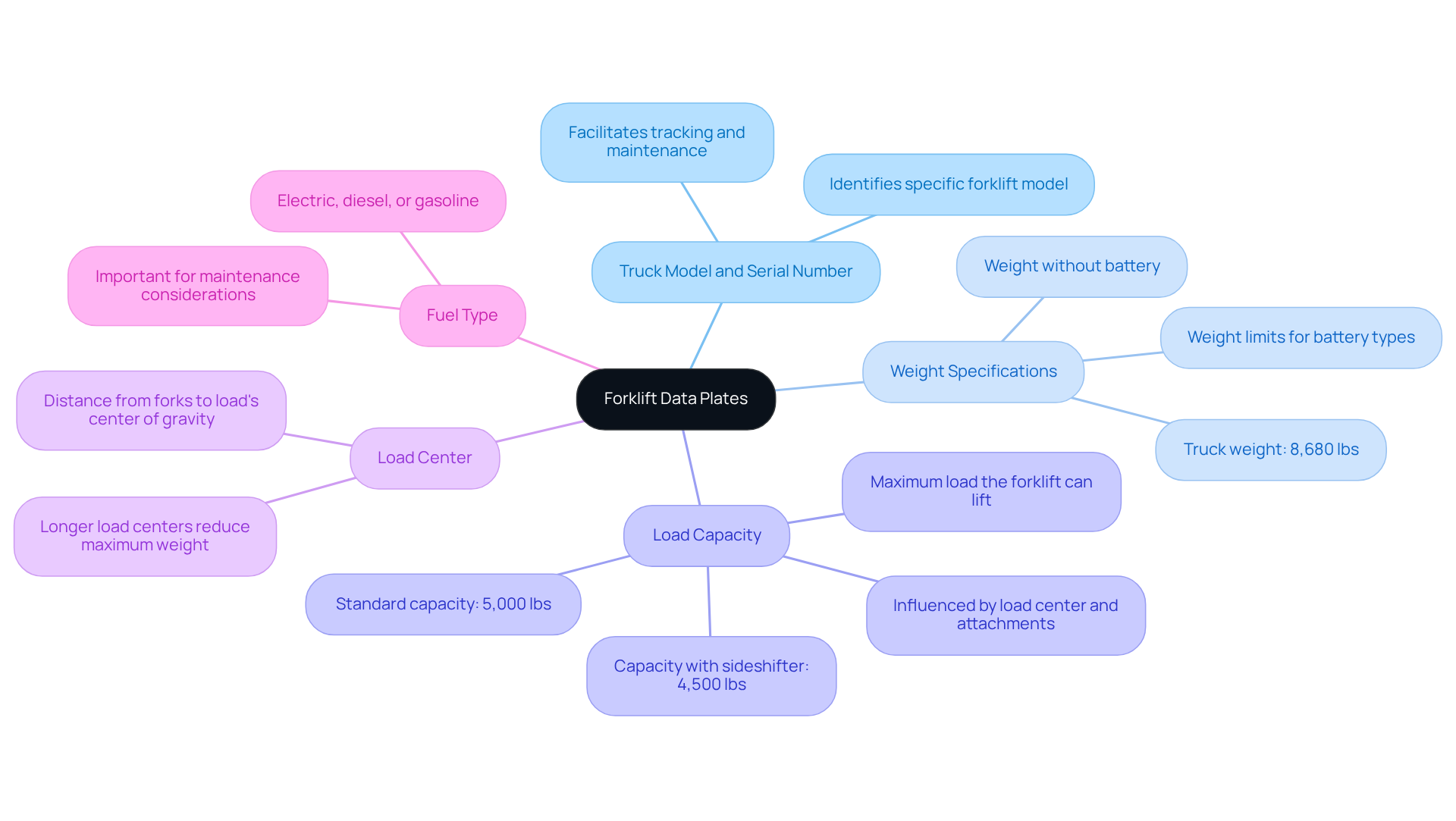

Data tags, often referred to as nameplates, are essential metal or plastic signs affixed to lift trucks, providing vital information about the vehicle's specifications and operational limits, in accordance with OSHA forklift data plate requirements. At EZ Equipment Rental, we offer a diverse selection of well-maintained lifting machines, ensuring clients find the perfect fit for their specific needs. Key details typically included on these plates are:

- Truck Model and Serial Number: This identifies the specific forklift model and its unique serial number, facilitating accurate tracking and maintenance.

- Weight Specifications: This indicates the vehicle's weight without the battery and outlines weight limits for various battery types, which is crucial for operational safety.

- Load Capacity: This specifies the maximum load the lifting machine can safely elevate, a critical factor in preventing overloads that could lead to severe accidents. For example, a lift truck with a standard capacity of 5,000 pounds can be reduced to 4,500 pounds when equipped with a sideshifter attachment, underscoring the need for operators to be aware of these limits. As David Tullis notes, "Your lift's maximum capacity will be diminished by longer load centers, additional attachments, lift height, and other factors."

- Load Center: This defines the distance from the vertical face of the forks to the load's center of gravity, significantly affecting the stability of the lifting device. Longer load centers can reduce the maximum weight that can be lifted, emphasizing the importance of understanding load characteristics.

- Fuel Type: This indicates whether the vehicle operates on electricity, diesel, or gasoline, which is vital for maintenance and operational considerations.

Moreover, the OSHA forklift data plate requirements and ANSI regulations require that each lift truck attachment must possess its own data plate, highlighting the importance of adherence to compliance standards. Understanding these elements is essential for operators to ensure the safe and efficient use of lift trucks across various settings. Compliance with OSHA regulations necessitates that operators are trained to read and interpret this information accurately, as neglecting to do so can lead to significant hazards, including overloading, tip-overs, and mechanical failures. Adequate training on lifting vehicle information labels not only enhances safety but also ensures compliance with regulatory standards, thereby promoting a secure working environment.

Outline OSHA Requirements for Forklift Data Plates

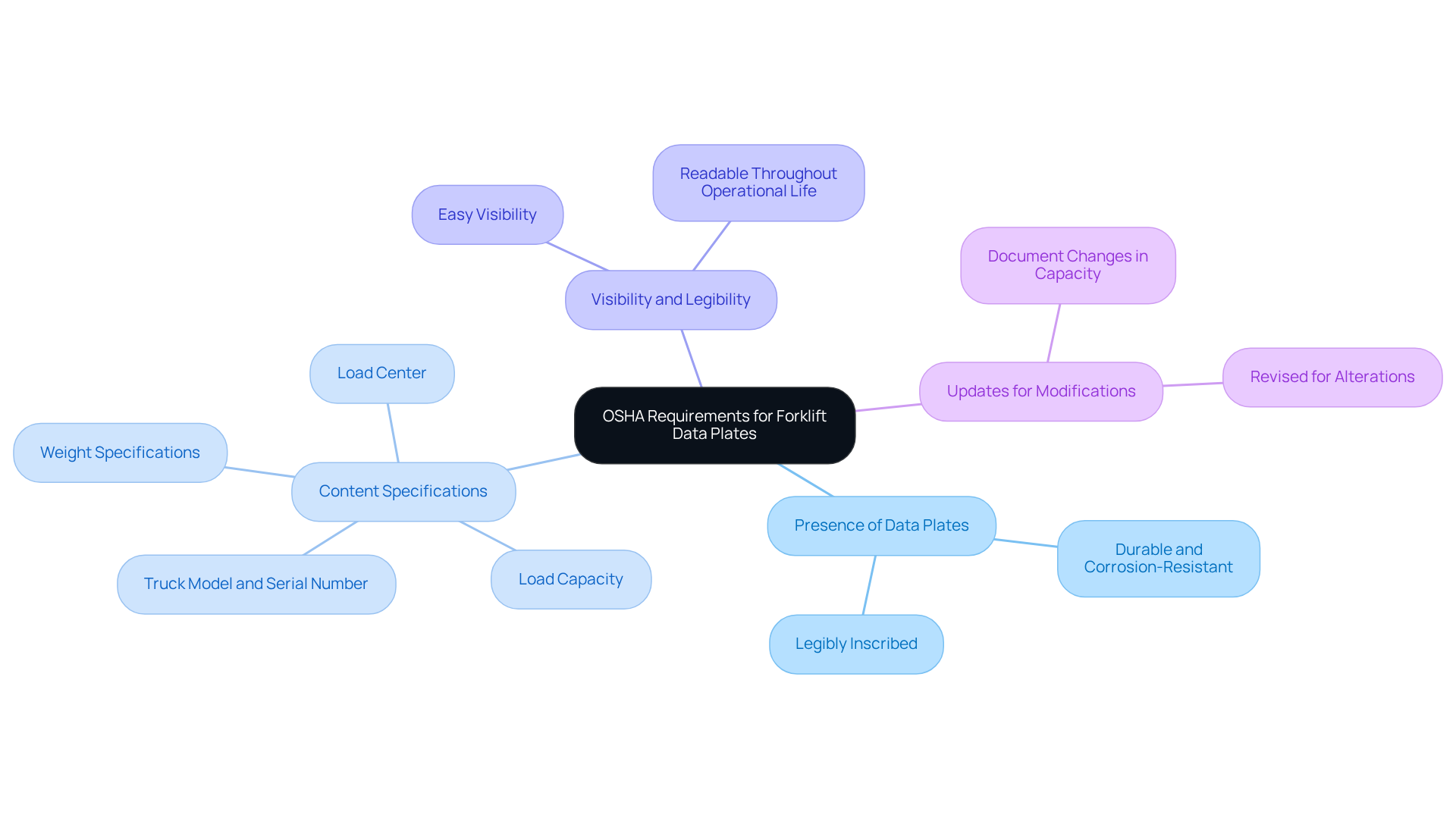

The Occupational Safety and Health Administration (OSHA) mandates specific requirements for lift truck information tags under regulation 29 CFR 1910.178. Key requirements include:

- Presence of Data Plates: Every forklift must have a durable, corrosion-resistant data plate that is legibly inscribed with essential information. This information tag is crucial for compliance and safety, as using a lifting machine with an incorrect or absent capacity chart can lead to fines and penalties.

- Content Specifications: The information label must include the truck model, serial number, weight specifications, load capacity, and load center. This information is vital as it directly impacts safe operation and helps prevent product loss, property damage, and serious injuries.

- Visibility and Legibility: Data tags must be positioned for easy visibility by operators, such as near the dashboard or operator seat, and must remain readable throughout the vehicle's operational life. An absent or unreadable information tag can result in significant compliance breaches and operational risks. According to the OSHA forklift data plate requirements, the user shall ensure that all nameplates and markings are in place and maintained in a legible condition.

- Updates for Modifications: If any alterations are made to the lift that impact its capacity or function, the information tag must be revised accordingly to reflect these changes. This includes modifications due to attachments, which can alter the load capacity and center of gravity.

Compliance with these requirements is not only a legal obligation but also a critical aspect of maintaining a safe working environment. Organizations that consistently adhere to these OSHA standards demonstrate a commitment to safety, reducing the likelihood of accidents and ensuring operational efficiency.

Examine Risks of Operating Forklifts Without Data Plates

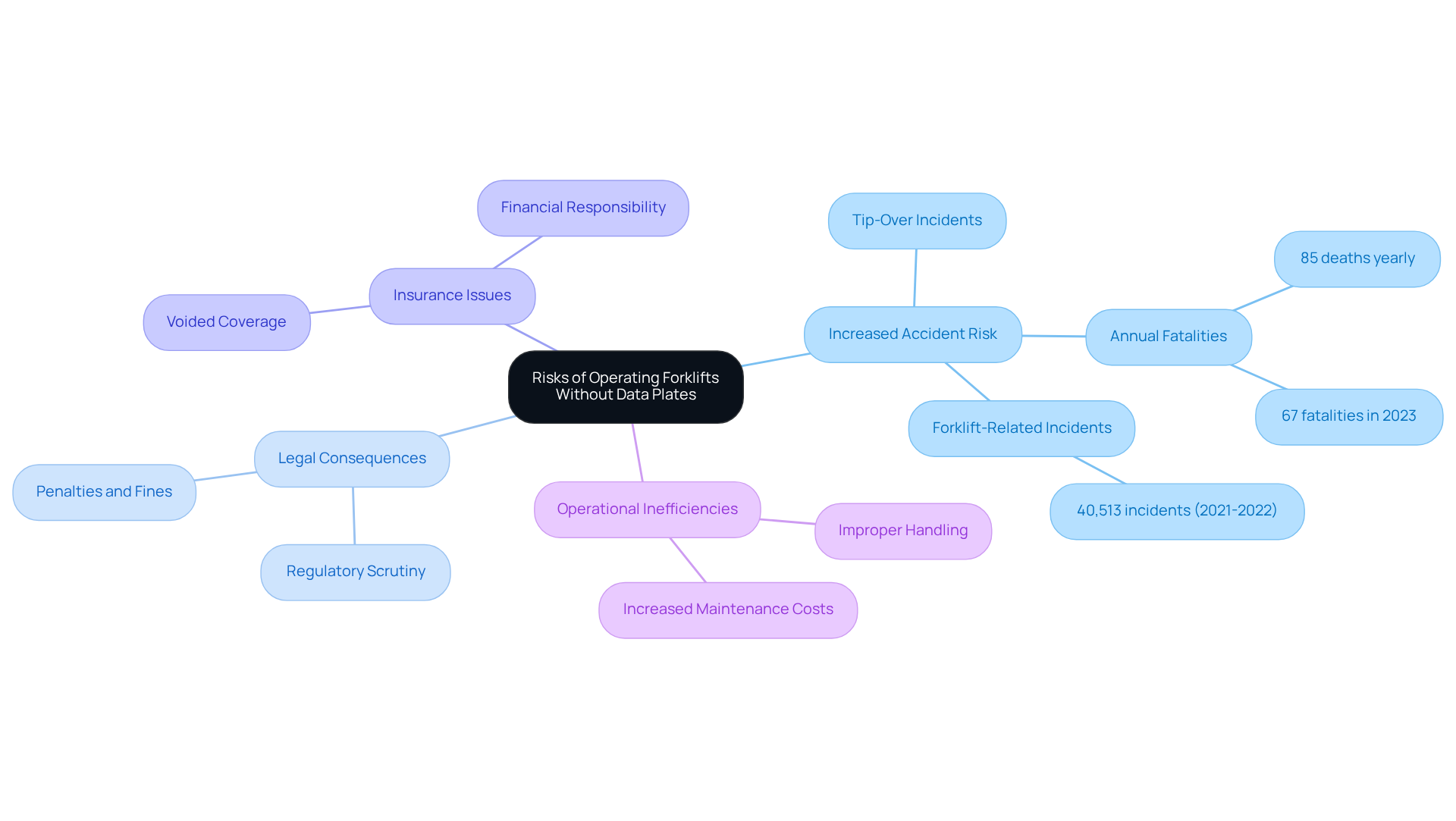

Operating a forklift without following the OSHA forklift data plate requirements poses significant risks that can compromise safety and compliance. These risks include:

- Increased Accident Risk: Without clear load capacity and operational guidelines, operators may overload the forklift, which greatly increases the chances of tip-overs and accidents. In fact, lift truck accidents are responsible for approximately 85 deaths annually, with 67 fatalities reported in 2023 alone. This statistic underscores the dangers associated with improper operation.

- Legal Consequences: Failing to comply with OSHA regulations can lead to severe penalties, including substantial fines and legal liabilities. Companies may also face heightened scrutiny from regulatory bodies, potentially resulting in further operational disruptions.

- Insurance Issues: Operating without a registration label could void insurance coverage in the event of an accident, leaving both the operator and employer financially responsible for damages. This situation can lead to significant financial losses, especially in cases involving serious injuries or property damage.

- Operational Inefficiencies: The lack of essential information can result in improper handling of lifting equipment, causing damage to machinery and increasing maintenance costs. In 2021-2022, there were 40,513 forklift-related incidents, highlighting the critical need for proper operational protocols.

Recognizing these hazards emphasizes the necessity of maintaining accurate and visible information tags on all lift trucks to comply with the OSHA forklift data plate requirements for safety.

Provide Solutions for Missing Forklift Data Plates

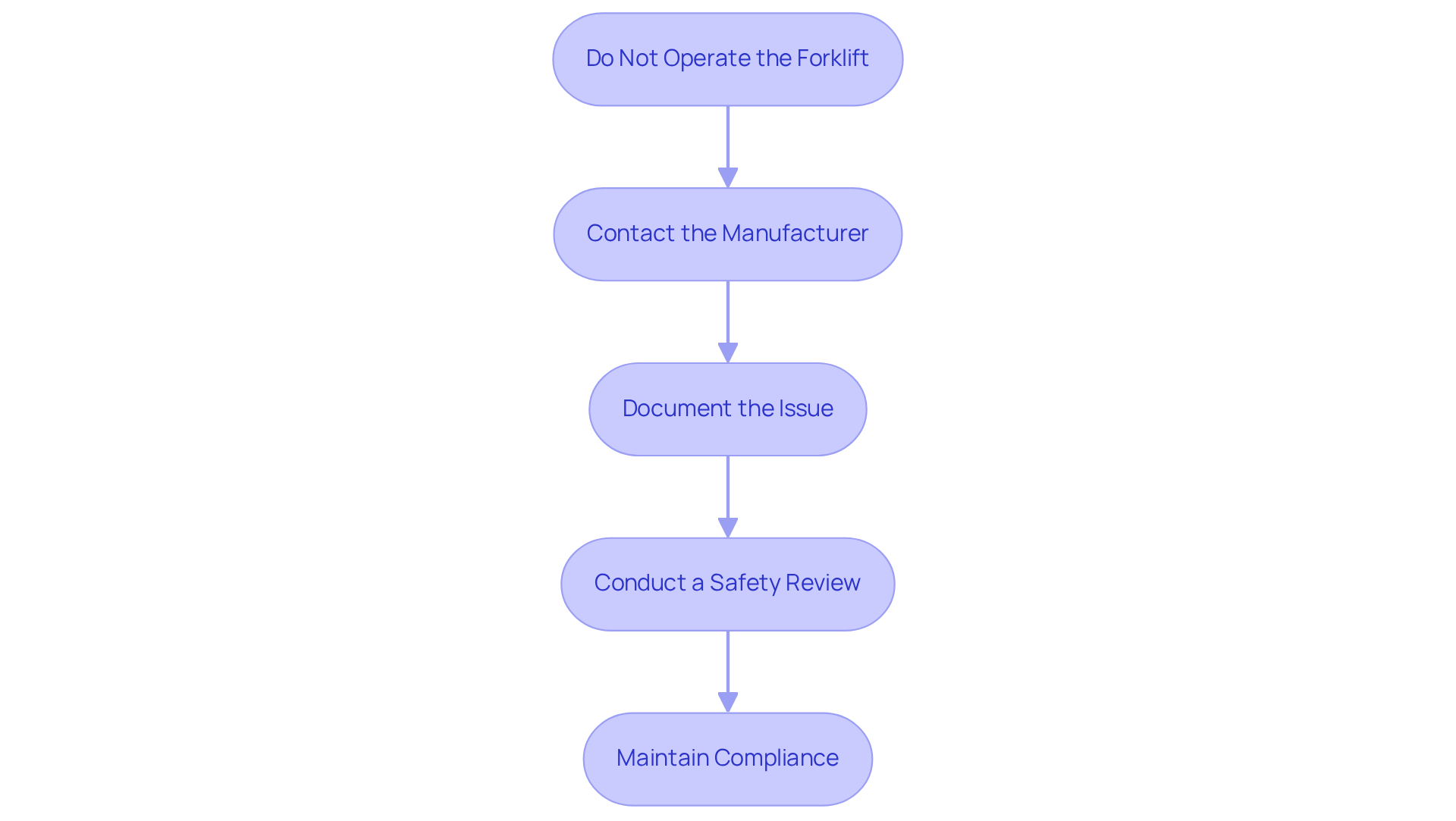

If a lift's information tag is absent or unreadable, prompt action is necessary to ensure compliance and safety. Here are the steps to take:

-

Do Not Operate the Forklift: Cease all operations until the data plate is replaced or restored. This precaution helps prevent accidents and ensures adherence to safety regulations.

-

Contact the Manufacturer: Reach out to the forklift's manufacturer or an authorized dealer to request a replacement identifier. They can provide the necessary specifications to ensure compliance with the OSHA forklift data plate requirements.

-

Document the Issue: Keep a record of the missing information tag and the steps taken to resolve the problem. This documentation is crucial for compliance audits and demonstrates a commitment to safety.

-

Conduct a Safety Review: Use this opportunity to review safety protocols. Ensure all operators are trained on the importance of the OSHA forklift data plate requirements and how to read them effectively.

By following these steps, operators can maintain compliance and ensure safe forklift operations.

Conclusion

Understanding and adhering to OSHA forklift data plate requirements is essential for ensuring safety and compliance in any workplace that utilizes lift trucks. These data plates serve as crucial informational resources that outline the specifications and operational limits of forklifts, helping operators make informed decisions to prevent accidents and maintain a secure working environment.

This article delves into the critical components of forklift data plates, including:

- Truck model

- Weight specifications

- Load capacity

- Fuel type

It emphasizes the importance of compliance with OSHA regulations, detailing the risks associated with operating forklifts without proper data plates, such as increased accident rates and potential legal consequences. Furthermore, it provides actionable solutions for addressing missing or unreadable data plates, ensuring that operators can maintain safety standards effectively.

In summary, the significance of forklift data plates cannot be overstated. They are not merely regulatory requirements but vital tools for promoting safety and operational efficiency. Organizations must prioritize training and adherence to these regulations to mitigate risks and foster a culture of safety. By being proactive in maintaining and understanding forklift data plates, businesses can protect their employees and enhance overall productivity while complying with current OSHA standards.

Frequently Asked Questions

What are forklift data plates?

Forklift data plates, also known as nameplates, are essential metal or plastic signs affixed to lift trucks that provide vital information about the vehicle's specifications and operational limits, in accordance with OSHA forklift data plate requirements.

What key information is typically included on a forklift data plate?

Key details typically included on forklift data plates are the truck model and serial number, weight specifications, load capacity, load center, and fuel type.

Why is the truck model and serial number important?

The truck model and serial number identify the specific forklift model and its unique serial number, facilitating accurate tracking and maintenance.

What do weight specifications indicate on a forklift data plate?

Weight specifications indicate the vehicle's weight without the battery and outline weight limits for various battery types, which is crucial for operational safety.

What is load capacity and why is it important?

Load capacity specifies the maximum load the lifting machine can safely elevate. It is critical for preventing overloads that could lead to severe accidents.

How does the load center affect forklift operation?

The load center defines the distance from the vertical face of the forks to the load's center of gravity, significantly affecting the stability of the lifting device. Longer load centers can reduce the maximum weight that can be lifted.

What does the fuel type indicate on a forklift data plate?

The fuel type indicates whether the vehicle operates on electricity, diesel, or gasoline, which is vital for maintenance and operational considerations.

What regulations govern forklift data plates?

OSHA forklift data plate requirements and ANSI regulations govern the information that must be included on the data plates, including the requirement that each lift truck attachment must possess its own data plate.

Why is it important for operators to understand forklift data plates?

Understanding forklift data plates is essential for operators to ensure the safe and efficient use of lift trucks, as neglecting this information can lead to significant hazards such as overloading, tip-overs, and mechanical failures.

What role does training play in interpreting forklift data plates?

Adequate training on lifting vehicle information labels enhances safety and ensures compliance with regulatory standards, promoting a secure working environment.

List of Sources

- Define Forklift Data Plates and Their Essential Information

- eTool : Powered Industrial Trucks (Forklift) - Types & Fundamental - Parts - Nameplate | Occupational Safety and Health Administration (https://osha.gov/etools/powered-industrial-trucks/types-fundamentals/parts/name-plate)

- The Importance of a Forklift Data Plate (https://hansler.ca/the-importance-of-a-forklift-data-plate)

- How to Read a Forklift Data Plate (https://sstlift.com/blog/how-to-read-a-forklift-data-plate)

- Understanding the Importance of Forklift Data Plates: Ensuring Safety and Compliance (https://linde-mh.us/insights/articles/forklift-data-plates)

- How to Read a Forklift Data Plate | Southeast Industrial Equipment Inc. (https://sielift.com/2024/02/how-to-read-a-forklift-data-plate)

- Outline OSHA Requirements for Forklift Data Plates

- Forklift Capacity Ratings Insights | Abel Womack, Inc. (https://abelwomack.com/forklift-capacity-ratings-blog)

- How to Read a Forklift Data Plate: Complete Specifications Guide (https://acelifting.com/blog/how-to-read-a-forklift-data-plate-complete-specifications-guide)

- Forklift Data Plates: How to Read and Understand Them (https://conger.com/forklift-data-plate)

- Examine Risks of Operating Forklifts Without Data Plates

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Work Safety: Forklifts - Data Details - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts/data-details)

- Provide Solutions for Missing Forklift Data Plates

- Understanding the Importance of Forklift Data Plates: Ensuring Safety and Compliance (https://linde-mh.us/insights/articles/forklift-data-plates)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Forklift Accidents Statistics: How to Increase Forklift Safety and Prevent Accidents – Powerfleet (formerly Fleet Complete) Blog (https://blog.fleetcomplete.com/forklift-accidents-statistics-how-to-increase-forklift-safety-and-prevent-accidents)

- How Much Does a Forklift Data Tag Cost? When Should You Replace One? (https://intellaparts.com/blog/how-much-does-a-forklift-data-tag-cost-when-should-you-replace-one?srsltid=AfmBOooNRJCbixfSEkU0pB_321cxugvlVsIB_AClD5kukwSFmZOOmsBT)

- Work Safety: Forklifts - Data Details - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts/data-details)