Overview

This article serves as an authoritative guide for project managers on the effective utilization of rental survey equipment. It underscores the importance of understanding a variety of tools, including total stations, GPS receivers, levels, and 3D laser scanners. By outlining best practices for equipment use and troubleshooting common issues, the article highlights how pre-rental research and proper training can significantly enhance project success while minimizing downtime.

In addition, the article delves into the benefits of each type of equipment, providing detailed descriptions that emphasize their reliability and quality. For example, total stations offer precision in measurements, while GPS receivers ensure accurate positioning. These tools are essential for any project manager aiming to optimize their workflow and achieve superior results.

Furthermore, the significance of thorough training is emphasized, as it equips teams with the necessary skills to operate equipment effectively. Testimonials from satisfied customers reinforce the reliability of these tools, showcasing real-world applications that resonate with project managers.

To conclude, project managers are encouraged to take action by exploring rental options and investing in the right equipment for their upcoming projects. By leveraging the insights shared in this article, they can ensure a seamless project execution and a competitive edge in their field.

Key Highlights:

- Understanding rental survey equipment is crucial for effective management in construction and land development.

- Key types of survey equipment include total stations, GPS receivers, levels, and 3D laser scanners, each serving specific measurement needs.

- Total stations combine electronic theodolites and distance metres, projected to grow to $2.2 billion by 2027 due to increased demand.

- GPS receivers enable accurate positioning over large areas but require clear skies for optimal performance.

- Levels are essential for establishing horizontal planes, while 3D laser scanners capture detailed spatial information.

- Best practises for using rental survey equipment include conducting pre-rental research, inspecting tools before use, following manufacturer guidelines, training staff, and maintaining equipment.

- Common issues with rental survey equipment include equipment malfunction, calibration issues, information recording errors, and environmental factors affecting performance.

- Proactive troubleshooting can minimise downtime and enhance project success rates.

Introduction

Mastering rental survey equipment is essential for project managers navigating the intricate landscape of construction and land development. With the right tools—such as total stations and GPS receivers—project managers can significantly enhance accuracy and efficiency, driving project success.

However, the challenge lies not only in selecting the appropriate equipment but also in effectively managing its use throughout the project lifecycle.

What best practices can ensure that rental survey equipment is utilized to its fullest potential? Furthermore, how can common issues be swiftly addressed to maintain project momentum?

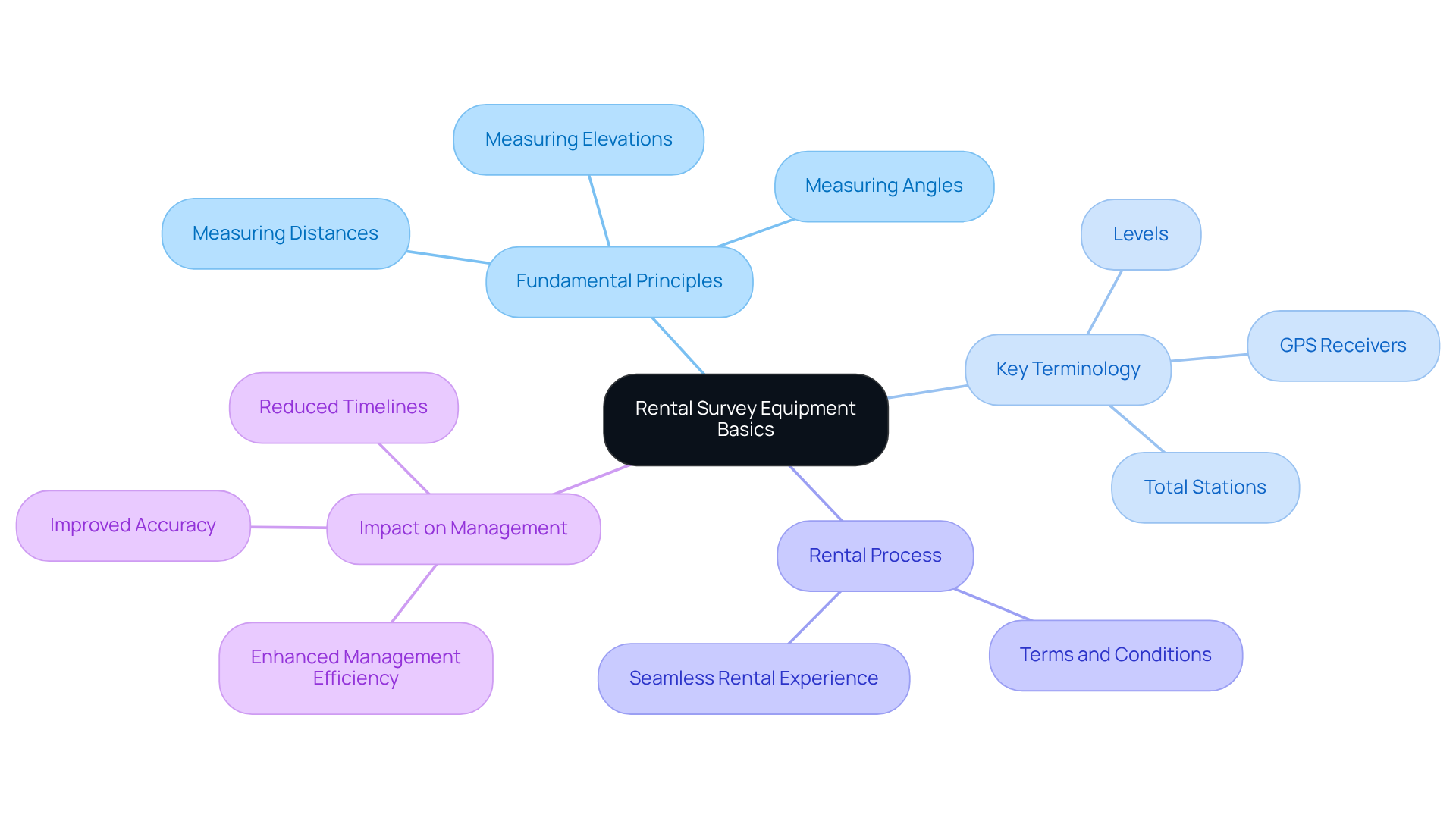

Understand the Basics of Rental Survey Equipment

To effectively manage rental survey equipment, it is imperative for managers to grasp the fundamental principles that underpin these essential instruments. This equipment is crucial for measuring distances, angles, and elevations—key factors in construction and land development projects. Understanding key terminology such as total stations, GPS receivers, and levels is essential. By comprehending how these tools operate and their specific applications, managers can select the most suitable resources tailored to their needs.

Furthermore, familiarity with the rental process, including terms and conditions for rental survey equipment, is vital for ensuring a seamless rental experience. Industry leaders emphasize that integrating advanced survey tools can significantly enhance management efficiency, leading to improved accuracy and reduced timelines. For instance, the effective use of GPS technology in surveying has been shown to streamline workflows and minimize errors, ultimately contributing to overall project success. By prioritizing a thorough understanding of surveying tools, managers can align their strategies with their objectives, paving the way for optimal outcomes.

Identify Key Types of Survey Equipment for Rental

When renting survey equipment, it is crucial to understand the key types available for achieving success. The primary options include:

- Total Stations: These instruments are essential for measuring angles and distances, making them invaluable for layout and construction tasks. They merge an electronic theodolite with an electronic distance meter, enabling accurate measurements essential in intricate tasks. The total station market is projected to grow significantly, reaching an estimated $2.2 billion by 2027, with a compound annual growth rate (CAGR) of 6.1% from 2022 to 2027, driven by increasing demand for accurate measurements in construction. Total stations have been credited with dramatically improving accuracy in land surveying and significantly increasing productivity.

- GPS Receivers: These devices offer accurate location information, which is especially vital for large-scale projects. GNSS surveying, utilizing satellite-based positioning systems, allows for quick data collection over expansive areas, achieving accuracy within 10mm to 30mm. However, GNSS surveying is dependent on satellite signals and requires a clear view of the sky, which can limit its effectiveness in certain environments. The cost-effectiveness and ease of use of GNSS receivers make them a popular option in contemporary building projects.

- Levels: Used to establish a horizontal plane, levels are vital for grading and foundation work. Electronic levels, which measure height differences using laser technology, enhance precision and speed in construction tasks.

- 3D Laser Scanners: These innovative instruments capture intricate spatial information, making them valuable for complex tasks that require high precision. They are increasingly being integrated into surveying practices to improve efficiency and data quality.

Evaluating your needs is crucial to identify which rental survey equipment will best meet your requirements. Consider factors such as scale, terrain, and specific measurement requirements to make an informed decision.

Implement Best Practices for Using Rental Survey Equipment

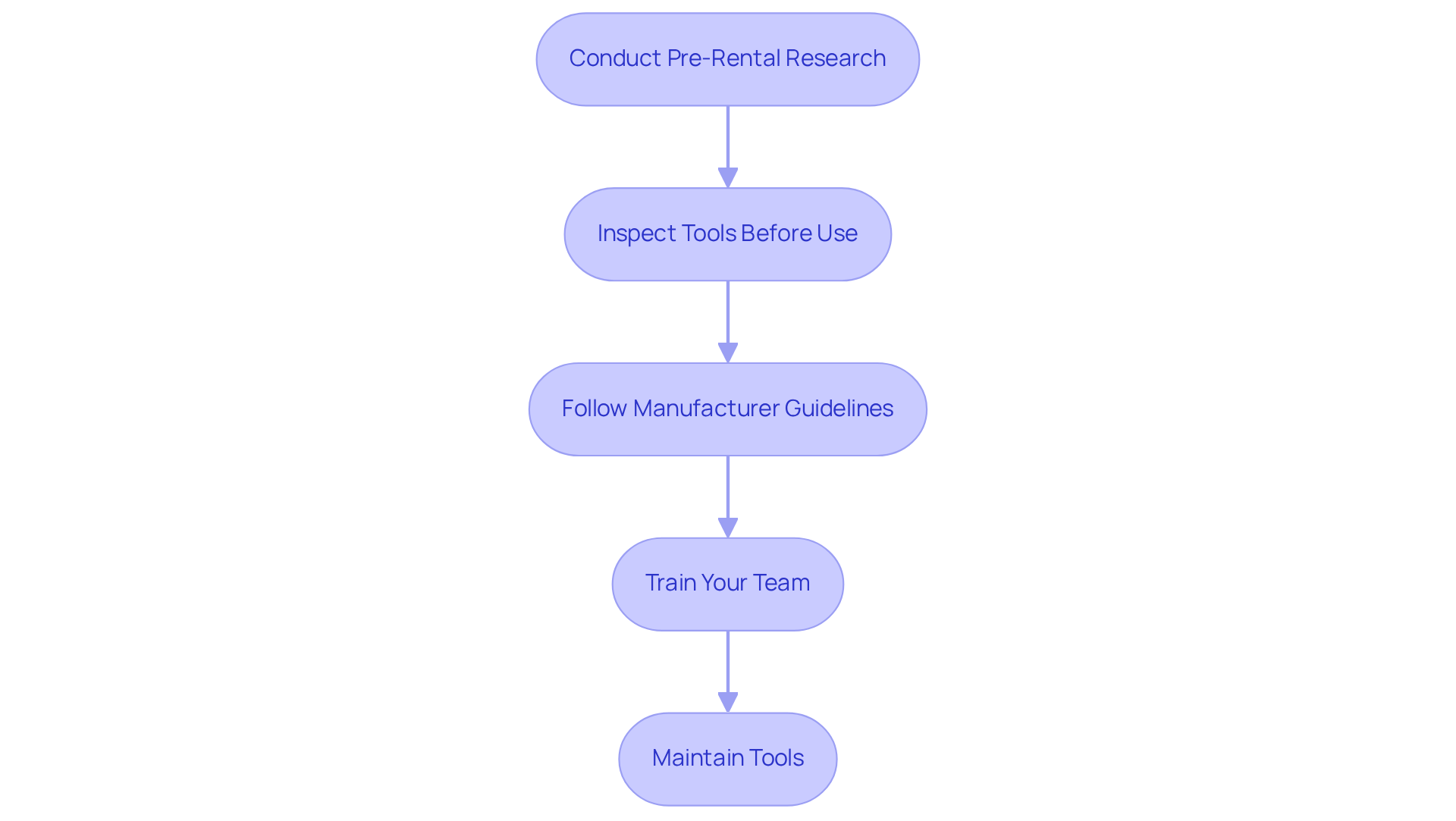

To ensure the successful utilization of rental survey equipment, it is crucial to adhere to the following best practices:

- Conduct Pre-Rental Research: Begin by clearly outlining your requirements and investigating available tool options. Engage with rental companies to clarify the specifications and capabilities of rental survey equipment, ensuring you select the right tools for your needs. Notably, 62% of contractors rented construction machinery for greater flexibility than ownership, underscoring the necessity of comprehensive research in making informed choices.

- Inspect Tools Before Use: Prior to commencing your project, thoroughly examine the tools for any damages or missing components. Document their condition meticulously to prevent disputes later on. For example, renting a mini excavator can amount to approximately $300 daily or $900 weekly, making it essential to verify that the machinery is in optimal condition to prevent unforeseen expenses.

- Follow Manufacturer Guidelines: Strictly adhere to the operating instructions provided by the manufacturer. This guarantees secure and efficient use of the devices, thereby reducing the chance of accidents or failures.

- Train Your Team: Provide comprehensive training for all team members on the proper use of the machinery. This not only reduces the likelihood of errors but also enhances overall safety on-site. As observed by construction supervisors, appropriate training is crucial for enhancing machinery efficiency and safety.

- Maintain Tools: Regularly inspect and care for the tools throughout the rental period to ensure optimal performance and reliability. This proactive approach to using rental survey equipment can significantly impact project success rates, as demonstrated in various case studies where consistent maintenance led to improved outcomes.

Troubleshoot Common Issues with Rental Survey Equipment

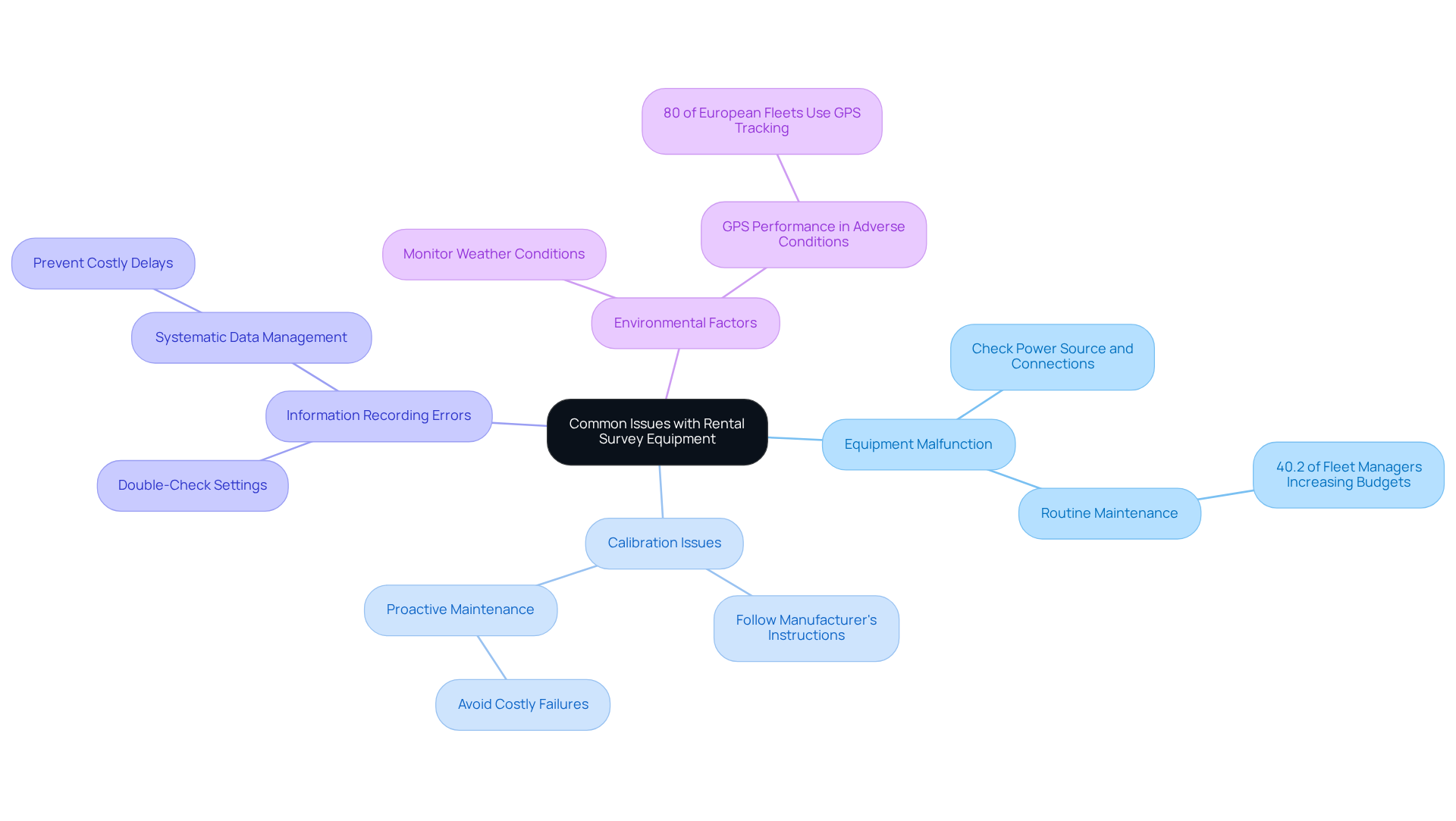

Even with meticulous preparation, challenges can arise when using rental survey equipment. Understanding these prevalent issues and their solutions is essential for effective project management.

- Equipment Malfunction: When equipment fails to operate, the first step is to check the power source and connections. Ensure that all components are correctly assembled, as improper setup is a common cause of malfunction. Notably, 40.2% of surveyed fleet managers have indicated raising maintenance budgets to prolong the useful life of their assets, underscoring the significance of routine maintenance and troubleshooting.

- Calibration Issues: Inaccurate measurements often signal a need for recalibration. Adhering to the manufacturer's calibration instructions is crucial, as regular adjustments maintain measurement accuracy. As industry expert Seth Carlson emphasizes, proactive maintenance is essential to avoid costly equipment failures.

- Information Recording Errors: It is vital to confirm that information is recorded accurately. Double-check settings and ensure that all essential information points are captured. Inconsistent information recording can lead to costly delays and rework. Implementing a systematic approach to data management has proven effective in various construction projects.

- Environmental Factors: Be mindful of how weather conditions can influence tool performance. For example, GPS accuracy may be compromised in heavy cloud cover or dense foliage, leading to significant discrepancies in survey results. With nearly 80% of surveyed European fleets utilizing GPS fleet tracking, it is clear that monitoring equipment performance in varying conditions is of utmost importance.

By adopting a proactive approach and preparing to troubleshoot these common issues, project managers can minimize downtime and sustain project momentum by utilizing rental survey equipment.

Conclusion

Mastering the use of rental survey equipment is essential for project managers who aim to enhance efficiency and accuracy in construction and land development projects. By understanding the fundamental principles and types of equipment available, managers can make informed decisions that align with their project objectives, ultimately leading to successful outcomes.

Familiarity with various survey tools—including total stations, GPS receivers, levels, and 3D laser scanners—cannot be overstated. Best practices for utilizing rental equipment include:

- Conducting thorough pre-rental research

- Inspecting tools before use

- Adhering to manufacturer guidelines

- Training team members

- Maintaining equipment throughout the rental period

Furthermore, addressing common issues that may arise with practical troubleshooting tips ensures smooth operations, reinforcing the reliability of the equipment used.

In conclusion, effective management of rental survey equipment not only streamlines workflows but also significantly contributes to project success. By implementing the insights and best practices discussed, project managers can navigate the complexities of rental equipment with greater confidence. Embracing these strategies will not only enhance project outcomes but also foster a culture of safety and efficiency in the construction industry.

Frequently Asked Questions

What is the importance of understanding rental survey equipment for managers?

Understanding rental survey equipment is crucial for managers as it enables them to effectively measure distances, angles, and elevations, which are essential in construction and land development projects.

What are some key terms related to rental survey equipment that managers should know?

Key terms include total stations, GPS receivers, and levels, which are fundamental tools used in surveying.

How does familiarity with the rental process benefit managers?

Familiarity with the rental process, including terms and conditions, ensures a seamless rental experience for managers when acquiring survey equipment.

What impact do advanced survey tools have on management efficiency?

Integrating advanced survey tools enhances management efficiency by improving accuracy and reducing project timelines.

How does GPS technology contribute to surveying?

The effective use of GPS technology in surveying streamlines workflows and minimizes errors, contributing to overall project success.

Why is it important for managers to understand surveying tools?

A thorough understanding of surveying tools allows managers to align their strategies with their objectives, leading to optimal project outcomes.