Overview

This article serves as a comprehensive step-by-step guide for managers on effectively renting a table saw. It underscores the critical importance of:

- Understanding project requirements

- Selecting the appropriate type of saw

- Navigating the rental process

- Implementing essential safety practices

By detailing key factors such as:

- Material type

- Cutting dimensions

- Safety features

the article equips managers with the knowledge necessary to make informed decisions regarding equipment rentals. Furthermore, it outlines vital steps to ensure a smooth rental experience and safe operation. Ultimately, this guide empowers managers to optimize their equipment rental choices, ensuring reliability and quality in their projects.

Key Highlights:

- Understand project requirements by assessing material type, cutting dimensions, task scale, and budget constraints.

- Different types of table saws include job site saws for portability, contractor saws for power and stability, and cabinet saws for precision.

- Ensure the saw accommodates the necessary cutting tool size, with a 10-inch tool being standard for most applications.

- Prioritise safety features such as cutting guards, riving knives, and emergency shut-off switches to enhance user protection.

- Research local rental companies and cheque the availability of specific table saw models before renting.

- Understand rental terms including duration, pricing, and any additional fees to avoid unexpected costs.

- Inspect the equipment for damage before finalising the rental to ensure it is in good working condition.

- Wear protective gear, maintain a clean workspace, and follow safe cutting methods to minimise injury risk during operation.

- Conduct regular maintenance on the saw and follow the manufacturer's guidelines for optimal performance and safety.

Introduction

Navigating the world of table saw rentals can be a formidable challenge for managers overseeing various projects. It is crucial to understand the nuances of equipment selection, project requirements, and safety practices to make informed decisions that save both time and money. This guide explores the essential steps in renting a table saw, providing insights on selecting the right model, assessing project needs, and implementing effective safety protocols.

With numerous options available, how can one ensure they are making the optimal choice for their specific project requirements while minimizing risks and costs?

Understand Your Project Requirements

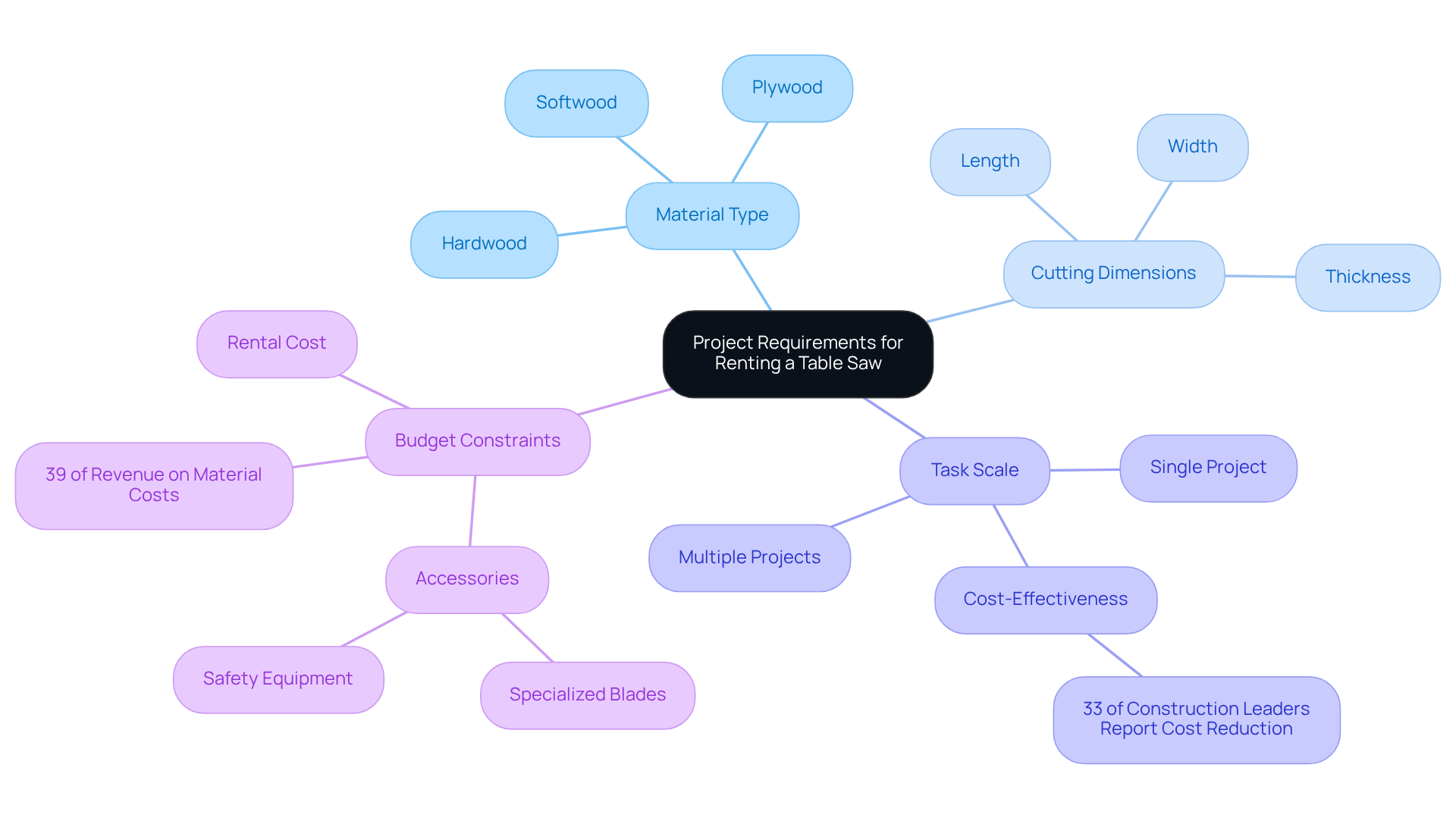

To effectively assess the scope of your project when renting a table saw, it is essential to begin with a clear understanding of the following factors:

- Material Type: Identify the materials you will be cutting, such as hardwood, softwood, or plywood. Each material may necessitate specific blade types to achieve optimal results.

- Cutting Dimensions: Determine the dimensions of the pieces you need to cut. This evaluation clarifies the cutting capacity needed from the table saw, ensuring it meets your requirements.

- Task Scale: Assess whether this is a singular endeavor or part of a broader series of activities. Understanding the scale can help you decide if renting a table saw is more cost-effective than purchasing equipment outright. Notably, 33% of construction leaders report reduced costs as a significant benefit of data-driven decision-making. Furthermore, 57% of construction experts believe that workflow optimization will be the most crucial management skill going forward, emphasizing the necessity for effective processes in scope evaluation.

- Budget Constraints: Establish a comprehensive budget that includes not only the rental cost but also any additional accessories you may require, such as specialized blades or safety equipment. Considering that material expenses represent around 39% of income in equipment rental companies, meticulous budgeting is crucial to control overall costs efficiently.

By thoroughly grasping these requirements, you can navigate the process of renting a table saw with confidence, ensuring that you choose the appropriate equipment for your task while optimizing costs and resources. As KPMG highlighted, "71% of surveyed construction experts state that it’s a vital aspect of managers’ response to disruptions," underscoring the significance of clear requirements in attaining successful results.

Choose the Right Table Saw for Your Needs

When selecting a table saw for your project, several key factors should guide your decision.

Type of Table Saw: Choose between a job site saw, contractor saw, or cabinet saw based on the size of your task and mobility requirements.

- Job Site Tool: These tools are portable and designed for smaller projects, making them ideal for on-site work.

- Contractor Tool: Offering enhanced power and stability, contractor tools are suitable for larger cuts and more demanding tasks. In 2023, contractor tools comprised over 40% of the market share owing to their versatility.

- Cabinet Saw: Best suited for professional use, cabinet saws provide exceptional precision and durability, making them a staple in high-end woodworking shops.

Cutting Tool Size and Type: Ensure the saw can accommodate the necessary cutting tool size for your materials. A 10-inch cutting tool is standard for most applications, but larger sizes may be needed for specific tasks. The 10-inch segment is expected to witness the fastest growth during the forecast period.

Protection Attributes: Emphasize crucial protection attributes like cutting guards, riving knives, and emergency shut-off switches. Contemporary saws frequently include innovative protective technologies, significantly decreasing the likelihood of accidents. For example, riving knives assist in preventing kickback by keeping cut sections from pinching the cutting tool, while guards cover the tool to reduce direct contact. Technologies such as SawStop's flesh detection system can halt the blade nearly instantly upon contact with skin, improving user protection.

Check with local rental companies, such as EZ Equipment Rental, to determine the rental availability for renting table saw models and their rental terms. Comprehending the market share of job site tools, contractor tools, and cabinet tools can also guide your decision, as contractor tools currently possess a substantial segment of the market owing to their adaptability and efficiency.

By thoroughly assessing these factors, you can choose a table saw that effectively fulfills your project needs, ensuring both security and efficiency.

Navigate the Rental Process Efficiently

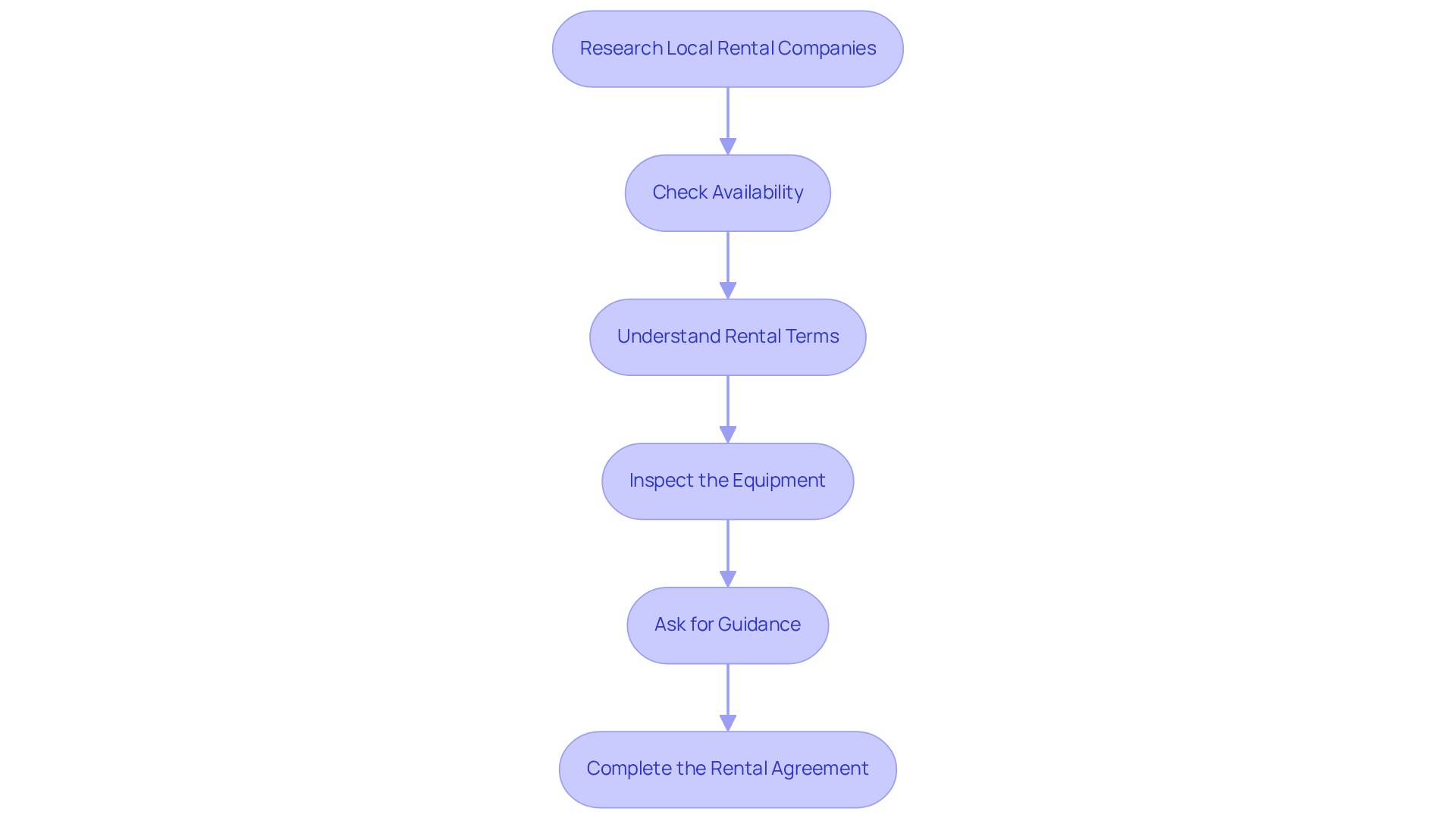

To navigate the rental process effectively, follow these steps:

-

Research local rental companies by identifying those in the DFW area, such as EZ Equipment Rental, located at 1307 W Airport Fwy, Irving, TX, which specializes in renting table saws. This initial step is crucial in ensuring you have access to the right equipment.

-

Check Availability: Reach out to EZ Equipment Rental to confirm the availability of the specific table saw model you require. Knowing the availability allows you to plan your project timeline accordingly.

-

Understand Rental Terms: Inquire about the rental duration, pricing, and any additional fees, such as those for late returns or damage. Understanding these terms will help you avoid unexpected costs.

-

Inspect the Equipment: Prior to finalizing the rental, thoroughly inspect the table saw for any damage or missing parts, ensuring it is in good working condition. As emphasized by industry experts, "Inspecting rental equipment before use is crucial to avoid unexpected issues."

-

Ask for Guidance: If you are not acquainted with the saw, request a brief tutorial from the rental staff about its operation and protective features. This step enhances safety and ensures you are comfortable using the equipment.

-

Complete the Rental Agreement: Fill out the necessary paperwork, providing identification and payment details as required. Completing this step efficiently will expedite the rental process.

By adhering to these steps, you can ensure a smooth and efficient rental experience at EZ Equipment Rental, minimizing potential complications during your project.

Implement Safety and Maintenance Practices

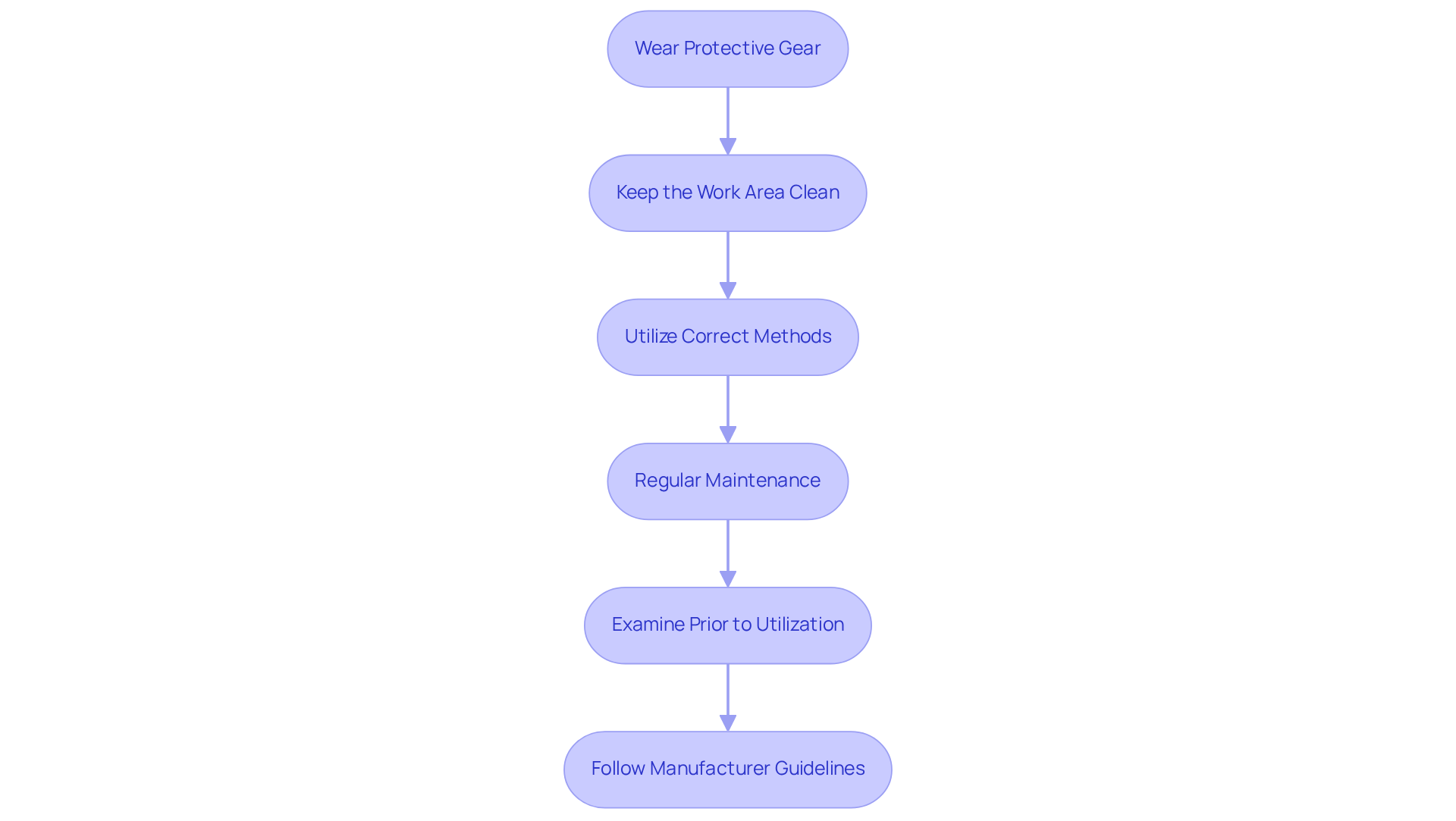

To ensure the safe and effective use of your rented table saw, it is imperative to adhere to the following practices:

- Wear Protective Gear: Always don safety glasses, ear protection, and a dust mask to shield yourself from debris and noise. The importance of protective gear cannot be overstated, as it significantly reduces the risk of injury during operation.

- Keep the Work Area Clean: Maintain a tidy workspace to prevent accidents. Clutter and obstacles around the saw can lead to serious injuries, so ensure that the area is free from distractions.

- Utilize Correct Methods: Familiarize yourself with safe cutting methods, such as using a push stick for narrow cuts and keeping hands away from the sharp edge. Proper technique is essential in minimizing the risk of accidents, especially given that over 30,000 table saw injuries occur annually, primarily affecting fingers and hands.

- Regular Maintenance: After use, clean the saw to remove sawdust and debris. Check the blade for sharpness and replace it if necessary. Routine upkeep not only extends the lifespan of the equipment but also guarantees optimal performance and protection.

- Examine Prior to Utilization: Always check the saw before each use to ensure all protective features are operating properly. This proactive approach can prevent accidents that may arise from equipment malfunction.

- Follow Manufacturer Guidelines: Adhere to the manufacturer's instructions for operation and maintenance to ensure optimal performance. Understanding and following these guidelines is crucial for safe operation and can help mitigate risks associated with improper use.

Integrating contemporary protective technology, such as SawStop, which halts the saw blade upon contact with skin, can further enhance security and avert serious injuries. By applying these precautionary and maintenance practices while renting a table saw, you can enhance your experience and ensure the equipment's durability while significantly reducing the risk of accidents. Remember, safety is a mindset that begins with you.

Conclusion

Mastering the art of renting a table saw is a pivotal skill for managers overseeing projects that demand precision and efficiency. Understanding project requirements, selecting the right saw, navigating the rental process, and implementing safety and maintenance practices are essential for ensuring successful outcomes. This comprehensive approach not only enhances project execution but also mitigates risks associated with equipment use.

Key considerations highlighted throughout the guide include:

- Identifying material types

- Assessing cutting dimensions

- Establishing budget constraints

The importance of choosing the appropriate table saw type—whether job site, contractor, or cabinet—cannot be overstated, as is the necessity of prioritizing safety features. Furthermore, navigating the rental process through diligent research and thorough inspections is crucial to avoid unexpected complications.

Ultimately, careful planning and adherence to safety protocols are paramount. By applying the insights from this guide, managers can enhance their project outcomes while fostering a culture of safety and efficiency. Embracing these practices not only ensures the successful completion of tasks but also safeguards the well-being of all individuals involved in the process.

Frequently Asked Questions

What factors should I consider when assessing the scope of my project for renting a table saw?

You should consider the material type you will be cutting, the cutting dimensions needed, the scale of the task, and your budget constraints.

Why is it important to identify the material type when renting a table saw?

Different materials, such as hardwood, softwood, or plywood, may require specific blade types to achieve optimal cutting results.

How do cutting dimensions impact the choice of a table saw?

Determining the dimensions of the pieces you need to cut helps clarify the cutting capacity required from the table saw, ensuring it meets your project needs.

What should I evaluate regarding the task scale when renting a table saw?

You should assess whether the task is a one-time project or part of a larger series of activities, which can influence whether renting is more cost-effective than purchasing equipment.

How can budget constraints affect my decision to rent a table saw?

Establishing a comprehensive budget that includes rental costs and any additional accessories, like specialized blades or safety equipment, is crucial for controlling overall costs efficiently.

What percentage of material expenses is considered in equipment rental companies?

Material expenses represent around 39% of income in equipment rental companies, highlighting the importance of meticulous budgeting.

What is the significance of understanding project requirements in construction management?

Clear requirements are vital for effective decision-making and can help in managing disruptions, as emphasized by 71% of surveyed construction experts.