Key Highlights:

- Rough terrain forklifts are designed for outdoor use on uneven ground, essential in construction and landscaping.

- Key features include all-wheel drive for better traction, large flotation tyres to prevent sinking, and elevated ground clearance for obstacle navigation.

- Approximately 70% of construction projects utilise rough terrain forklifts for material management.

- Safety training is critical; pre-operation inspections and knowledge of controls can significantly reduce accident risks.

- Operators must be at least 18 years old, complete an instructional programme, pass a practical assessment, and renew certification every three years.

- Comprehensive training reduces workplace injuries, enhances operational efficiency, and ensures compliance with safety regulations.

- Forklift incidents account for a significant portion of workplace injuries, with training potentially preventing 70% of these accidents.

- The rugged equipment market for rough terrain forklifts is projected to grow significantly, approaching $10 billion by 2030.

Introduction

Rough terrain forklifts are essential assets in the construction and landscaping sectors, expertly engineered to handle the challenges posed by uneven outdoor surfaces. Their unique features and operational requirements are critical for ensuring safety and efficiency on job sites. However, despite the advantages they offer, many operators may neglect vital safety protocols and training, which can lead to hazardous situations. So, how can operators effectively navigate these challenges while fully leveraging the benefits of rough terrain forklifts?

Understanding the operational intricacies of these forklifts is paramount. They are designed to provide stability and power on rugged terrain, making them indispensable for various tasks. By familiarizing themselves with the equipment's capabilities, operators can enhance their performance and ensure a safer working environment. Furthermore, adhering to safety protocols not only protects the operators but also contributes to the overall efficiency of the job site.

To maximize the advantages of rough terrain forklifts, operators must prioritize training and safety measures. Engaging in comprehensive training programs equips them with the necessary skills to operate these machines confidently. Additionally, implementing regular safety checks and maintenance routines can significantly reduce the risk of accidents. In this way, operators can enjoy the reliability and quality that rough terrain forklifts bring to their projects.

In conclusion, the effective use of rough terrain forklifts hinges on a commitment to safety and training. By understanding the equipment's features and adhering to safety protocols, operators can navigate the challenges of outdoor work with confidence. Don't wait-ensure your team is equipped with the knowledge and skills needed to operate these powerful machines safely and efficiently.

Understand Rough Terrain Forklifts

Rough terrain forklifts are specialized vehicles designed for outdoor use on uneven ground, making them essential in construction, landscaping, and other outdoor applications. Key features include:

- All-Wheel Drive: This technology enhances traction and maneuverability, allowing operators to navigate challenging terrains effectively.

- Large Floatation Tires: These tires distribute weight evenly, preventing the vehicle from sinking into soft ground, which is crucial for maintaining stability in various conditions.

- Elevated Ground Clearance: This design allows the lift truck to navigate obstacles and cross uneven surfaces without getting trapped, ensuring operational efficiency.

The importance of rugged ground lifting equipment, particularly the rough terrain forklift, is underscored by their extensive application on building sites, where approximately 70% of projects employ these machines to manage heavy materials and traverse challenging landscapes. Experts in construction safety emphasize the necessity of understanding these lifting machines. Proper training and knowledge of their capabilities can significantly reduce the risk of accidents. For instance, a construction manager might state that 'comprehending the operational limits and characteristics of rugged landscape vehicles is crucial for ensuring site safety and efficiency.'

Real-world examples demonstrate their effectiveness. During a recent infrastructure project, a fleet of rough terrain forklifts was utilized to move materials across a rugged site, showcasing their reliability and versatility in challenging conditions. As the industry progresses, staying informed about the latest trends in all-terrain lifting equipment technology, including innovations in electric and hybrid models, will be essential for optimizing performance and sustainability on job sites. Furthermore, the rugged equipment market is anticipated to expand considerably, possibly approaching around $10 billion by 2030, emphasizing the rising need for these vital machines in construction. However, challenges such as high initial investment costs may hinder adoption for smaller companies, making it vital for stakeholders to stay updated on technological innovations and market dynamics.

Learn How to Operate a Rough Terrain Forklift Safely

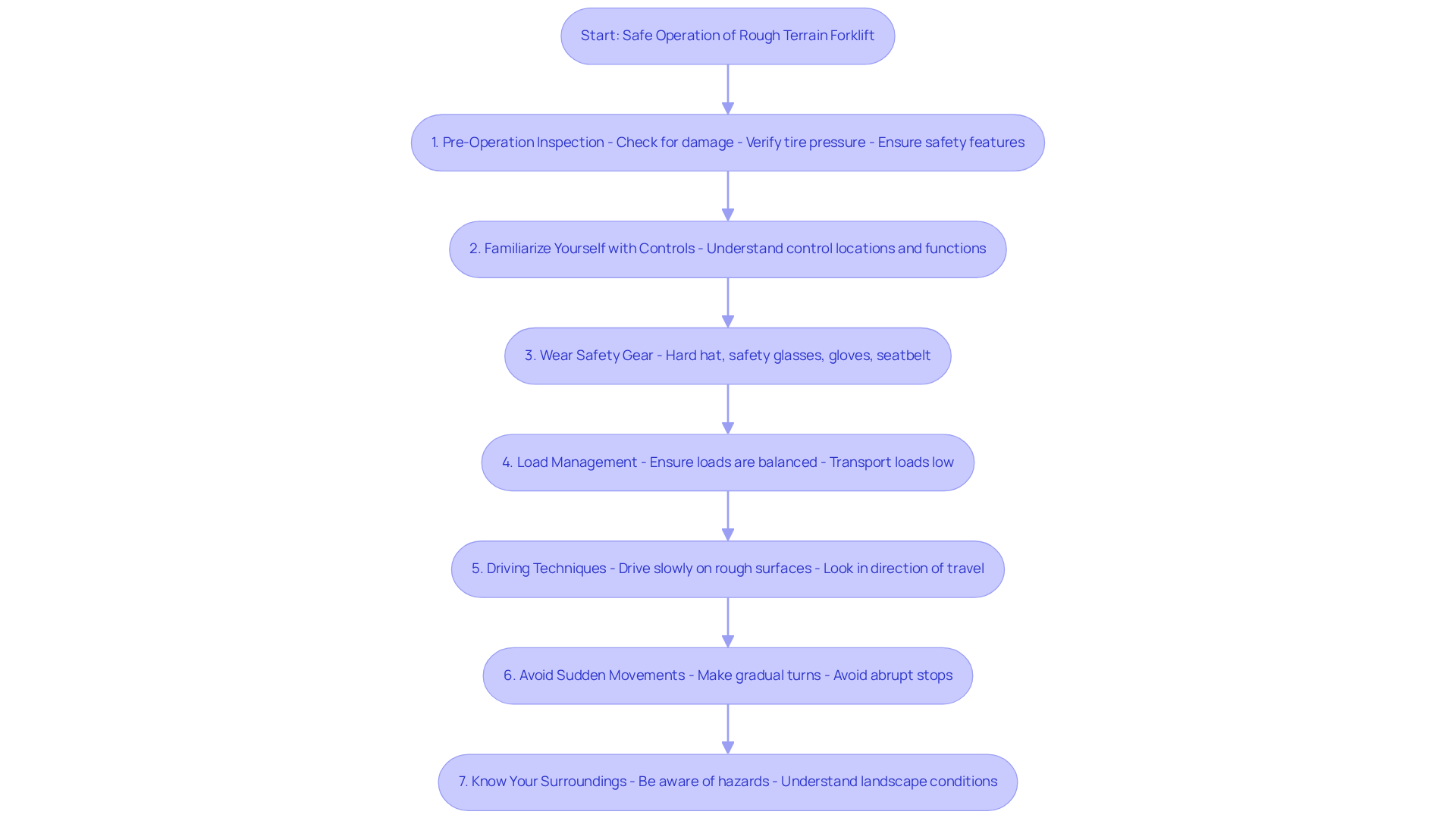

To operate a rough terrain forklift safely, follow these essential steps:

-

Pre-Operation Inspection: Begin with a thorough inspection before starting the lifting vehicle. Check for visible damage, verify tire pressure, and ensure all safety features are operational. As safety instructors emphasize, "A pre-operation inspection can reveal possible problems that might result in accidents, making it an essential step in safe vehicle operation." Furthermore, OSHA mandates daily inspections to catch mechanical issues that could lead to injuries or fatalities.

-

Familiarize Yourself with Controls: Understand the location and function of all controls, including steering, lifting, and tilting mechanisms. This knowledge is crucial for effective and safe operation.

-

Wear Safety Gear: Always wear appropriate safety equipment, including a hard hat, safety glasses, gloves, and a seatbelt while operating the vehicle. This gear is vital for protecting against potential injuries.

-

Load Management: Ensure loads are balanced and within the vehicle's weight capacity. Transport loads as low as feasible to maintain stability. Tip-overs from instability, overloading, or unsafe maneuvers are the primary causes of accidents involving lifting machines, accounting for nearly 25% of all related incidents.

-

Driving techniques for a rough terrain forklift suggest that you drive slowly, especially on rough surfaces. Always look in the direction of travel and utilize mirrors to maintain awareness of your surroundings. Poor visibility can significantly increase the risk of collisions.

-

Avoid Sudden Movements: Make gradual turns and avoid abrupt stops to prevent tipping. Sudden maneuvers can destabilize the lifting vehicle, leading to serious accidents.

-

Know Your Surroundings: Be aware of the landscape and any potential hazards, such as slopes, ditches, or obstacles. Recent incidents involving challenging landscapes highlight the importance of understanding environmental conditions to prevent mishaps.

By prioritizing these steps, operators can significantly reduce the likelihood of accidents and ensure a safer working environment. The lessons learned from previous incidents underscore the critical importance of pre-operation inspections and the need for ongoing education and awareness in lift truck operations.

Review Certification Requirements for Safe Operation

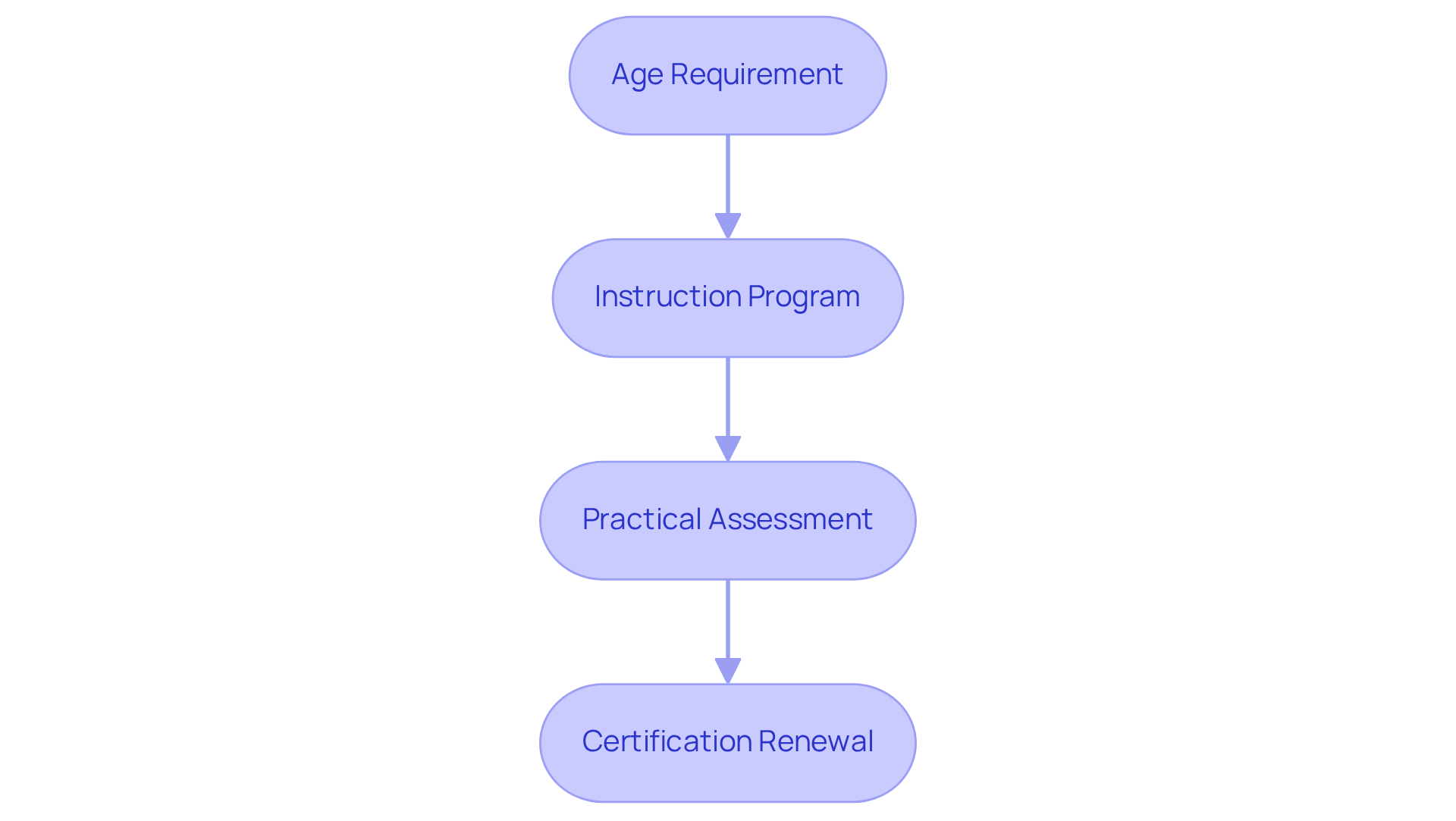

To legally and safely operate a rough terrain forklift, operators must meet specific certification requirements that ensure both compliance and workplace safety.

-

Age Requirement: First and foremost, operators must be at least 18 years old. This age requirement is crucial for ensuring that individuals have the maturity and responsibility needed to handle heavy machinery.

-

Instruction Program: Next, operators are required to complete an instructional course that covers the operation, safety protocols, and maintenance of rough terrain forklifts. This training can be obtained through accredited organizations or employers, providing a solid foundation for safe operation.

-

Practical Assessment: After finishing the instruction, operators must demonstrate their skills in a hands-on evaluation. This practical assessment is vital to confirm that they can handle the lift safely and effectively, ensuring that they are prepared for real-world scenarios.

-

Certification Renewal: Lastly, it's important to note that certifications typically need to be renewed every three years. This renewal process may involve refresher courses or re-evaluations, which help maintain ongoing compliance with safety standards and reinforce the importance of safety in operations.

Recognize the Importance of Rough Terrain Forklift Training

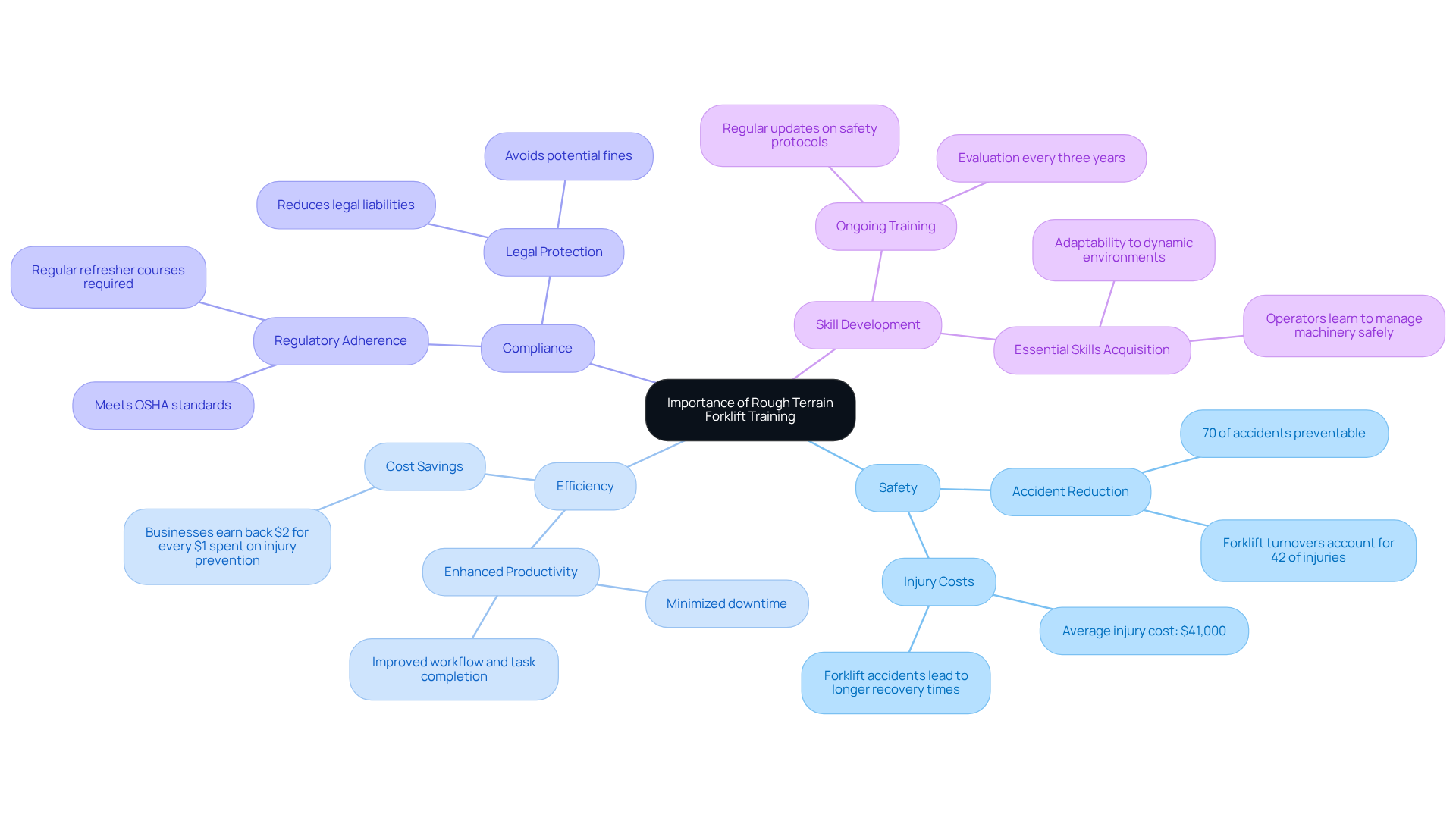

Training for rough terrain forklift operation is not just a regulatory obligation; it’s essential for several compelling reasons:

-

Safety First: Comprehensive training significantly reduces the risk of accidents and injuries on job sites. Operators gain crucial skills to manage machinery safely and effectively. Consider this: lift truck incidents account for a substantial portion of workplace injuries, with 70% being preventable through adequate instruction. Notably, forklift turnovers represent 42% of all recorded injuries, highlighting the specific risks tied to forklift operation.

-

Boosting Efficiency: Skilled operators are key to enhancing operational efficiency. They minimize downtime and elevate productivity on construction projects. Organizations that invest in training often see marked improvements in workflow and task completion rates, leading to smoother operations.

-

Ensuring Compliance: Adhering to OSHA and other regulatory standards protects the company from legal liabilities and potential fines. Regular training keeps operators updated on safety protocols, which is vital for maintaining compliance. This includes the necessity for refresher courses every three years or after an incident, ensuring operators stay informed about best practices.

-

Developing Skills: Training equips operators not only with essential skills but also prepares them to face various challenges that may arise during operation. This adaptability is crucial in dynamic construction environments where conditions can shift rapidly.

Investing in robust development programs for operators of rough terrain forklifts is vital for creating a safer and more productive work environment. This commitment leads to improved operational outcomes and reduced accident rates. Moreover, each injury requiring medical attention costs companies an average of $41,000, underscoring the economic advantages of investing in training programs. Don't wait-prioritize training today for a safer tomorrow.

Conclusion

Mastering the operation of rough terrain forklifts is essential for safety and efficiency in outdoor work environments. By understanding their unique features and adhering to proper operational protocols, you not only enhance productivity but also significantly reduce the risks associated with their use. Comprehensive training and certification are vital, ensuring that operators are well-equipped to tackle the challenges posed by uneven terrains.

This guide has shared key insights on the essential steps for safe operation, including:

- Pre-operation inspections

- Effective load management

- The critical necessity of wearing safety gear

Furthermore, the discussion on certification requirements underscores the legal and safety obligations that operators must fulfill to maintain compliance and protect their work environment. Investing in training programs fosters a culture of safety, boosts operational efficiency, and minimizes costs related to workplace injuries.

Ultimately, prioritizing safety through proper training and adherence to operational guidelines is not merely a regulatory necessity; it is a commitment to creating a safer workplace for everyone involved. As the demand for rough terrain forklifts continues to rise, staying informed and proactive in training and safety practices will empower operators to navigate the complexities of their roles effectively. This proactive approach paves the way for a more secure and productive future in construction and beyond.

Frequently Asked Questions

What are rough terrain forklifts designed for?

Rough terrain forklifts are specialized vehicles designed for outdoor use on uneven ground, making them essential in construction, landscaping, and other outdoor applications.

What are the key features of rough terrain forklifts?

Key features include all-wheel drive for enhanced traction and maneuverability, large flotation tires that distribute weight evenly, and elevated ground clearance for navigating obstacles and uneven surfaces.

How prevalent are rough terrain forklifts in construction?

Approximately 70% of construction projects employ rough terrain forklifts to manage heavy materials and traverse challenging landscapes.

Why is training important for operating rough terrain forklifts?

Proper training and knowledge of the capabilities of rough terrain forklifts can significantly reduce the risk of accidents and ensure site safety and efficiency.

Can you provide an example of the effectiveness of rough terrain forklifts?

During a recent infrastructure project, a fleet of rough terrain forklifts was utilized to move materials across a rugged site, demonstrating their reliability and versatility in challenging conditions.

What trends are emerging in the rough terrain forklift market?

There are innovations in electric and hybrid models, and the rugged equipment market is anticipated to expand considerably, possibly approaching around $10 billion by 2030.

What challenges do smaller companies face in adopting rough terrain forklifts?

High initial investment costs may hinder adoption for smaller companies, making it vital for stakeholders to stay updated on technological innovations and market dynamics.