Overview

This article presents an authoritative step-by-step guide for effectively operating a sod rolling machine. It underscores the crucial aspects of preparation, safety protocols, and troubleshooting common issues. By detailing the essential components of the machine and the operational procedures, it illustrates the significance of proper use and maintenance. Such diligence is critical for achieving optimal sod installation and minimizing workplace accidents.

Understanding the operational procedures is vital for anyone looking to utilize a sod rolling machine effectively. The guide emphasizes safety measures that must be adhered to, ensuring that users are well-informed and prepared. In addition, it addresses common challenges faced during operation, providing troubleshooting tips that enhance reliability and quality.

Ultimately, this guide serves as an indispensable resource for those seeking to achieve the best results in sod installation. By following the outlined procedures and prioritizing safety, users can significantly reduce the risk of accidents while ensuring a successful project outcome. Engage with this guide today to elevate your sod installation efforts and ensure a seamless experience.

Key Highlights:

- The sod rolling machine consists of key components: roller drum, handle, engine, wheels, and safety guards, each serving a specific function for effective operation.

- The sod compactor market is projected to grow to USD 2.1 billion by 2033, indicating a rising demand for sod rolling technology.

- Preparation for using a sod rolling machine includes clearing the area, checking the weather, wearing protective gear, inspecting the machine, and establishing a safe work zone.

- Falls and slips account for a significant percentage of construction injuries, emphasising the importance of site safety and proper equipment checks.

- Operating a sod rolling machine involves starting the engine, adjusting height, rolling in a straight path, making overlapping passes, and monitoring performance.

- Proper sod maintenance post-installation includes watering three times a day for the first ten days to ensure rooting.

- Common issues during operation include uneven rolling, machine stalling, excessive vibration, difficulty steering, and sod not pressing properly, each with specific troubleshooting steps.

- Regular maintenance and professional inspections are crucial for ensuring the reliability and performance of sod rolling machines.

Introduction

Understanding the intricacies of a sod rolling machine can elevate landscaping projects from ordinary to extraordinary. As the sod compactor market continues to grow, it is essential for both professionals and enthusiasts to grasp the fundamental components and operational techniques that maximize efficiency and effectiveness. However, navigating the complexities of machine operation and site preparation can present significant challenges. To ensure not only a successful sod installation but also a safe working environment, it is crucial to identify the key steps involved.

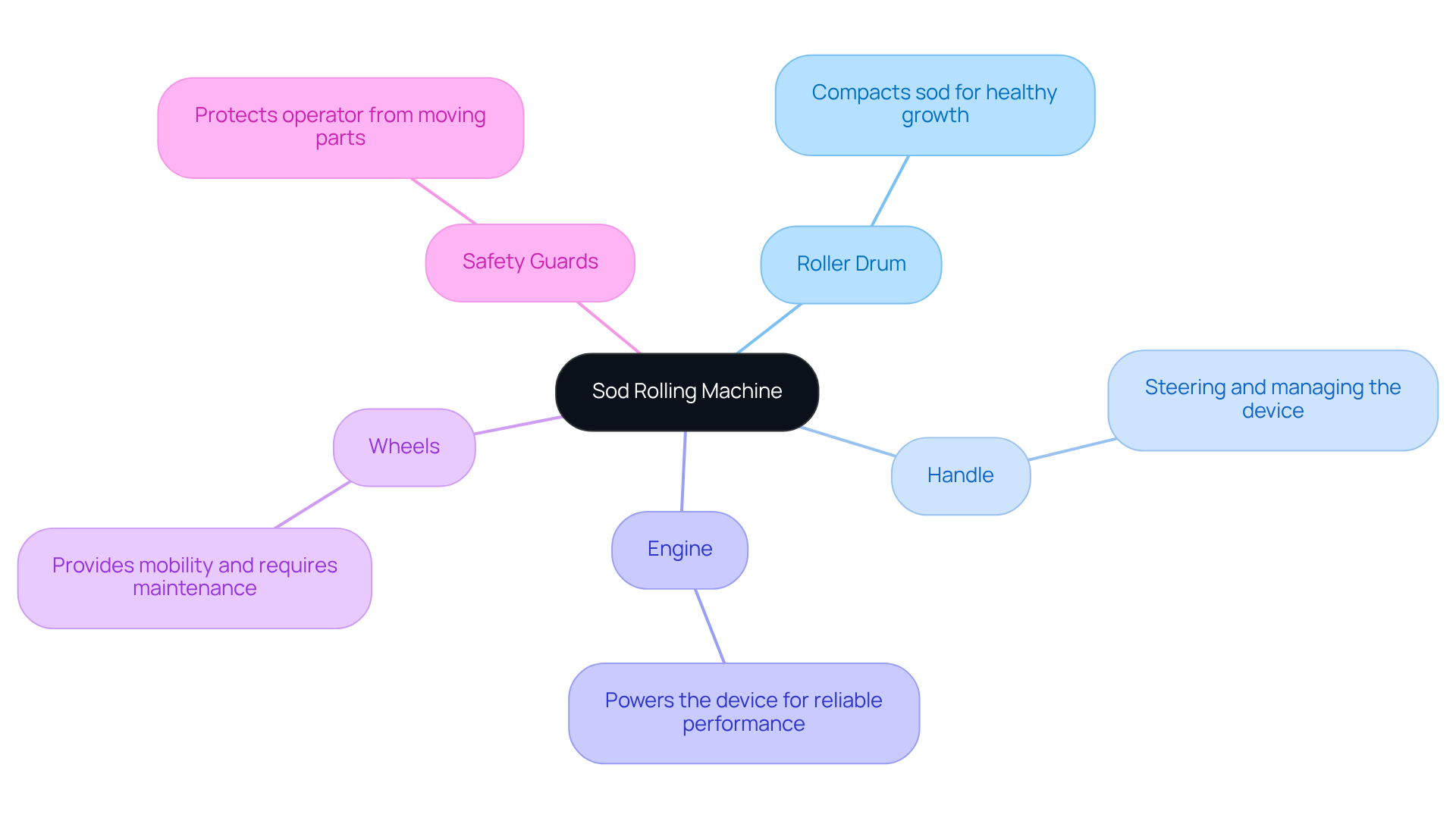

Identify the Sod Rolling Machine and Its Components

Understanding the key elements of a sod rolling machine is essential for efficient operation and optimal results in landscaping projects. Familiarizing yourself with the primary components will enhance your effectiveness:

- Roller Drum: This large cylindrical component is vital for compacting the sod into the soil, creating a firm and level surface that fosters healthy grass growth.

- Handle: The handle is crucial for steering and managing the device, allowing for precise maneuverability during operation.

- Engine: The engine powers the device, and maintaining it properly is important for reliable performance.

- Wheels: These provide mobility to the machine, necessitating regular checks for proper inflation and alignment to ensure smooth movement across various terrains.

- Safety Guards: These components protect the operator from moving parts, making it essential to verify their integrity before use.

The sod compactor market is projected to reach USD 2.1 billion by 2033, growing at a CAGR of 7.5% from 2026 to 2033. This statistic underscores the importance of understanding these components in a rapidly expanding industry. For a deeper insight into your specific model, refer to the operator's manual, which includes detailed diagrams and descriptions of each part. This knowledge not only enhances operational efficiency but also contributes to the durability of the sod rolling machine, aligning with the increasing demand for advanced sod technology. Notably, John Deere introduced smart-enabled sod machines with GPS technology in 2022, reflecting the industry's shift towards innovation. Furthermore, the rising need for specialized sod rolling machines for sports fields emphasizes the importance of understanding the components of the sod rolling machine for specific applications.

Prepare the Site and Ensure Safety Protocols

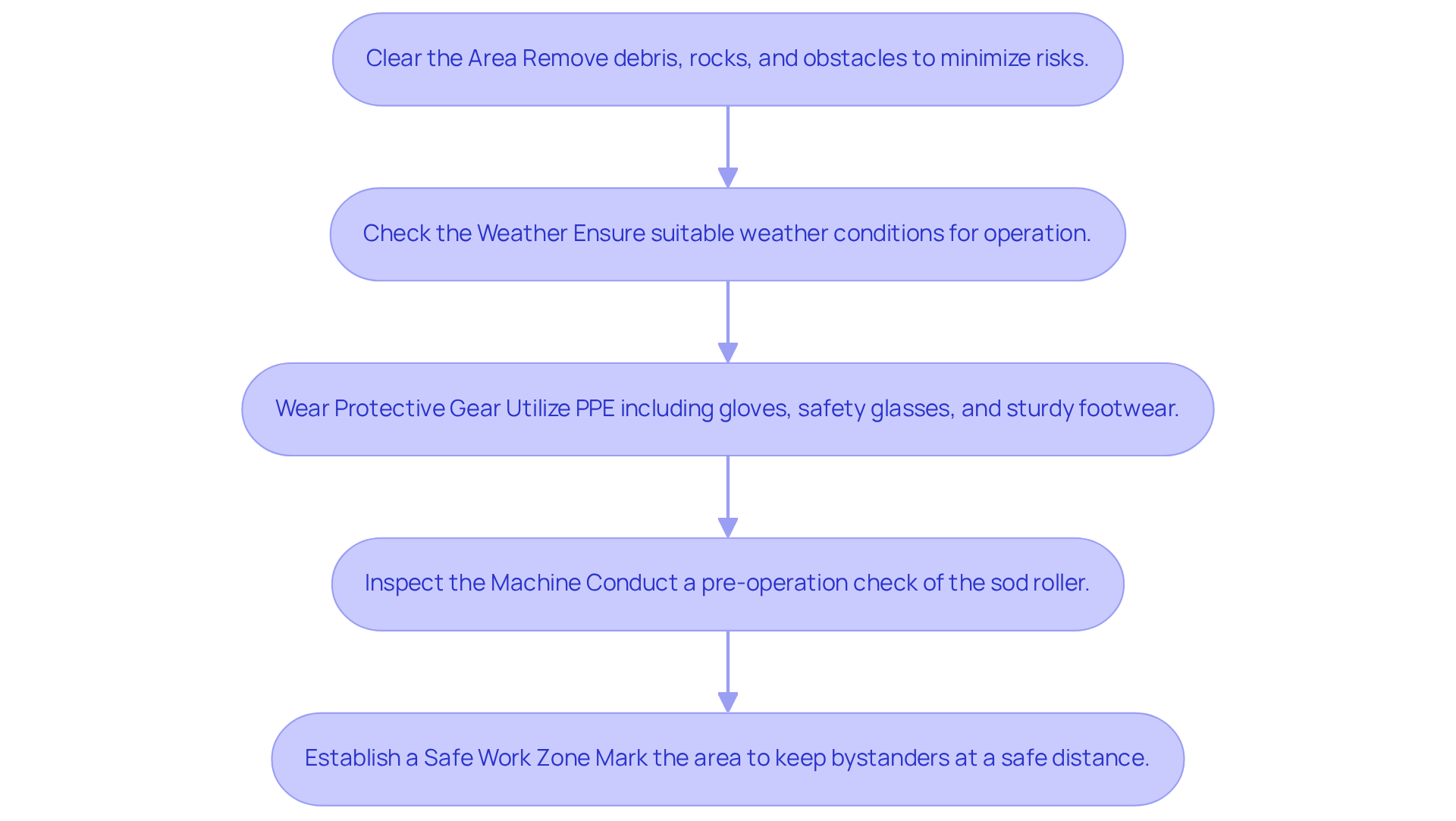

To effectively prepare the site and ensure safety when using sod rolling machines, it is essential to follow these steps:

-

Clear the Area: Remove all debris, rocks, and obstacles from the work area to minimize the risk of accidents. A clean site is crucial; falls, slips, and trips account for 31% of injuries in construction, with falls alone responsible for 35% of construction deaths.

-

Check the Weather: Ensure that weather conditions are suitable for sod rolling. Avoid operating in wet or muddy conditions, as these can lead to equipment instability and increase the risk of accidents.

-

Wear Protective Gear: Always utilize appropriate personal protective equipment (PPE), including gloves, safety glasses, and sturdy footwear. This is vital; 14% of construction workers experience hearing problems, and 25% of noise-exposed construction workers suffer from material hearing impairment. Proper gear can significantly mitigate various risks.

-

Inspect the Machine: Conduct a thorough pre-operation check of the sod roller. This includes verifying fluid levels, tire pressure, and ensuring that all safety guards are in place. Regular inspections can prevent mechanical failures that contribute to workplace injuries. Remember, over 99% of all construction accidents are preventable, underscoring the importance of these checks.

-

Establish a Safe Work Zone: Clearly mark the area where the equipment will function to keep bystanders at a safe distance. This practice is essential for maintaining a safe environment; nearly 1 in 5 workplace fatalities occur in construction settings due to preventable accidents. A construction safety manager plays a crucial role in overseeing these safety protocols, ensuring compliance, and protecting workers.

By adhering to these best practices, construction teams can significantly decrease the chances of accidents and foster a safer working environment when operating a sod rolling machine.

Operate the Sod Rolling Machine: Step-by-Step Instructions

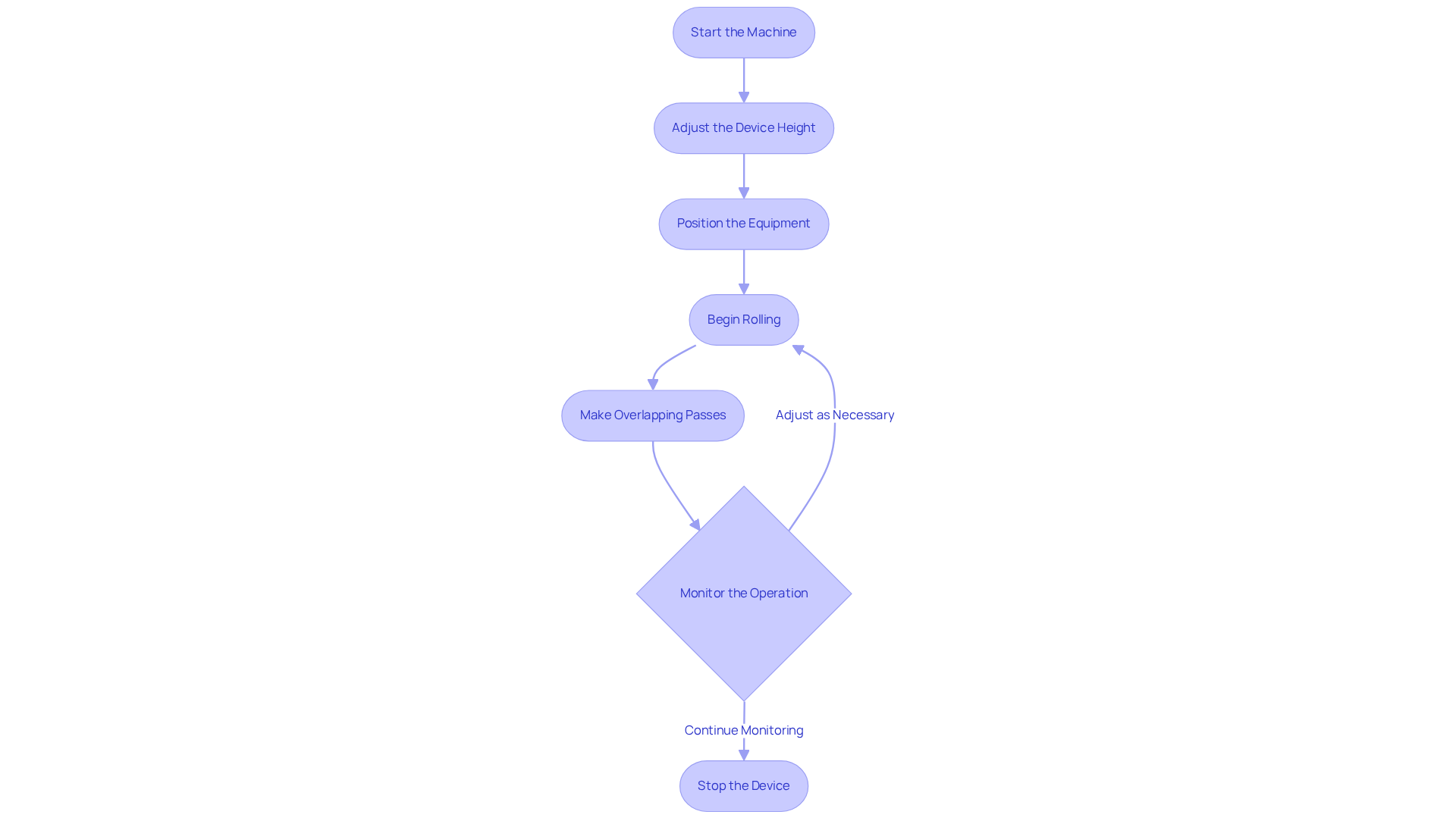

To effectively operate a sod rolling machine, follow these essential steps:

- Start the Machine: Begin by turning on the engine and allowing it to warm up for a few minutes. This ensures optimal performance.

- Adjust the Device Height: Set the equipment to the appropriate height based on the type of sod being used. This adjustment can significantly impact the quality of installation.

- Position the Equipment: Align the equipment at the starting point of the designated rolling area, ensuring a straight path for your initial pass.

- Begin Rolling: Move forward slowly, allowing the roller to press the sod firmly into the soil. Maintaining a steady pace is crucial for achieving even coverage across the area.

- Make Overlapping Passes: As you roll, overlap each pass slightly. This ensures that no areas are left unrolled, which can lead to uneven sod settling.

- Monitor the Operation: Keep a close watch on the equipment's performance and the condition of the sod throughout the process. Make adjustments as necessary to ensure optimal results.

- Stop the Device: After covering the entire area, turn off the engine and allow the equipment to cool down before performing any maintenance.

Expert insights indicate that the proper use of the sod rolling machine can improve the establishment of the sod. Professionals observe that sod should be watered sufficiently for the initial ten days to ensure rooting. As Johnathan, a landscaping professional, emphasizes, "Sod will die if it's not watered three times a day for 30 minutes for the first 10 days." Case studies indicate that effective turf methods can significantly reduce the time required for sod installation, typically taking between 2 to 5 days for complete establishment. By following these guidelines, you can maximize the efficiency and effectiveness of your sod installation project.

Troubleshoot Common Issues During Operation

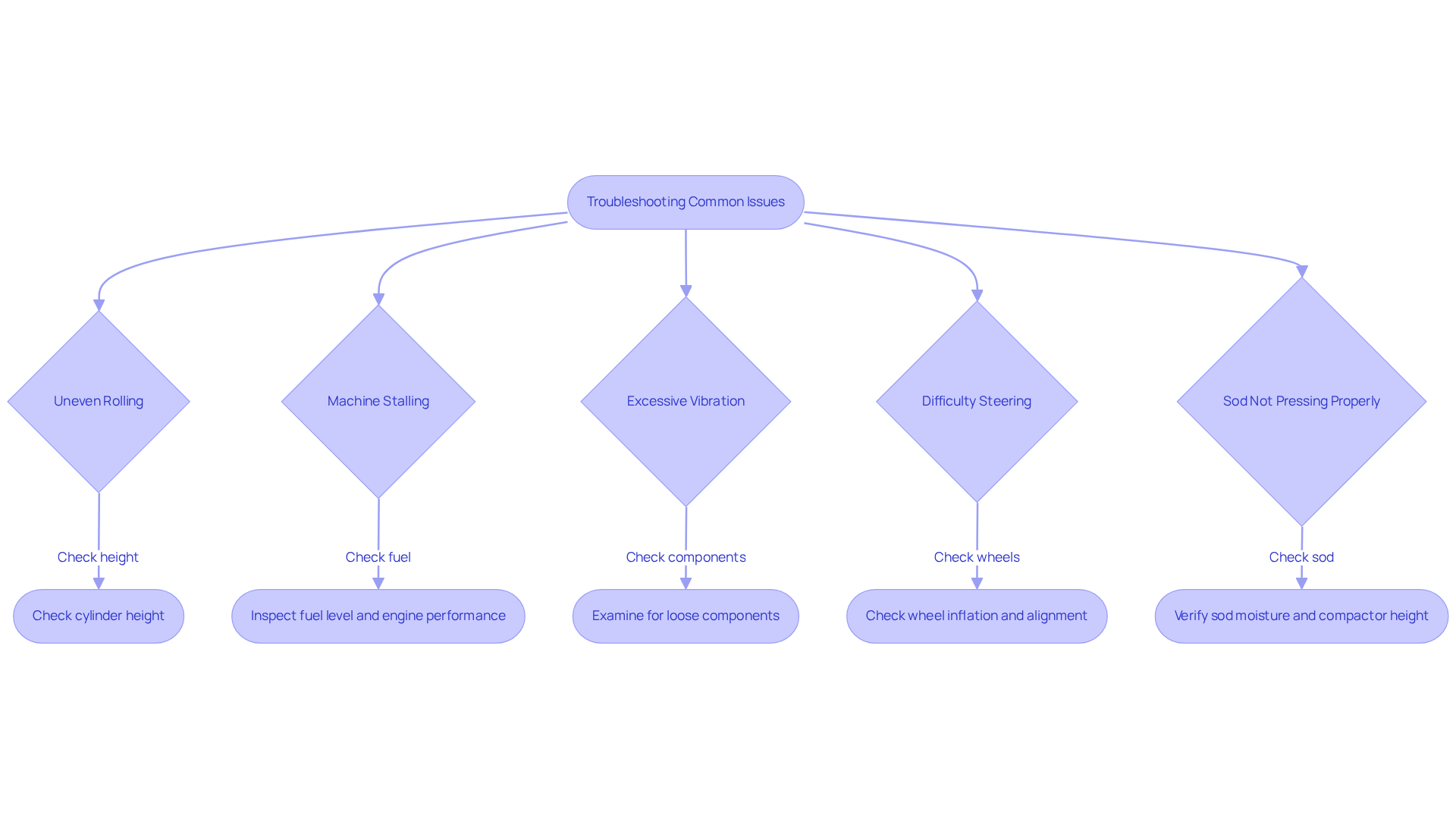

While using the sod rolling machine, you may face specific issues that need to be addressed. Here are some essential troubleshooting tips to ensure optimal performance:

-

Uneven Rolling: Begin by checking the height of the cylinder and adjust as necessary. It is crucial to ensure that the machine is level, as misalignment can lead to uneven compaction, often caused by incorrect positioning of the equipment.

-

Machine Stalling: Next, inspect the fuel level and engine performance. Blockages in the fuel line can hinder fuel flow, causing the machine to stall, so ensure there are no obstructions present.

-

Excessive Vibration: Examine the machine for loose components or uneven weight distribution on the cylinder. Regular maintenance, including tightening bolts and ensuring proper weight distribution, is vital to prevent excessive vibrations.

-

Difficulty Steering: Confirm that the wheels are properly inflated and aligned. Additionally, check for any obstructions or misalignments that could impede steering capabilities.

-

Sod Not Pressing Properly: Finally, verify that the sod is adequately moist and that the compactor is set to the correct height. Dry sod can resist compaction, while incorrect roller settings may lead to ineffective pressing.

For tailored troubleshooting steps specific to your device model, always consult the operator's manual. Implementing regular maintenance practices, such as checking fluid levels and inspecting for wear, is essential for enhancing the performance and reliability of your sod rolling machine. Furthermore, scheduling professional inspections periodically can help detect hidden issues, ensuring your equipment remains in optimal condition.

Conclusion

Mastering the operation of a sod rolling machine is vital for achieving professional results in landscaping projects. By understanding the machine's components, preparing the site adequately, and following step-by-step operational instructions, users can ensure a smooth and effective sod installation process. Emphasizing safety protocols and regular maintenance further underscores the significance of responsible machine operation.

Familiarization with the sod rolling machine's parts, such as the roller drum, handle, and engine, is essential for effective use. Preparing the site by clearing debris, checking weather conditions, and wearing appropriate protective gear significantly reduces the risk of accidents. Furthermore, adhering to detailed operational steps not only enhances the quality of sod installation but also addresses common issues that may arise during use, ensuring optimal performance.

Ultimately, the insights provided in this guide underscore the importance of proper training and maintenance in the effective use of sod rolling machines. As the demand for advanced landscaping solutions continues to grow, understanding how to operate these machines proficiently becomes increasingly vital. Embracing these practices will not only elevate the quality of landscaping projects but also contribute to a safer working environment, paving the way for successful outcomes in sod installation endeavors.

Frequently Asked Questions

What is a sod rolling machine and why is it important?

A sod rolling machine is a device used in landscaping to compact sod into the soil, creating a firm and level surface that promotes healthy grass growth. Understanding its components is essential for efficient operation and optimal results in landscaping projects.

What are the main components of a sod rolling machine?

The main components of a sod rolling machine include the roller drum, handle, engine, wheels, and safety guards. Each part plays a vital role in the machine's operation and effectiveness.

What is the function of the roller drum in a sod rolling machine?

The roller drum is a large cylindrical component that compacts the sod into the soil, helping to create a firm and level surface for grass growth.

How does the handle contribute to the operation of the sod rolling machine?

The handle is crucial for steering and managing the device, allowing for precise maneuverability during operation.

Why is the engine important for the sod rolling machine?

The engine powers the sod rolling machine, and proper maintenance is essential for reliable performance.

What role do the wheels play in the functionality of the sod rolling machine?

The wheels provide mobility to the machine, and it's important to regularly check them for proper inflation and alignment to ensure smooth movement across various terrains.

What are safety guards and why are they important?

Safety guards protect the operator from moving parts of the machine, making it essential to verify their integrity before use to ensure operator safety.

What is the projected market growth for sod compactors?

The sod compactor market is projected to reach USD 2.1 billion by 2033, growing at a CAGR of 7.5% from 2026 to 2033.

How can I gain deeper insight into my specific sod rolling machine model?

For deeper insight into your specific model, refer to the operator's manual, which includes detailed diagrams and descriptions of each part.

What recent innovations have been introduced in the sod rolling machine industry?

Notably, John Deere introduced smart-enabled sod machines with GPS technology in 2022, reflecting the industry's shift towards innovation.

Why is it important to understand the components of a sod rolling machine for specific applications?

Understanding the components is crucial for the effective operation of specialized sod rolling machines, particularly for applications such as sports fields, where specific requirements may exist.