Overview

This article serves as an essential guide for construction managers aiming to master the use of walk-behind cranes. These cranes are not only efficient but also equipped with advanced safety features, making them indispensable in urban construction settings. By enhancing maneuverability and productivity, walk-behind cranes have been reported to increase project efficiency by an impressive 30%.

In addition, it is crucial to adhere to safety guidelines and select a reliable rental service, such as EZ Equipment Rental, to ensure optimal performance and safety on the job site.

Key Highlights:

- Walk-behind cranes are designed for transporting heavy materials in confined urban spaces, enhancing maneuverability.

- Key features include compact size, user-friendly controls, high load capacity (up to 4,400 lbs), adjustable boom heights, and battery-powered options.

- Recent statistics show a 30% increase in efficiency for projects utilizing walk-behind cranes, particularly in material handling.

- Safety guidelines include conducting pre-operational checks, respecting load limits, maintaining clear work areas, ensuring operator training, and securing devices for towing.

- When selecting a rental service, consider the provider's reputation, tool condition, and flexible rental terms to optimize project success.

- EZ Equipment Rental is highlighted as a reliable provider in Irving, TX, known for quality service and a well-maintained fleet.

Introduction

In the dynamic realm of construction, efficiency and adaptability stand as critical pillars, especially in urban settings where space is limited. Introducing walk-behind cranes—these compact, innovative lifting devices are expertly crafted to maneuver through tight spaces while safely transporting heavy materials. Not only do these machines elevate operational efficiency, but they also tackle the unique challenges presented by densely populated construction sites. As the industry increasingly embraces these versatile tools, it becomes essential for project managers to comprehend their mechanics, applications, and safety protocols to optimize workflows and ensure successful outcomes. This article explores the features, benefits, and practical applications of walk-behind cranes, underscoring their rising importance in contemporary construction practices.

Understanding Walk-Behind Cranes: An Overview

Walk-behind lifting machines represent a cutting-edge solution for transporting and positioning heavy materials within confined spaces. These compact devices, uniquely engineered for urban environments, are operated by an individual walking behind them, allowing for unparalleled maneuverability in tight settings. Their significance in building management is profound, especially in densely populated areas where space constraints pose a consistent challenge.

A thorough understanding of the mechanics and functionalities of mobile hoists is vital for effective project planning and execution.

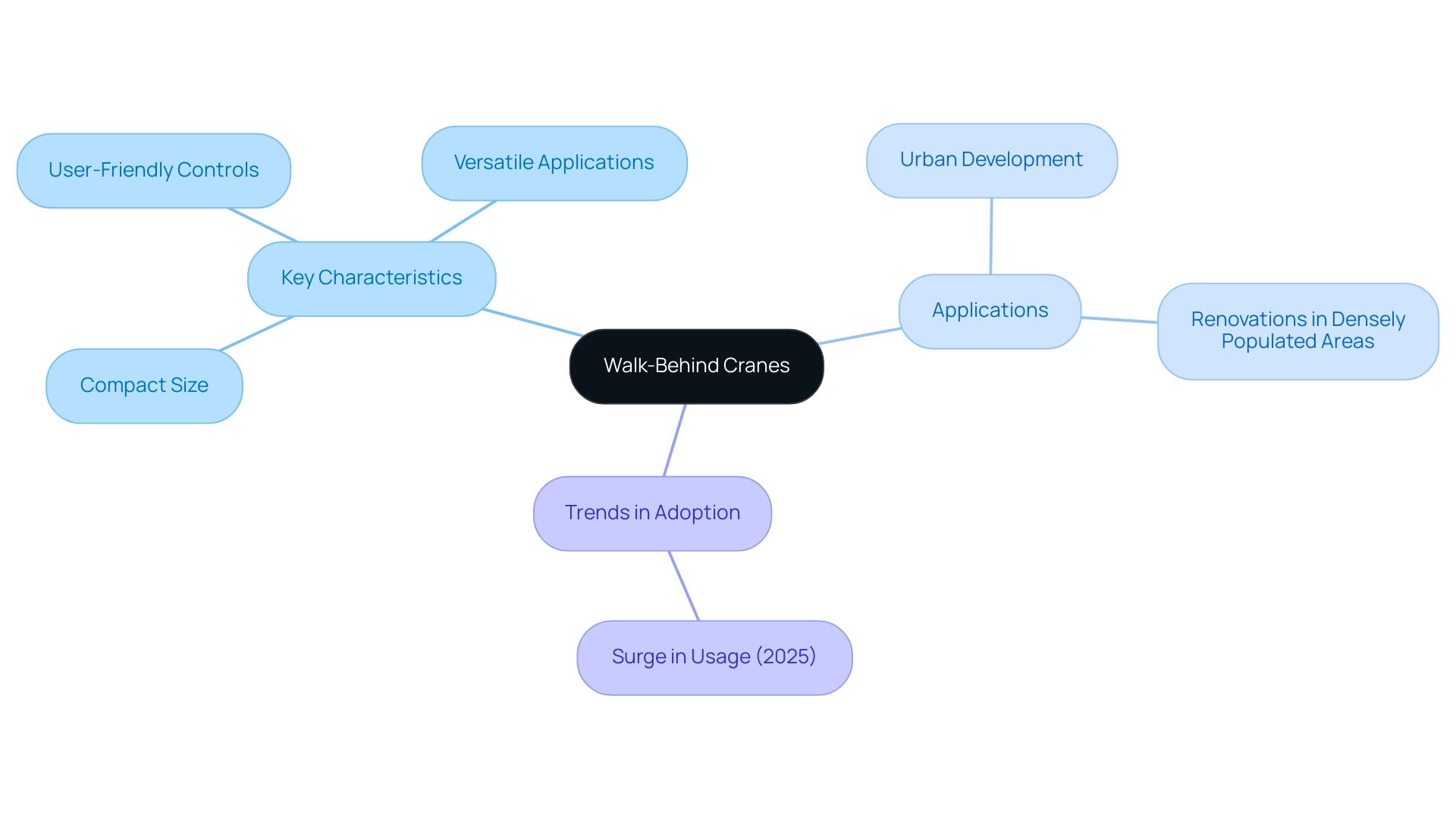

Key characteristics of walk-behind cranes include:

- Compact Size: Their design enables navigation through narrow pathways and tight corners, making them ideal for urban construction sites.

- User-Friendly Controls: Equipped with intuitive controls, these machines facilitate quick adjustments during lifting tasks, thereby enhancing operational efficiency.

- Versatile Applications: Walk-behind equipment is suitable for a wide range of tasks, from lifting heavy materials to assisting in intricate installations, significantly boosting productivity on site.

In 2025, the adoption of walk-behind cranes has surged, with statistics indicating a notable increase in their usage across various construction projects. This trend underscores a growing acknowledgment of the advantages that walk-behind cranes provide, particularly in urban settings where maneuverability is crucial. Construction managers have observed that the ability to operate in tight spaces without sacrificing safety or efficiency is transformative.

Expert opinions affirm that machines like the walk-behind crane not only streamline operations but also mitigate the risk of accidents, as operators maintain close proximity to the load, enhancing visibility and control. Adhering to load charts and lift plans is essential for ensuring safe lifting practices, thereby further bolstering the operational safety of these machines.

Practical applications of mobile hoisting equipment illustrate their effectiveness in urban development. For example, projects involving renovations in densely populated neighborhoods have successfully leveraged these machines to navigate through narrow streets and tight access points. Bobcat Contracting states, "Contact Bobcat Contracting today for a free consultation and discover how we can simplify your building process with our premium equipment rentals in Austin," emphasizing the tangible benefits of utilizing portable machinery.

Recent advancements in mobile hoisting technology have further augmented their capabilities, incorporating features such as enhanced lifting power and improved safety mechanisms, rendering them indispensable assets for project managers striving to optimize workflows in challenging environments.

Key Features and Benefits of Walk-Behind Cranes

Rear-operated hoists are equipped with a range of innovative features that significantly enhance their usability and effectiveness on building sites.

- High Load Capacity: Many models boast a remarkable lifting capacity of up to 4,400 lbs, making them versatile for handling various materials across different projects.

- Adjustable Boom Heights: This feature enables operators to lift materials to varying heights, catering to the specific requirements of each building task.

- Battery-Powered Options: The introduction of electric models not only reduces emissions but also minimizes noise, making them particularly suitable for indoor applications or environmentally sensitive areas.

The benefits of utilizing rear-operated hoists from EZ Equipment Rental are substantial.

- Increased Efficiency: Their compact design allows for maneuverability in tight spaces, facilitating quicker material handling and significantly reducing downtime on site. Recent studies indicate that projects utilizing a walk-behind crane have reported efficiency improvements of up to 30% in material transport. This efficiency is further improved by the essential role of forklifts in building, which streamline the movement of heavy materials and equipment, ensuring that projects stay on schedule.

- Enhanced Safety: Operators benefit from improved visibility and control while moving materials, which helps to minimize the risk of accidents. This is particularly crucial in busy building environments where safety is paramount. The incorporation of wheeled lifting devices and forklifts from EZ Equipment Rental enhances site safety, enabling improved oversight of material handling and minimizing possible dangers.

As the typical load capacity of wheeled lifting devices continues to develop, numerous models currently available from EZ Equipment Rental offer advanced features to satisfy the requirements of contemporary building projects. Additionally, it is crucial to recognize that mobile hoisting equipment with a rated capacity exceeding 10 tons must be registered with Workplace Health and Safety Queensland, emphasizing the necessity for adherence and safety factors in hoisting operations.

The case study on EZ Equipment Rental demonstrates the practical uses and advantages of pedestrian-operated machines in real-world situations, highlighting their significance in the building sector.

Practical Applications of Walk-Behind Cranes in Construction

Walk-behind cranes are indispensable tools in the construction industry, offering versatility across a range of applications.

- Material Handling: These cranes excel in lifting and transporting heavy materials, such as steel beams and concrete blocks, particularly in confined spaces where traditional cranes may struggle. Their compact design allows for maneuverability in tight areas, enhancing operational efficiency. Recent statistics indicate that the use of mobile hoists significantly enhances material handling efficiency, with studies showing a marked increase in productivity on construction sites.

- Installation Tasks: A walk-behind crane is essential for the accurate setup of heavy machinery, including HVAC units and lighting fixtures. Their ability to navigate narrow pathways ensures that installations are completed accurately and safely, minimizing the risk of damage to surrounding structures. Construction managers have reported that mini hoists facilitate operations in tight spaces, allowing for seamless workflow and improved safety.

- Event Setup: In the event management sector, rear-operated lifts are frequently utilized for arranging stages and audiovisual equipment in venues with limited space. Their efficiency in handling heavy loads allows event planners to execute setups swiftly and effectively.

As the building sector continues to embrace digital technologies and eco-friendly practices, the integration of walk-behind cranes is becoming increasingly vital. According to a case study on building technology statistics, the modern industry is increasingly adopting digital technologies, indicating a shift towards more efficient practices. Sagar Joshi, a previous content marketing expert at G2, remarked that 'tech-enabling building, particularly in the design and management sectors, will assist numerous companies in reducing expenses and enhancing their profits.'

For individuals seeking to rent mobile hoisting devices, EZ Equipment Rental is a trustworthy provider in Irving, TX, offering a broad selection of machinery, including boom lifts, excavators, and forklifts, to satisfy diverse project requirements across the DFW Metroplex. Customers can contact EZ Equipment Rental at (214) 951-7800 for inquiries and reservations. By understanding these applications, construction managers can strategically plan their projects and allocate resources more effectively, ensuring successful outcomes.

Safety Guidelines for Operating Walk-Behind Cranes

To ensure the safe operation of walk-behind cranes, it is essential to adhere to the following guidelines:

- Pre-Operational Checks: Conduct thorough inspections of the crane for any signs of wear or damage before use. Verify that all controls are functioning correctly; neglecting this step can lead to serious safety incidents. OSHA mandates daily inspections, highlighting their critical role in preventing accidents. A simple checklist for the walk-behind crane can help identify potential issues before operation, significantly reducing the risk of breakdowns. As noted in the case study titled "Daily Inspections Misconception," many operators assume that if a lifting device operated yesterday, it will function today, neglecting the importance of daily inspections.

- Load Limits: Always respect the manufacturer's specified load limits. Overloading is a leading cause of hoist failures, which can result in catastrophic accidents. Statistics indicate that just over half of all fatal injuries involving hoisting equipment relate to workers being struck by objects or machinery, underscoring the importance of safety precautions, especially when operating a walk-behind crane. Larry Dunville, president of Dearborn Crane & Engineering, emphasizes that this is one of the most common mistakes made with overhead equipment.

- Clear Work Area: Maintain a clear operational path, free from obstacles and personnel. This practice minimizes the risk of accidents and ensures that operators can safely maneuver the walk-behind crane. A cluttered work area can lead to unexpected hazards, making it crucial to establish a designated zone for lifting operations.

- Training: Ensure that all operators are adequately trained and familiar with the crane's controls and safety features. Proper training is essential for safe operation, as it equips operators with the knowledge to manage the tools effectively and respond to emergencies.

- Device Security and Towing Compatibility: It is crucial to ensure proper device security and vehicle compatibility for towing. This aspect is vital for maintaining safety during transportation and operation, aligning with the services provided by EZ Equipment Rental.

By implementing these guidelines, site managers can significantly enhance safety and efficiency on their job sites, fostering a culture of safety that protects both workers and equipment.

Choosing the Right Rental Service for Walk-Behind Cranes

When selecting a rental service for walk-behind cranes, managers must meticulously evaluate several key factors to guarantee optimal performance and project success.

- Reputation: It is essential to prioritize rental companies that boast a strong reputation and positive reviews. EZ Equipment Rental distinguishes itself in the Irving area through its unwavering commitment to quality and customer satisfaction, making it a dependable choice for construction needs. Their extensive range of tools—including boom lifts, excavators, and forklifts—combined with flexible rental terms and knowledgeable staff, further enhances their appeal in the DFW Metroplex. Customers consistently praise EZ Equipment Rental for their prompt service and well-maintained tools, reinforcing their status as a trusted provider.

- Tool Condition: The condition of the tools is of utmost importance. A well-maintained fleet not only boosts performance but also ensures safety on the job site. In 2025, a significant 48% of rental firms are projected to invest in new tools, highlighting a growing emphasis on maintaining high standards in quality. Senior analyst Mircea 'Mig' Dobre notes that effectively managing excess fleet will be a major concern for rental companies, underscoring the importance of choosing a provider like EZ Rental that prioritizes maintenance. Opt for a rental service that offers knowledgeable staff who can assist with equipment selection and troubleshooting, ensuring that any issues can be resolved swiftly. EZ Equipment Rental's dedication to customer service guarantees that project managers receive the support they need to enhance project efficiency.

- Flexible Rental Terms: Seek out providers that offer flexible rental agreements. This adaptability is crucial for accommodating varying project timelines and budgets, enabling managers to optimize their resources effectively. EZ Equipment Rental presents customizable rental terms that cater to the specific needs of each project, empowering construction managers to secure the right rental service for walk-behind cranes, ultimately enhancing project efficiency and success.

Conclusion

The rise of walk-behind cranes signifies a pivotal advancement in the construction industry, especially within urban settings where space is limited. These compact lifting devices are engineered for exceptional maneuverability and safety, enabling operators to transport heavy materials efficiently in confined areas. Featuring high load capacities, adjustable boom heights, and battery-powered options, walk-behind cranes not only enhance operational efficiency but also significantly improve safety on construction sites.

The practical applications of walk-behind cranes encompass a wide range of tasks, from material handling to precise installations, showcasing their versatility across the construction sector. Their capability to navigate tight spaces renders them indispensable for projects in densely populated areas, fostering increased productivity and streamlined workflows. As the industry evolves, the integration of walk-behind cranes into construction practices is becoming increasingly essential for effectively managing modern project demands.

To fully leverage the advantages of walk-behind cranes, adhering to safety guidelines is paramount, including regular inspections and comprehensive operator training. Opting for a reputable rental service like EZ Equipment Rental ensures access to well-maintained equipment and expert support, ultimately leading to successful project outcomes. Embracing walk-behind cranes is not merely a choice but a forward-thinking strategy in construction that prioritizes efficiency, safety, and adaptability in an ever-evolving industry landscape.

Frequently Asked Questions

What are walk-behind lifting machines?

Walk-behind lifting machines are compact devices designed for transporting and positioning heavy materials in confined spaces, operated by an individual walking behind them.

What are the key characteristics of walk-behind cranes?

Key characteristics include a compact size for navigating narrow pathways, user-friendly controls for quick adjustments, and versatile applications for various lifting tasks.

Why is it important to understand the mechanics of mobile hoists?

A thorough understanding of mobile hoists is vital for effective project planning and execution, ensuring safe and efficient operations.

How has the adoption of walk-behind cranes changed in recent years?

In 2025, the usage of walk-behind cranes has surged, particularly in urban construction projects, highlighting their importance in maneuvering in tight spaces.

What benefits do walk-behind cranes provide in urban settings?

They allow for safe and efficient operations in confined areas, enhancing visibility and control for operators while minimizing the risk of accidents.

What practical applications demonstrate the effectiveness of mobile hoisting equipment?

Mobile hoisting equipment is effectively used in urban development projects, such as renovations in densely populated neighborhoods, where navigating narrow streets is essential.

What recent advancements have been made in mobile hoisting technology?

Recent advancements include enhanced lifting power and improved safety mechanisms, making these machines indispensable for project managers in challenging environments.

What are the features of rear-operated hoists?

Rear-operated hoists have high load capacities (up to 4,400 lbs), adjustable boom heights, and battery-powered options for reduced emissions and noise.

How do rear-operated hoists improve efficiency on building sites?

Their compact design allows for quick material handling in tight spaces, reportedly improving efficiency by up to 30% in material transport.

What safety benefits do rear-operated hoists provide?

They enhance visibility and control for operators, reducing the risk of accidents in busy construction environments.

What regulations apply to mobile hoisting equipment with high load capacities?

Mobile hoisting equipment with a rated capacity exceeding 10 tons must be registered with Workplace Health and Safety Queensland, highlighting the importance of safety adherence.