Key Highlights:

- Key features of skid steer tillers include tilling width, depth, hydraulic requirements, tine configuration, and durability.

- Wider tilling widths enhance productivity but may require more power.

- Adjustable tilling depths (0-6 inches) allow customization for soil conditions.

- Hydraulic flow requirements typically range from 15 to 30 gallons per minute.

- High-quality tines improve performance in breaking up compacted soil.

- Best practises for operation include pre-use inspections, adjusting depth and speed, and monitoring performance.

- Proper maintenance extends the longevity of tillers, including cleaning after use, lubricating parts, and inspecting tines.

- Skid steer tillers are versatile for applications like soil preparation, garden bed creation, site preparation, erosion control, and agricultural tasks.

- Using quality components for repairs and following manufacturer guidelines is crucial for optimal performance.

Introduction

Maximizing efficiency in land preparation involves more than just powerful machinery; it requires a comprehensive understanding of the tools available, particularly skid steer tillers. These versatile attachments can significantly boost productivity when utilized effectively, offering benefits such as soil aeration and efficient site preparation. However, many operators face challenges in optimizing their performance.

What best practices can transform a skid steer tiller from a simple tool into a powerhouse of efficiency?

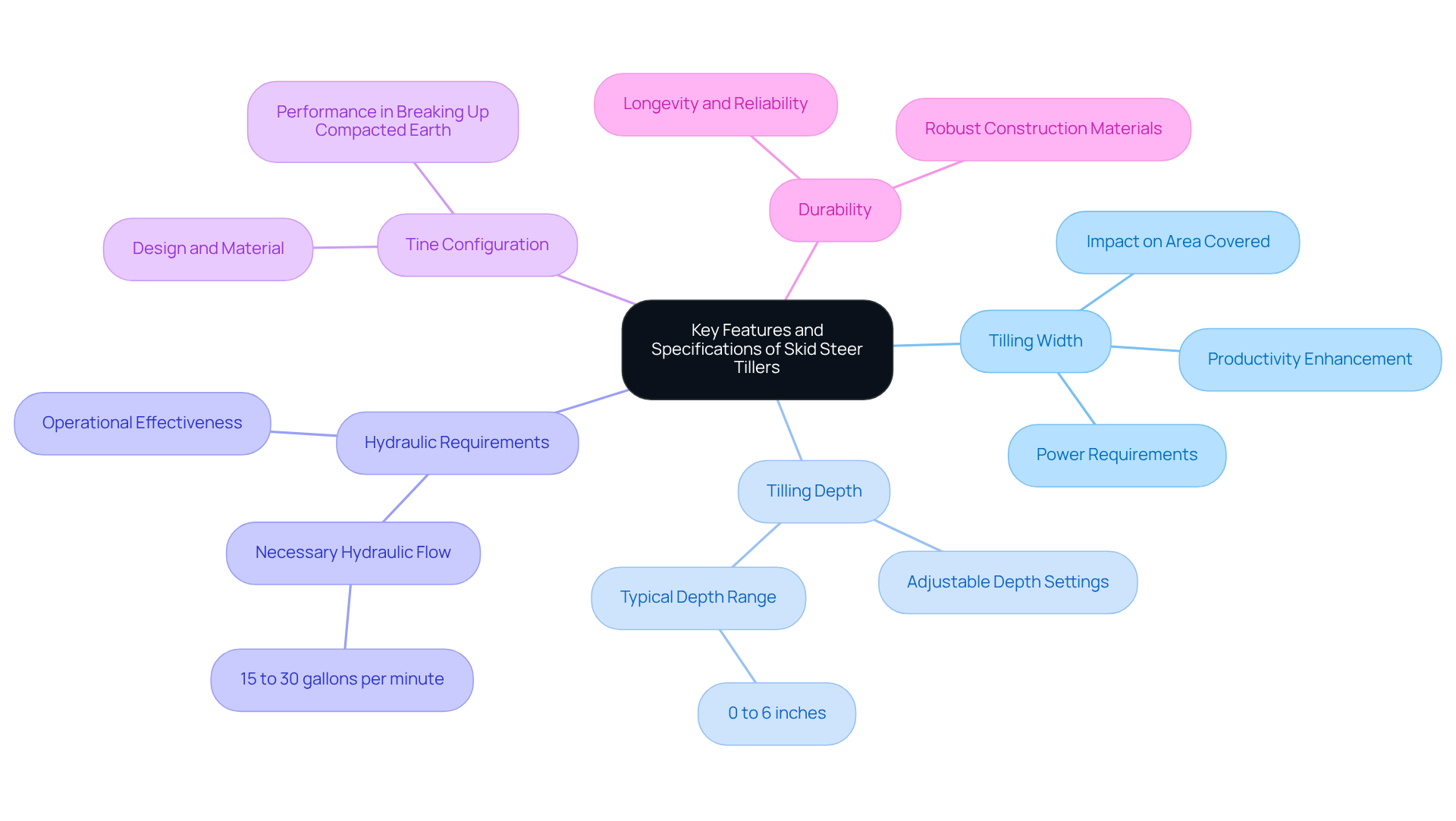

Understand Key Features and Specifications of Skid Steer Tillers

When selecting a skid steer tiller, understanding its key features and specifications is crucial. Key aspects to consider include:

- Tilling Width: The width of the tiller significantly impacts the area covered in a single pass. Wider plant stems can enhance productivity, although they may require more power.

- Tilling Depth: Adjustable depth settings enable operators to tailor the tilling process to specific soil conditions, with typical depths ranging from 0 to 6 inches.

- Hydraulic Requirements: It is essential to ensure that the skid steer tiller can deliver the necessary hydraulic flow, typically between 15 to 30 gallons per minute, to operate the cultivating tool effectively.

- Tine Configuration: The design and material of the tines play a vital role in the implement's performance. High-quality tines are more effective at breaking up compacted earth.

- Durability: Seek robust construction materials that can endure the demands of heavy-duty use, ensuring longevity and reliability.

By understanding these specifications, operators can select the appropriate cultivator for their specific tasks, thereby enhancing overall efficiency and effectiveness in land preparation.

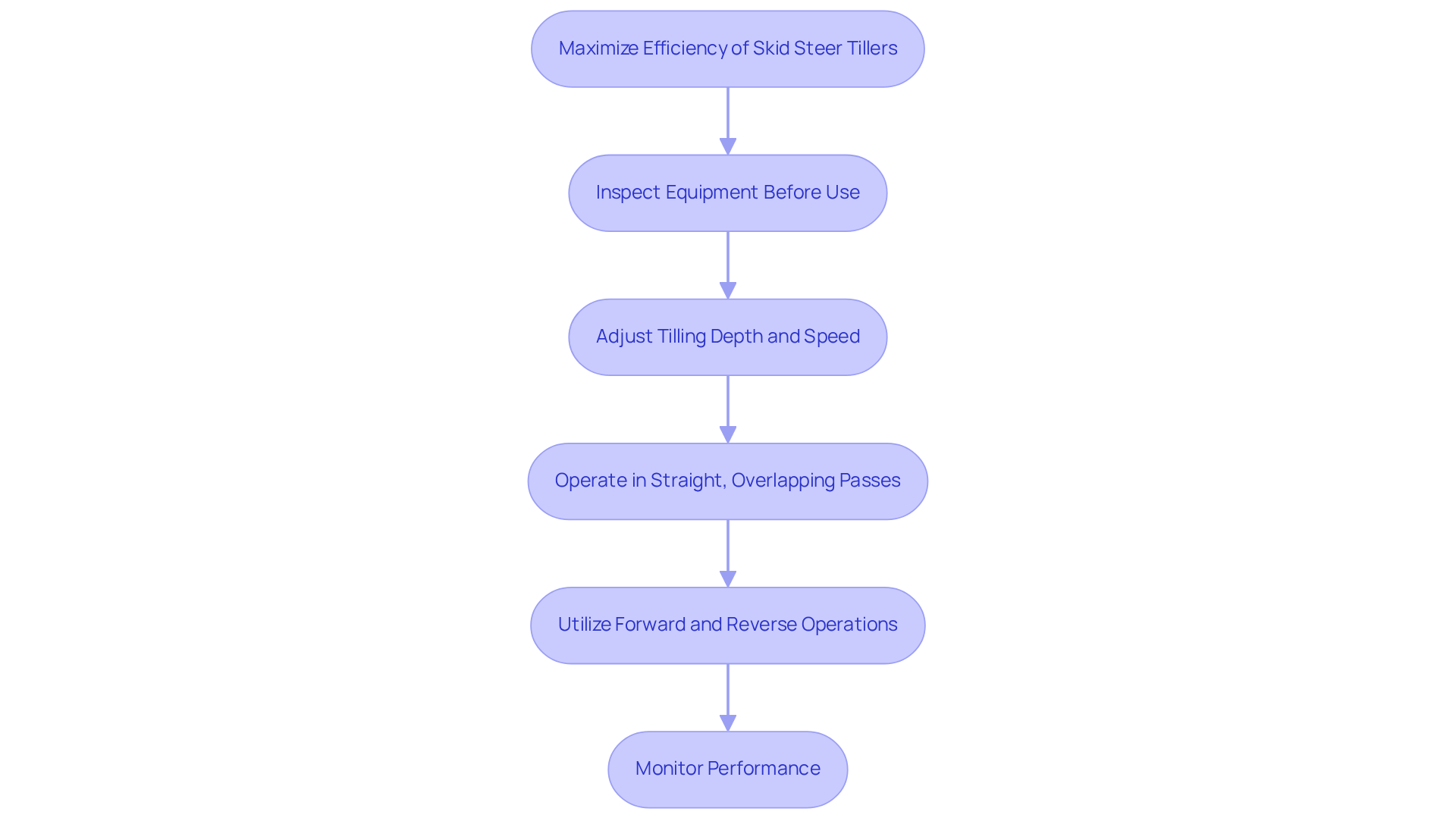

Implement Best Operational Techniques for Skid Steer Tillers

To maximize the efficiency of skid steer tillers, operators should implement several best practices:

- Inspect Equipment Before Use: Conduct a thorough pre-operation inspection to identify any damage or debris that could impact performance.

- Adjust Tilling Depth and Speed: Set the tilling depth according to ground conditions. Begin with a shallow pass if the ground is hard, gradually increasing the depth as necessary. Adjust the operational speed to align with the tilling conditions for optimal results.

- Operate in Straight, Overlapping Passes: For uniform ground preparation, operate the tiller in straight lines, overlapping each pass slightly to ensure complete coverage.

- Utilize Forward and Reverse Operations: Depending on the task, alternating between forward and reverse tilling can enhance the mixing and preparation of the ground. Forward operation maximizes power, while reverse can assist in fine-tuning the soil texture.

- Monitor Performance: Continuously observe the equipment's performance during operation. If the steering mechanism struggles, it may indicate that adjustments are needed in depth or speed.

By adhering to these operational methods, users can ensure that their equipment functions at its peak, resulting in efficient and effective ground preparation.

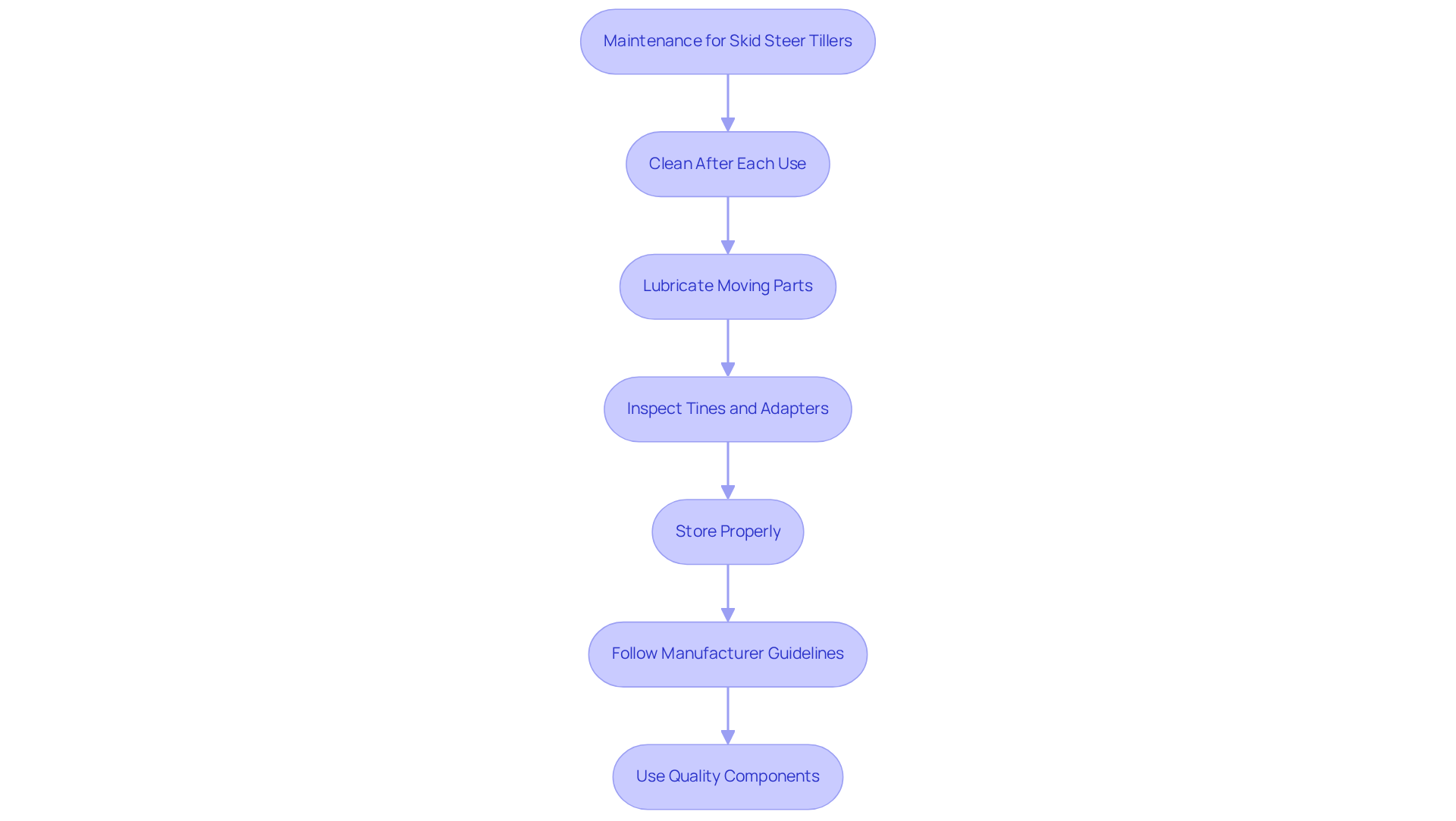

Prioritize Maintenance and Post-Operation Care for Longevity

To maximize the longevity of skid steer tillers, operators should implement essential maintenance practices that guarantee reliability and performance.

-

Clean After Each Use: It is crucial to thoroughly remove soil, plant matter, and debris from the tiller and adapter after each operation. This practice prevents corrosion and ensures smooth operation, significantly extending the equipment's lifespan.

-

Lubricate Moving Parts: Regular lubrication of bearings and other moving components is vital. This reduces friction and wear, maintaining optimal performance and reliability over time.

-

Inspect Tines and Adapters: Operators should regularly check tines for signs of wear and replace them as necessary. Ensuring that all bolts and set screws are tight is essential to prevent operational issues that could lead to costly repairs. Regular inspections help identify potential issues before they escalate into major problems.

-

Store Properly: When not in use, it is important to keep the gardening tool in a dry, sheltered location. This protects it from environmental damage, such as rust and corrosion, which can shorten its lifespan. Prolonged moisture exposure can significantly impact the machine's durability.

-

Follow Manufacturer Guidelines: Always refer to the manufacturer's manual for specific maintenance recommendations and schedules. Adhering to these guidelines ensures that the equipment remains in optimal condition.

-

Use Quality Components: When replacing parts, it is advisable to opt for high-quality, durable components. Cheap or incompatible parts may fail quickly, leading to more extensive damage and increased repair needs.

By diligently following these maintenance practices, operators can significantly extend the life of their skid steer tiller, thereby reducing the frequency of repairs and ensuring consistent, reliable performance. Well-maintained skid loaders can last between 5,000 to 7,000 hours before significant repairs are required, with some models surpassing 10,000 hours with appropriate maintenance.

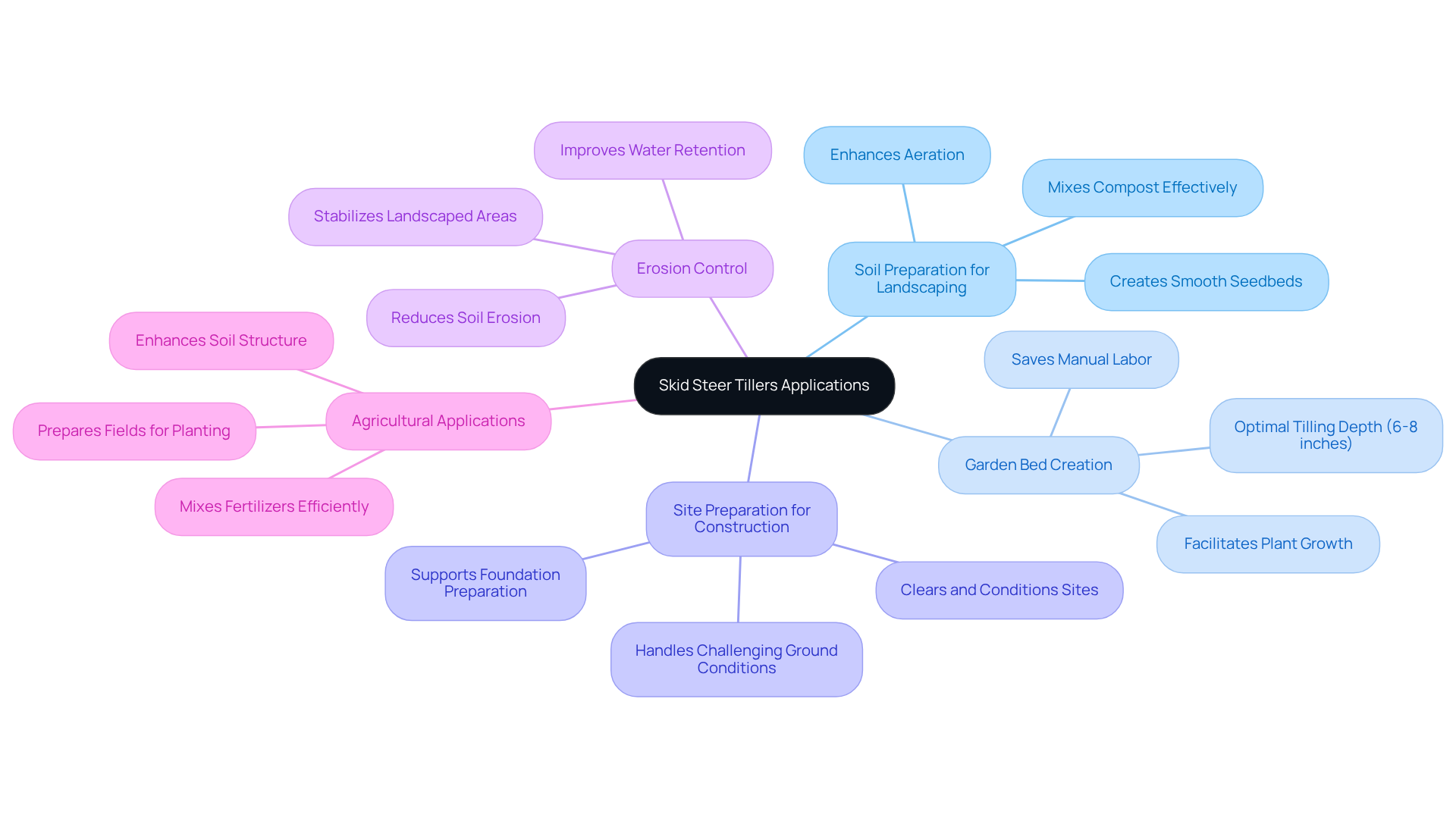

Explore Versatile Applications of Skid Steer Tillers in Landscaping and Construction

Skid steer tillers are versatile tools that excel in various applications:

- Soil Preparation for Landscaping: These attachments effectively break up compacted soil, mix in compost, and create smooth seedbeds for planting. Their ability to penetrate soil enhances aeration and nutrient distribution, leading to healthier plants.

- Garden Bed Creation: Ideal for preparing garden plots, these cultivators enable effective planting and growth of flowers, vegetables, and other plants. Achieving a tilling depth of 6 to 8 inches ensures optimal conditions for root development.

- Site Preparation for Construction: In construction projects, compact machinery is invaluable for clearing and preparing sites, ensuring the ground is adequately conditioned for foundations and landscaping. Their sturdy design allows them to handle challenging ground conditions, making them crucial for efficient site management.

- Erosion Control: By cultivating and blending earth, skid steer machines help form a more stable surface that reduces erosion in landscaping projects. This is particularly beneficial in regions prone to displacement, as it encourages improved water retention and ground health.

- Agricultural Applications: These cultivators are effective for preparing fields for planting, mixing fertilizers, and enhancing soil structure for improved crop yields. Their efficiency in processing large areas quickly saves time and labor costs, making them a cost-effective solution for farmers.

Additionally, Renter Center has added 8 new cultivators to their stock, reflecting the growing availability and demand for compact equipment in the market. Investing in mini equipment attachments optimizes workflow and improves the quality of work delivered. Understanding these applications enables operators to maximize the utility of their skid steer tiller, enhancing productivity and project outcomes across various tasks.

Conclusion

Maximizing efficiency with skid steer tillers hinges on a thorough understanding of their features, operational techniques, and maintenance practices. Selecting the appropriate tiller based on specifications like tilling width, depth, and hydraulic requirements allows operators to boost productivity and achieve optimal results in soil preparation.

Key insights emphasize the significance of implementing effective operational techniques:

- Conducting pre-operation inspections

- Adjusting tilling depth and speed

- Utilizing both forward and reverse operations to enhance soil mixing

Furthermore, prioritizing maintenance through regular cleaning, lubrication, and inspections can greatly extend the lifespan of skid steer tillers, ensuring consistent performance and minimizing repair costs.

The versatile applications of skid steer tillers in landscaping, construction, and agriculture underscore their value as essential tools for a range of projects. By adopting these best practices and understanding their capabilities, operators can improve efficiency and contribute to the success of their landscaping and construction endeavors. Embracing these strategies leads to enhanced productivity and better project outcomes, making skid steer tillers a wise investment for any operator aiming to optimize their workflow.

Frequently Asked Questions

What is the importance of tilling width in a skid steer tiller?

Tilling width significantly impacts the area covered in a single pass, with wider widths enhancing productivity but potentially requiring more power.

How does tilling depth affect the tilling process?

Adjustable depth settings allow operators to customize the tilling process to specific soil conditions, with typical depths ranging from 0 to 6 inches.

What are the hydraulic requirements for operating a skid steer tiller?

A skid steer tiller typically requires a hydraulic flow of between 15 to 30 gallons per minute to operate effectively.

Why is tine configuration important in skid steer tillers?

The design and material of the tines are crucial for the implement's performance, as high-quality tines are more effective at breaking up compacted earth.

What should be considered regarding the durability of a skid steer tiller?

It is important to seek robust construction materials that can withstand the demands of heavy-duty use, ensuring the tiller's longevity and reliability.

How can understanding these specifications benefit operators?

By understanding these specifications, operators can select the appropriate cultivator for their specific tasks, enhancing overall efficiency and effectiveness in land preparation.

List of Sources

- Prioritize Maintenance and Post-Operation Care for Longevity

- "How Many Hours Should A Skid Steer Last?" Maintenance Tips That Make or Break Heavy Equipment Life - Sur-Flow Hydraulics and Equipment Repair (https://surflowrepair.com/blog/how-many-hours-should-a-skid-steer-last-maintenance-heavy-equipment)

- Understanding Skid Steer Lifespan: How Long Do They Last? (https://typhonmachinery.com/understanding-skid-steer-lifespan?srsltid=AfmBOooSff_d0tpjynwVKpP_F_d2yxrIkf-CHjrRSoqPvupVAMmtmPSn)

- (https://wickhamtractor.com/blog-posts/revealed-what-is-the-life-expectancy-of-a-skid-steer)

- The Average Life Span of Construction Equipment - H.O. Penn (https://hopenn.com/blog/average-life-span-of-construction-equipment)

- Guide to Skid Steer Maintenance - H.O. Penn (https://hopenn.com/blog/guide-to-skid-steer-maintenance)

- Explore Versatile Applications of Skid Steer Tillers in Landscaping and Construction

- Understanding Skid Steer Rototillers (https://backyardprovider.com/blogs/blue-diamond/understanding-skid-steer-rototillers?srsltid=AfmBOorcZra0VEFthZK6rh1Q51kXrBuchkxvhAIfQuBP8zJR6CG8afZB)

- Tillers Make Gardening Simpler | Renter Center (https://rentercenter.net/tillers-make-gardening-simpler)

- Unlocking Soil Preparation Efficiency: The Power of the Mini Skid Stee (https://impordo.com/blogs/news/mini-skid-steer-tiller-soil-prep-efficiency)

- 7 Benefits of Using Mini Skid Steer Tiller Attachments (https://blog.ezequipmentrental.com/7-benefits-of-using-mini-skid-steer-tiller-attachments)

- Rotary Tiller for Skid Steers The Ultimate Tool for Soil Preparation-ealita.com (https://ealita.com/blog/rotary-tiller-for-skid-steers-the-ultimate-tool-for-soil-preparation_b141)