Overview

To maximize output with rented machinery, project managers must:

- Define project requirements

- Select appropriate equipment

- Implement effective monitoring and maintenance strategies

This approach not only streamlines operations but also enhances overall project efficiency. Furthermore, establishing measurable objectives is crucial; it allows teams to gauge progress and make necessary adjustments. Training operators effectively ensures that they can utilize the equipment to its fullest potential, thereby reducing downtime and increasing productivity.

In addition, implementing key performance indicators (KPIs) serves as a benchmark for success. These metrics provide invaluable insights into resource utilization and project timelines, facilitating timely project completion. By focusing on these critical elements, project managers can ensure that every aspect of the equipment rental process is optimized for success. The article supports this structured approach, offering a step-by-step guide that underscores the importance of each phase in the project lifecycle.

Ultimately, the combination of clear objectives, skilled operators, and robust performance metrics fosters a culture of accountability and excellence. Engaging with these strategies not only enhances project outcomes but also builds a foundation for future success. For project managers looking to elevate their operations, embracing these principles is essential. Take action today to ensure your projects are executed with precision and efficiency.

Key Highlights:

- Define the project scope by clarifying deliverables and necessary tasks for effective management.

- Compile a list of essential machinery and tools based on project requirements to maximise output.

- Set measurable objectives including timelines, budget constraints, and quality standards to enhance project success.

- Engage with stakeholders to align expectations and identify potential challenges early in the project.

- Research equipment options thoroughly, considering size, power, and functionality before selection.

- Examine lease conditions carefully to understand costs and support associated with equipment rentals.

- Conduct a cost comparison of machinery, including leasing rates and operational expenses, to identify cost-effective options.

- Confirm the availability of leased equipment in advance to prevent project delays.

- Train operators on machinery usage, safety, and maintenance to promote efficiency and safety.

- Implement a maintenance schedule to keep equipment in peak condition and avoid operational delays.

- Monitor usage of machinery to identify inefficiencies and improve performance through data analysis.

- Establish Key Performance Indicators (KPIs) to assess resource utilisation and project performance.

- Conduct regular evaluations to identify areas for improvement and ensure project goals are met.

- Collect feedback from operators to identify improvement opportunities and enhance project outcomes.

- Make informed modifications based on evaluations and feedback to optimise resource utilisation.

Introduction

Maximizing efficiency in construction is fundamentally linked to the strategic use of rented machinery. As project demands evolve, it is crucial to assess requirements effectively, select the right tools, and optimize equipment utilization. However, the complexities of machinery rental present challenges—how can project managers ensure informed decisions that lead to successful outcomes?

This guide provides a comprehensive, step-by-step approach to harnessing the full potential of rented machinery, paving the way for enhanced productivity and budget efficiency.

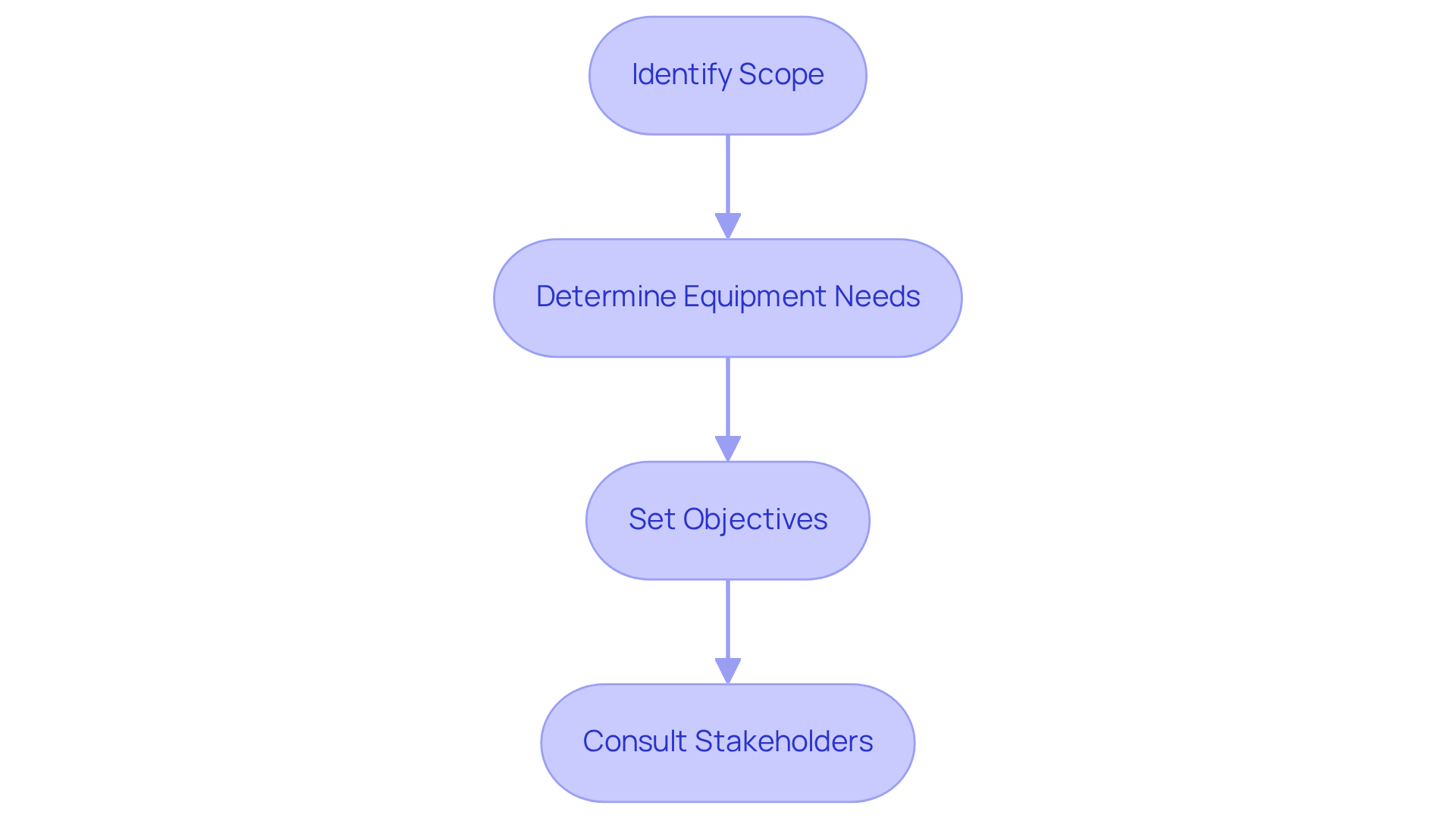

Assess Project Requirements and Objectives

-

Identify Scope: Begin by precisely defining the overall extent of your endeavor. Clarify key deliverables and outline the tasks that must be completed. Documenting these details establishes a structured framework, which is crucial for effective management.

-

Determine Equipment Needs: Based on the defined scope of work, compile a list of essential machinery and tools. Consider the scale, terrain, and specific tasks to ensure you select the appropriate tools for maximizing output with rented machinery and tools.

-

Set Objectives: Establish measurable goals for your undertaking, including timelines, budget constraints, and quality standards. Clear objectives not only guide your equipment selection but also enhance overall task efficiency. Research indicates that projects with well-defined objectives are 2.5 times more successful, highlighting the importance of this step.

-

Consult Stakeholders: Engage with team members, clients, and other stakeholders to gather insights and ensure all requirements are addressed. This collaborative approach aligns expectations and helps identify potential challenges early, reducing the risk of delays and budget overruns. Effective communication is vital; 55% of professionals primarily use email to interact with clients, underscoring the need for clear documentation and dialogue throughout the lifecycle of the work.

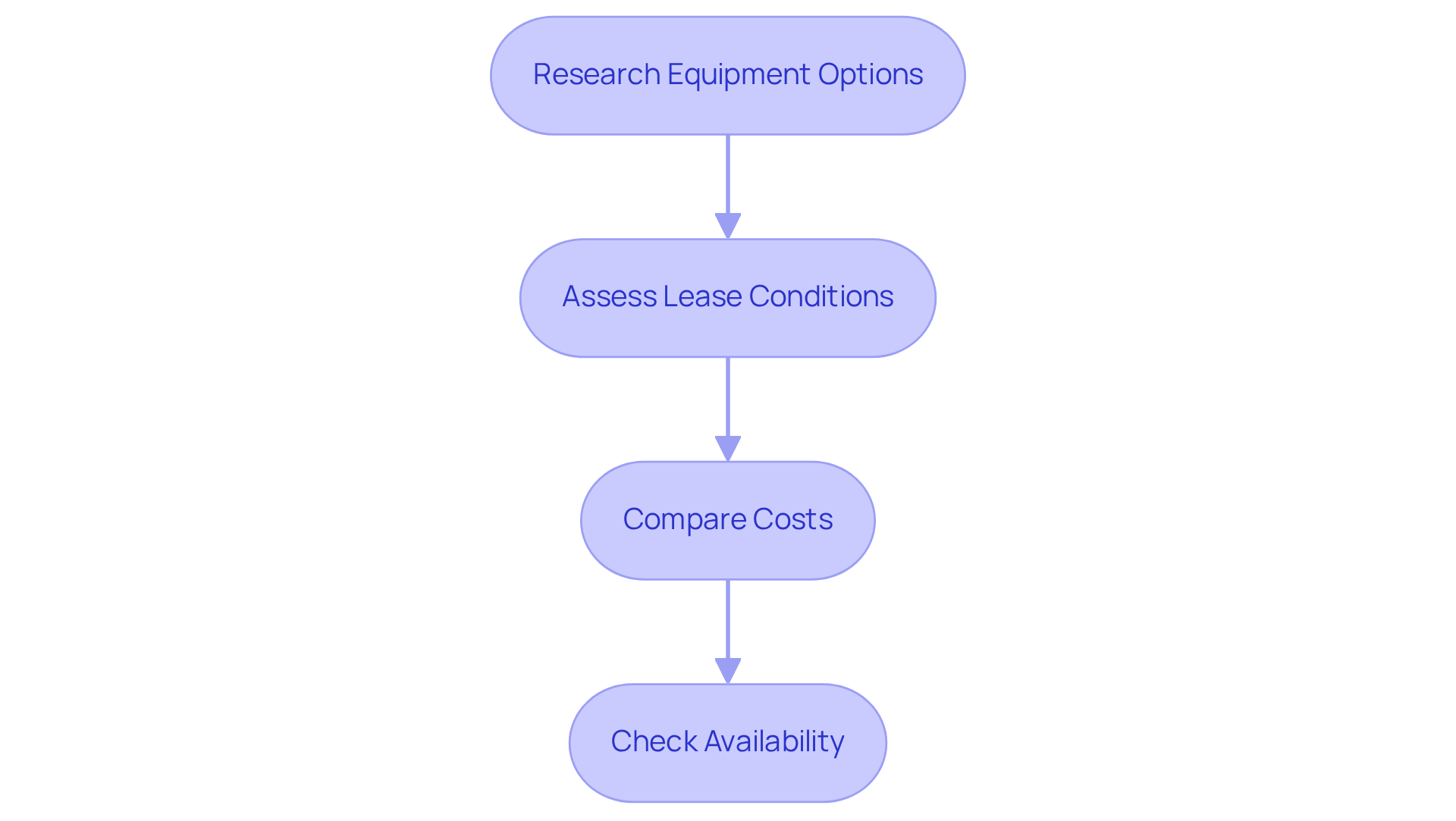

Select Appropriate Machinery and Tools

-

Research Equipment Options: Start by conducting a thorough investigation into machinery that meets your project requirements. Consider crucial factors such as size, power, and functionality. Leverage resources like tool leasing websites or consult directly with rental firms to gather valuable insights on the available choices.

-

Assess Lease Conditions: Examine the lease terms and conditions associated with each piece of equipment meticulously. Pay attention to flexibility in leasing duration, maintenance support, and any additional fees that may apply. A clear understanding of these terms is essential, as they can significantly influence your project's budget and timeline.

-

Compare Costs: Perform a comprehensive cost comparison for the selected machinery. Include leasing rates, transportation expenses, and potential operational costs in your analysis. This thorough evaluation will allow you to identify the most cost-effective options, which is essential for maximizing output with rented machinery and tools while ensuring budget efficiency.

-

Check Availability: Verify that the items you intend to lease are available for your required time frame. It is advisable to reach out to rental companies, such as EZ Equipment Rental, to confirm availability and secure your machinery in advance. This proactive approach helps prevent delays and guarantees that you have the necessary tools on-site when needed.

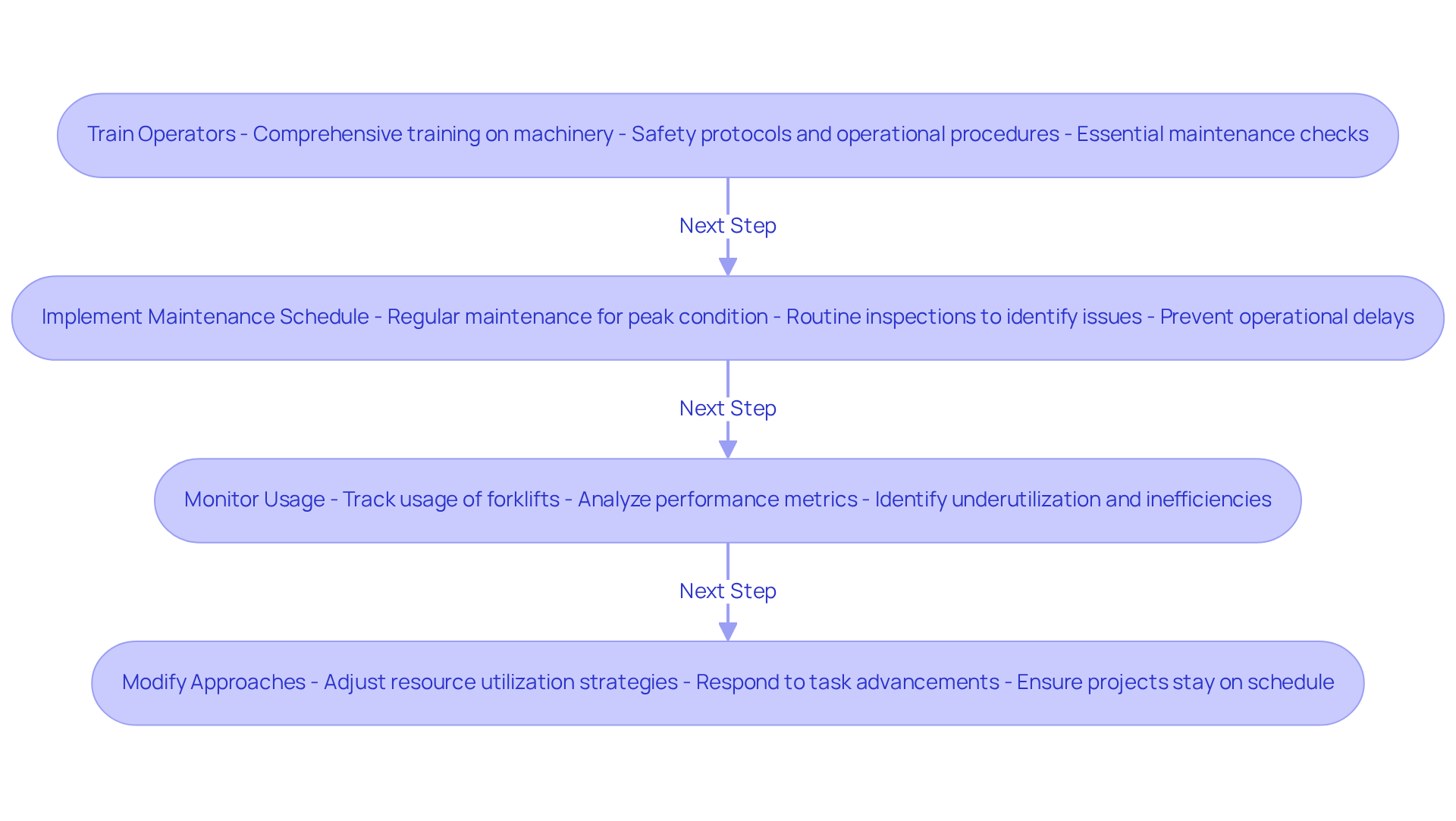

Optimize Equipment Utilization During Operations

-

Train Operators: It is essential to ensure that all operators receive comprehensive training on the machinery they will be using, including forklifts. This training should encompass safety protocols, operational procedures, and essential maintenance checks, promoting safe and efficient usage. Forklifts play a pivotal role in enhancing construction efficiency and safety, making this training crucial for optimal performance.

-

Implement a Maintenance Schedule: Establishing a regular maintenance schedule is vital for keeping machinery, including forklifts, in peak condition. Routine inspections should be arranged to quickly identify and resolve any issues, thus avoiding operational delays and enhancing machinery reliability. As noted by Iron Mechanical, "Preventing this early on puts the machinery back onto rent, and increases your profitability."

-

Monitor Usage: Actively tracking the usage of each item, especially forklifts, is key to assessing their effectiveness. Utilizing monitoring tools or software to analyze performance metrics can help identify underutilization or inefficiencies, allowing for targeted improvements. For example, a commercial construction company that implemented predictive maintenance reported a 25% reduction in downtime, showcasing the significant impact of effective monitoring.

-

Modify Approaches as Necessary: It is important to remain flexible by adjusting your resource utilization strategies in response to task advancements and unexpected challenges. This adaptability is crucial for sustaining productivity and ensuring that projects stay on schedule. A well-organized maintenance strategy not only saves funds by avoiding costly emergency repairs but also prolongs equipment lifespan, enhances safety, maximizes uptime, and increases efficiency, which is essential for maximizing output with rented machinery and tools, particularly with vital machinery like forklifts.

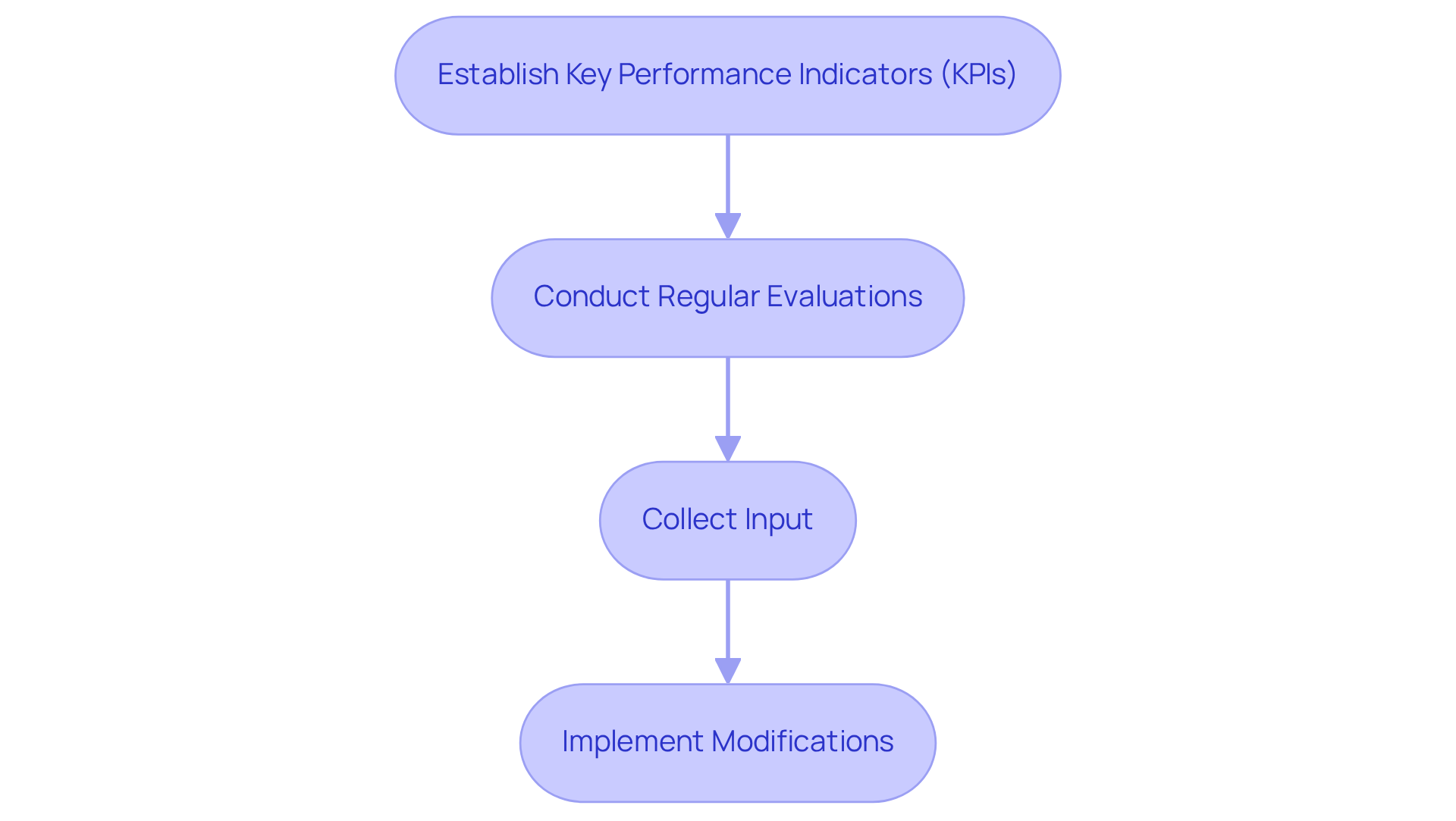

Monitor Performance and Adjust Strategies

-

Establish Key Performance Indicators (KPIs): Defining KPIs is crucial for assessing the success of resource utilization and overall project performance. Common KPIs include machinery downtime, which can account for 20-30% of unplanned downtime in construction, operational efficiency, and cost per unit of output. Understanding these metrics is vital; an hour of machinery downtime can cost construction firms an average of $260,000, and every hour a piece of machinery remains unused can lead to substantial financial losses.

-

Conduct Regular Evaluations: It is essential to arrange consistent assessments to evaluate how effectively the initiative is advancing toward its goals. These reviews should be utilized to identify discrepancies and pinpoint areas for improvement, ensuring that the project remains on track.

-

Collect Input: Gathering insights from operators and team members regarding performance and any difficulties encountered is invaluable. Employees are up to eight times more likely to identify improvement opportunities when they receive honest feedback, making this input crucial for making necessary adjustments.

-

Implement Modifications: Based on your observations and the input collected, make informed choices regarding resource utilization, timelines, and allocation. Taking initiative in addressing problems can significantly enhance results, as demonstrated by a construction manager who reported a 50% decrease in machinery downtime after implementing a systematic review process. Additionally, it is important to recognize that aging machinery is nearly three times more likely to cause unplanned downtime compared to operator errors, underscoring the necessity for proactive maintenance strategies. By focusing on these strategies, project managers can achieve maximizing output with rented machinery and tools while also enhancing productivity and budget efficiency.

Conclusion

Maximizing output through the strategic rental of machinery is a crucial approach for successful project management. By thoroughly assessing project requirements, selecting the right tools, optimizing equipment use, and continuously monitoring performance, organizations can significantly enhance their operational efficiency and effectiveness. This structured methodology not only streamlines processes but also ensures that projects are completed within budget and on time.

Key insights from this guide highlight the importance of:

- Defining project scopes

- Consulting with stakeholders

- Conducting diligent research on available equipment

Emphasizing training, maintenance, and performance monitoring further underscores the necessity of a proactive approach to machinery utilization. Implementing these best practices can lead to substantial improvements in productivity and cost management, ultimately resulting in a more successful project outcome.

In an industry where every minute counts and efficiency is paramount, embracing these strategies can transform how projects are executed. As organizations strive to optimize their operations, the insights provided in this guide serve as a valuable resource. By taking decisive action to maximize output with rented machinery, project managers can not only improve their current projects but also set a precedent for future success.

Frequently Asked Questions

What is the first step in assessing project requirements and objectives?

The first step is to identify the scope of the project by precisely defining the overall extent of the endeavor, clarifying key deliverables, and outlining the tasks that must be completed.

Why is documenting project details important?

Documenting project details establishes a structured framework, which is crucial for effective management.

How do you determine the equipment needs for a project?

To determine equipment needs, compile a list of essential machinery and tools based on the defined scope of work, considering the scale, terrain, and specific tasks to ensure appropriate tool selection.

What should be included in setting project objectives?

Project objectives should include measurable goals such as timelines, budget constraints, and quality standards to guide equipment selection and enhance overall task efficiency.

What is the significance of having well-defined objectives in a project?

Research indicates that projects with well-defined objectives are 2.5 times more successful, highlighting the importance of this step.

Why is it important to consult stakeholders during the project planning phase?

Consulting stakeholders, including team members and clients, helps gather insights, align expectations, and identify potential challenges early, reducing the risk of delays and budget overruns.

What role does effective communication play in project management?

Effective communication is vital in project management, as it helps ensure clear documentation and dialogue throughout the lifecycle of the work. Statistics show that 55% of professionals primarily use email to interact with clients, underscoring its importance.