Overview

The primary aim of this article is to serve as a comprehensive guide on the usage and safety of pallet jacks available for rental in Dallas, TX. It underscores that renting pallet jacks, whether manual or electric, not only provides significant cost savings and flexibility for businesses but also stresses the critical importance of adhering to safety guidelines and implementing proper maintenance practices. This ensures both efficient and safe operation, which is paramount in any workplace.

Key Highlights:

- Pallet jacks are essential for material handling, classified into manual and electric types.

- Manual pallet jacks require physical effort, while electric models automate lifting, enhancing efficiency.

- EZ Equipment Rental in Dallas offers both types, catering to diverse operational needs.

- The pallet jack rental market is growing, driven by demand in retail and e-commerce sectors.

- Renting pallet jacks saves costs associated with purchase and maintenance, making it ideal for short-term projects.

- EZ Equipment Rental provides competitive pricing, often lower than market averages.

- Safety guidelines include inspecting equipment, proper load management, and using personal protective equipment.

- Common issues with pallet jacks include hydraulic problems and steering difficulties, which can be resolved with regular maintenance.

- Regular maintenance practices can extend the lifespan of pallet jacks and reduce unexpected repair costs.

- Customer feedback emphasizes the importance of service quality and safety features when renting equipment.

Introduction

In the dynamic realm of material handling, pallet jacks stand out as essential tools for businesses aiming to enhance both efficiency and safety. These adaptable devices, offered in manual and electric variants, meet a wide array of operational demands—ranging from light-duty tasks to the transportation of heavy loads. As the need for effective material handling solutions escalates, particularly within the fast-evolving sectors of retail and e-commerce, it becomes imperative for project managers to grasp the nuances of pallet jacks.

This article explores the different types of pallet jacks, their functionalities, the benefits of renting versus purchasing, and key safety guidelines. Each aspect is designed to empower businesses to make informed choices that boost productivity and foster a safer work environment.

Understanding Pallet Jacks: Types and Functions

Lifting vehicles, commonly known as pallet trucks, are vital in material handling, facilitating the raising and transport of platforms. These devices are primarily categorized into two types: manual and electric. Manual lifting devices require the operator's physical effort to lift and maneuver loads, making them ideal for lighter tasks or environments with limited power sources.

In contrast, electric lifting devices come equipped with a motor that automates lifting and moving, significantly reducing physical strain on operators and enhancing efficiency, particularly in high-volume settings. At EZ Equipment Rental in Dallas, we proudly offer both manual and electric lifting devices, such as pallet jack rental Dallas TX, ensuring that construction project managers can select the right tools tailored to their specific needs. Our electric lifting devices can manage loads ranging from 1.2 tons to 1.6 tons, making them increasingly preferred in industries like retail and e-commerce, where the swift movement of products is essential. This versatility guarantees that you acquire the appropriate equipment, enhancing productivity and safety on the job site.

Recent statistics indicate that the lift truck market is evolving, with significant contributions from the retail and e-commerce sectors across Asia Pacific, North America, and Europe. This growth is partly driven by the demand for efficient material handling solutions that can keep pace with escalating needs. Furthermore, the competition between manual and electric lifting devices is intensifying as companies explore innovative designs and strategic partnerships to elevate their offerings.

The challenges faced in the platform trolley market underscore the necessity for such innovations. Practical applications illustrate the effectiveness of both types of lifting carts. For example, in a bustling warehouse, electric hand trucks can streamline operations by enabling workers to transport heavier items effortlessly, while manual hand trucks remain a reliable choice for smaller tasks or in confined spaces. Expert opinions stress the importance of selecting the appropriate type of lifting equipment based on specific operational contexts, load capacities, and the physical capabilities of the workforce.

As Tajammul Pangarkar emphasizes, understanding these distinctions is crucial for enhancing material handling procedures. This tailored access to a diverse range of specialized forklifts, including pallet jack rental Dallas TX, at EZ Equipment Rental not only boosts productivity but also prioritizes safety on the job site. As the lifting equipment market continues to evolve, comprehending the differences between manual and electric models will empower construction project managers to make informed decisions that enhance both productivity and safety. Additionally, global market dynamics, including substantial export contributions from Germany and the United States, further influence the landscape of loading devices and their applications.

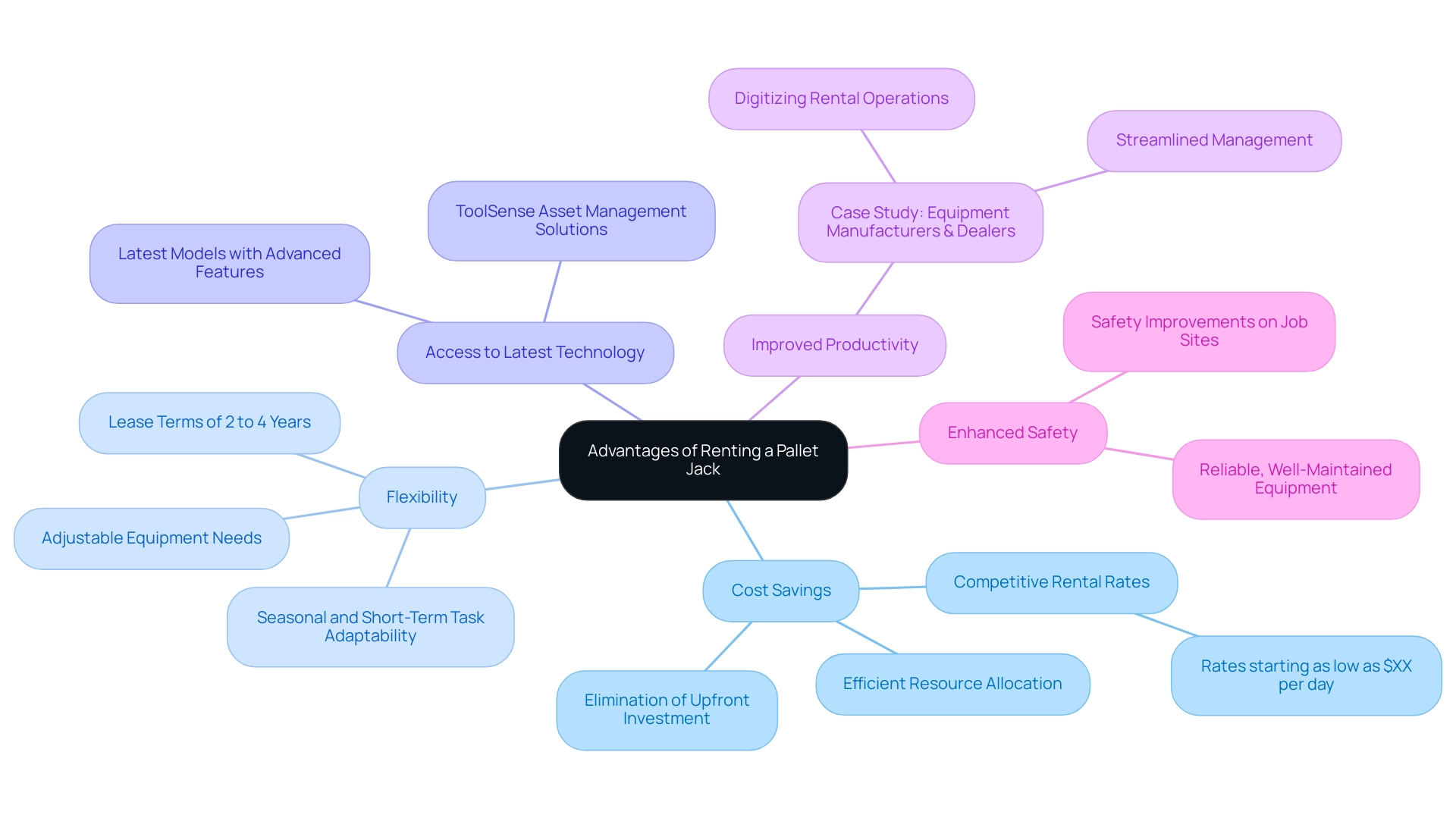

The Advantages of Renting a Pallet Jack

Renting a pallet jack in Dallas, TX, offers numerous advantages that can significantly benefit businesses, particularly in the construction sector. One of the primary benefits is cost savings; renting eliminates the substantial upfront investment required for purchasing tools, along with the ongoing maintenance costs associated with ownership. EZ Equipment Rental in Dallas provides competitive pricing options, making quality forklifts accessible and affordable for businesses of all sizes.

For example, our rental rates start as low as $XX per day, allowing businesses to manage their budgets effectively. In fact, statistics indicate that a significant percentage of businesses prefer renting tools for short-term projects, as it allows them to allocate resources more efficiently. Lease terms typically range from 2 to 4 years, providing flexibility for project managers considering rental agreements. Flexibility is another key advantage of renting.

Businesses can easily adjust their equipment needs based on project demands, which is especially useful for seasonal or short-term tasks. This adaptability ensures that companies can respond swiftly to changing project requirements without the burden of excess equipment. Moreover, leasing a material handling device provides access to the latest models equipped with advanced features, enhancing operational efficiency.

For instance, companies that have embraced pallet jack rental in Dallas, TX, have reported notable improvements in productivity and safety on job sites. A case study involving manufacturers and dealers showcased how digitizing rental operations streamlined management, leading to significant cost savings and enhanced efficiency.

In 2025, the benefits of renting items continue to be evident, with many businesses recognizing the financial advantages. By opting for rental from EZ Equipment Rental, companies can focus on their core operations while enjoying the peace of mind that comes with reliable, well-maintained equipment. Our customers have shared their positive experiences, stating, 'EZ Equipment Rental made our project seamless with their affordable rates and excellent service.' Additionally, solutions like ToolSense provide asset management functions that improve maintenance and operational efficiency, further reinforcing the advantages of renting equipment.

In summary, the choice to lease a lifting device not only supports cost-effective operations but also enhances flexibility and access to cutting-edge technology, making it a strategic decision for construction project managers seeking to optimize their resources.

Where to Rent Pallet Jacks in Dallas, TX

In Dallas, TX, EZ Equipment Rental distinguishes itself among companies offering pallet jack rental Dallas TX through its extensive selection and competitive pricing. Clients can explore a variety of lifting devices tailored for diverse applications, ensuring they meet their specific needs. Committed to exceptional customer service, EZ Equipment Rental operates with accessible store hours:

- Monday to Friday from 7:30 AM to 5:30 PM

- Saturday from 7:30 AM to 5:00 PM

- Closed on Sundays

Customer feedback consistently praises EZ Equipment Rental for its unwavering dedication to quality and service. One satisfied client remarked, 'The lifting device I rented was easy to operate and made my job considerably more efficient!' Such positive testimonials reinforce EZ Equipment Rental's status as a preferred choice among construction project managers and businesses. In 2025, the company has garnered numerous accolades for its lifting equipment options, with many customers highlighting the ease of use and efficiency of the tools.

A comparative analysis of rental prices for forklifts in Dallas, including pallet jack rental Dallas TX, shows that EZ Equipment Rental remains highly competitive, frequently offering better rates than its competitors. For instance, while the average rental cost for lifting devices in the area hovers around $50 per day, EZ Equipment Rental often provides rates as low as $45, making it an attractive option for budget-conscious clients. For those considering rental alternatives, expert insights emphasize the importance of choosing a provider that not only offers a diverse range of tools but also prioritizes customer support and satisfaction.

As one industry expert noted, "Reconstruction post-natural disasters necessitates immediate access to equipment," highlighting the essential role of dependable rental services. EZ Equipment Rental embodies these qualities, positioning itself as a leading contender in the pallet jack rental Dallas TX market. With a commitment to addressing diverse customer needs, EZ Equipment Rental is well-equipped to tackle any project, regardless of size.

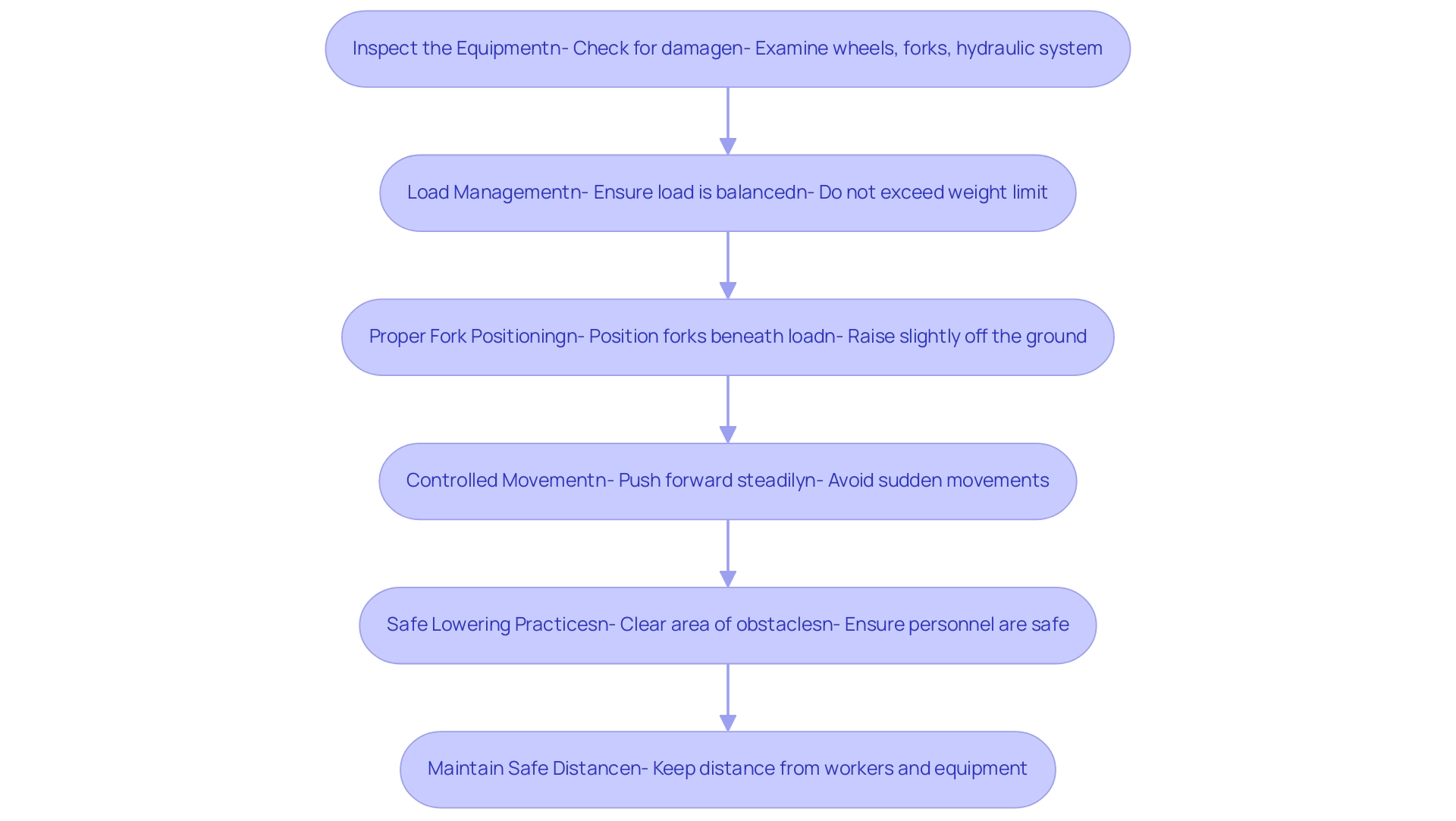

Step-by-Step Guide to Using a Pallet Jack Safely

To ensure the safe operation of a pallet jack, it is imperative to adhere to the following guidelines:

- Inspect the Equipment: Before use, conduct a thorough check of the lifting device for any visible damage or mechanical issues. This includes examining the wheels, forks, and hydraulic system to confirm that everything is functioning properly.

- Load Management: Ensure that the load is balanced and does not exceed the weight limit of the transport device. An unbalanced load can lead to tipping or loss of control during transport, which poses significant risks.

- Proper Fork Positioning: Carefully position the forks beneath the load and raise it slightly off the ground. This minimizes the risk of the load shifting during movement, enhancing stability.

- Controlled Movement: Push the transport device forward while maintaining load stability. Avoid sudden movements or sharp turns, as these can destabilize the load and increase the risk of accidents.

- Safe Lowering Practices: When lowering the load, ensure the area is clear of obstacles and personnel. This precaution helps prevent injuries to yourself and others in the vicinity.

Maintaining a safe distance from other workers and equipment is crucial throughout the operation. Statistics reveal that from 2002 to 2016, there were eight reported amputations related to platform truck usage, underscoring the importance of adhering to safety protocols. Furthermore, a study analyzing non-occupational injuries associated with platforms indicated an estimated 30,493 emergency department visits due to platform-related incidents from 2014 to 2018, with the elderly being particularly vulnerable.

Industry experts emphasize the need for ongoing education about the dangers of improper pallet jack use. Judd Michael, Nationwide Insurance Professor of Safety & Health at Penn State University, asserts, "While the number of fatalities and injuries tallied over the 5-year period may seem small, it should be noted that minor injuries and near misses are not counted in these figures." Regular training sessions can significantly enhance compliance rates and reduce workplace accidents.

As highlighted by recent news, improper use of powered industrial trucks (PITs) has led to frequent OSHA fines, particularly in wood-based companies, indicating an urgent need for improved precautions.

By adhering to these precautionary guidelines and procedures, operators can substantially reduce hazards associated with lifting equipment usage, ensuring a more secure working environment. This is especially significant for individuals using pallet jack rentals in Dallas, TX, where compliance with safety regulations is essential for both personal and business activities.

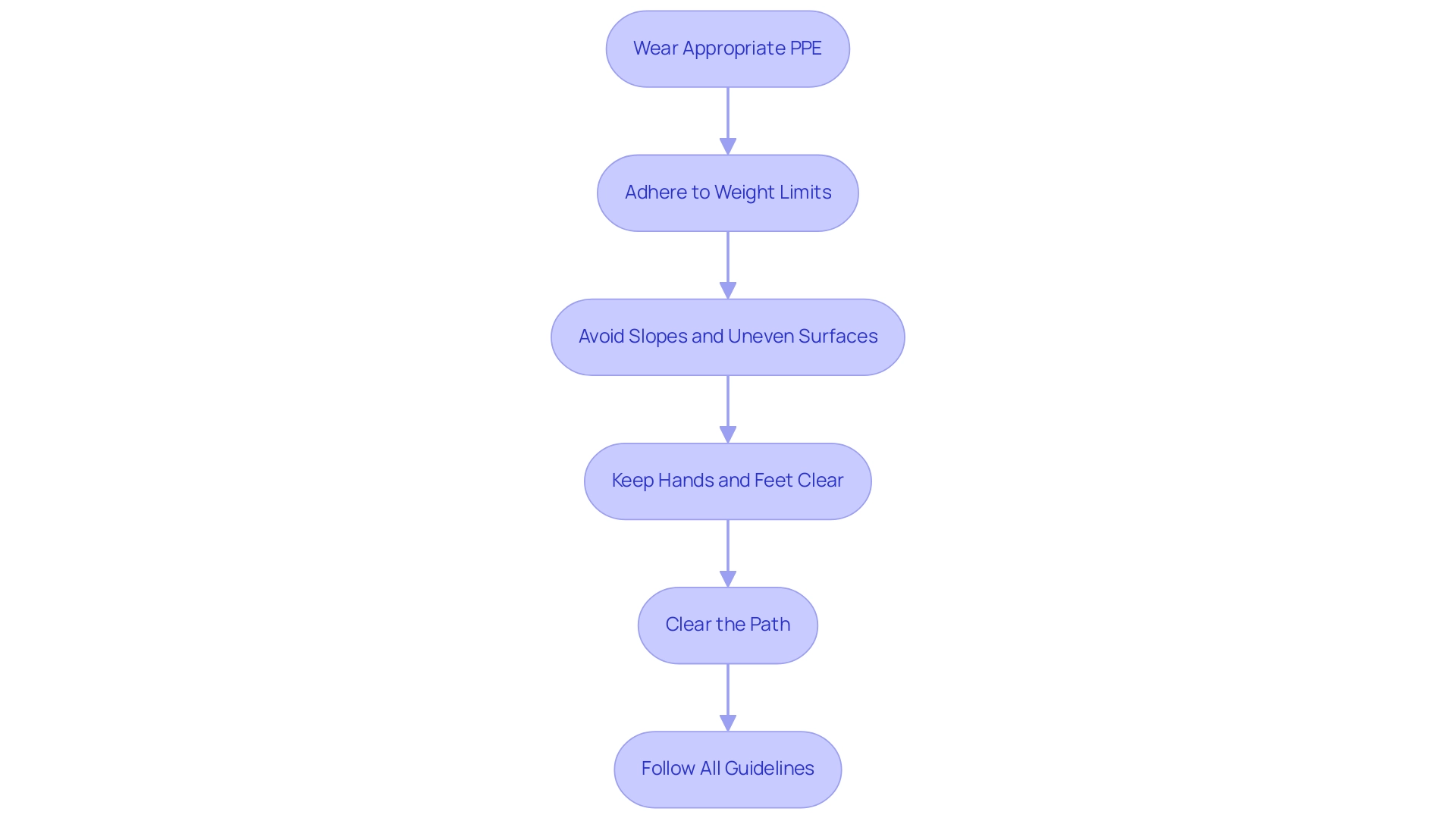

Safety Guidelines for Pallet Jack Operation

Using a lifting device safely is essential for avoiding accidents and injuries in the workplace. To ensure safe operation, follow these essential guidelines:

- Wear Appropriate Personal Protective Equipment (PPE): Always don steel-toed shoes and other necessary protective gear to safeguard against potential injuries.

- Adhere to Weight Limits: Never surpass the designated weight capacity of the lifting device to maintain stability and control.

- Avoid Slopes and Uneven Surfaces: Operating on inclines or uneven terrain increases the risk of accidents. Always choose flat, stable surfaces for movement.

- Keep Hands and Feet Clear: Ensure that your hands and feet are positioned away from the equipment during operation to prevent injuries.

- Clear the Path: Before moving any load, check that the route is free of obstacles to avoid collisions and ensure a smooth transit.

Recent statistics indicate that approximately 14% of pallet-related injuries happen in retail environments, highlighting the critical importance of following protocols. As Fady Attia, a Project Engineer at Damotech, emphasizes, "Implementing strict protocols is crucial to reduce hazards related to lift operations."

A thorough examination of forklift and pallet-related injuries in wood-related industries uncovered 17 fatalities and 211 severe injuries from 2015 to 2019, with most incidents involving pedestrians hit by forklifts. This underscores the urgent need for stringent protection measures and operator training.

In 2025, revised regulations highlight the necessity of PPE for forklift operators, reinforcing the significance of protective equipment in reducing hazards. Furthermore, operator error contributes to a substantial portion of pallet jack accidents, making proper training and adherence to guidelines crucial for all users of pallet jack rental Dallas TX. By following these expert precautions, operators can significantly reduce the likelihood of accidents and ensure a safer working environment.

EZ Equipment Rental remains committed to customer satisfaction and safety, providing the necessary resources and training to support safe equipment usage.

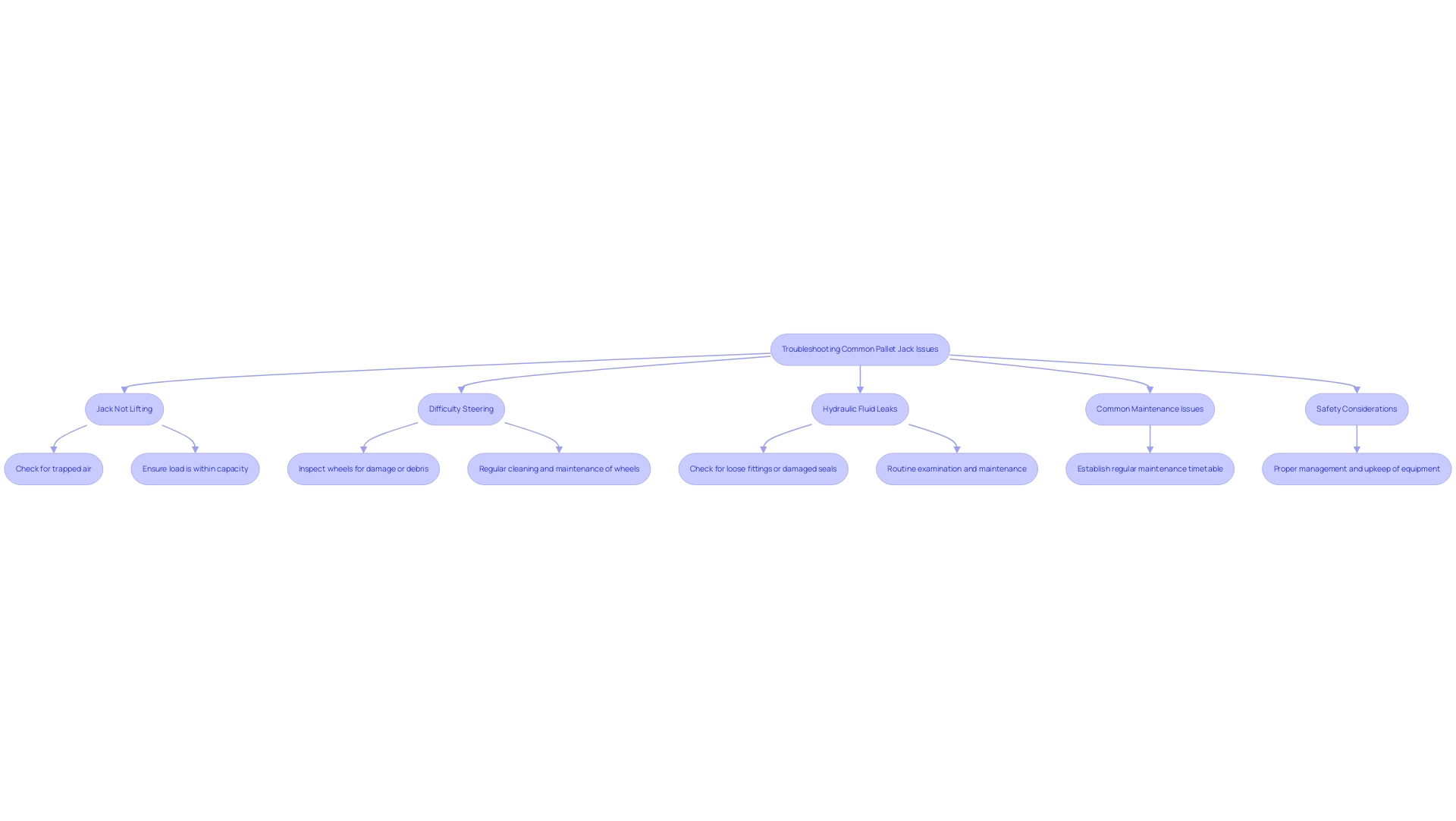

Troubleshooting Common Pallet Jack Issues

Pallet jack rental in Dallas, TX, provides essential tools for material handling, yet several common issues can impede their performance. Understanding these challenges and their solutions, including options like pallet jack rental in Dallas, TX, is crucial for maintaining operational efficiency. Below are some prevalent issues along with expert-recommended solutions:

- Jack Not Lifting: A frequent complaint among users, the first step in troubleshooting is to check for trapped air in the hydraulic system. If air is present, bleeding the system can restore functionality. Additionally, ensure that the load is within the device's capacity, as overloading can prevent lifting.

- Difficulty Steering: If maneuverability is compromised, inspect the wheels for any damage or debris obstructing movement. Regular cleaning and maintenance of the wheels can significantly enhance steering performance.

- Hydraulic Fluid Leaks: Leaks can lead to significant downtime and operational inefficiencies. Check for loose fittings or damaged seals, as these are common culprits. Routine examination and maintenance are essential for keeping hydraulic lifting equipment in peak condition and avoiding leaks, particularly for those utilizing pallet jack rental in Dallas, TX. Regular inspection and servicing are vital for maintaining hydraulic lifting devices and preventing downtime.

- Common Maintenance Issues: In 2025, maintenance-related downtime remains a critical concern, with statistics indicating that improper maintenance can lead to increased equipment failure rates. Establishing a regular maintenance timetable for pallet jack rental in Dallas, TX, can mitigate these risks and prolong the lifespan of lifting equipment.

- Case Studies on Troubleshooting: Recent market transformations highlight how key players in the lifting equipment sector are investing in advanced solutions and strategic partnerships to enhance product offerings. These innovations not only improve performance but also effectively address common maintenance issues. For instance, companies are focusing on innovation and sustainability to thrive in a competitive landscape.

- Safety Considerations: It's important to note that the elderly are particularly vulnerable to pallet-related injuries, often resulting from slip, trip, and fall incidents. Ensuring proper management and upkeep of lifting equipment can help reduce these risks.

As Tajammul Pangarkar, a tech blogger, emphasizes, "Proper equipment handling and maintenance are crucial for operational efficiency and safety." By adopting proactive maintenance practices and understanding how to troubleshoot these common issues, users can ensure their lifting devices operate smoothly, minimizing downtime and enhancing productivity on the job site.

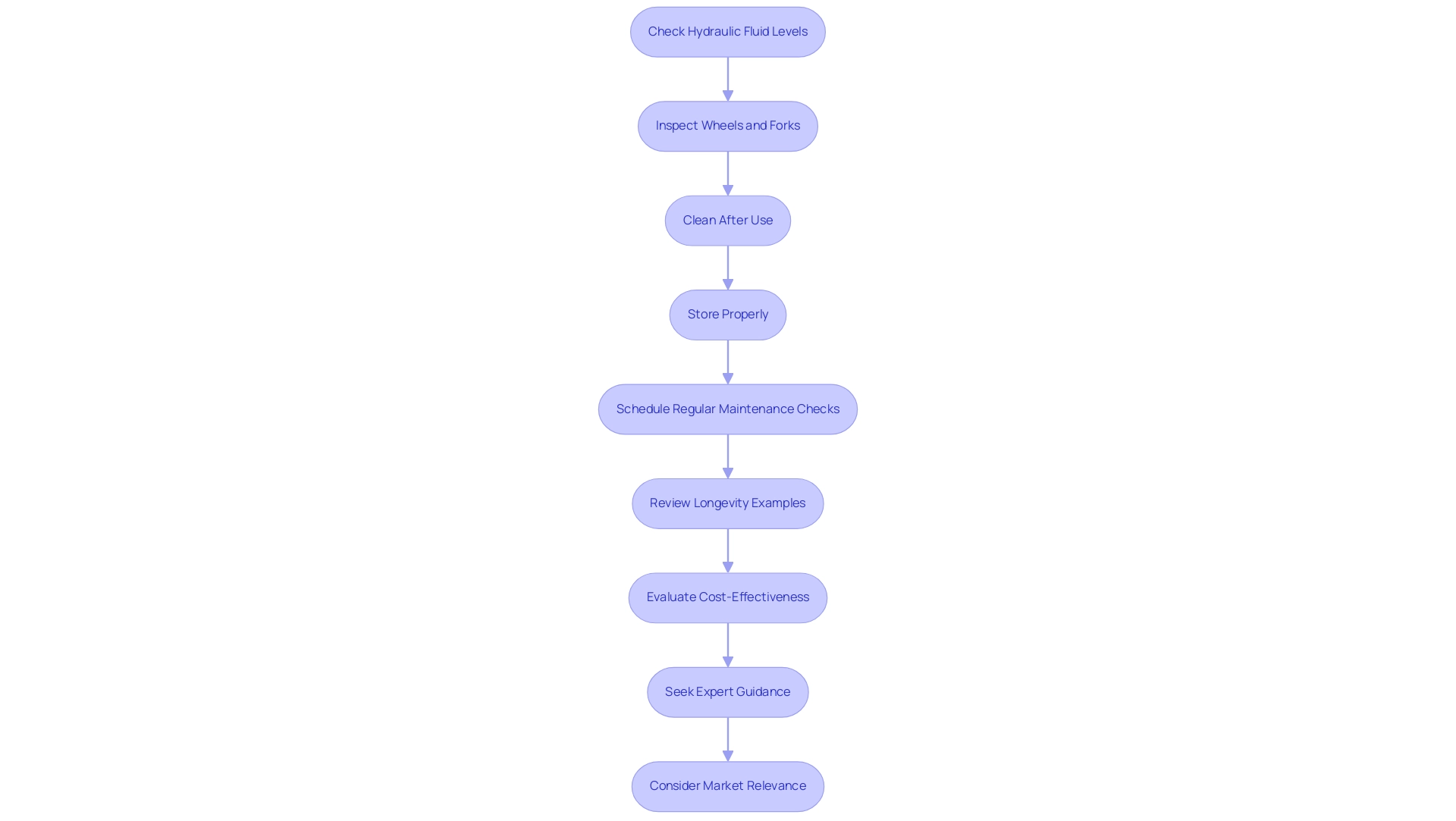

Maintenance Tips for Longevity of Your Pallet Jack

To ensure the longevity and optimal performance of your pallet jack, adhere to the following maintenance best practices:

- Hydraulic Fluid Maintenance: Regularly check and replenish hydraulic fluid levels to ensure smooth operation. Low fluid levels can lead to inefficient lifting and potential damage, underscoring the importance of this routine task.

- Wheel and Fork Inspection: Conduct routine inspections of the wheels and forks for signs of wear. Replace any worn components promptly to maintain safety and functionality, ensuring your equipment operates at its best.

- Cleaning Protocol: After each use, clean the lifting device thoroughly to prevent dirt and debris accumulation, which can hinder performance and lead to premature wear. A clean machine is a reliable machine.

- Proper Storage: Keep the lifting equipment in a dry setting with the forks lowered. This practice helps prevent damage and prolongs the lifespan of the devices, enhancing their reliability in your operations.

- Regular Maintenance Checks: Implement a schedule for regular maintenance checks, including lubrication of moving parts and inspection of the hydraulic system. This proactive approach can significantly reduce maintenance costs over time, making it a wise investment.

- Real-World Longevity Examples: Businesses that have implemented strict maintenance routines report an increase in the durability of their forklifts, with some units enduring over a decade with adequate care. For example, a case study highlighted a company that reduced production downtime by 15% through effective maintenance practices, showcasing how rigorous upkeep can enhance market position in a competitive landscape.

- Cost-Effectiveness of Maintenance: Statistics indicate that regular maintenance can lower overall costs by preventing major repairs. Investing in maintenance can save businesses up to 30% in unexpected repair expenses, making it a financially sound strategy.

- Expert Guidance: Consulting with rental specialists, such as WT Hight, can provide customized advice on maintaining your platform trolley. Hight emphasizes, "Whether you’re interested in a manual lift for lighter loads or an electric lift for increased efficiency, I can guide you in selecting the best solution for your business." Regular upkeep is crucial for ensuring durability and reliability, making it a key focus for any operation.

- Market Relevance: As industrial activities expand, the need for heavy-duty lifting carts is anticipated to increase. This underscores the importance of maintaining equipment to meet increasing operational demands effectively.

By adhering to these maintenance suggestions, you can maintain your lift truck in outstanding shape, guaranteeing it fulfills the requirements of your projects effectively and securely. For questions and bookings regarding pallet jack rental in Dallas, TX, reach out to EZ Equipment Rental at (214) 951-7800.

Final Thoughts on Pallet Jack Rental and Usage

Renting a platform mover presents an economical and flexible solution for your material handling needs. With a diverse range of platform trucks available, including low-lift versions specifically designed for horizontal transportation, understanding their unique functionalities is essential. The pallet jack rental market in Dallas, TX, is experiencing steady growth, driven by an increasing demand for automated material handling solutions, particularly in sectors influenced by e-commerce and automation trends.

As John Jeanguenat, president of RentalMax, states, 'The rental business by its nature is a green industry,' highlighting the sustainability aspect of renting tools. This commitment to sustainability not only benefits the environment but also aligns with the growing consumer preference for eco-friendly practices.

Safety is paramount in tool rental, especially when handling heavy loads. Ensuring that the platform truck is well-maintained and that operators are trained in safe handling practices can significantly reduce the risk of accidents. Customer feedback trends indicate that users prioritize safety features and reliability when selecting rental tools, underscoring the necessity of partnering with a reputable provider.

When selecting a trolley rental service, it is crucial to consider:

- Their reputation

- The variety of tools available

- The quality of customer support

Successful rental experiences often stem from providers who not only offer competitive pricing but also prioritize customer satisfaction and support throughout the rental process. In addition, a solid reputation can be a strong indicator of reliability and quality.

Statistics reveal that the demand for tailored transport solutions is on the rise, reflecting the diverse requirements of different sectors. The case study titled "Low-Lift Transport Device Market Overview" suggests that the market is primarily focused on low-lift transport devices for horizontal movement, with a consistent growth rate fueled by the increasing demand for automated material handling tools. Major players in the market, such as Toyota Industries Corporation and Crown Equipment Corporation, are adapting to these trends by offering specialized equipment that meets specific operational needs.

In summary, choosing a pallet jack rental in Dallas, TX, not only provides flexibility and cost savings but also enhances operational efficiency when done through a trusted provider. By focusing on safety, understanding market dynamics, and leveraging customer insights, you can make informed decisions that will greatly benefit your material handling operations.

Conclusion

Pallet jacks are essential tools in the material handling industry, providing a combination of efficiency and safety for a variety of operational requirements. This article has examined the different types of pallet jacks—manual and electric—highlighting their functionalities and applications in sectors such as retail and e-commerce. Recognizing the distinctions between these models is vital for project managers who seek to optimize productivity and create a safer work environment.

Renting a pallet jack presents a strategic advantage for businesses, particularly in construction, where cost savings and flexibility are crucial. By opting to rent, companies can circumvent the significant upfront costs associated with purchasing equipment while gaining access to the latest technology and models that enhance operational efficiency. EZ Equipment Rental distinguishes itself in Dallas, TX, offering a comprehensive selection of pallet jacks tailored to meet diverse customer needs, further solidifying its reputation for quality and service.

Safety guidelines and maintenance practices are fundamental to ensuring the longevity and proper functioning of pallet jacks. Operators must follow safety protocols to mitigate risks and accidents, while routine maintenance can greatly extend the equipment's lifespan. By adhering to these best practices, businesses can protect their workforce and sustain operational efficiency.

In conclusion, whether renting or purchasing, comprehending the functionalities, safety measures, and maintenance requirements of pallet jacks is essential for improving material handling processes. As the market continues to evolve, making informed decisions will not only enhance productivity but also cultivate a safer and more efficient work environment.

Frequently Asked Questions

What are the main types of lifting devices available for material handling?

The main types of lifting devices are manual and electric. Manual devices require physical effort from the operator, while electric devices use a motor to automate lifting and moving.

When should I use a manual lifting device?

Manual lifting devices are ideal for lighter tasks or environments where power sources are limited, making them suitable for smaller tasks or confined spaces.

What advantages do electric lifting devices offer?

Electric lifting devices significantly reduce physical strain on operators and enhance efficiency, particularly in high-volume settings, allowing them to manage heavier loads more easily.

What load capacities can electric lifting devices handle?

Electric lifting devices can manage loads ranging from 1.2 tons to 1.6 tons.

Why is it important to choose the right type of lifting equipment?

Selecting the appropriate type of lifting equipment based on specific operational contexts, load capacities, and workforce capabilities is crucial for enhancing material handling procedures and ensuring safety on the job site.

What are the benefits of renting a pallet jack in Dallas, TX?

Renting a pallet jack offers cost savings by eliminating upfront purchase costs and ongoing maintenance expenses. It also provides flexibility to adjust equipment needs based on project demands and access to the latest models with advanced features.

How do rental rates for pallet jacks in Dallas compare?

Rental rates for pallet jacks start as low as $XX per day, making them accessible and affordable for businesses of all sizes.

What is the typical lease term for renting equipment?

Lease terms for renting equipment typically range from 2 to 4 years.

How does renting equipment improve operational efficiency?

Renting equipment allows businesses to focus on core operations while benefiting from well-maintained tools, and digitizing rental operations can streamline management, leading to significant cost savings.

What feedback have customers provided about EZ Equipment Rental?

Customers have reported positive experiences, stating that EZ Equipment Rental made their projects seamless with affordable rates and excellent service.