Key Highlights:

- Stand-up forklifts allow operators to stand, enhancing visibility and manoeuvrability in narrow spaces, ideal for warehouses with aisles 8-10 feet wide.

- Seated forklifts offer comfort for extended use, featuring car-like controls, making them intuitive for operators but less manoeuvrable in tight areas.

- Stand-up forklifts can lift loads between 2,000 and 5,500 pounds and reach heights around 20 feet, suitable for high-density storage.

- Choosing the right forklift can impact warehouse efficiency by up to 30%, emphasising the need for informed decisions.

- Stand-up models may cause worker fatigue during long shifts, increasing injury risks, while seated models prioritise comfort but can hinder manoeuvrability.

- Stand-up forklifts excel in order picking and high-frequency tasks in confined spaces, while seated models are better for outdoor use and heavier loads.

- Initial costs for stand-up forklifts range from $26,000 to $34,000, compared to seated models priced between $21,500 and $25,500.

- Operational costs for seated models can be higher due to fuel consumption and maintenance, while stand-up forklifts may have lower long-term expenses.

- Proper training is essential for both forklift types to enhance safety and reduce accidents, which can decrease by up to 70% with adequate training.

Introduction

Selecting the appropriate forklift is crucial for enhancing warehouse efficiency and safety. Project managers often face a decision between stand-up and sit-down models, each offering unique advantages tailored to specific operational needs.

- Stand-up forklifts are known for their exceptional maneuverability and visibility, making them ideal for tight spaces.

- In contrast, sit-down forklifts prioritize operator comfort and stability, which can be beneficial for longer shifts.

Navigating the trade-offs between these two designs is essential for optimizing productivity and ensuring safety in the workplace.

Understand Stand-Up and Sit-Down Forklifts

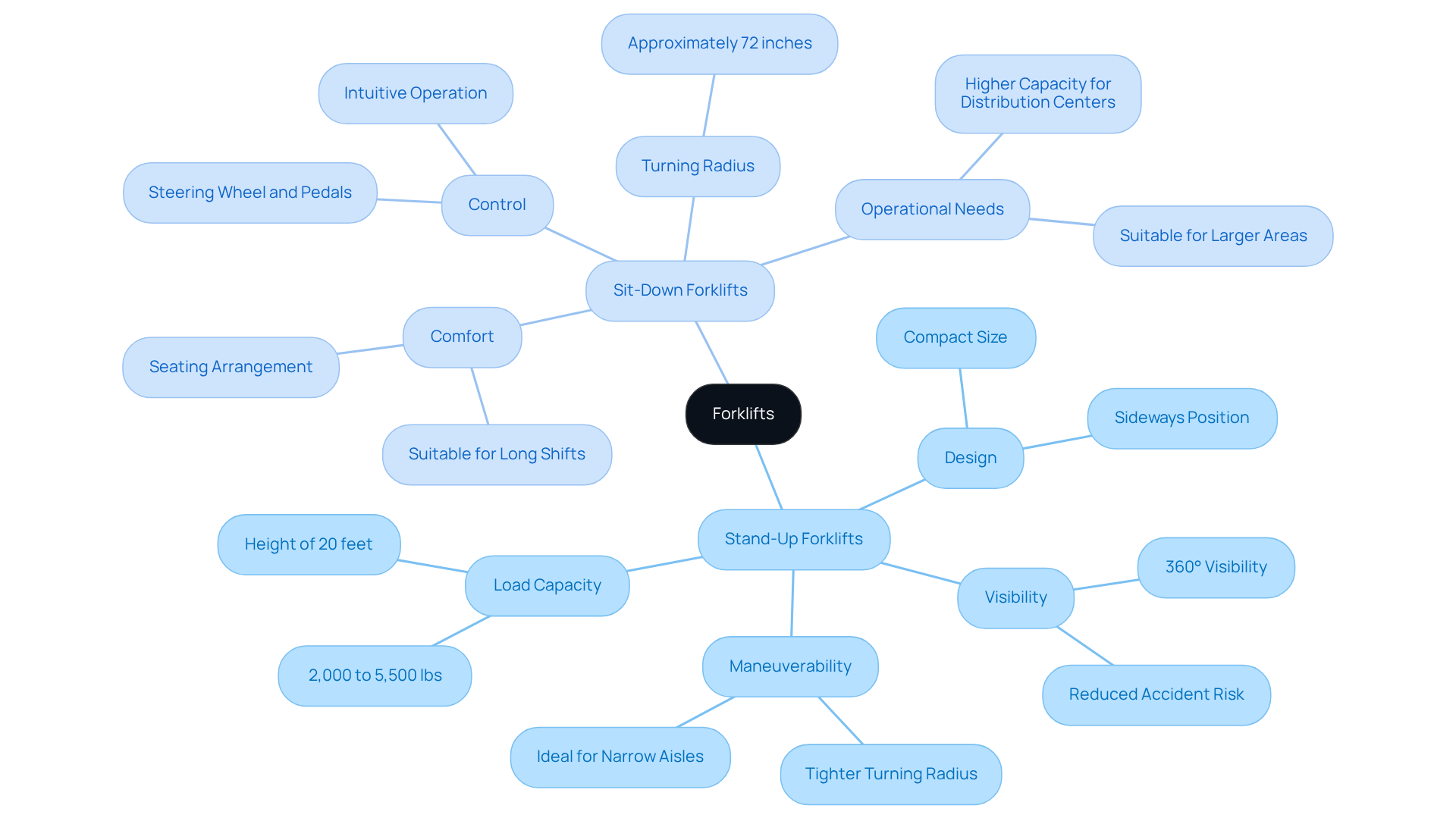

Stand-up lifting machines are engineered for operators to stand while driving, offering a compact design that excels in navigating narrow spaces. Their unique sideways position enhances visibility and facilitates quicker entry and exit, making them particularly effective in areas with narrow aisles, typically ranging from 8 to 10 feet wide. Conversely, seated lifting machines provide a comfortable seating arrangement, which is advantageous for extended shifts and tasks requiring less frequent movement. These models often incorporate a steering wheel and pedals, similar to a car's controls, making them intuitive for those accustomed to driving. Notably, seated lift trucks have a turning radius of approximately 72 inches for similar capacity, which can limit their maneuverability in tight spaces compared to stand-up models.

The decision between stand-up and seated lifting machines is primarily driven by specific operational needs. For instance, a used stand up forklift can elevate loads between 2,000 and 5,500 pounds and reach heights of around 20 feet, making it suitable for high-density storage and efficient material handling in warehouses. Real-world examples underscore their effectiveness in confined spaces, where their compact design allows for maneuverability that sit-down models cannot achieve. Industry experts emphasize that the choice of lifting equipment can significantly influence productivity; selecting the wrong type can reduce warehouse efficiency by up to 30%, underscoring the importance of making an informed decision.

In 2026, trends in material handling vehicle design focus on enhanced agility and safety features, with an emphasis on improving operator training and ergonomics. Proper training and certification are essential for the safe operation of both stand-up and sit-down lifting devices. As project managers assess their equipment needs, understanding the advantages and disadvantages of each type of lift device, including the higher initial costs and comfort limitations of stand-up models, is vital for optimizing operations and ensuring safety in material handling.

Evaluate Advantages and Disadvantages

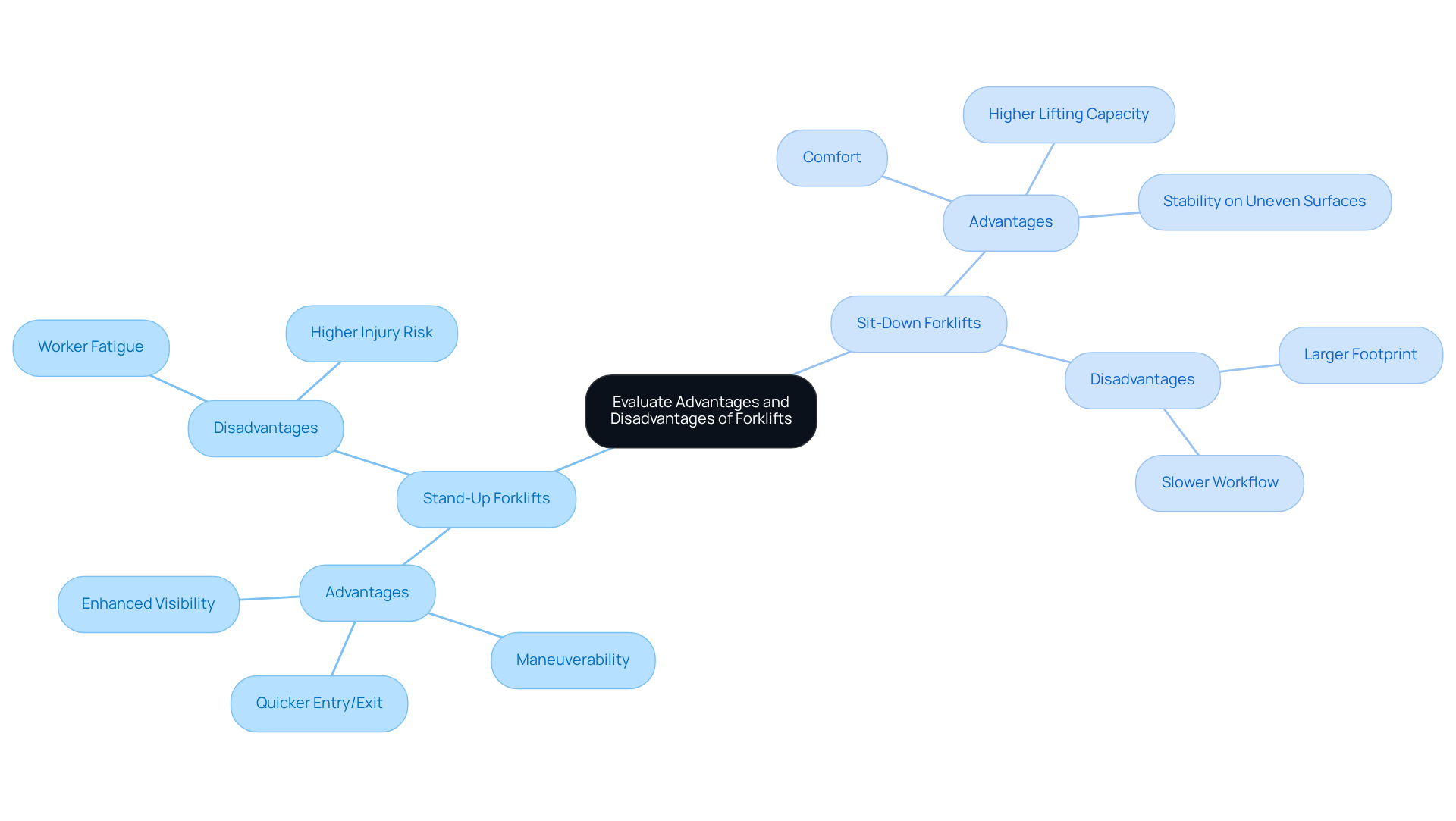

A used stand up forklift is particularly adept at maneuverability, especially in tight spaces, allowing users to navigate narrow aisles effortlessly. Their design promotes quicker entry and exit, which is essential in fast-paced environments where frequent stops occur. Enhanced visibility while standing also plays a crucial role in safety by minimizing collision risks. However, the standing position may lead to worker fatigue during extended shifts, which can adversely affect overall productivity. According to OSHA, workers on 12-hour shifts face a 37% higher risk of injury, underscoring the importance of considering employee comfort in relation to productivity.

Conversely, sit-down vehicles prioritize comfort, making them suitable for prolonged use. They generally provide higher lifting capacities and greater stability on uneven surfaces, which is vital for managing heavier loads. Despite these benefits, their larger footprint can impede operations in confined areas, and the time needed for operators to mount and dismount may slow workflow efficiency. This trade-off between comfort and maneuverability is a critical consideration for project managers when selecting a used stand up forklift as the appropriate type of lifting equipment for their specific operational needs. Furthermore, adequate training is essential for both categories of lifting vehicles, as it can reduce accidents by as much as 70%, highlighting the necessity for a skilled workforce to enhance safety and efficiency.

Identify Suitable Applications for Each Forklift Type

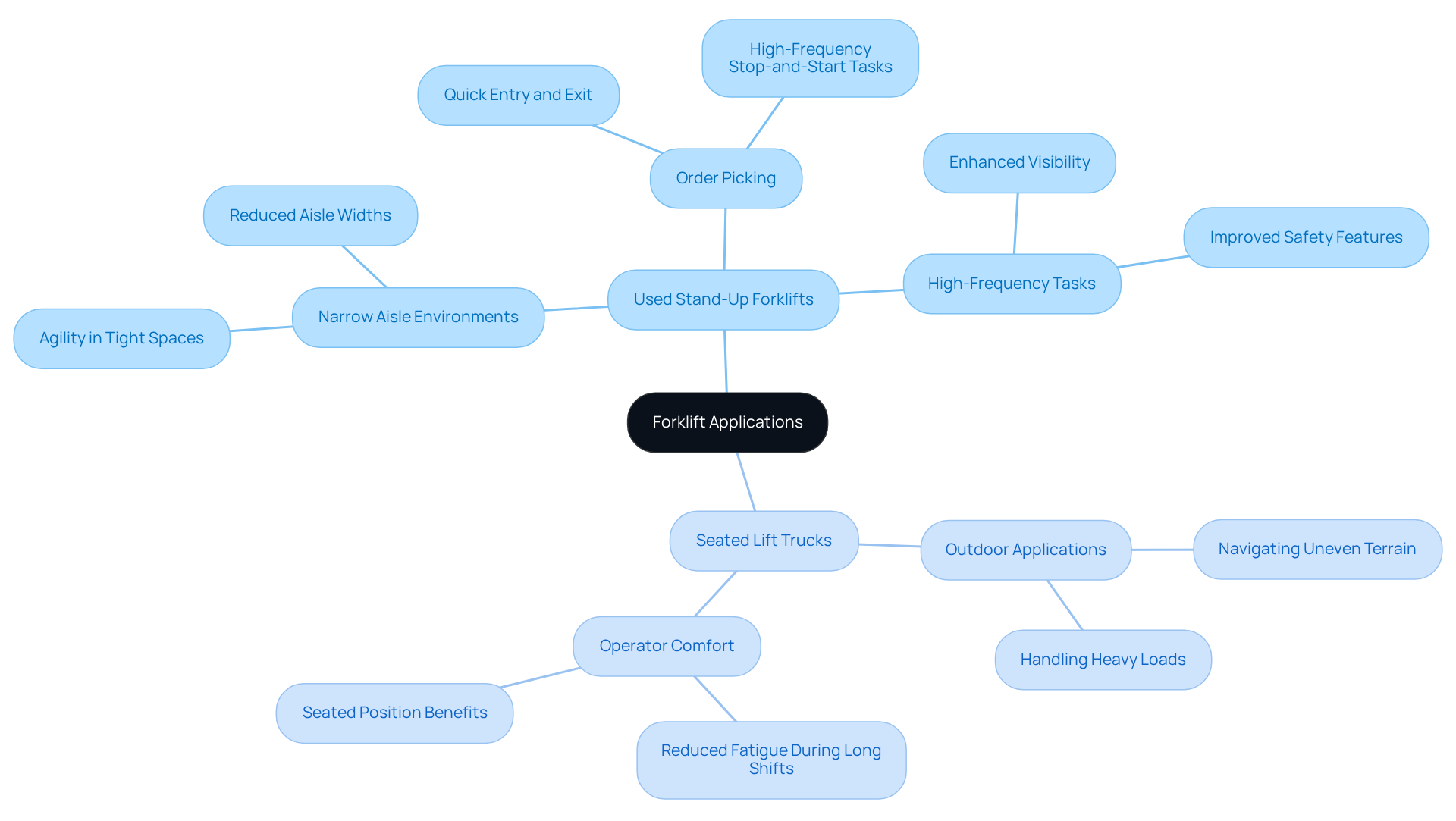

Used stand up forklifts are particularly effective in narrow aisle environments, such as warehouses and distribution centers, where agility is essential for operations like order picking. Their design facilitates quick maneuvering, making a used stand up forklift ideal for high-frequency stop-and-start tasks. Conversely, seated lift trucks are more suitable for outdoor applications, especially on construction sites, where they can navigate uneven terrain and efficiently handle heavier loads. These lift trucks also prove advantageous for longer travel distances within expansive facilities, prioritizing operator comfort during extended shifts. Operators working 8-10 hour shifts may experience fatigue without proper ergonomics, highlighting the importance of comfort in sit-down vehicles.

Moreover, it is important to note that in 2023, lifting vehicles were responsible for 67 work-related fatalities on construction sites. This statistic underscores the critical need for selecting the appropriate type of lifting equipment, emphasizing safety considerations. Understanding these applications is vital for project managers to determine the most suitable lift for their specific operational needs, ensuring both efficiency and safety on the job site.

Analyze Cost and Investment Factors

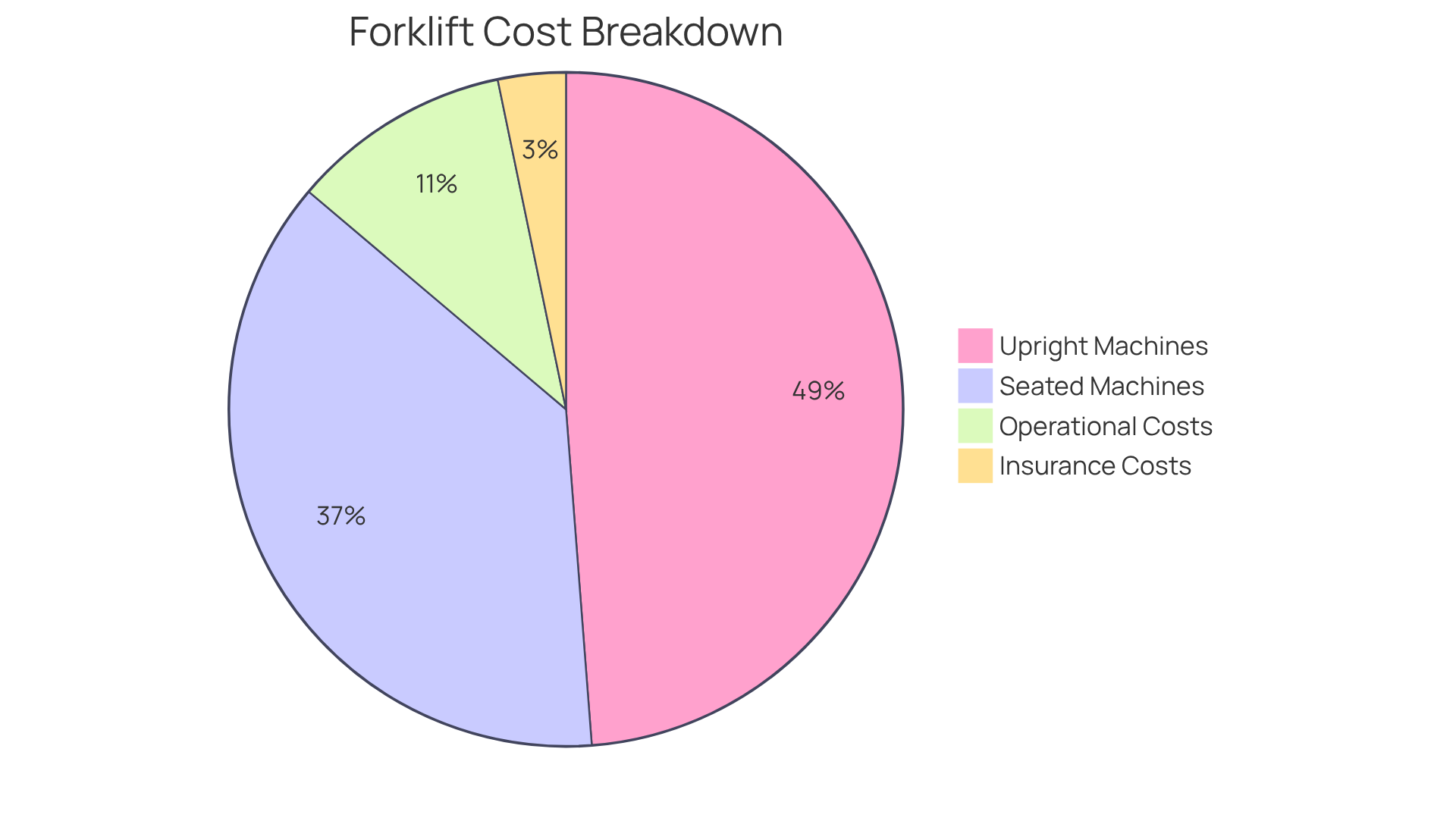

When evaluating expenses, upright lifting machines typically have a higher initial acquisition cost compared to seated models. Seated versions are priced between $21,500 and $25,500, while upright machines range from $26,000 to $34,000, reflecting their advanced design and enhanced features. Their exclusive battery-powered operation can optimize space utilization and improve operational efficiency in confined environments, leading to significant long-term savings. Conversely, seated lifting machines, while generally more affordable upfront, may incur higher operational costs due to their larger size and limited maneuverability in tight spaces. For instance, the annual operational expenses for sit-down lifting machines can range from $3,000 to $10,000, influenced by factors such as fuel consumption and maintenance needs. Maintenance costs are comparable for both types, but a used stand up forklift may result in lower long-term expenses due to fewer moving parts.

Additionally, project managers should factor in insurance costs, with Comprehensive Coverage insurance ranging from $800 to over $2,000 annually, and Equipment Breakdown insurance costing between $300 and $900 each year. Ergonomic considerations and operator comfort are also crucial in the decision-making process. It is essential for project managers to carefully evaluate these financial implications alongside their budget constraints and specific operational requirements. Testing forklifts in the actual work environment before making a purchase decision is vital to ensure a cost-effective investment in forklift solutions.

Conclusion

The choice between stand-up and sit-down forklifts is pivotal in optimizing warehouse operations and boosting productivity. Each forklift type presents unique advantages and limitations that must be carefully considered in light of a project's specific needs. By understanding these distinctions, project managers can make informed decisions that align with their operational goals and safety standards.

Stand-up forklifts are particularly adept in tight spaces, providing superior maneuverability and visibility, which are crucial in high-density environments. They excel in tasks that require frequent stops. In contrast, sit-down forklifts offer enhanced comfort and stability, making them ideal for longer shifts and heavier loads. However, the higher initial costs associated with stand-up models and the potential for worker fatigue during extended use warrant careful consideration. Additionally, comprehensive training and safety measures are essential for both types to mitigate risks and enhance overall efficiency.

Ultimately, the decision should stem from a thorough analysis of operational requirements, cost implications, and ergonomic considerations. By dedicating time to evaluate the specific applications and environments in which these forklifts will be utilized, project managers can significantly enhance safety and productivity. This ensures that the right equipment is in place to meet both current and future demands.

Frequently Asked Questions

What are the main features of stand-up forklifts?

Stand-up forklifts are designed for operators to stand while driving, featuring a compact design that excels in navigating narrow spaces. They offer enhanced visibility and facilitate quicker entry and exit, making them effective in areas with narrow aisles, typically ranging from 8 to 10 feet wide.

What are the advantages of seated forklifts?

Seated forklifts provide a comfortable seating arrangement, which is beneficial for extended shifts and tasks that require less frequent movement. They often include a steering wheel and pedals similar to a car's controls, making them intuitive for those familiar with driving.

How do the maneuverability and turning radius of stand-up and seated forklifts compare?

Stand-up forklifts have better maneuverability in tight spaces due to their compact design, while seated forklifts have a turning radius of approximately 72 inches, which can limit their maneuverability in confined areas compared to stand-up models.

What are the load capacity and height capabilities of stand-up forklifts?

Stand-up forklifts can elevate loads between 2,000 and 5,500 pounds and reach heights of around 20 feet, making them suitable for high-density storage and efficient material handling in warehouses.

How can the choice between stand-up and seated forklifts impact warehouse productivity?

The choice of lifting equipment can significantly influence productivity, with selecting the wrong type potentially reducing warehouse efficiency by up to 30%. It is crucial to make an informed decision based on specific operational needs.

What trends are expected in material handling vehicle design by 2026?

Trends in material handling vehicle design are expected to focus on enhanced agility and safety features, emphasizing improvements in operator training and ergonomics.

Why is proper training and certification important for forklift operation?

Proper training and certification are essential for the safe operation of both stand-up and seated lifting devices, ensuring safety in material handling and optimizing operations.

What factors should project managers consider when assessing equipment needs?

Project managers should understand the advantages and disadvantages of each type of lift device, including the higher initial costs and comfort limitations of stand-up models, to optimize operations and ensure safety in material handling.

List of Sources

- Understand Stand-Up and Sit-Down Forklifts

- Pros & Cons of Stand-up Forklifts, Sit Down Forklifts and Pallet Jacks - Liftoff Certifications™ (https://liftoffcerts.com/blog/pros-cons-of-stand-up-forklifts-sit-down-forklifts-and-pallet-jacks)

- Top Reasons to Choose a Stand Up Forklift for Your Warehouse (https://clarkmhc.com/top-reasons-to-choose-a-stand-up-forklift-for-your-warehouse)

- Industrial Forklift Comparison: Sit-Down vs. Stand-Up Models (https://totalwarehouse.com/blogs/sit-down-stand-up-forklifts)

- Advantages of Stand Up Forklifts: #1 Standing Forklift Guide (https://phsinc.com/guides/advantages-of-stand-up-forklifts?srsltid=AfmBOoqhxXfUaqyYHrl3B_E0D5E6qtRbBRzvooKxz3PmsmhVjclXxfdQ)

- Evaluate Advantages and Disadvantages

- Industrial Forklift Comparison: Sit-Down vs. Stand-Up Models (https://totalwarehouse.com/blogs/sit-down-stand-up-forklifts)

- Stand-Up vs. Sit-Down Forklifts: Pros, Cons & Uses | Certified Lift Specialist (https://clsforklift.com/stand-up-vs-sit-down-forklifts-pros-cons-uses)

- Top 10 Most Common Forklift Accidents [With Statistics] | Conger (https://conger.com/forklift-accidents)

- Identify Suitable Applications for Each Forklift Type

- Stand-Up vs. Sit-Down Forklifts: Pros, Cons & Uses | Certified Lift Specialist (https://clsforklift.com/stand-up-vs-sit-down-forklifts-pros-cons-uses)

- Pros & Cons of Stand-up Forklifts, Sit Down Forklifts and Pallet Jacks - Liftoff Certifications™ (https://liftoffcerts.com/blog/pros-cons-of-stand-up-forklifts-sit-down-forklifts-and-pallet-jacks)

- Top Reasons to Choose a Stand Up Forklift for Your Warehouse (https://clarkmhc.com/top-reasons-to-choose-a-stand-up-forklift-for-your-warehouse)

- Industrial Forklift Comparison: Sit-Down vs. Stand-Up Models (https://totalwarehouse.com/blogs/sit-down-stand-up-forklifts)

- Forklift-related incidents: A growing concern on construction sites - Presight Solutions AS (https://presight.com/forklift-related-incidents-a-growing-concern-on-construction-sites)

- Analyze Cost and Investment Factors

- Breaking Down Forklift Operating Costs: Fuel, Maintenance, and Insurance - Industrial Forklift Truck (https://ca.industrialforklifttruck.org/2025/05/16/breaking-down-forklift-operating-costs-fuel-maintenance-and-insurance)

- Industrial Forklift Comparison: Sit-Down vs. Stand-Up Models (https://totalwarehouse.com/blogs/sit-down-stand-up-forklifts)

- Stand-Up vs. Sit-Down Forklifts: Pros, Cons & Uses | Certified Lift Specialist (https://clsforklift.com/stand-up-vs-sit-down-forklifts-pros-cons-uses)

- 10 Key Considerations When Buying a Forklift for Your Business (https://aaaforklifts.com/blogs/news/10-key-considerations-when-buying-a-forklift-for-your-business-1?srsltid=AfmBOor4d3iMkXDxzsbuXf5BGPoqN0ee9VAgUmaYcdkHW1Uvh7b_9_jH)