Overview

The article emphasizes the critical role of portable material lifts in boosting efficiency, safety, and productivity within construction projects. These lifts, available in various lifting capacities and compact designs, play a significant role in minimizing manual handling risks and enhancing project timelines. Supported by industry reports and case studies, the evidence clearly demonstrates their positive impact on worker well-being and operational effectiveness.

In addition, the versatility of these lifts allows for seamless integration into diverse construction environments, making them an invaluable asset. The ability to reduce labor intensity while increasing output not only enhances productivity but also fosters a safer working atmosphere. Furthermore, organizations that adopt these lifts report improved project completion rates, underscoring their reliability and quality.

For example, testimonials from satisfied customers highlight their experiences with portable material lifts, showcasing how these tools have transformed their operations. The evidence is compelling: investing in portable material lifts is not merely a choice but a strategic decision that pays dividends in the long run.

To maximize the benefits of your construction projects, consider incorporating portable material lifts into your operations. Their ability to enhance efficiency and safety makes them a crucial component in modern construction practices. Don't hesitate—take action now to elevate your projects with the reliability and quality that portable material lifts offer.

Key Highlights:

- Portable material lifts are crucial for improving efficiency in construction by enabling the safe transport of heavy materials.

- Lifting capacities range from 1.8 tons to 48 tons, making them versatile for various construction tasks.

- Their compact design allows for effective use in confined spaces and multi-level buildings.

- Using portable lifts reduces manual handling risks, thereby enhancing worker safety and productivity.

- Companies utilizing these lifts report significant improvements in project timelines and employee well-being.

- Key models include Genie Superlift, Sumner Material Lift, and LiftSmart, each tailored for different construction needs.

- Important features to consider in portable lifts include load capacity, height reach, portability, ease of setup, and safety features.

- Automation in material handling through portable lifts can reduce labor costs by up to 30%.

- Future trends include increased automation, enhanced safety measures, and a focus on sustainability in equipment design.

- The market for portable material lifts is expected to grow, driven by technological advancements and changing consumer preferences.

Introduction

In the ever-evolving construction industry, efficiency and safety are paramount. Portable material lifts have emerged as essential tools that address both needs. These innovative devices are designed to facilitate the lifting and transportation of heavy materials, significantly enhancing productivity while reducing the physical toll on workers.

With their impressive lifting capacities and compact designs, portable lifts are revolutionizing how construction sites operate, allowing teams to navigate tight spaces and multi-story structures with ease. As the demand for safer and more efficient construction practices grows, understanding the capabilities and advantages of these lifts becomes crucial for any project manager looking to optimize operations and mitigate risks.

Understanding Portable Material Lifts: A Key to Construction Efficiency

Portable material lifts are essential resources in the building sector, meticulously engineered to facilitate the raising and movement of heavy items across diverse work locations. In 2025, these elevators are recognized for their ability to significantly enhance productivity, enabling employees to transport goods swiftly and securely, thereby minimizing the physical exertion associated with manual handling. With lifting capacities ranging from 1.8 tons to 48 tons, the portable material lift addresses a wide array of building needs, making it an adaptable tool for any project.

The compact design and mobility of the portable material lift are particularly advantageous in confined spaces and multi-level structures, allowing teams to operate efficiently without sacrificing safety or effectiveness. Forklifts, an integral component of these portable equipment rentals at EZ Equipment Rental, play a pivotal role in bolstering efficiency and safety in construction projects. These forklifts are outfitted with advanced protective features and ergonomic designs that ensure operator comfort and adherence to workplace standards.

This commitment to safety is echoed by industry leaders who highlight that the integration of a portable material lift not only boosts operational efficiency but also mitigates risks associated with manual handling. Real-world examples illustrate the transformative impact of portable devices on productivity in construction. Businesses utilizing EZ Equipment Rental's forklifts have reported significant improvements in project timelines and employee well-being after incorporating these machines into their workflows. Furthermore, platforms like SC Training are enhancing training and compliance, ensuring that workers are well-prepared to operate these devices effectively, which is crucial for maximizing their benefits.

Expert insights underscore the importance of the portable material lift in advancing construction efficiency. Industry leaders advocate for the use of portable material lifts, citing benefits such as reduced labor costs, increased speed in handling materials, and improved overall site security. As the construction landscape continues to evolve, the reliance on portable material lifts, including forklifts from EZ Equipment Rental, is expected to grow, solidifying their status as essential tools for modern construction projects.

Overcoming Construction Challenges: The Role of Portable Lifts

Construction projects frequently face various challenges, such as delays, inefficiencies, and safety concerns. Portable material lifts are essential tools that effectively address these issues by optimizing the material handling process. By mechanizing the raising of heavy loads, these devices significantly reduce downtime and mitigate the risks associated with manual handling, a leading cause of injuries on construction sites.

In fact, statistics indicate that companies can save between $4 to $6 for every dollar invested in effective protective measures, underscoring the financial benefits of prioritizing worker well-being.

The incorporation of a portable material lift not only enhances worker protection but also optimizes workflows, enabling projects to adhere to schedules and budget constraints. For example, case studies demonstrate that building crews utilizing a portable material lift experience a significant reduction in project delays, as this tool facilitates faster and safer material management. Furthermore, experts highlight that the use of portable hoists can lead to a notable decrease in injuries, reinforcing their importance in fostering a more secure work environment.

As Amber Schiada, Head of Work Dynamics Research at JLL, observes, "The changing dynamics of the building sector require innovative solutions that improve both security and efficiency."

As the construction landscape evolves in 2025, the significance of portable equipment becomes increasingly apparent. These tools not only help overcome challenges posed by labor shortages and rising costs but also align with the industry's commitment to enhanced safety standards and operational efficiency. Moreover, the recent case study titled 'Evolving Policy Landscape and Tariff Impacts' emphasizes how increasing tariffs on strategic materials can affect building expenses, making the use of efficient equipment like a portable material lift even more critical.

Contractors are advised to strengthen demand forecasting and diversify their supplier bases to navigate these challenges effectively.

With federal infrastructure investments poised to continue benefiting nonresidential projects, the importance of portable devices in this evolving landscape cannot be overstated. By investing in a portable material lift, contractors can adeptly navigate the complexities of modern construction while enhancing overall productivity and security.

Exploring the Top 7 Portable Material Lifts for Construction

- Genie Superlift Advantage: Renowned for its robust construction and user-friendly design, the Genie Superlift Advantage supports loads of up to 650 lbs, making it an exceptional choice for a wide range of building tasks. Its versatility and reliability have earned high praise from construction managers, who appreciate its efficiency on job sites, particularly in enhancing security and streamlining operations.

- Sumner Material Lift: This lift distinguishes itself with an impressive height reach of 25 feet while remaining lightweight for convenient transport. Its adaptability makes it a preferred option among contractors who demand mobility without compromising performance, further boosting overall project efficiency.

- LiftSmart Portable Lift: Specifically designed for HVAC applications, the LiftSmart is compact yet powerful, capable of handling loads with remarkable efficiency. Users have highlighted its ease of use, especially in confined spaces, enhancing productivity on the job and ensuring security during operations.

- JET SkyHyker Material Lift: Built for heavy-duty tasks, the JET SkyHyker boasts a lifting capacity of 2,000 lbs. Its robust design and dependability make it a favored choice for building projects that require strength and durability, underscoring the importance of utilizing reliable equipment for security and efficiency.

- Vestil Manual Material Lift: A cost-effective option for smaller projects, the Vestil offers manual operation and portability. Its simplicity and effectiveness have garnered positive feedback from users seeking a straightforward lifting solution, ensuring that even minor tasks are completed safely and efficiently.

- Alum-a-Lift: Focused on ergonomic lifting solutions, Alum-a-Lift is suitable for various industries. Its design prioritizes user comfort, reducing strain during operation, which is a significant advantage for long-term use and security on the job site.

- ToughLift Material Lift: Recognized for its durability and rapid setup, the ToughLift is ideal for job sites that require frequent use. Its sturdy design guarantees it can withstand the challenges of daily operations, establishing it as a dependable option for contractors who prioritize security and efficiency.

In 2025, the market for portable equipment continues to expand, with leading brands capturing significant market share. The United States ranked third in exports valued at USD 2,381.7 million in 2022, highlighting the importance of portable material lifts in the construction sector. Customer feedback emphasizes the effectiveness of the Genie Superlift and other leading models, underscoring their role in enhancing operational efficiency and security.

Expert evaluations further validate these insights, showcasing the real-world performance of these devices across various construction scenarios. As the industry evolves, the significance of safety and operator training, as underscored by the new OSHA guidelines issued in 2023, remains critical. According to tech blogger Tajammul Pangarkar, these guidelines are essential for ensuring that equipment like these hoists is used effectively and safely.

Furthermore, findings from the Specialized Warehousing And Storage Global Market Report 2025 indicate that portable material lifts are increasingly being utilized across diverse sectors, further emphasizing their relevance in contemporary building practices.

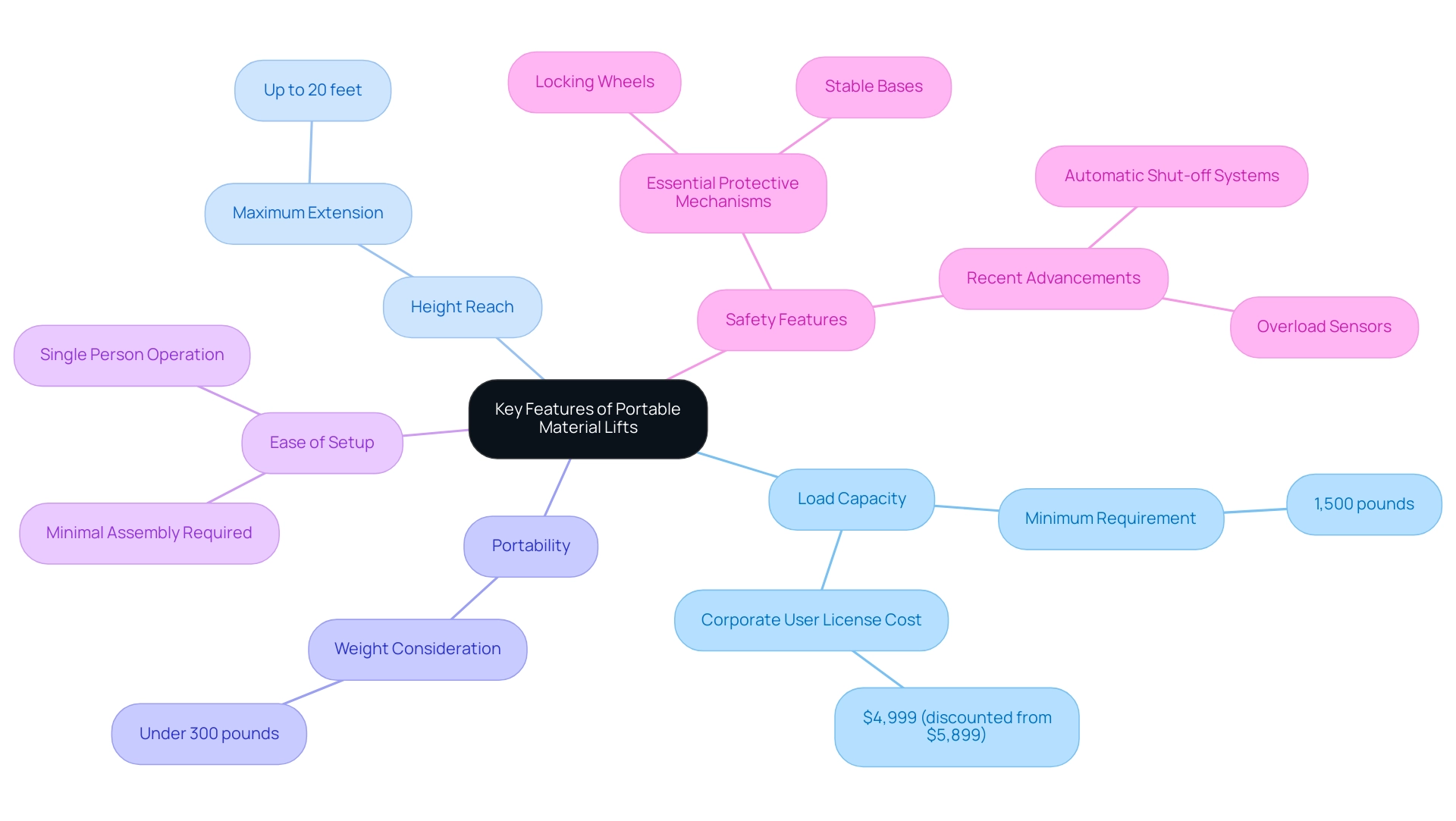

Key Features to Consider in Portable Material Lifts

When selecting a portable material lift, it is essential to prioritize several key features to ensure optimal performance and safety on construction sites.

-

Load Capacity is crucial; verify that the lift can accommodate the maximum weight of materials intended for lifting. In 2025, industry standards suggest that building hoists generally need a load capacity of at least 1,500 pounds for most uses, reflecting the growing demands of contemporary projects. Notably, statistics indicate that corporate user license costs for equipment rental can be significant, with prices starting at $4,999, discounted from $5,899. This underscores the importance of choosing the right equipment for budget considerations.

-

Height Reach is another vital feature. The ability to reach necessary heights is essential, as many portable material lifts available today can extend up to 20 feet, making them suitable for a variety of construction tasks, from roofing to interior work.

-

Additionally, Portability plays a significant role; lightweight designs enhance maneuverability on job sites. Models that weigh under 300 pounds are particularly advantageous, allowing for easier transport and setup in tight spaces.

-

Ease of Setup is also important. Look for devices that require minimal assembly and can be operated by a single person. This feature not only saves time but also reduces the risk of injury during setup.

-

Furthermore, Safety Features should never be compromised. Ensure the lift is equipped with essential protective mechanisms, such as locking wheels and stable bases, to prevent accidents. Recent advancements in protective technology have led to the integration of features like automatic shut-off systems and overload sensors, which are becoming standard in 2025. A case study on human-machine collaboration highlights how forklifts are being designed to work alongside human operators, enhancing security and productivity in material handling environments.

Integrating these characteristics not only boosts operational efficiency but also greatly enhances security at building sites. As noted by equipment rental specialists, "The right load capacity and safety features are paramount in ensuring that projects run smoothly and without incident." Moreover, Tajammul Pangarkar, a technology blogger, highlights that the retail and e-commerce industry's growth is closely linked to progress in equipment rental, stressing the significance of choosing the right tools for building projects.

By thoughtfully evaluating these factors, project managers can select the most suitable portable material lift for their specific requirements, ultimately resulting in more efficient building processes.

How Portable Material Lifts Streamline Construction Operations

Portable material lifts play a crucial role in optimizing building operations by automating the raising and transport of supplies. This automation significantly diminishes the reliance on manual labor, allowing workers to focus on more critical tasks that require their expertise. The adaptability of these devices enables them to navigate confined areas and uneven ground, making them highly suitable for various work sites.

The impact of portable mechanisms extends beyond mere convenience; they enhance the efficiency and safety of handling processes. Consequently, projects can be completed more swiftly, which is essential in an industry where time is often equated with cost. Notably, the integration of automation in handling supplies has been shown to lead to substantial labor cost reductions, with data indicating that businesses can lower labor expenses by as much as 30% when utilizing portable equipment.

Moreover, the demand for handling equipment is underscored by the production volume of forklifts in China, which reached 76,600 units in 2020, highlighting a growing need for effective solutions in the sector.

Expert opinions underscore the transformative influence of these devices on building operations. Numerous project managers in the construction industry have observed that adopting automation technologies, including portable material lifts, not only streamlines workflows but also enhances overall project timelines. Tajammul Pangarkar, a technology blogger, notes that this consistent growth trajectory reflects the increasing demand for forklift trucks globally, spurred by heightened industrial activities and advancements in handling technologies.

For instance, a recent case study on human-machine collaboration in logistics revealed that systems enabling forklifts to operate alongside human workers resulted in improved safety and productivity in warehouses. This principle can also be applied effectively on building sites.

As the construction sector continues to evolve, the necessity for efficient handling solutions is expected to rise. With infrastructure investments projected to create up to 80 million jobs, the significance of portable material lifts in facilitating these projects cannot be overstated. By enhancing operational efficiency and reducing labor costs, these devices are set to become indispensable tools in the construction sector of 2025.

Choosing the Right Portable Material Lift for Your Project

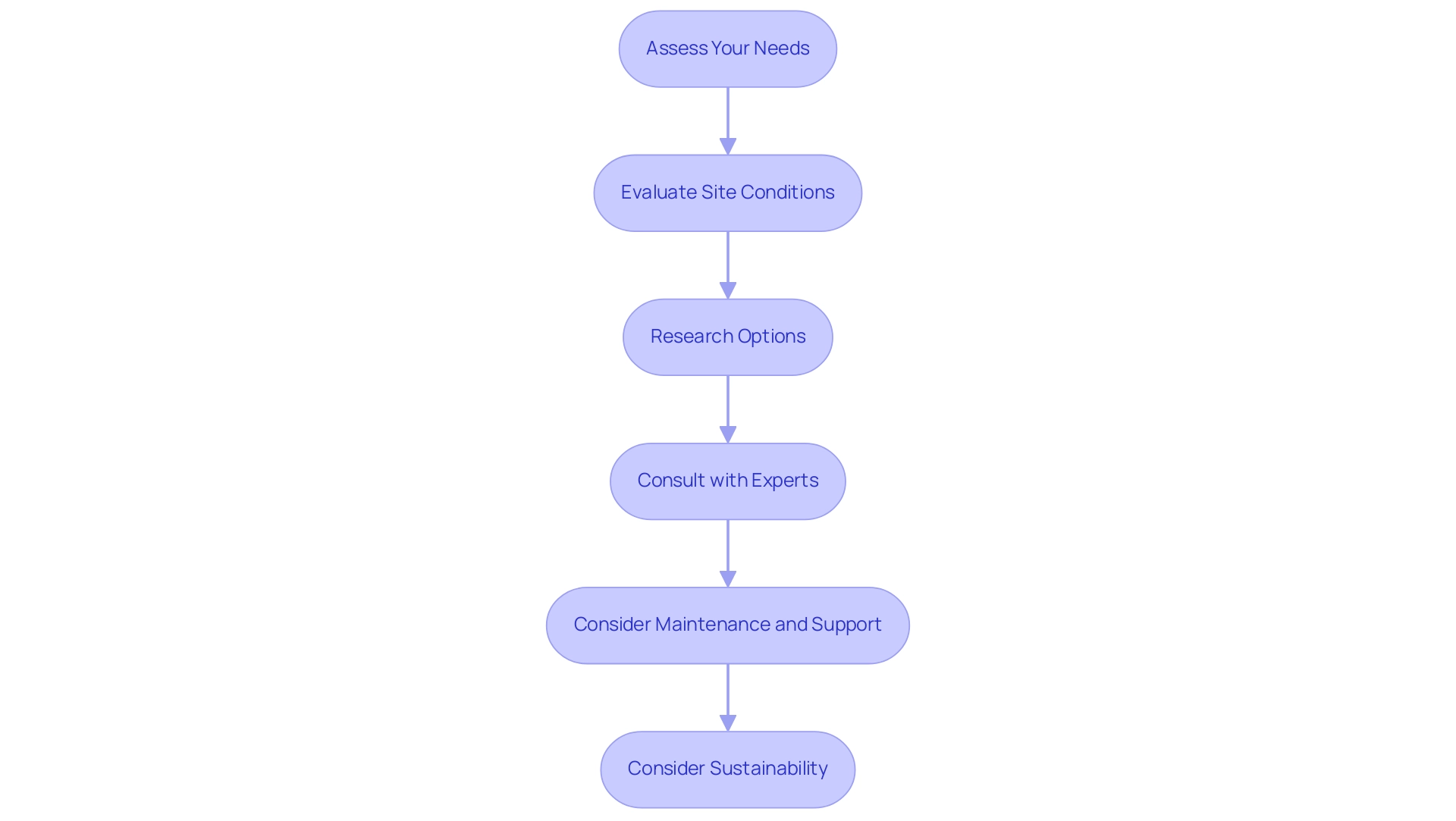

Selecting the appropriate portable material lift for your construction project requires a methodical approach to guarantee both efficiency and safety.

- Assess Your Needs: Begin by identifying the types of materials you will be lifting, including their weights and dimensions. Comprehending your raising requirements is essential, as it directly impacts the capacity and kind of equipment you will need.

- Evaluate Site Conditions: Analyze the layout of your job site, taking into account space constraints, surface types, and any potential obstacles. For instance, uneven terrain or limited access points can significantly influence the selection of an elevation system. According to industry insights, common site conditions can affect equipment choice, with approximately 20-30% of construction professionals reporting challenges related to site layout and accessibility.

- Research Options: Investigate various models of portable material lifts available in the market. Compare their features, lifting capacities, and user reviews to find options that align with your project requirements. This research phase is essential, as it enables you to identify options that not only meet your needs but also provide reliability and ease of use.

- Consult with Experts: Engage with equipment rental companies or industry professionals who can provide valuable insights tailored to your specific situation. Their knowledge can assist you in managing the intricacies of equipment selection, ensuring that you select a model that improves productivity while complying with regulations. As Thomas D. Fama remarked, "As we look forward to 2025, the building sector is poised to experience significant transformations propelled by essential industry trends like tackling security issues through technology."

- Consider Maintenance and Support: Renting from a reputable company like EZ Equipment Rental ensures you receive well-maintained forklifts. Their equipment undergoes regular maintenance, including thorough inspections and timely repairs, reducing the risk of breakdowns during critical operations. Additionally, their team provides comprehensive support, such as 24/7 assistance and on-site troubleshooting, addressing any issues promptly to minimize downtime. This aspect is crucial for project managers who need reliable equipment to keep their operations running smoothly, as it directly impacts the efficiency and safety of using portable material lifts.

- Consider Sustainability: Incorporate insights from case studies, such as the one titled "Criteria for the Selection of Sustainable Onsite Construction Equipment," which emphasizes the importance of selecting equipment based on sustainability criteria. This is increasingly relevant in 2025 as the industry adapts to new regulations and economic factors.

By following these steps, you can make informed decisions that enhance your building processes. As the building sector evolves in 2025, adapting to new technologies and site conditions will be essential for success. Highlighting the significance of professional advice and comprehensive evaluation will enable project managers to choose the most appropriate portable equipment for their requirements.

The Future of Portable Material Lifts in Construction Projects

The future of portable material lifts in construction is on the brink of significant transformation, propelled by technological advancements that promise smarter and more efficient designs. Key trends include:

- The integration of automation, enhancing operational efficiency and reducing manual labor.

- Improved features that prioritize worker protection on job sites.

- The adoption of eco-friendly substances, aligning with the industry's increasing focus on sustainability.

As the construction landscape evolves, the portable material lift emerges as an essential tool that not only boosts productivity but also enhances safety protocols. Advancements in hoisting technology are anticipated to elevate operations, enabling faster and safer handling of goods. For example, the latest models are designed with user-friendly interfaces and advanced stability systems, contributing to a safer working environment.

The average revenue scale for firms in the equipment raising sector is estimated at $765 million this year, underscoring the economic environment's influence on market dynamics. Expert forecasts suggest that the market for portable material lifts will continue to expand, driven by continuous innovations and shifting consumer preferences. Bridget McCrea, Editor at Large for Modern Materials Handling, notes that a recent survey found that 59% of respondents intend to upgrade or implement network design and optimization software in the next two years, highlighting the industry's push towards technological integration.

Looking ahead, the forecast for the portable material lift market over the next five years is positive, with expectations of heightened demand for versatile and efficient lifting solutions that cater to various building needs. As these trends unfold, construction experts anticipate a new era of productivity and safety, making portable equipment indispensable in contemporary construction endeavors. Additionally, insights from the "Mobile Cranes Global Market Report 2025" provide valuable context on trends and forecasts relevant to the discussion of portable material lifts.

Conclusion

Portable material lifts are revolutionizing the construction landscape by significantly enhancing productivity and safety on job sites. These innovative tools streamline the lifting and transportation of heavy materials, allowing construction teams to operate more efficiently while minimizing physical strain and the risk of injury. With impressive lifting capacities and compact designs, portable lifts cater to a variety of construction needs, making them indispensable assets for project managers aiming to optimize operations.

The advantages of portable material lifts extend beyond mere convenience. They effectively address common construction challenges such as delays and inefficiencies, enabling teams to adhere to timelines and budget constraints. As evidenced by real-world case studies, companies that have integrated these lifts into their operations have reported substantial improvements in project timelines and worker safety. The emphasis on safety and ergonomic design in modern lifts further underscores their critical role in promoting a safer working environment.

Looking ahead, the demand for portable material lifts is expected to grow as the construction industry continues to evolve. With increasing federal infrastructure investments and an ongoing focus on improved safety standards, these tools will be essential for navigating the complexities of modern construction projects. By prioritizing the selection of the right portable lifts and ensuring proper training and maintenance, project managers can leverage these innovations to enhance operational efficiency and achieve successful project outcomes. The future of construction lies in embracing these technological advancements that promise to redefine how material handling is approached in the industry.

Frequently Asked Questions

What are portable material lifts and why are they important in the construction sector?

Portable material lifts are essential tools designed to raise and move heavy items across various work locations in the building sector. They enhance productivity by enabling swift and secure transportation of goods, reducing the physical effort required for manual handling.

What lifting capacities do portable material lifts have?

Portable material lifts have lifting capacities ranging from 1.8 tons to 48 tons, making them adaptable for a wide array of building needs and projects.

How does the design of portable material lifts benefit construction teams?

The compact design and mobility of portable material lifts are advantageous in confined spaces and multi-level structures, allowing teams to operate efficiently while maintaining safety and effectiveness.

What role do forklifts play in portable material lifts?

Forklifts are an integral component of portable material lifts, significantly enhancing efficiency and safety in construction projects. They are equipped with advanced protective features and ergonomic designs to ensure operator comfort and compliance with workplace standards.

How do portable material lifts improve safety in construction?

The integration of portable material lifts reduces the risks associated with manual handling, which is a leading cause of injuries on construction sites. Their use also helps in optimizing workflows, adhering to schedules, and budget constraints.

What financial benefits are associated with using portable material lifts?

Companies can save between $4 to $6 for every dollar invested in effective protective measures, highlighting the financial advantages of prioritizing worker well-being and using portable material lifts.

How do portable material lifts impact project timelines?

Case studies show that building crews utilizing portable material lifts experience significant reductions in project delays, as these tools facilitate faster and safer material management.

What expert insights support the use of portable material lifts in construction?

Experts advocate for portable material lifts due to their ability to reduce labor costs, increase material handling speed, and improve overall site security, which is crucial as the construction landscape evolves.

How do portable material lifts help contractors navigate industry challenges?

Portable material lifts help address challenges such as labor shortages and rising costs while aligning with the industry's commitment to enhanced safety standards and operational efficiency.

What is the significance of investing in portable material lifts for contractors?

Investing in portable material lifts allows contractors to effectively navigate the complexities of modern construction, enhancing overall productivity and security in their projects.