Introduction

In the fast-evolving landscape of construction and industrial operations, the 10K telehandler emerges as a vital tool, adept at tackling the challenges of heavy material handling. With its impressive lift capacity and versatile attachments, this machine not only enhances efficiency but also provides the agility needed to navigate complex job sites. However, the journey to maximizing its potential involves understanding key features, operational best practices, and essential safety protocols.

From rental considerations to maintenance tips, this article delves into the multifaceted world of the 10K telehandler, offering insights that empower users to harness its capabilities effectively while prioritizing safety and cost efficiency.

Overview of the 10K Telehandler: Key Features and Specifications

The 10K telescopic handler, often called a telescopic handler, is designed for challenging tasks in construction and industrial environments. Its key specifications include:

- Lift Capacity: With the ability to lift loads up to 10,000 pounds, it is ideal for transporting heavy materials across job sites.

- Reach: Featuring a maximum reach of approximately 42 feet, it enables operators to access materials at considerable heights and distances with precision.

- Versatility: This machine can be outfitted with a variety of attachments—such as forks, buckets, and winches—allowing it to perform a multitude of functions, from lifting to loading diverse materials.

- Maneuverability: Its compact design, coupled with a four-wheel drive system, facilitates navigability on uneven terrain and in confined job site spaces.

- Stability: Equipped with outriggers or stabilizers, the 10K equipment enhances balance during heavy lifting, which is crucial for maintaining security on-site.

These specifications not only underscore the 10K equipment's importance in construction but also in agriculture and landscaping applications. By offering efficiency and adaptability in material handling tasks, this equipment plays a crucial role in addressing the challenges presented by job site conditions, such as high winds and rough terrain.

Crucially, all forklift operators must obtain certification according to OSHA standard 1910.178, highlighting the importance of training for effective operation. As mentioned by the Occupational Safety and Health Administration, 'Your first reaction is likely to jump, but despite your instinct, for your protection, keep your seatbelt fastened and stay inside the cab.'

Following operational protocols, including acquiring OSHA certification and conducting pre-operation checks, as emphasized in the case study on equipment guidelines, further guarantees that operators can use this powerful machinery efficiently and securely.

Operational Insights: Renting and Operating a 10K Telehandler

When renting a 10K material handler, consider the following operational insights:

- Selecting a Rental Company: Choose a reputable rental agency that offers well-maintained equipment and thorough customer support. Always check the company’s reviews and ratings.

- Rental Agreements: Understand the terms of the rental agreement, including duration, costs, insurance policies, and maintenance responsibilities. Ensure you have a clear understanding of any additional fees for damage or late return.

- Training and Certification: Operators should be trained and certified to use telehandlers. Acquaint yourself with the machine’s controls and features prior to operation to guarantee protection and efficiency.

- Protocols: Always wear suitable personal protective equipment (PPE) and follow guidelines. Perform a pre-operation checklist to inspect the equipment for any mechanical issues before use.

- Best Practices: Follow best practices for loading and lifting, such as keeping the load close to the machinery and not exceeding the maximum lift capacity. Consistently stay mindful of your environment and interact efficiently with ground crew members to promote a secure working atmosphere.

By grasping these elements, users can improve their experience with the 10K lift and confirm that they operate within protection guidelines while maximizing effectiveness on the job site.

Maintenance and Care for the 10K Telehandler

To guarantee the optimal performance of a 10K lift machine, adhere to the following maintenance practices:

- Regular Inspections: Conduct daily checks on critical components such as tires, brakes, and hydraulic systems before operation.

- Fluid Levels: Monitor and maintain appropriate levels of engine oil, hydraulic fluid, and coolant, as low levels can lead to equipment failure.

- Filter Changes: Replace air and fuel filters according to the manufacturer's recommendations to guarantee efficient engine performance.

- Cleaning: Regularly clean the lift machine to remove dirt and debris, particularly around the hydraulic system, to prevent blockages.

- Professional Servicing: Schedule periodic professional check-ups to identify and address any underlying issues before they escalate into major problems.

By following these maintenance tips, users can extend the lifespan of their lift machine and guarantee reliable performance on the job site.

Safety Protocols for Operating a 10K Telehandler

To operate a 10K lifting machine safely, implement these safety protocols:

- Training: Ensure that all operators are properly trained and certified to handle the equipment.

- Pre-operation Checks: Conduct thorough inspections of the machine before use, checking for any mechanical issues, leaks, or damage.

- Load Management: Always adhere to the machine's load capacity and distribute the load evenly to maintain balance.

- Clear Work Area: Maintain a clean and organized work environment, removing obstacles that may impede operation.

- Communication: Use hand signals or two-way radios to maintain clear communication with ground personnel during operations.

Adhering to these protocols can significantly reduce the risk of accidents and ensure a safe working environment when using a 10K lifting machine.

Common Applications for the 10K Telehandler

The 10K machine stands out as an exceptionally versatile piece of equipment, making it indispensable across several domains. Its applications include:

- Construction Sites: It excels in lifting and transporting materials such as steel beams, concrete blocks, and heavy machinery, enhancing project efficiency. A case study titled 'How Telehandlers Improve Concrete Operations' highlights that using telehandlers in concrete operations has led to a 30% increase in efficiency and precision in handling heavy materials.

- Agricultural Use: In farming, telehandlers are frequently employed for various tasks, including loading hay bales, feeding livestock, and transporting feed. According to industry statistics, these machines have seen a 20% increase in usage within the agricultural sector over the past year, demonstrating their adaptability in agricultural settings.

- Landscaping: The equipment aids in lifting and relocating landscaping materials, such as soil, rocks, and plants, facilitating smoother project workflows. Current trends indicate that landscaping companies are increasingly adopting these machines for their ability to maneuver in tight spaces, which is crucial for urban landscaping projects.

- Warehousing: Particularly valuable in warehouses, this equipment allows for loading and unloading goods, especially in confined spaces where traditional forklifts may struggle.

- Utility Work: Utility companies utilize this machinery to lift equipment and materials to elevated work areas, including power poles and communication towers, further demonstrating their multifaceted applications.

By comprehensively understanding these applications, construction project managers can optimize their operations. As Kiskunas notes,

And telehandlers can be a powerful platform to carry and work with them.

Leveraging the 10K equipment effectively not only streamlines tasks but also increases overall project efficiency.

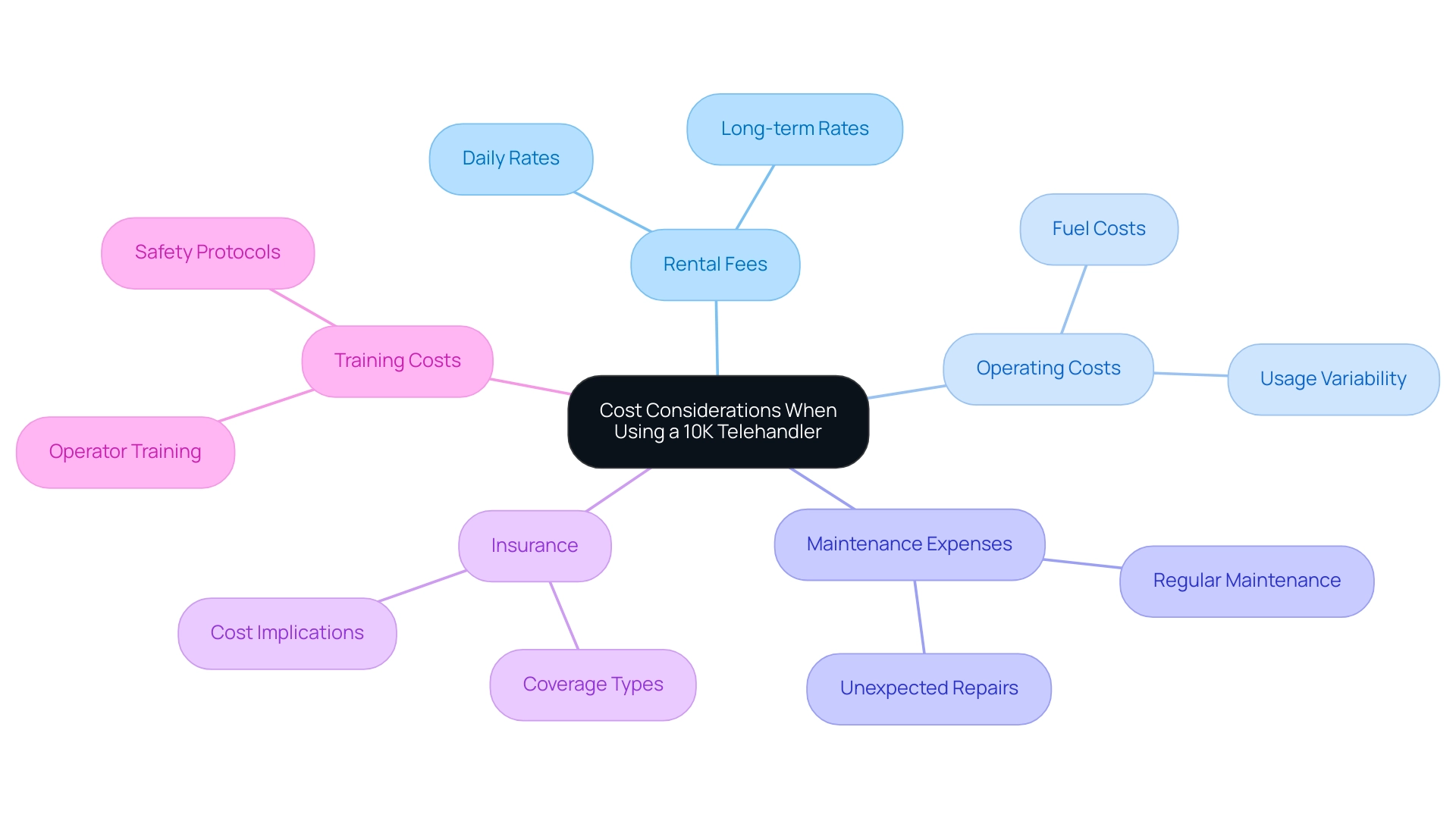

Cost Considerations When Using a 10K Telehandler

When considering the costs of using a 10K telehandler, keep in mind the following factors:

- Rental Fees: If renting, compare prices across rental companies, considering both daily and long-term rates.

- Operating Costs: Factor in fuel costs, which can vary based on usage and local fuel prices.

- Maintenance Expenses: Budget for regular maintenance and unexpected repairs, as these can impact overall costs.

- Insurance: Ensure you have appropriate insurance coverage for the telehandler, which can add a layer of cost but protects against financial loss in case of accidents.

- Training Costs: Include expenses for training operators to ensure safe and efficient use of the equipment.

By being aware of these cost considerations, users can better manage their budgets and ensure that their projects remain financially viable.

Conclusion

The 10K telehandler is an invaluable asset in the construction and industrial sectors, offering a combination of lift capacity, versatility, and maneuverability that addresses the complexities of material handling. Understanding its key features, such as the ability to lift 10,000 pounds and reach up to 42 feet, empowers operators to effectively utilize this equipment across various job sites, from construction to agriculture and landscaping.

Operational insights highlight the importance of selecting a reliable rental company and ensuring that operators are trained and certified. Adhering to safety protocols and best practices not only enhances efficiency but also prioritizes the well-being of all personnel on-site. Regular maintenance checks and proper care are crucial to prolonging the lifespan of the telehandler and ensuring it operates at peak performance, ultimately reducing the risk of costly downtime.

Moreover, recognizing the diverse applications of the 10K telehandler reinforces its role as a multi-faceted tool that can streamline operations in different contexts, including warehousing and utility work. By being mindful of cost considerations, users can manage their budgets effectively while maximizing the benefits of this powerful equipment.

In conclusion, the 10K telehandler stands as a testament to innovation in material handling, offering solutions to the challenges faced in demanding environments. By following best practices in operation, maintenance, and safety, users can unlock its full potential, enhancing productivity while ensuring a safe working environment. Embracing this technology leads to improved project outcomes and a more efficient workflow, making it a wise investment for any operation requiring heavy lifting capabilities.

Frequently Asked Questions

What is a 10K telescopic handler?

A 10K telescopic handler, commonly known as a telehandler, is a versatile piece of equipment designed for challenging tasks in construction and industrial environments, capable of lifting loads up to 10,000 pounds.

What are the key specifications of the 10K telescopic handler?

The key specifications include a lift capacity of 10,000 pounds, a maximum reach of approximately 42 feet, versatility with various attachments (like forks and buckets), compact design for maneuverability, and stability through outriggers or stabilizers.

In what applications is the 10K telescopic handler commonly used?

It is used in construction for lifting heavy materials, in agriculture for tasks like loading hay bales, in landscaping for moving soil and plants, in warehousing for loading and unloading goods, and in utility work for lifting equipment to elevated areas.

What safety protocols should be followed when operating a 10K telescopic handler?

Operators should be properly trained and certified, conduct pre-operation checks, manage loads according to capacity, maintain a clear work area, and ensure effective communication with ground personnel.

What maintenance practices are recommended for the 10K telescopic handler?

Recommended practices include regular inspections of critical components, monitoring fluid levels, changing filters as per manufacturer guidelines, cleaning the machine, and scheduling professional servicing.

What factors should be considered when renting a 10K telescopic handler?

Considerations include selecting a reputable rental company, understanding rental agreements, ensuring operator training and certification, following safety protocols, and adhering to best practices for operation.

What are the cost factors associated with using a 10K telescopic handler?

Cost factors include rental fees, operating costs (fuel), maintenance expenses, insurance coverage, and training costs for operators.

Why is OSHA certification important for telehandler operators?

OSHA certification is important because it ensures that operators are trained to use the equipment safely and effectively, which is crucial for maintaining safety standards on job sites.