Overview

This article provides a comprehensive comparison of the advantages and disadvantages of renting versus purchasing welding gas. It concludes that renting is ideal for occasional users, while purchasing proves more beneficial for frequent welders. Evidence supports this assertion, indicating that renting offers:

- Cost-effectiveness

- Flexibility

- Maintenance convenience for short-term projects

In contrast, purchasing provides:

- Long-term savings

- Immediate access for regular users

Ultimately, the choice between renting and purchasing depends on individual usage patterns and budget considerations.

Key Highlights:

- Common welding gases include argon, carbon dioxide, acetylene, helium, and mixed gases, each with specific applications in welding.

- Renting welding gas is cost-effective for short-term projects, with 70% of construction projects opting for rental to manage budgets.

- Rental companies handle maintenance and certification of gas cylinders, mitigating liability risks for users.

- Renting offers flexibility in cylinder size and type, catering to varying project needs, and often includes convenient delivery and pickup services.

- Purchasing welding gas can lead to long-term savings for frequent users, providing immediate access and customization options.

- Owning gas cylinders allows for better control over supply and potential resale value, making it a viable option for regular welders.

- The decision to rent or purchase welding gas depends on user needs, frequency of use, and budget considerations, with renting being practical for occasional users and purchasing advantageous for frequent welders.

Introduction

In the realm of welding, the decision to rent or purchase welding gas profoundly influences both project efficiency and overall costs. The selection of appropriate shielding gases is critical in safeguarding weld quality; thus, a comprehensive understanding of the available options—from argon to acetylene—is essential for industry professionals. As the welding gas market undergoes transformation, driven by pricing fluctuations and innovative advancements, decision-makers must carefully evaluate the merits of both renting and owning gas cylinders. This article explores the advantages and disadvantages of each strategy, offering valuable insights that empower project managers to optimize their operations amid the complexities of welding gas procurement.

Understanding Welding Gas Options

Welding substances are crucial for various joining techniques, providing essential shielding to protect the weld pool from environmental contamination. The most common types of welding gases include:

- Argon: An inert gas widely utilized for TIG and MIG processes, argon offers excellent arc stability and is ideal for joining aluminum and stainless steel.

- Carbon Dioxide (CO2): Frequently used in MIG processes, CO2 is more affordable than argon and provides good penetration, although it may lead to increased spatter.

- Acetylene: Typically employed in oxy-acetylene processes, acetylene generates a high-temperature flame suitable for cutting and joining ferrous and non-ferrous metals.

- Helium: Used in conjunction with argon, helium enhances heat input and is beneficial for joining thicker materials.

- Mixed Gases: Combinations of argon and CO2 are common in MIG fabrication, striking a balance between cost and performance.

Understanding these options is vital for making informed decisions regarding the rental or purchase of welding gas rental for metalworking. Recent trends in the gas market reveal a shift towards innovations and strategic partnerships that are reshaping the industry. For instance, as of August 2024, the average price of gas for metal joining has varied, with reports indicating an average cost of $4,111 USD. Moreover, the market share of various fusion substances is expected to evolve in 2025, reflecting the changing requirements of the industry.

Expert opinions underscore the significance of selecting the appropriate shielding substances, as they directly affect the quality and efficiency of joining processes. As noted by Air Products and Chemicals, Inc., the dynamics of the gas market for metal joining are shaped by various factors, including acquisitions and technological advancements. Furthermore, a case study on EZ Equipment Rental illustrates how expanding their offerings to include new equipment sales enables them to serve customers looking to purchase equipment, thereby boosting their revenue streams. Staying informed about the latest advancements in gas applications is essential for managers aiming to enhance their operations.

Advantages of Renting Welding Gas

Welding gas rental offers significant advantages tailored to the demands of construction projects.

- Cost-Effectiveness: For short-term endeavors, welding gas rental proves to be more economical, eliminating the substantial upfront costs associated with purchasing gas cylinders. Statistics reveal that approximately 70% of construction projects opt for welding gas rental solutions to effectively manage their budgets.

- Maintenance and Safety: Rental companies assume responsibility for the maintenance, testing, and certification of gas cylinders. This alleviates the burden on users, ensuring compliance with safety standards and mitigating liability risks. A case study by Dianne Miller underscores that welding gas rental not only conserves funds but also minimizes storage space requirements, thereby fostering greater opportunities for career advancement.

- Flexibility: Renting provides the ability to select the appropriate size and type of gas cylinder tailored to specific needs. This flexibility allows for easy adjustments in response to the scale of work, whether it involves minor repairs or extensive operations. CK Supply emphasizes that their rental program, including welding gas rental, accommodates a wide range of requirements, from short-term repairs to large-scale projects.

- Convenience: Numerous rental services offer delivery and pickup options, streamlining the process and saving valuable time for users. This convenience is particularly beneficial for busy managers who must juggle multiple tasks simultaneously.

- No Long-Term Commitment: Renting suits individuals who do not require gas regularly. This pay-as-you-go model for welding gas rental enables users to avoid the long-term commitments and expenses associated with ownership, making it a practical choice for occasional or smaller-scale fabrication projects.

These advantages illustrate why renting gas is gaining traction among construction professionals, especially in 2025, where cost savings and operational efficiency are paramount.

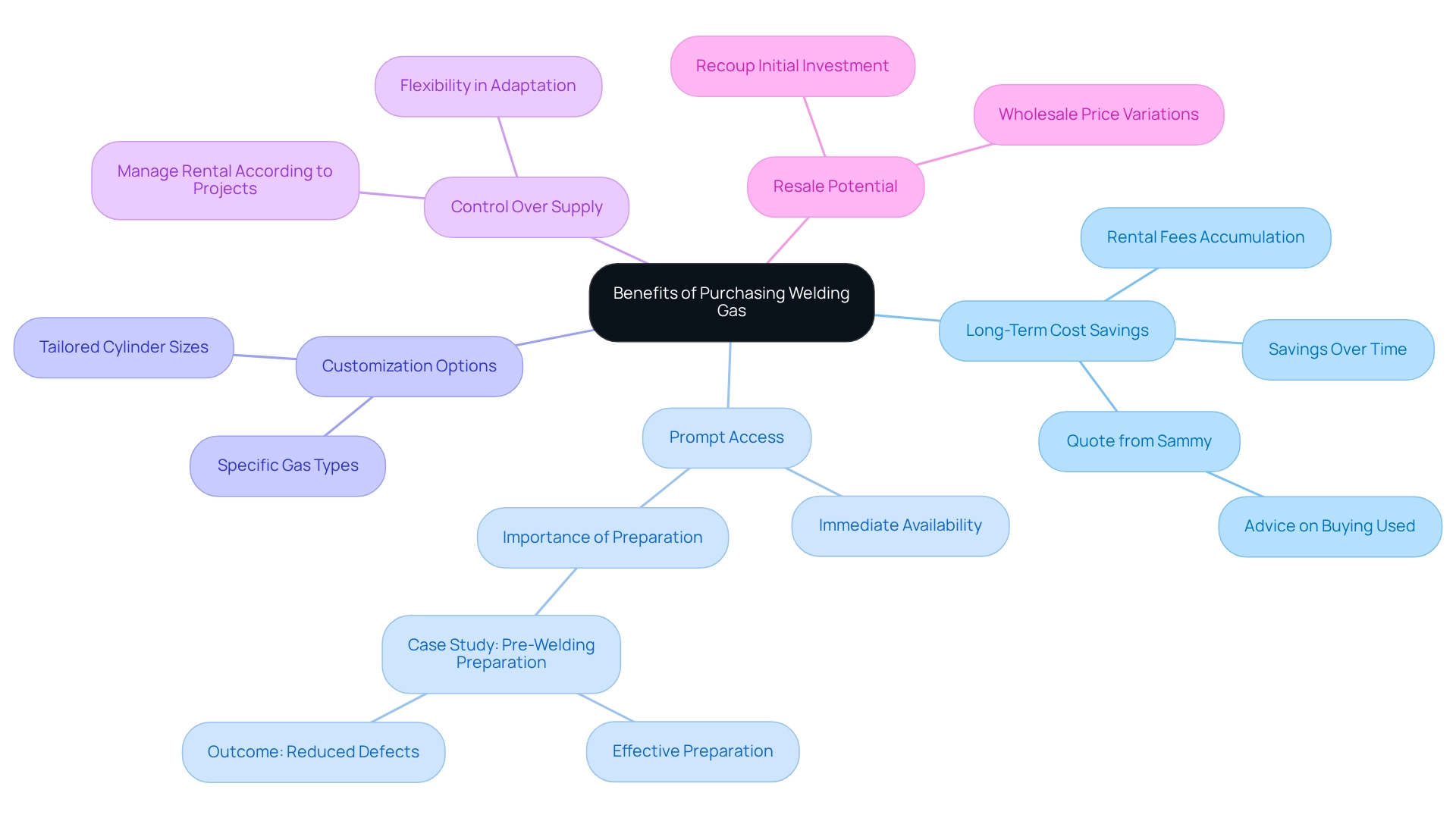

Benefits of Purchasing Welding Gas

Purchasing welding gas presents several significant advantages that should not be overlooked.

- Long-Term Cost Savings: For those who frequently utilize gas for metal joining, outright purchasing can lead to substantial savings over time. Welding gas rental fees can accumulate quickly, making ownership a more economical choice in the long run. As noted by Sammy, a senior industry member, "Thanks tons! I think that I will look out for some more options such as buying used. The $240 for a 50 CF probably isn't the best."

- Prompt Access: Owning gas cylinders guarantees immediate access to gas for metalworking, eliminating the delays associated with arranging rentals or exchanges. This is particularly crucial, as proper preparation of the solder joint is vital for successful joining. A case study illustrates that meticulous preparation leads to superior outcomes and fewer defects, underscoring the importance of having gas readily available.

- Customization Options: Ownership allows individuals to choose specific gas types and cylinder sizes tailored to their unique welding requirements, rather than being restricted by rental inventory. This flexibility enhances the overall welding experience.

- Control Over Supply: With ownership, individuals can manage their welding gas rental according to project timelines, providing the flexibility necessary to adapt without the constraints of rental agreements. This adaptability is essential in an industry that prioritizes continuous learning and adaptation.

- Resale Potential: In the event that demand for gas diminishes, owned cylinders can often be resold, enabling users to recoup part of their initial investment. Additionally, wholesale prices may vary among competing retailers based on their fuel purchase terms, making ownership a potentially more advantageous financial decision.

These benefits highlight the practicality of acquiring gas for individuals engaged in frequent metal joining tasks, offering both convenience and potential financial advantages. Furthermore, technical support and troubleshooting guidance from gas suppliers can significantly enhance the overall value proposition of ownership.

Comparative Analysis: Renting vs. Purchasing Welding Gas

When evaluating the decision regarding welding gas rental or purchase, several critical factors come into play that can significantly impact your operations:

- Initial Cost: Welding gas rental typically involves lower upfront costs, making it an attractive option for those with short-term needs. In contrast, purchasing requires a higher initial investment, which may deter occasional users from committing.

- Long-Term Cost: Although renting may appear economical at first glance, costs can accumulate over time, particularly for those who use gas frequently. On the other hand, purchasing gas becomes more cost-effective for regular users, as long-term savings can outweigh the initial expenses.

- Maintenance: One of the advantages of renting is that maintenance is handled by the rental company, alleviating users from additional responsibilities. Conversely, purchasing gas means users must manage maintenance themselves, which can lead to unforeseen costs and time commitments.

- Flexibility: Renting offers high flexibility, allowing users to choose the size and type of gas cylinders that best suit their project needs. In contrast, purchasing limits users to their owned cylinders, which may not always meet diverse task requirements.

- Convenience: Rental services often provide delivery and pickup, enhancing convenience for users. For example, refilling a tank can take less than a day if it is brought in before 10 AM, making it a time-efficient option. However, purchasing gas allows for instant access without delays, which is particularly advantageous for urgent tasks.

- Commitment: Renting does not require a long-term commitment, enabling users to adapt to changing project demands seamlessly. In contrast, purchasing represents a long-term investment that may not be suitable for everyone.

Ultimately, the decision between welding gas rental and purchasing hinges on specific user needs, frequency of use, and budget considerations. For those who weld occasionally, using welding gas rental may provide the most practical solution. Conversely, frequent welders stand to benefit from purchasing, as it can lead to substantial cost savings over time.

Furthermore, integrating contingency budgets in quotes can protect against unforeseen costs, as emphasized in the case study on including contingency budgets. This aspect further influences the financial decision-making process. As Michael Timbal observed, utilizing pre-made cost templates can simplify the estimation process, facilitating easier assessment of options for managers. Additionally, maintaining open communication with clients is essential for successful project management in welding, ensuring that all parties are aligned on expectations and costs.

Conclusion

The choice between renting and purchasing welding gas is pivotal for optimizing project efficiency and managing costs. Each option presents distinct advantages tailored to specific user needs. Renting welding gas is often the more economical choice for short-term projects, offering flexibility, convenience, and reduced maintenance responsibilities. This approach is particularly appealing for construction professionals who prioritize cost-effectiveness and operational efficiency.

Conversely, purchasing welding gas proves beneficial for those engaged in regular welding activities. Long-term cost savings, immediate availability, and control over gas supply are compelling reasons to invest in ownership. The ability to customize gas types and sizes further enhances the practicality of purchasing, making it a wise decision for frequent users.

In conclusion, the optimal choice between renting and purchasing welding gas ultimately depends on the frequency of use, project requirements, and budget considerations. By carefully evaluating these factors, project managers can make informed decisions that align with their operational goals. Staying attuned to market trends and innovations in welding gases will also empower professionals to adapt and thrive in an evolving industry landscape.

Frequently Asked Questions

What are welding substances and why are they important?

Welding substances are crucial for various joining techniques as they provide essential shielding to protect the weld pool from environmental contamination.

What are the common types of welding gases?

The most common types of welding gases include: 1. Argon: An inert gas used for TIG and MIG processes, ideal for aluminum and stainless steel. 2. Carbon Dioxide (CO2): Often used in MIG processes, it is more affordable than argon and provides good penetration but may increase spatter. 3. Acetylene: Used in oxy-acetylene processes, it generates a high-temperature flame suitable for cutting and joining metals. 4. Helium: Used with argon, it enhances heat input and is beneficial for joining thicker materials. 5. Mixed Gases: Combinations of argon and CO2 are common in MIG fabrication, balancing cost and performance.

How do recent trends affect the welding gas market?

Recent trends in the gas market indicate a shift towards innovations and strategic partnerships, with an average price of gas for metal joining reported at $4,111 USD as of August 2024. The market share of various fusion substances is expected to evolve in 2025, reflecting changing industry requirements.

Why is it important to select the appropriate shielding substances in welding?

Selecting the appropriate shielding substances is significant as they directly affect the quality and efficiency of the joining processes.

What factors shape the dynamics of the gas market for metal joining?

The gas market dynamics are shaped by various factors, including acquisitions, technological advancements, and industry trends.

How can companies enhance their operations in the welding gas market?

Companies can enhance their operations by staying informed about the latest advancements in gas applications and expanding their offerings, such as equipment sales, to meet customer needs and boost revenue streams.