Introduction

In the world of construction and landscaping, efficiency and precision are paramount, particularly when it comes to trenching tasks. Bobcat trencher attachments stand out as essential tools, designed to enhance the capabilities of compact equipment while tackling a variety of applications such as utility installations and drainage systems.

With innovative features that allow for customizable digging depths and widths, these attachments are engineered to meet the specific demands of any job site. As construction professionals seek ways to optimize their operations, understanding the functionality and advantages of Bobcat trenchers becomes crucial.

From improving productivity to ensuring safety during excavation, these attachments are not just tools but vital assets that can transform project outcomes and streamline workflows.

Introduction to Bobcat Trencher Attachments

The innovative Bobcat trencher attachment is specifically designed for use with Bobcat compact equipment, including skid-steer loaders and . These components are crucial in forming narrow trenches necessary for a range of uses such as utility installations, drainage systems, and landscaping tasks. The latest advancements in trenching technology enable the Bobcat trencher attachment to deliver precise and efficient excavation, significantly enhancing productivity on job sites.

For instance, the T86 model, equipped with a powerful 105 horsepower turbocharged diesel engine and a substantial 31.6-gallon fuel tank, is designed to handle demanding trenching tasks while maintaining fuel efficiency. The versatility is further improved by the three hydraulic flow options offered in the compact loader, enabling operators to tailor performance according to specific requirements. This not only enables contractors to complete tasks more effectively but also minimizes the need for manual labor, streamlining operations.

Furthermore, the dual-direction bucket positioning standard on these machines enhances maneuverability, making them invaluable for intricate work. As noted by Thompson Tractor, which has provided premium skid steer loader sales, support, and services for over 60 years, the integration of features like the hydraulic oil sight gauge in R-Series loaders simplifies daily maintenance checks. This particular feature is crucial for trenching operations with the Bobcat trencher attachment, as it allows operators to quickly monitor hydraulic oil levels, which ensures that the equipment remains in optimal condition and reduces downtime.

By comprehending the functionality and benefits of excavator attachments, construction experts can greatly enhance their equipment utilization and results, ultimately boosting productivity and efficiency on the job site.

Key Specifications and Features of Bobcat Trenchers

These excavating machines, such as the bobcat trencher attachment, are designed with a range of specifications aimed at enhancing performance on different job sites. Key features of the bobcat trencher attachment, such as adjustable digging depths and customizable chain widths, empower operators to tailor their trenching operations to meet specific project demands. For example, can achieve a digging depth of up to 48 inches, with chain widths that range from 4 to 12 inches, making it versatile for tasks like pipe installation or drainage system creation.

Furthermore, the tool's robust design guarantees durability and reliability, essential for enduring the rigors of challenging work environments. As noted by Barreto Manufacturing Inc.:

When preparing a digging machine for work, excavation depth and width are two of the important questions to consider. But a third question often stumps people: is this chain type right for the job?

This consideration underscores the importance of selecting the right equipment for optimal trenching performance. Additionally, advancements in technology are continuously enhancing machines like the bobcat trencher attachment, providing construction professionals with tools that not only boost productivity but also improve safety during underground utility work. For rental clients, comprehending the distinctions between ride-on and walk-behind equipment can further assist in making the suitable choice for their specific needs.

Notably, the 2023 LT113 is available for approximately $6,000 from Deitering Brothers, providing a practical financial perspective for project managers considering rentals. Moreover, the case study titled 'Equipment for Underground Utility Construction' highlights how advancements in trenching technology contribute to increased productivity and safety for workers in the field, reinforcing the value of choosing the appropriate equipment for the job.

Compatibility with Bobcat Models

Bobcat equipment is meticulously designed to ensure compatibility with a wide array of Bobcat models, notably including the highly regarded skid-steer loaders like and S770. Each implement is specifically designed to fit designated models, thereby improving operational efficiency and safety. To prevent expensive errors, it is crucial for users to refer to the manufacturer’s specifications before buying an accessory.

This diligence helps ensure that the trencher operates at its best with the chosen machine, ultimately maximizing the investment in equipment. As mentioned by Travis Kidder, a product expert at the company,

You can certainly encounter the opposite situation where the carrier is too large for an accessory,

highlighting the necessity for careful selection. Furthermore, it is crucial to be aware of the risks associated with hydraulic oil contamination, particularly when switching between different attachments.

Employing oil analysis can assist in tracking contamination problems and ensuring compatibility among different machinery, thereby protecting the integrity and lifespan of both the excavator and the loader models. Regular maintenance intervals are recommended for hydraulic systems to prevent issues and maintain performance. Additionally, the ASV VT-80 and VT-80 Forestry models, with a rated operating capacity of 2,800 lbs, exemplify the robust capabilities of these excavation machines.

The case study titled 'Hydraulic Oil Contamination Risks' highlights that monitoring oil quality through analysis helps mitigate contamination issues and ensures compatibility across different equipment.

Applications of Bobcat Trencher Attachments

The use of bobcat trencher attachments is essential in a variety of applications, especially for utility installations like laying electrical conduits, water lines, and telecommunications cables. With the bobcat trencher attachment, contractors can install trenches up to:

- 250 feet long

- 2 to 4 feet deep

- Up to 8 inches wide

This provides the precision needed for efficient work. Furthermore, their design permits effective landscaping endeavors, making the bobcat trencher attachment ideal for creating trenches for:

- Irrigation systems

- Drainage solutions

The bobcat trencher attachment's narrow trenching capability minimizes disruption in urban environments, where space is often at a premium. This versatility not only streamlines the construction process but also improves results and client satisfaction when using the bobcat trencher attachment. As mentioned by SiteOne Landscape Supply, '[insert quote here],' highlighting the significance of dependable equipment in landscape endeavors.

Additionally, the latest trends in the industry, such as , which features wide tracks on a narrow machine, reflect the ongoing innovation in trenching technology. Best practices such as utilizing trench boxes or shoring equipment are crucial for ensuring safety during the excavation of deep trenches, particularly in unstable soil conditions or near existing structures. This approach is supported by case studies demonstrating that trench boxes provide a secure enclosure for workers, helping to prevent accidents and ensuring compliance with safety regulations, which is vital for reducing the risk of injuries and project delays.

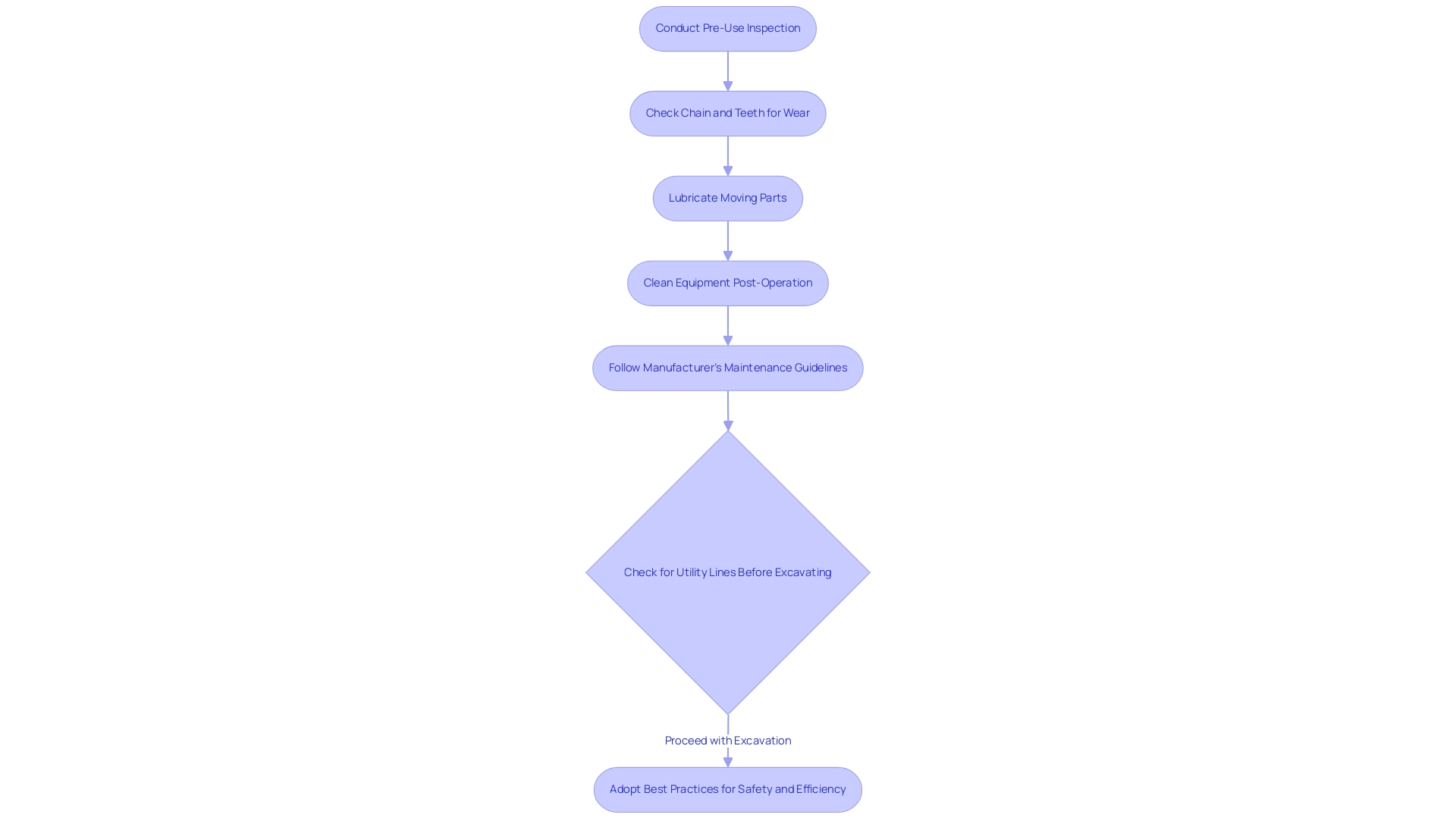

Maintenance and Best Practices for Bobcat Trenchers

Regular maintenance is essential for ensuring the longevity and optimal performance of the bobcat trencher attachment. Operators should conduct thorough inspections before each use, focusing on:

- Wear and tear on the chain and teeth

- Ensuring that all moving parts are adequately lubricated

Post-operation cleaning is essential, particularly in muddy or abrasive environments, as it prevents damage and sustains functionality.

Following the manufacturer’s maintenance guidelines, including the timely replacement of worn components, is critical in avoiding costly repairs and minimizing downtime. Notably, between 2011 and 2018, trench collapses or cave-ins resulted in the deaths of 166 workers, underscoring the importance of proper maintenance and safety practices. Additionally, neglecting to check for utility lines before excavating can lead to severe consequences, including electrocution and gas leaks.

Therefore, reaching out to local utility providers before excavating is a crucial aspect of the maintenance and safety protocol for excavation work. Adopting these best practices not only extends the lifespan of the equipment but also boosts overall productivity on construction sites. A proactive approach to maintenance can lead to and help mitigate common issues faced by operators of the bobcat trencher attachment.

Conclusion

Bobcat trencher attachments are indispensable tools that significantly enhance the efficiency and precision of trenching tasks across various applications. Their innovative features, such as customizable digging depths and widths, empower operators to tailor their equipment for specific project requirements, ultimately leading to improved productivity. The compatibility of these attachments with a wide range of Bobcat models further ensures that construction professionals can maximize their investments while minimizing downtime.

In addition to boosting operational efficiency, the safety and reliability of Bobcat trenchers are paramount. Regular maintenance and adherence to best practices play a crucial role in preventing accidents and equipment failures. By fostering a culture of safety and responsibility, operators can not only protect their investments but also ensure the well-being of their teams on job sites.

Ultimately, understanding and utilizing Bobcat trencher attachments can transform project outcomes, streamline workflows, and enhance overall performance in construction and landscaping endeavors. As technology continues to evolve, these attachments will remain vital assets that help contractors navigate the challenges of modern excavation tasks with confidence and efficiency. Embracing these advancements is essential for those looking to stay competitive in the ever-evolving construction landscape.

Frequently Asked Questions

What is the Bobcat trencher attachment designed for?

The Bobcat trencher attachment is designed for use with Bobcat compact equipment, including skid-steer loaders and compact track loaders, to create narrow trenches for utility installations, drainage systems, and landscaping tasks.

What are the key features of the Bobcat trencher attachment?

Key features include adjustable digging depths of up to 48 inches, customizable chain widths ranging from 4 to 12 inches, and dual-direction bucket positioning for enhanced maneuverability.

How does the T86 model enhance trenching tasks?

The T86 model is equipped with a 105 horsepower turbocharged diesel engine and a 31.6-gallon fuel tank, designed for demanding trenching tasks while maintaining fuel efficiency. It also offers three hydraulic flow options for tailored performance.

Why is regular maintenance important for the Bobcat trencher attachment?

Regular maintenance ensures the longevity and optimal performance of the trencher attachment, helping to prevent costly repairs and minimizing downtime. This includes inspecting wear and tear, lubricating moving parts, and cleaning post-operation.

What applications can the Bobcat trencher attachment be used for?

The Bobcat trencher attachment can be used for utility installations, such as laying electrical conduits and water lines, as well as for landscaping tasks like creating trenches for irrigation systems and drainage solutions.

What precautions should operators take before excavating?

Operators should check for utility lines to avoid severe consequences, such as electrocution and gas leaks, and reach out to local utility providers as part of their safety protocol.

How can the Bobcat trencher attachment improve productivity on job sites?

The trencher attachment enhances productivity by enabling precise and efficient excavation, reducing the need for manual labor, and streamlining operations through advanced technology and equipment design.

What role does hydraulic oil quality play in the operation of the trencher attachment?

Monitoring hydraulic oil quality is crucial to avoid contamination issues when switching between different attachments, ensuring compatibility and protecting the integrity and lifespan of the machinery.

What should operators do to ensure optimal performance of the trencher attachment?

Operators should follow the manufacturer’s maintenance guidelines, conduct thorough inspections before use, clean the equipment after operations, and replace worn components in a timely manner.