Introduction

In the fast-evolving landscape of construction and manufacturing, conveyor systems have emerged as indispensable tools for enhancing operational efficiency and safety. These mechanical marvels streamline the movement of materials, reducing reliance on manual labor and minimizing the risk of workplace injuries. As industries increasingly adopt these systems, understanding the various types available, the benefits of renting, and the critical factors to consider becomes essential for decision-makers.

With a growing emphasis on cost-effectiveness and flexibility, businesses can leverage conveyor technology to not only meet their immediate needs but also adapt to the dynamic demands of their projects. This article delves into the intricacies of conveyor systems, offering insights that empower organizations to make informed choices and optimize their material handling processes.

Introduction to Conveyor Systems: What You Need to Know

Conveyor mechanisms function as essential mechanical devices that aid in the movement of materials across different areas within a facility or construction site. With over 40 years of experience, West River Conveyors has recognized their essential role in industries such as manufacturing, warehousing, and construction, where efficiency in moving large volumes of goods is paramount. These setups can be customized regarding length, width, and arrangement, ensuring they satisfy particular operational needs and enhancing overall material handling abilities.

The range of transport mechanisms includes:

- Belt types

- Roller types

- Screw types

Each providing distinct benefits. By understanding the differences among these types, businesses can select the most suitable system for their needs, which not only enhances productivity but also minimizes the reliance on manual labor. This reduction significantly lowers the risk of workplace injuries related to heavy lifting. Moreover, advancements in transport technology have led to the integration of safety features that comply with OSHA regulations. As emphasized by West River Conveyors, we can assist you in navigating through the often-complex maze of safety regulations and requirements. This commitment to safety is further exemplified through the practical use of proper stickers and warning labels. These components offer clear guidance and notifications regarding possible dangers, acting as reminders for the use of essential protective equipment and directing safe machinery operation.

In 2024, the utilization of transport mechanisms across sectors continues to grow, with a reported rise of 15% in adoption rates, fueled by their efficiency and safety advantages. For example, a case study from a manufacturing facility demonstrated that introducing a transportation mechanism decreased material handling time by 30%, greatly enhancing workflow. Furthermore, specialists in the area claim that transport mechanisms can improve operational efficiency by as much as 25% in manufacturing environments, illustrating their essential role in contemporary industrial operations. By utilizing these methods, construction managers can not only enhance operations but also establish safer work environments.

Exploring Rental Options for Conveyor Systems: Benefits and Considerations

Leasing transport systems offers many benefits for companies, particularly those with temporary requirements. A major benefit is the significant cost savings, as renting eliminates the hefty upfront costs associated with purchasing equipment. Moreover, lease agreements typically encompass maintenance and support, alleviating the responsibility of managing repairs and upkeep for the company.

When assessing a lease, companies should analyze:

- The length of the task

- The particular kinds of transport systems available

- The overall cost comparison between leasing and buying over time

Additionally, evaluating the reliability of the leasing provider and the condition of the equipment is crucial. By carefully considering these factors, companies can make informed choices about integrating transport mechanisms into their projects, ensuring they effectively meet operational demands while avoiding unnecessary costs.

As Timea Iancu notes, 'Despite back-to-office policies from high-profile companies, office utilization remained unchanged and vacancy rates continued to rise.' This emphasizes the need for businesses to adapt to the evolving landscape—renting equipment can be a strategic response to current economic conditions, reflecting a growing trend in the construction sector where flexibility and cost-efficiency are paramount.

Furthermore, the Final Demand for Services was up 0.2% month-over-month, indicating a positive shift in the market that could influence rental decisions. A relevant case study is EQT Exter's acquisition of an 817,750-square-foot distribution center in the Inland Empire for $197 million, which underscores the importance of strategic decision-making in the context of asset utilization. This example illustrates how businesses are increasingly recognizing the benefits of flexibility in their operational strategies.

Types of Conveyor Systems Available for Rent

In the realm of construction and dirt transport, several types of transport systems are available for rent, each tailored to distinct applications.

- Belt systems are particularly popular for their ability to transport bulk materials over extended distances, making them an excellent choice for projects requiring continuous operation. According to market analysis, belt systems are anticipated to maintain a considerable market share of around 40% in 2024 due to their versatility and efficiency.

- Roller systems, designed to facilitate the movement of packages and pallets, are ideal for warehouses and distribution centers where efficiency is paramount, with experts noting that they can increase operational throughput by up to 30% in such environments.

- For managing granular materials, screw systems are the preferred solution, frequently employed in the agricultural and chemical industries because of their efficient material handling abilities. A practical illustration involves a construction task where screw devices were used to move sand and gravel, greatly decreasing labor expenses and duration.

- Furthermore, modular transport solutions provide the benefit of simple assembly and personalization, addressing various needs.

By comprehending these different choices and their market dynamics, construction managers can choose the most appropriate transport solution to improve operational efficiency and tackle specific logistical challenges on site.

Factors to Consider When Renting Conveyor Systems

When leasing conveyor systems, it is essential to assess several key elements to enhance the usage experience and guarantee success. Begin by thoroughly assessing your endeavor's specific needs, which include the types of materials to be moved and the required capacity for efficient operation. The significance of leasing duration cannot be overstated; while short-term leases are ideal for one-time tasks, longer leasing periods can often provide more cost-effective solutions for extended operations. Current trends suggest that numerous construction supervisors are favoring adaptable leasing periods to correspond with timelines.

It’s also crucial to examine the standing of the leasing provider. A provider that offers robust support services—such as reliable maintenance and timely delivery—can significantly influence the success of your project. As Steve Hogarty emphasizes, ensuring all aspects of the lease agreement are clear, particularly concerning liability, insurance, and equipment condition, is vital to preventing disputes down the line.

Furthermore, familiarizing yourself with different lease types, including triple net leases and gross leases, can help clarify expense responsibilities, which is crucial for budgeting and financial planning. For instance, the case study on the comparison of lease types highlights how understanding these differences can aid in making informed decisions based on individual circumstances. Additionally, utilizing RentalMan's asset management, which allows up to five methods for asset depreciation, can provide valuable insights into financial planning for properties.

By addressing these considerations, alongside the support from the Wynne Team for ERP implementation to enhance operational efficiency, construction managers can mitigate the risks often associated with equipment rentals.

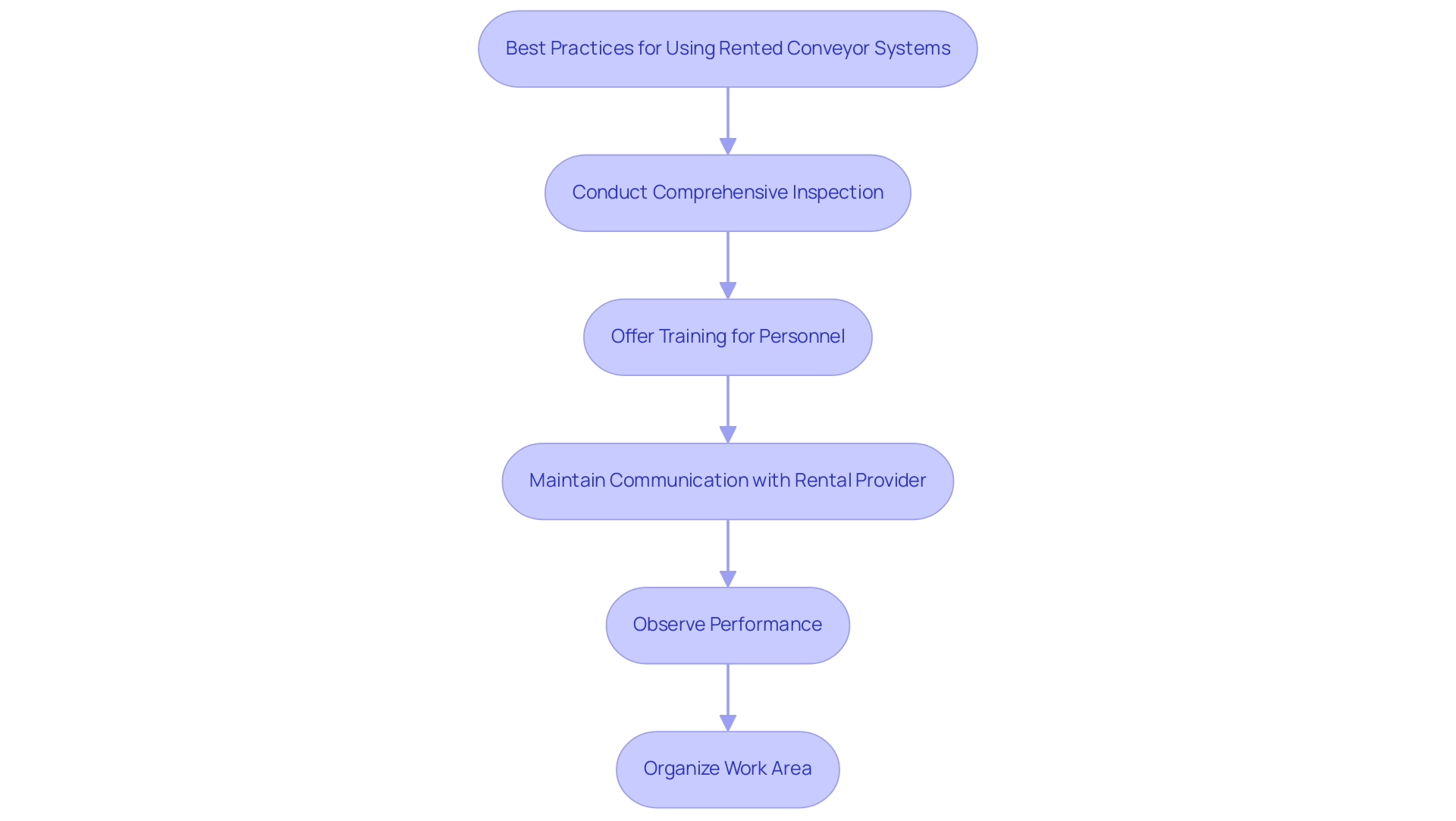

Best Practices for Using Rented Conveyor Systems

To enhance the effectiveness and security of leased transport mechanisms, construction project managers should adopt several crucial best practices. Firstly, it is critical to conduct a comprehensive inspection of the equipment upon delivery. This ensures that it adheres to safety and operational standards, which is vital given that improper equipment can significantly increase equipment failure rates—studies show that up to 30% of equipment failures are due to inadequate maintenance and initial checks.

Secondly, offering comprehensive training for personnel on the appropriate functioning of the transport system is essential. This training should cover safety protocols, emergency procedures, and the specific characteristics of the type of transport system being used—whether it's a flat belt, modular belt, timing belt, or V-belt. For instance, training programs could include hands-on sessions that allow staff to familiarize themselves with the equipment's operation and safety features.

Maintaining clear and ongoing communication with the rental provider is also crucial, as this can facilitate prompt assistance in case issues arise during use, ultimately minimizing downtime. Consistent observation of the transport mechanism's performance aids in recognizing potential issues early, facilitating prompt interventions. Furthermore, ensuring that the work area remains organized and free of obstacles is key to facilitating smooth operation and enhancing overall efficiency. By adhering to these best practices, construction companies can significantly optimize the use of rented conveyor systems, thereby improving project outcomes and ensuring a safer work environment.

Conclusion

In the modern construction and manufacturing sectors, conveyor systems are not just optional tools; they are essential for enhancing operational efficiency and safety. By streamlining material transport, these systems reduce the burden of manual labor, thereby minimizing workplace injuries and improving overall productivity. Understanding the various types of conveyor systems—such as belt, roller, and screw conveyors—enables businesses to choose the most suitable option tailored to their specific needs, ultimately leading to a more efficient workflow.

Renting conveyor systems presents a strategic solution for companies looking to manage costs while maintaining flexibility. The financial advantages of renting, including the absence of high upfront costs and the inclusion of maintenance support, make it an attractive option for short-term projects. By carefully evaluating project requirements and rental agreements, organizations can make informed decisions that align with their operational demands without incurring unnecessary expenses.

Moreover, the importance of best practices in using rented conveyor systems cannot be overstated. Conducting thorough inspections, providing staff training, and maintaining clear communication with rental providers are crucial steps that ensure equipment is used effectively and safely. By adhering to these guidelines, construction managers can significantly enhance project outcomes, ensuring that conveyor systems contribute positively to the efficiency and safety of their operations.

As industries continue to evolve, the adoption of conveyor systems will likely grow, driven by the need for increased efficiency and safety. Embracing these innovations not only meets immediate operational needs but also prepares businesses for future challenges in a competitive landscape.

Frequently Asked Questions

What are conveyor mechanisms and their primary functions?

Conveyor mechanisms are essential mechanical devices that assist in moving materials across various areas within a facility or construction site. They play a crucial role in industries such as manufacturing, warehousing, and construction by enhancing efficiency in transporting large volumes of goods.

What types of transport mechanisms are available?

The main types of transport mechanisms include belt systems, roller systems, and screw systems. Each type offers distinct benefits tailored to different operational needs.

How do transport mechanisms improve workplace safety?

By minimizing reliance on manual labor, transport mechanisms significantly reduce the risk of workplace injuries associated with heavy lifting. Additionally, advancements in transport technology have incorporated safety features that comply with OSHA regulations, including proper stickers and warning labels to guide safe operation.

What is the current trend in the adoption of transport mechanisms?

In 2024, the adoption of transport mechanisms is reported to have increased by 15%, driven by their efficiency and safety advantages. Case studies indicate that their use can decrease material handling time by up to 30%, thus enhancing workflow.

What are the advantages of leasing transport systems?

Leasing transport systems offers significant cost savings by eliminating upfront purchase costs and typically includes maintenance and support. This approach allows companies to avoid the responsibility of managing repairs and upkeep.

What factors should companies consider when assessing a lease?

Companies should evaluate the length of the task, the types of transport systems available, and the overall cost comparison between leasing and buying over time. Reliability of the leasing provider and the condition of the equipment are also crucial considerations.

How do different types of transport systems serve specific needs?

Belt systems are ideal for transporting bulk materials over long distances; roller systems enhance efficiency in warehouses; screw systems are suited for managing granular materials; and modular transport solutions offer simple assembly and customization.

What best practices should be followed when leasing conveyor systems?

Best practices include conducting a thorough inspection of the equipment upon delivery, providing comprehensive training for personnel, maintaining clear communication with the rental provider, observing the performance of the transport mechanism, and keeping the work area organized.

Why is training important for personnel using transport systems?

Training is essential to ensure personnel understand the operation of the transport system, safety protocols, and emergency procedures, which helps prevent accidents and improves overall efficiency during use.

How can construction managers ensure effective use of rented conveyor systems?

By following best practices such as inspecting equipment, training staff, communicating with rental providers, observing performance, and organizing the work area, construction managers can optimize the use of rented conveyor systems and enhance project outcomes.