Introduction

In the world of heavy lifting, the 20,000 lb forklift emerges as an indispensable tool, seamlessly integrating into various industrial sectors such as construction, warehousing, and logistics. These robust machines not only facilitate the movement of hefty materials but also enhance productivity and streamline operations in environments where time and efficiency are paramount.

As infrastructure projects proliferate, particularly in regions like the Middle East and Africa, the demand for reliable forklifts continues to surge. This article delves into the key features, applications, safety guidelines, and maintenance practices associated with 20,000 lb forklifts, providing essential insights for businesses looking to optimize their material handling processes and ensure operational excellence.

Understanding these elements is crucial for making informed decisions that drive success in today's competitive landscape.

Introduction to 20,000 lb Forklifts: A Key Player in Heavy Lifting

The 20,000 lb forklift stands out as a powerful resource in the realm of heavy lifting and goods handling across diverse industrial environments. These sturdy machines are essential in fields such as construction, warehousing, and logistics, where the daily movement of heavy goods is not only a necessity but a critical operation. Their capacity to lift substantial weights with efficiency significantly contributes to streamlining workflows and enhancing overall productivity.

In 2024, as the market for heavy-duty lifting machines continues to grow, particularly in regions like the Middle East and Africa—driven by extensive infrastructure projects—the demand for reliable 20,000 lb forklift models remains strong. Notably, Manitou held a 3.11% market share in 2021, highlighting the competitive landscape in this sector. Grasping the functions and operational roles of these lifting machines is essential for companies seeking to enhance their handling processes.

As pointed out by industry specialists, like Conger, a dealer, 'You have several options for where to purchase a lifting device.' But we do feel that factory-authorized dealerships can be the easiest and most reassuring way to go about your purchase.' Additionally, the demand for the 20,000 lb forklift and other machines in the Middle East and Africa is illustrated by the region's ongoing infrastructure development projects, which underscore their essential role in material handling tasks, making them indispensable in modern operations.

Key Features and Specifications of 20,000 lb Forklifts

The 20,000 lb forklift stands out for its powerful engines and sturdy raising mechanisms, designed specifically to manage heavy loads with ease. These machines, like the 20,000 lb forklift, typically boast impressive features such as a high lifting capacity, durable construction, and the versatility to operate effectively in diverse environments, ranging from warehouses to rugged outdoor construction sites. Key specifications for these lifting machines often include maximum lift heights, which can vary but are crucial for reaching elevated areas, as well as the type of fuel used—diesel or electric—depending on the operational needs.

It's important to note that lift capacities for telehandlers include:

- 10,000 lb.

- 12,000 lb.

- 14,000 lb.

- 15,000 lb.

This provides a broader context for understanding the capabilities of heavy-duty lifting machines. Additionally, various attachment options like forks, clamps, and buckets enhance their functionality, allowing for tailored solutions to specific lifting tasks. The gear-driven valve train of the C-D Series, for instance, delivers high torque at low RPM, resulting in improved performance and efficiency in equipment operation.

With an average ground clearance of 11.1 inches for models like the D80S-9 and D90S-9, these vehicles are designed to navigate uneven terrain smoothly. Understanding these critical specifications is essential for selecting the right lifting equipment, ensuring operational efficiency, and maximizing productivity on-site. For further assistance or inquiries, Lift, Inc. encourages contacting their support at (877) 886-1478.

Applications of 20,000 lb Forklifts in Various Industries

The 20 000 lb forklift serves a pivotal role in diverse industries, particularly in construction and warehousing. These powerful machines, including the 20 000 lb forklift alongside our range of boom lifts, mini excavators, and scissor lifts available for rent in Irving, TX, are integral for tasks like loading and unloading heavy materials, moving pallets, and transporting essential construction supplies throughout the DFW Metroplex. Located at 1307 W Airport Fwy, Irving, TX 75062, you can contact us at (214) 951-7800 for more information.

In the construction sector, using a 20 000 lb forklift is critical for raising steel beams and other substantial components to elevated positions, ensuring structural integrity and safety. In warehousing, using a 20 000 lb forklift enhances operational efficiency by facilitating the rapid movement of goods, thus enabling quick and effective loading and unloading of trucks. Furthermore, within logistics, the 20 000 lb forklift is indispensable for managing inventory and streamlining supply chain operations.

As narrow warehouse aisles become more prevalent, the demand for a 20 000 lb forklift is increasing, highlighting its versatility and crucial role in sectors that require heavy lifting and precise handling. Recent trends indicate a significant reliance on such equipment, as evidenced by the average compensation costs in private industry, which stand at $44.40 per hour worked, highlighting the investment in efficient material handling solutions. As Stacy, a verified buyer, noted, 'I would have given it a better rating, but the video file was corrupted and had to be replaced.

Customer service was very helpful and resolved my situation promptly, illustrating the importance of customer support in the equipment industry.

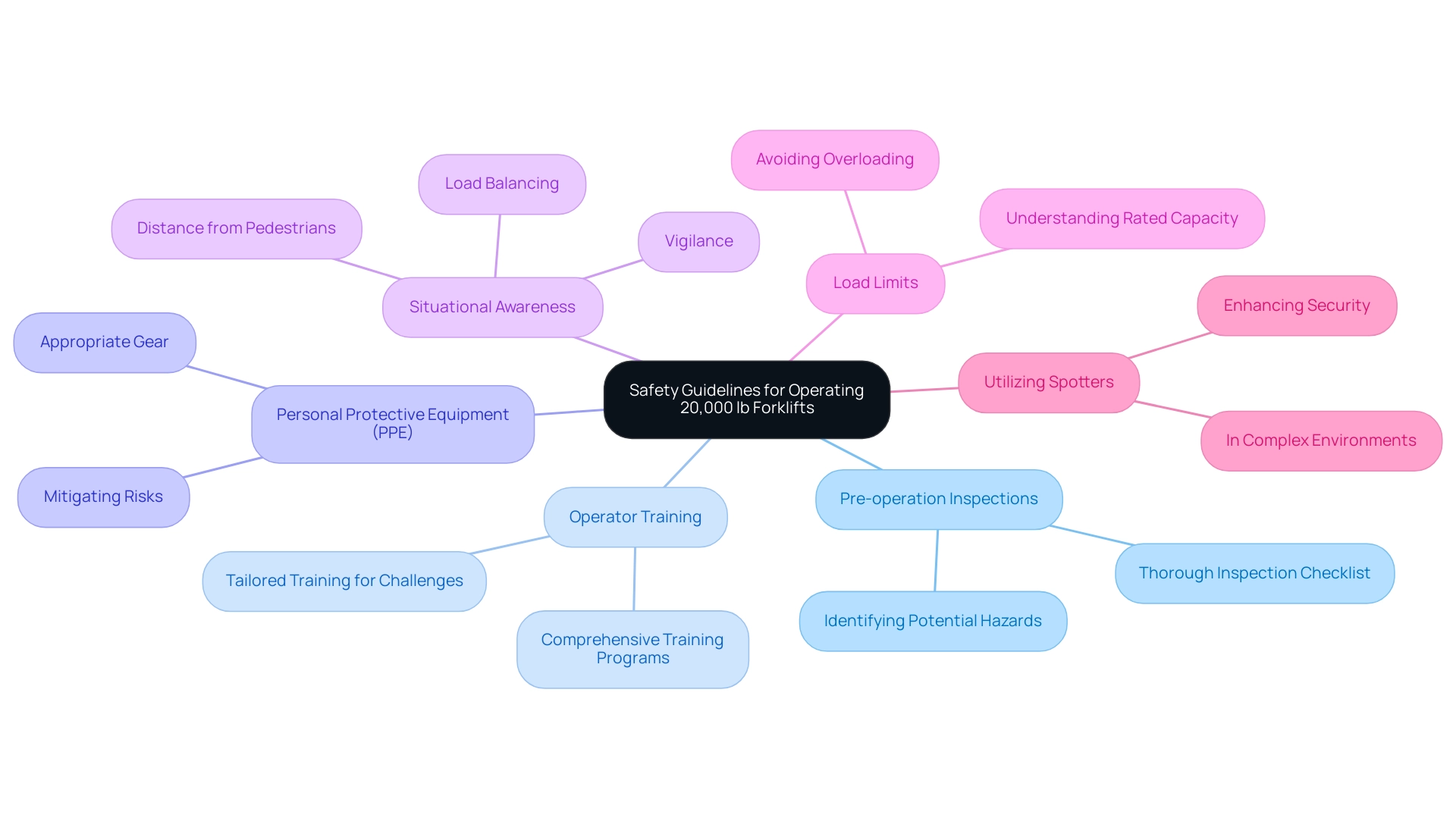

Safety Guidelines for Operating 20,000 lb Forklifts

Operating a 20,000 lb forklift demands rigorous adherence to safety guidelines to safeguard both operators and the surrounding workplace. Essential practices encompass:

- Conducting thorough pre-operation inspections

- Ensuring that operators receive comprehensive training tailored to the specific challenges of using a 20,000 lb forklift

The importance of personal protective equipment (PPE) cannot be overstated; it is vital for operators to wear appropriate gear to mitigate risks.

Additionally, situational awareness is crucial—operators should:

- Remain vigilant of their surroundings

- Maintain a safe distance from pedestrians

- Ensure that loads are balanced before lifting to prevent instability

Understanding load limits is fundamental; operators must not exceed the rated capacity of the 20,000 lb forklift to avert potential hazards. Utilizing spotters in complex or congested environments can further enhance security by providing an additional layer of oversight.

Recent statistics reveal a concerning trend in forklift-related incidents, with 40,513 occurrences reported from 2021 to 2022, as highlighted in the National Forklift Safety Day Statistics report. This data highlights the urgent need for improved protection measures, including enhanced training programs that address these incidents and promote best practices for operator well-being. Professionals in risk management advocate for such training, with one expert stating, "Comprehensive training is not just about compliance; it’s about creating a culture of protection that safeguards everyone on the job site."

Moreover, the recent purchase of Maximal Forklift by Hyster-Yale for $400 million highlights the competitive environment of lift truck manufacturing, where security must stay a priority. Implementing these guidelines is not merely a regulatory obligation but a critical step in fostering a secure work environment where accidents can be significantly reduced.

Maintenance Tips for Ensuring Longevity of 20,000 lb Forklifts

Regular maintenance is crucial for ensuring the longevity and optimal functioning of a 20,000 lb forklift. Operators should adhere to a structured routine that includes essential tasks such as:

- Checking fluid levels

- Inspecting tires for wear

- Verifying that all safety features are operational

Furthermore, cleaning the vehicle after each use helps prevent the accumulation of debris that could hinder performance.

Recent advancements in maintenance technology, particularly data visualization software, have shown significant benefits. For instance, in 2017, one company reported a remarkable reduction of 320 production hours while simultaneously increasing output by 15%, showcasing the effectiveness of leveraging technology in maintenance practices. Implementing a preventive maintenance program that involves regular servicing by qualified technicians is vital for identifying potential issues before they escalate into costly repairs.

Given that 37.2% of maintenance managers have noted that budget constraints have intensified in recent years, prioritizing maintenance becomes even more essential. The automotive industry exemplifies this urgency, facing unplanned downtime costs averaging $22,000 per minute, which underscores the real-world consequences of inadequate maintenance. By emphasizing these best practices and utilizing new technologies, businesses can achieve a more efficient and cost-effective operation while extending the lifespan of their operations with a 20,000 lb forklift and mitigating downtime risks.

Conclusion

The significance of 20,000 lb forklifts in heavy lifting cannot be overstated. These powerful machines are integral to various industries, effectively enhancing productivity and operational efficiency. With their robust features and versatility, they cater to the demanding needs of construction, warehousing, and logistics, ensuring the seamless movement of heavy materials. As infrastructure projects expand, particularly in regions like the Middle East and Africa, the reliance on these forklifts grows, underscoring their essential role in modern operations.

Safety remains a paramount concern when operating these forklifts. Adhering to established safety guidelines, including rigorous training and proper use of personal protective equipment, is crucial for safeguarding operators and coworkers alike. With a notable increase in forklift-related incidents, the emphasis on creating a culture of safety through comprehensive training and situational awareness is more important than ever.

Maintenance practices are equally vital for optimizing the performance and longevity of 20,000 lb forklifts. Implementing a structured maintenance routine, leveraging technology for predictive insights, and adhering to preventive measures can significantly reduce downtime and repair costs. In a competitive landscape where operational efficiency directly impacts the bottom line, prioritizing the maintenance of these heavy-duty machines is a strategic imperative.

In summary, understanding the capabilities, safety protocols, and maintenance requirements of 20,000 lb forklifts is critical for businesses aiming to thrive in today's fast-paced industrial environment. By investing in the right equipment and practices, organizations can not only enhance productivity but also ensure a safer and more efficient workplace.

Frequently Asked Questions

What is the significance of the 20,000 lb forklift in industrial environments?

The 20,000 lb forklift is a powerful resource essential for heavy lifting and goods handling in various industrial settings, such as construction, warehousing, and logistics. Its ability to efficiently lift substantial weights enhances workflow and productivity.

What factors are driving the demand for 20,000 lb forklifts in 2024?

The demand for 20,000 lb forklifts is strong due to the growth of the heavy-duty lifting machine market, particularly in the Middle East and Africa, driven by extensive infrastructure projects.

What is Manitou's market share in the forklift industry?

In 2021, Manitou held a 3.11% market share in the forklift industry, indicating the competitive landscape of this sector.

Where is the best place to purchase a 20,000 lb forklift?

According to industry specialists, factory-authorized dealerships are often considered the easiest and most reassuring option for purchasing a lifting device.

What features make the 20,000 lb forklift suitable for diverse environments?

The 20,000 lb forklift is designed with powerful engines and sturdy raising mechanisms, allowing it to manage heavy loads effectively in various environments, from warehouses to rugged outdoor construction sites.

What are some key specifications of the 20,000 lb forklift?

Key specifications include maximum lift heights, fuel type (diesel or electric), and average ground clearance, which is typically around 11.1 inches for models like the D80S-9 and D90S-9.

What are the lift capacities available for telehandlers?

Telehandlers have lift capacities that typically include 10,000 lb, 12,000 lb, 14,000 lb, and 15,000 lb, providing a broader context for the capabilities of heavy-duty lifting machines.

How do attachments enhance the functionality of forklifts?

Various attachment options, such as forks, clamps, and buckets, allow forklifts to perform tailored solutions for specific lifting tasks, improving their versatility.

What is the benefit of the gear-driven valve train in the C-D Series forklifts?

The gear-driven valve train in the C-D Series delivers high torque at low RPM, resulting in improved performance and efficiency during equipment operation.

How can I get further assistance regarding 20,000 lb forklifts?

For further assistance or inquiries, you can contact Lift, Inc. at (877) 886-1478.