Key Highlights:

- Compaction force plate compactors are designed to compress materials like soil and asphalt, creating a stable base for construction.

- They utilise high-frequency vibrations to eliminate air pockets and increase material density, crucial for structural integrity.

- The effectiveness of a compactor is determined by its centrifugal force, impacting the pressure applied to the ground.

- Proper soil compaction prevents structural issues such as cracks and uneven surfaces, which can lead to costly repairs.

- Compactors have evolved from manual techniques to advanced mechanical devices, with modern models featuring adjustable vibration settings.

- Key specifications include weight (200 to 500 pounds), engine power (4 to 10 horsepower), and centrifugal force, which influence performance.

- Plate compactors are versatile, used for concrete subgrades, asphalt repairs, and landscaping, enhancing the longevity of installations.

- Investing in quality compactors is essential for successful construction projects, ensuring durability and stability.

Introduction

A compaction force plate compactor stands as an essential tool in the construction industry, expertly designed to forge a solid foundation by compressing materials like soil and asphalt. By enhancing the density of these materials, it plays a pivotal role in preventing structural issues and ensuring the longevity of construction projects. But with a plethora of options available, how do you pinpoint the ideal compactor for your specific needs? This article explores the significance, functionality, and evolution of compaction force plate compactors, underscoring their indispensable role in achieving successful construction outcomes.

In addition to their foundational importance, compaction force plate compactors offer numerous benefits that enhance project efficiency and reliability. These machines not only improve material density but also reduce the risk of future repairs, saving time and costs in the long run. Furthermore, their versatility allows them to be used across various applications, from road construction to landscaping. As you consider your options, remember that investing in quality equipment is crucial for the success of your projects.

Ultimately, the right compactor can make all the difference in your construction endeavors. By understanding the features and benefits of these machines, you can make an informed decision that aligns with your project goals. Don't hesitate to reach out for expert advice or to explore our range of compaction force plate compactors tailored to meet your needs.

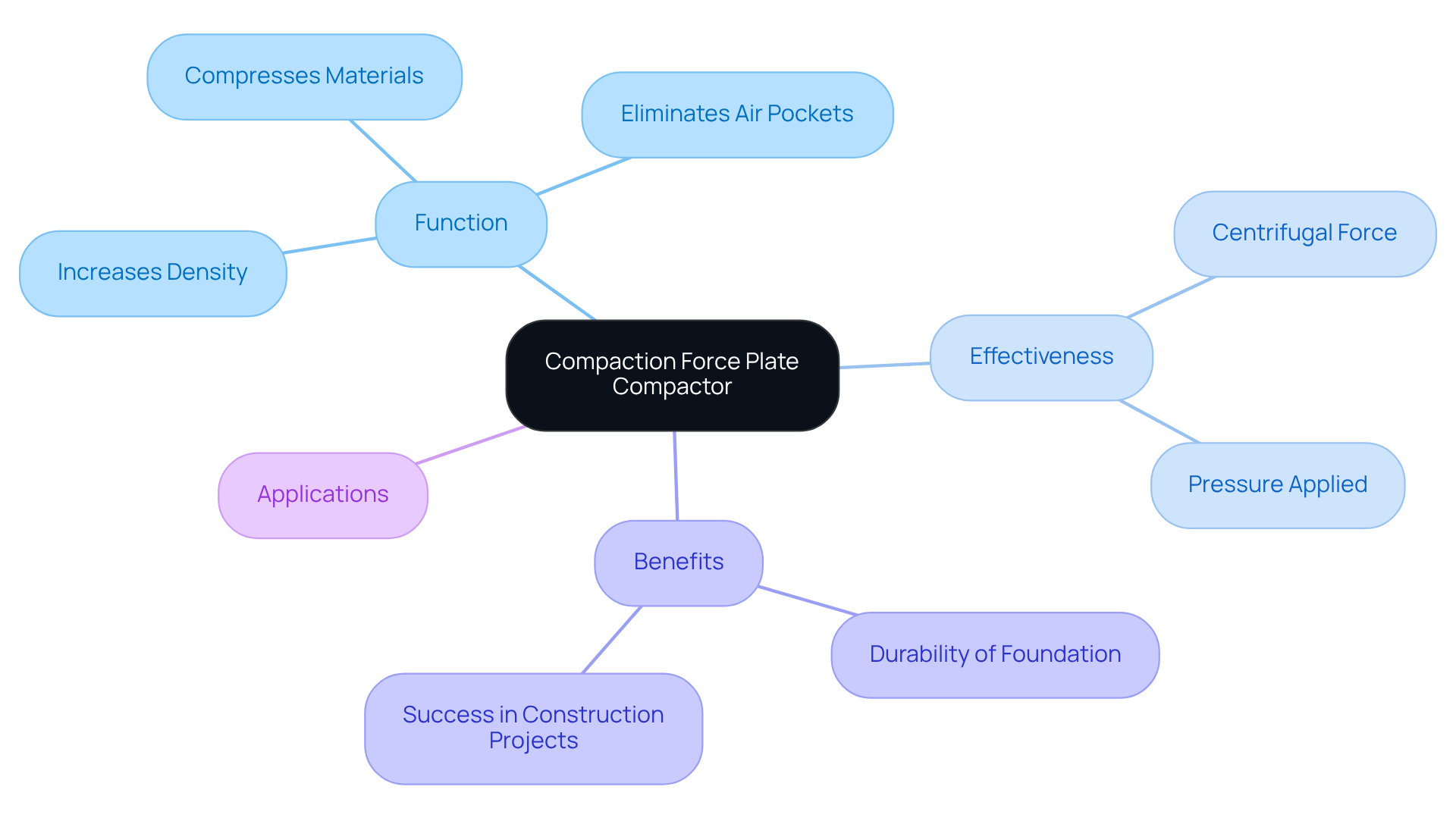

Define Compaction Force Plate Compactor

A compaction force plate compactor serves as a crucial mechanical instrument, expertly designed to compress soil, gravel, asphalt, and other materials. This process establishes a stable and solid base for building projects, ensuring that surfaces are level and capable of supporting structures, paving, or landscaping. By exerting high-frequency vibrations through a heavy steel surface, the device effectively eliminates air pockets and increases the density of the material beneath it.

The effectiveness of a compactor is often assessed based on its centrifugal force, which determines the pressure it can apply to the ground. This makes it an essential tool in various building applications, where reliability and quality are paramount. In addition, utilizing a compaction force device not only enhances the durability of the foundation but also contributes to the overall success of construction projects.

For those looking to ensure their building projects are built on a solid foundation, investing in a compaction force plate compactor is a wise choice. With proven results and satisfied customers, this equipment is designed to meet the demands of any construction site. Don't hesitate - equip yourself with the right tools for success.

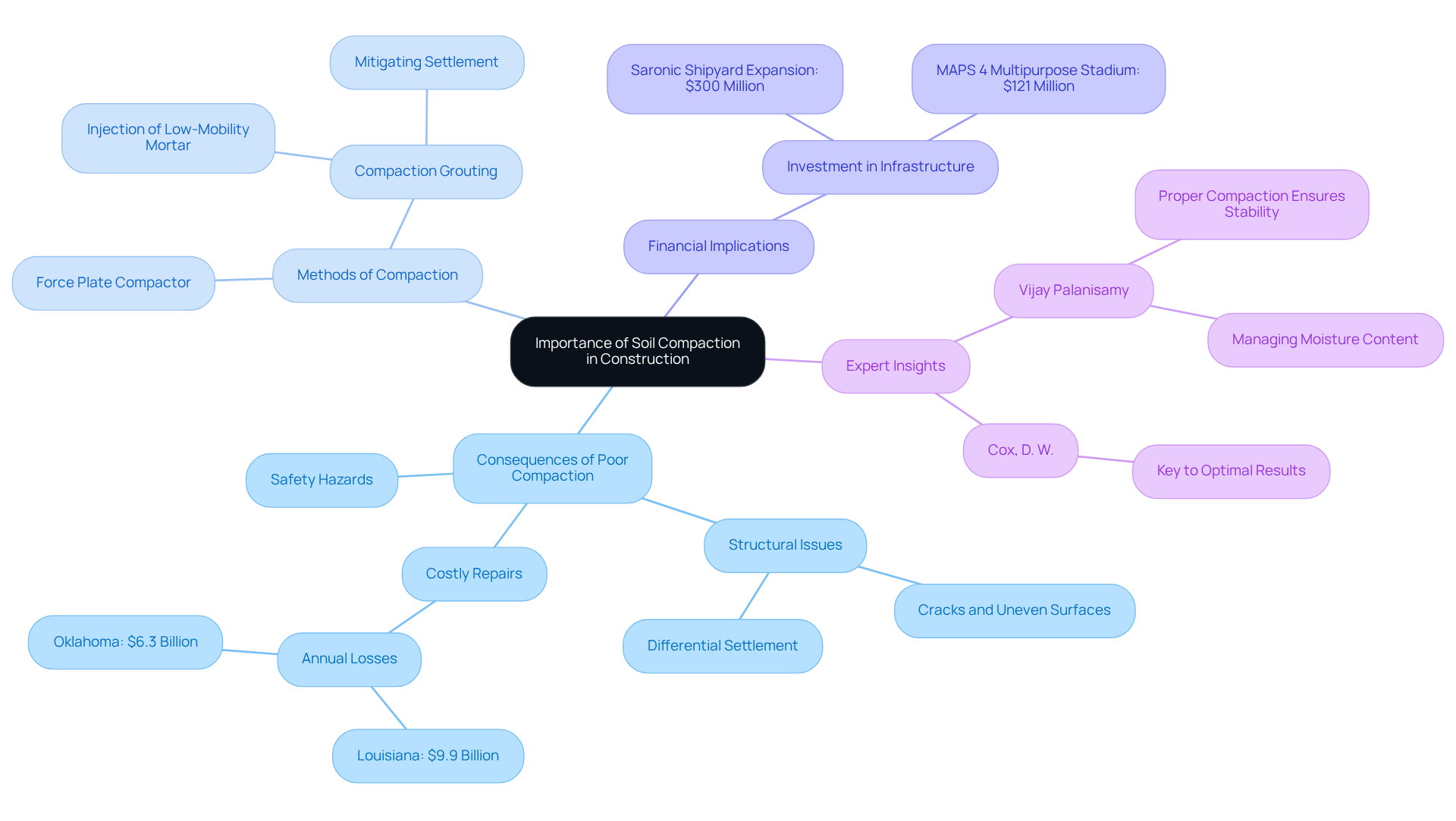

Context and Importance in Construction

In the construction field, the force plate compactor is indispensable for preparing the ground for various projects, including roads, foundations, and landscaping. Adequate compression is not just a recommendation; it’s essential to prevent future settling that can lead to serious structural issues like cracks and uneven surfaces. Research has shown that insufficient soil density can cause movements of 20 mm to 30 mm across joints, leading to costly repairs and safety hazards. For instance, a sports club structure experienced distress linked to uneven settlement due to poor soil consolidation practices, underscoring the critical need for effective soil management.

By utilizing a compaction force plate compactor to ensure a well-compacted base, contractors significantly enhance the load-bearing capacity of the ground, which in turn boosts the durability and stability of the structures built upon it. Compaction grouting, a method that involves injecting rigid, low-mobility mortar under high pressure, has proven effective in reducing settlement in weak deposits, thereby improving overall stability. This technique is particularly beneficial in infrastructure projects, where inadequate density can lead to staggering annual losses of $9.9 billion for Louisiana drivers due to poor road conditions and structural failures.

Moreover, effective densification minimizes the risk of water infiltration and erosion, making it a fundamental practice in construction site management. Civil engineers emphasize that proper densification ensures uniformity and stability, preventing structural failures such as rutting, cracking, and potholes. As Vijay Palanisamy, Vice President of Product Management, aptly states, "Proper consolidation ensures uniformity and stability, preventing structural failures such as rutting, cracking, and potholes." As the construction sector evolves, the importance of soil density remains a pivotal factor in achieving long-term stability and safety in construction projects.

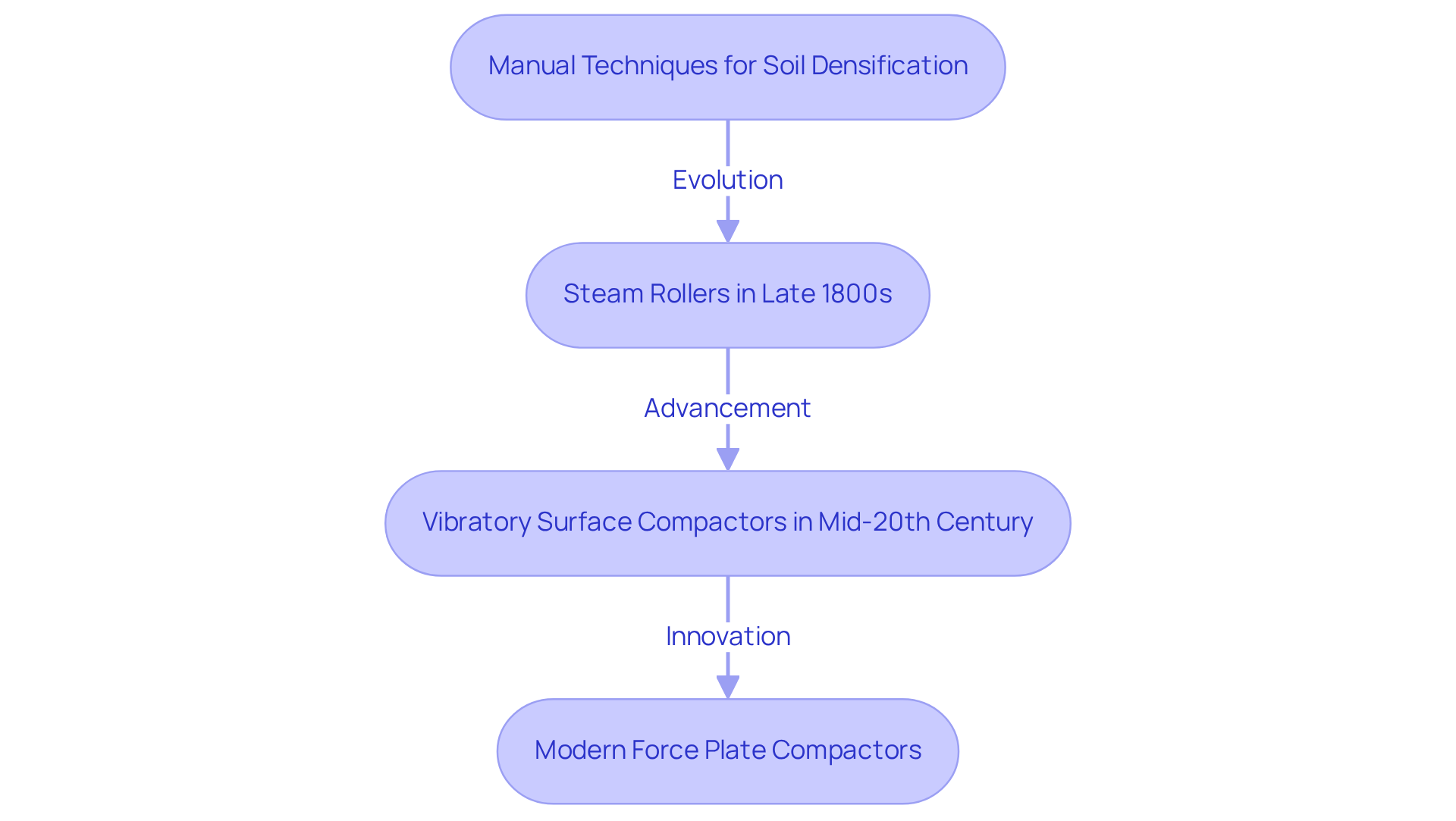

Historical Development of Compactors

The evolution of compactors marks a significant milestone in construction technology, beginning in the early 20th century with manual techniques for soil densification. The industry underwent a remarkable transformation with the advent of mechanical compactors, particularly steam rollers that emerged in the late 1800s. As technology progressed, vibratory surface compactors gained traction in the mid-20th century, employing high-frequency vibrations to enhance compaction efficiency. This innovation drastically reduced the time and effort needed for ground preparation, establishing these machines as indispensable on construction sites.

According to industry forecasts, the global vibratory compactor market is projected to reach USD 1,293.2 million by 2025, underscoring the growing reliance on these machines in construction. Today's modern compaction force plate compactors feature advanced technologies, including adjustable vibration settings and enhanced engine power, further solidifying their status as essential tools in the building sector. As Rama Prasad aptly notes, "Soil compaction is one of the most critical elements in the development of roads, airfields, embankments, and foundations."

The continuous advancements in compactor technology are driving improvements in construction efficiency, highlighting the vital role these machines play in contemporary projects. With their reliability and quality, compactors are not just tools; they are key contributors to successful construction outcomes. Engage with us today to explore our range of compactors and elevate your construction projects to new heights.

Key Features and Specifications

Maximize Your Construction Efficiency with Compaction Force Plate Compactors

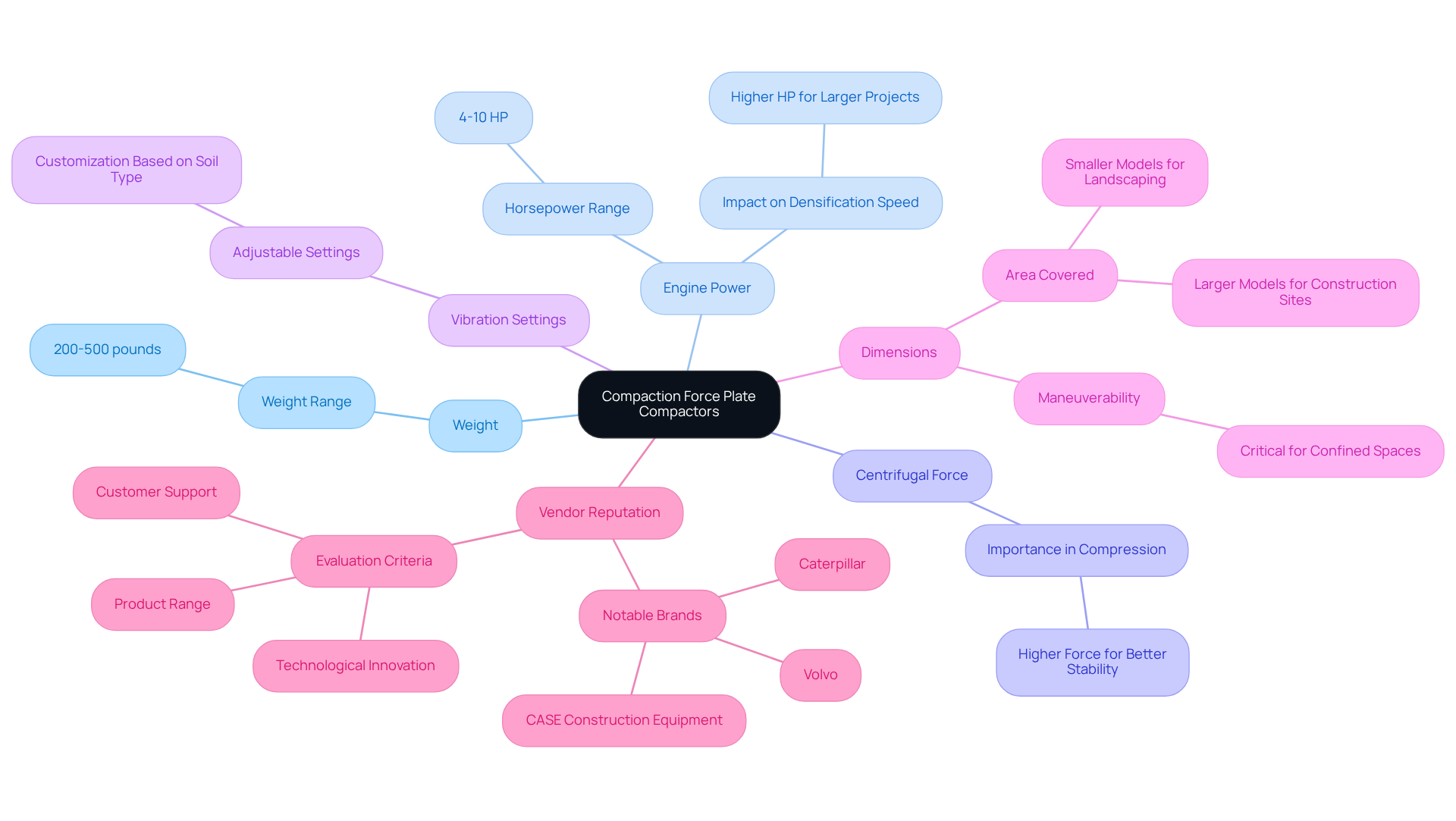

Compaction force plate compactors are indispensable in the construction industry, boasting several key features that significantly enhance their performance. Typically weighing between 200 to 500 pounds, these machines leverage their weight to deliver increased compression force, crucial for achieving optimal soil density. With engine power ranging from 4 to 10 horsepower, the efficiency and operational speed of these compactors vary accordingly. For instance, a model with higher horsepower can achieve quicker densification, making it ideal for larger projects.

Centrifugal force, measured in pounds, is another vital specification that influences the effectiveness of a compactor in compressing materials. A higher centrifugal force results in superior material compression, essential for establishing a stable foundation. Modern compactors often come equipped with adjustable vibration settings, allowing users to customize the compression process based on soil type and specific task requirements.

When considering a compaction force plate compactor, the dimension size is a critical factor that influences the area covered during densification, as well as maneuverability, which is essential for operating in confined spaces. For example, a compact model with a smaller surface area may be perfect for landscaping tasks, while larger surfaces are better suited for extensive construction sites.

It's also crucial to evaluate the vendor's reputation and product variety when selecting a force plate compactor. Renowned brands like Caterpillar and Volvo are recognized for their durable and innovative compression solutions. By understanding these features and the significance of choosing the right equipment provider, project managers can confidently select the appropriate compaction equipment for their specific needs, ensuring efficiency and effectiveness in soil compaction.

Choose wisely and elevate your project outcomes today!

Practical Applications in Construction

Unlock the Power of Plate Compactors in Construction

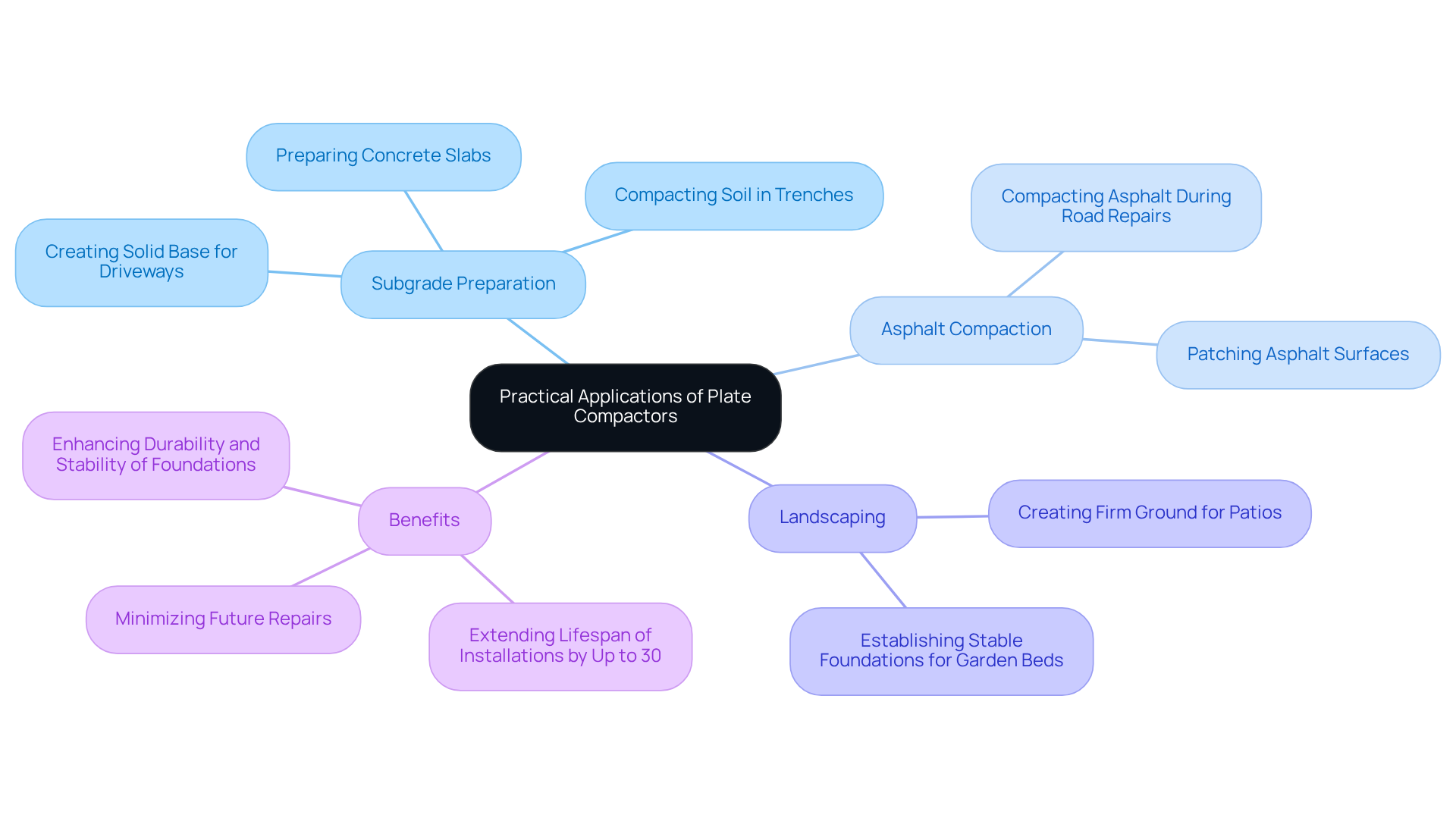

Plate compactors are indispensable in various construction applications, particularly when preparing subgrades for concrete slabs, paving, and landscaping. The compaction force plate compactor is crucial for compacting soil in trenches, ensuring stability for underground utilities, and creating a solid base for driveways and walkways. Furthermore, the compaction force plate compactor excels at compacting asphalt during road repairs and patching, resulting in a smooth and durable surface.

Their versatility extends to landscaping tasks, where a compaction force plate compactor is used to establish firm ground for patios and garden beds, significantly enhancing the longevity of these installations. Proper compaction with a compaction force plate compactor is essential; studies show that well-compacted soil can extend the lifespan of building endeavors by up to 30%, minimizing the chances of future repairs. Successful initiatives employing compactors in landscaping include the creation of community parks and residential gardens, where a stable foundation is vital for both aesthetic and functional purposes.

The practical applications of the compaction force plate compactor underscore its significance in achieving high-quality construction outcomes. These tools, particularly the compaction force plate compactor, are not just equipment; they are essential assets for any construction project manager aiming for excellence. Don't compromise on quality - invest in plate compactors to ensure your projects stand the test of time.

Conclusion

A compaction force plate compactor is not just a tool; it’s a cornerstone of the construction industry. This essential equipment ensures that building projects rest on solid, stable ground. By effectively compressing soil and other materials, it enhances the durability of structures and significantly reduces the risk of future issues like settling and uneven surfaces. For anyone involved in construction, understanding the importance of this machinery is crucial, as it directly influences the quality and longevity of the work.

The significance of proper soil compaction cannot be overstated. Compaction force plate compactors prevent structural failures and improve load-bearing capacities, showcasing their undeniable benefits. The evolution of compactors from manual methods to advanced technologies highlights their indispensable role in modern construction practices. Furthermore, the specifications and features of these compactors emphasize the necessity of careful selection to maximize efficiency on construction sites.

Investing in a compaction force plate compactor is not merely a choice; it’s a necessity for achieving high-quality construction outcomes. As the industry evolves, embracing the latest advancements in compaction technology ensures that projects are completed with reliability and safety. For those in the construction field, prioritizing effective soil management through these compactors is a step toward excellence, leading to successful and enduring projects. Don’t wait-equip your site with the best tools available and experience the difference in quality and performance.

Frequently Asked Questions

What is a compaction force plate compactor?

A compaction force plate compactor is a mechanical instrument designed to compress soil, gravel, asphalt, and other materials to create a stable and solid base for building projects. It uses high-frequency vibrations through a heavy steel surface to eliminate air pockets and increase material density.

How does the effectiveness of a compactor get assessed?

The effectiveness of a compactor is assessed based on its centrifugal force, which determines the pressure it can apply to the ground, making it an essential tool in various building applications.

Why is adequate compression important in construction?

Adequate compression is essential to prevent future settling that can lead to structural issues like cracks and uneven surfaces. Insufficient soil density can cause significant movements that result in costly repairs and safety hazards.

What are the consequences of poor soil consolidation practices?

Poor soil consolidation practices can lead to uneven settlement, resulting in structural distress and costly repairs, as evidenced by a sports club structure that experienced issues due to inadequate soil management.

How does a compaction force plate compactor enhance construction projects?

By ensuring a well-compacted base, a compaction force plate compactor enhances the load-bearing capacity of the ground, which boosts the durability and stability of the structures built upon it.

What is compaction grouting and how does it help?

Compaction grouting is a method that involves injecting rigid, low-mobility mortar under high pressure to reduce settlement in weak deposits, thereby improving overall stability, especially in infrastructure projects.

What are the risks of inadequate soil density in construction?

Inadequate soil density can lead to significant issues such as water infiltration, erosion, and structural failures like rutting, cracking, and potholes, which can result in substantial economic losses.

Why is soil density considered a pivotal factor in construction?

Soil density is crucial for achieving long-term stability and safety in construction projects, as it ensures uniformity and prevents structural failures, making it a fundamental practice in construction site management.