Introduction

In the realm of construction and demolition, the concrete chainsaw stands out as an essential tool, engineered to tackle some of the toughest materials with remarkable precision. As projects demand greater accuracy and efficiency, understanding the capabilities and maintenance of these powerful machines becomes crucial for contractors. From cutting through reinforced concrete to facilitating complex renovations, the role of concrete chainsaws is evolving alongside technological advancements that enhance their performance and sustainability.

However, with the benefits come challenges, including high maintenance costs and the necessity for rigorous safety protocols. This article delves into the multifaceted world of concrete chainsaws, exploring their uses, rental options, safety considerations, and maintenance practices to empower professionals in making informed decisions that elevate their project outcomes.

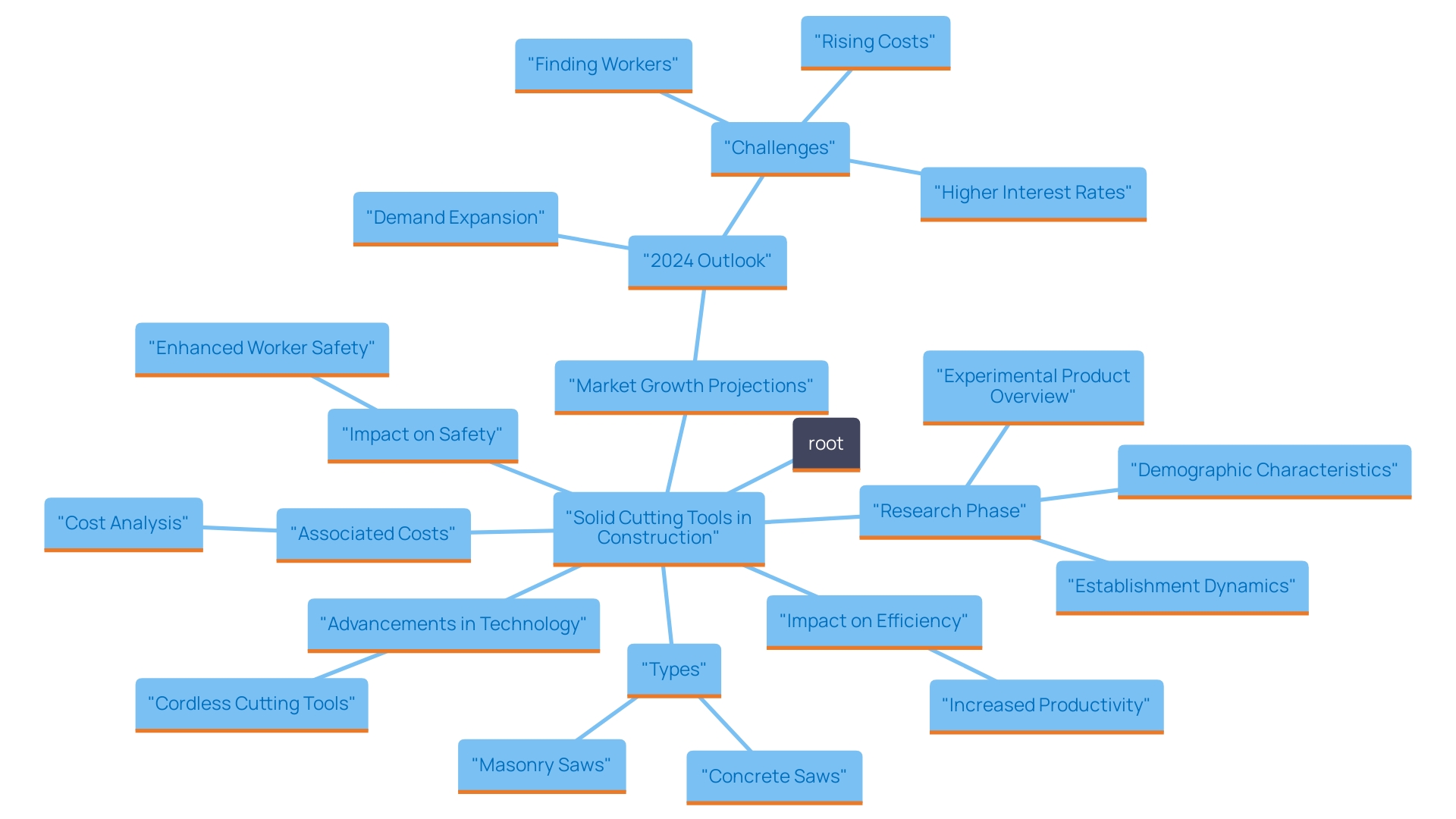

Understanding Concrete Chainsaws: Definition and Uses

A solid cutting tool is an essential instrument created to slice through stone, masonry, and other tough substances effectively. Unlike conventional saws designed for wood cutting, masonry saws employ diamond blades or carbide-tipped teeth, enabling them to cut through the hardest surfaces with accuracy. These tools are particularly vital in demolition and renovation projects where accurate cuts are essential for structural modifications or removals.

Recent advancements, such as the launch of Husqvarna's new cordless cutting tools, have significantly enhanced performance and sustainability, establishing them as a favored option in the industry. As mentioned by industry specialists, 'The advancement of cutting technology has changed our approach to intricate cutting tasks, improving both efficiency and safety on-site.' The increasing use of these advanced tools is evident in the market's path, with forecasts suggesting the will reach $7.51 billion by 2032. This growth, however, must be viewed in light of the high maintenance and procurement costs associated with masonry cutting equipment, which can range from $4.75 to $7.5 per foot, potentially restraining market expansion.

Concrete saws are essential for tasks like creating openings for windows and doors, cutting expansion joints, and performing controlled demolitions. Their capability to slice through fortified materials ensures that contractors can achieve cleaner cuts with minimal damage to surrounding substances, ultimately enhancing the overall quality of the work. For instance, in a recent demolition endeavor, utilizing a specialized saw facilitated accurate removal of a structurally essential wall, allowing for safe and effective advancement.

The use of cutting tools in construction is not only about precision but also about efficiency and minimizing operational risks. By incorporating these tools, contractors are better equipped to meet the demanding needs of modern construction endeavors, ensuring structural integrity and high-quality outputs. As emphasized by a recent case analysis, initiatives employing specialized saws have noted considerably decreased labor time and enhanced safety results, demonstrating their worth in modern construction techniques.

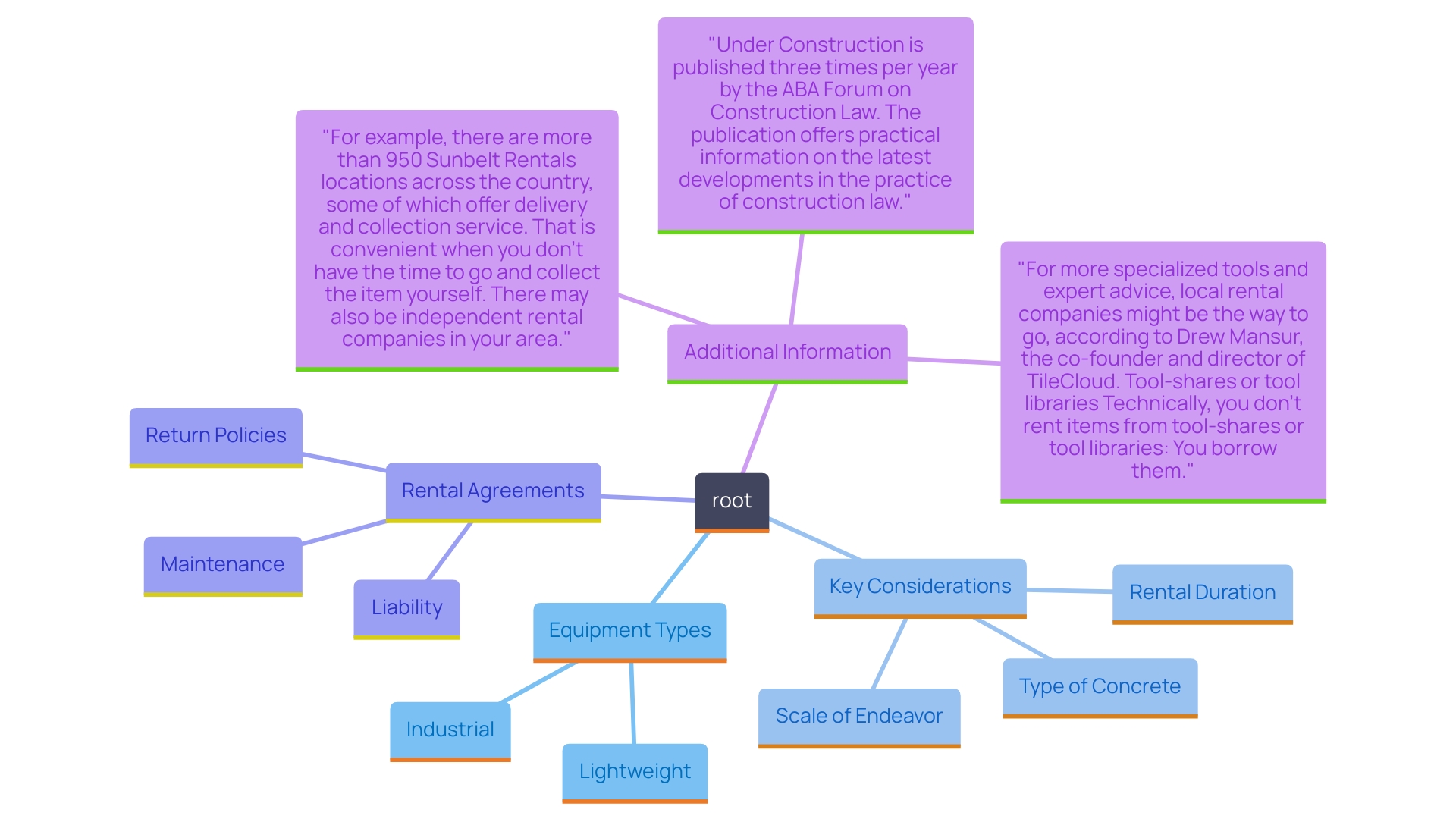

Exploring Rental Options for Concrete Chainsaws

When investigating , it is essential to assess the various choices offered. Equipment rental firms usually provide a range of models, from smaller, lightweight chainsaws suitable for home use to robust, high-powered versions intended for industrial applications. For example, models such as the XYZ 2000 series are popular for their balance of power and ease of use, while larger industrial models like the ABC 5000 are suited for extensive commercial tasks. Key considerations when renting include:

- The scale of the endeavor

- The specific type of concrete to be cut

- The intended rental duration

It's also advisable to consider services that offer comprehensive training on operating the equipment safely and effectively, particularly beneficial for those with limited experience. Furthermore, carefully reviewing rental agreements is essential to fully understand terms related to:

- Maintenance responsibilities

- Damage liability

- Return policies

By thoroughly assessing these factors, contractors can select the most appropriate equipment for their needs, ensuring their project proceeds smoothly and efficiently. Furthermore, it's important to mention that forklifts are a popular rental category, which can enhance cutting tasks by aiding the transport of heavy materials on site.

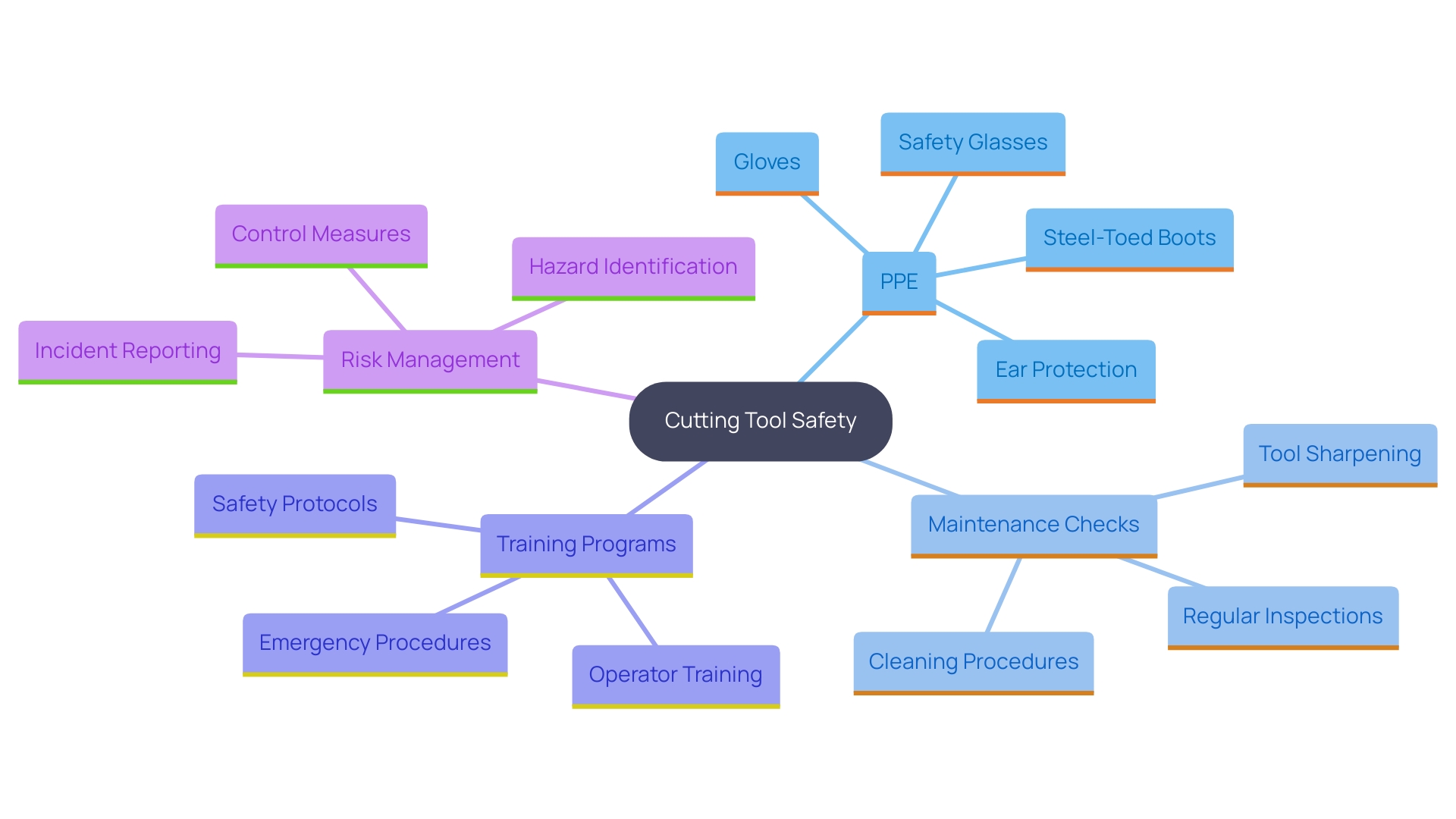

Safety Considerations When Using Concrete Chainsaws

When operating a solid cutting tool, following strict is essential to avoid accidents and injuries. Operators must wear essential personal protective equipment (PPE), such as:

- Safety goggles

- Gloves

- Hearing protection

- Dust masks

to protect against flying debris and noise hazards. Joe Tacconga, marketing services manager for ICS, stresses the importance of regularly checking the integrity of the chain side cover and the attachment of the bottom guard flap, as these components are vital for ensuring user safety.

Additionally, the work area should be free of obstacles, and bystanders must be kept at a safe distance to mitigate risks. Operators need to be well-versed in the tool's controls and ensure that the equipment is properly maintained. Training programs, which include hands-on practice and simulations, are essential to equip operators with the skills to avoid kickback and ensure smooth operation.

Implementing higher-order control measures, such as substituting hazards with safer alternatives, plays a significant role in effective risk management. PPE should be considered a supplementary measure and not a primary solution for risk control. Statistics indicate that eliminating the use of quick cut saws, when reasonably practicable, significantly reduces the likelihood of accidents.

By prioritizing safety and adhering to these guidelines, contractors can minimize risks and maintain a productive and secure work environment. Ignoring these safety measures can lead to severe consequences, underscoring the need for vigilance and commitment to safety in every operation.

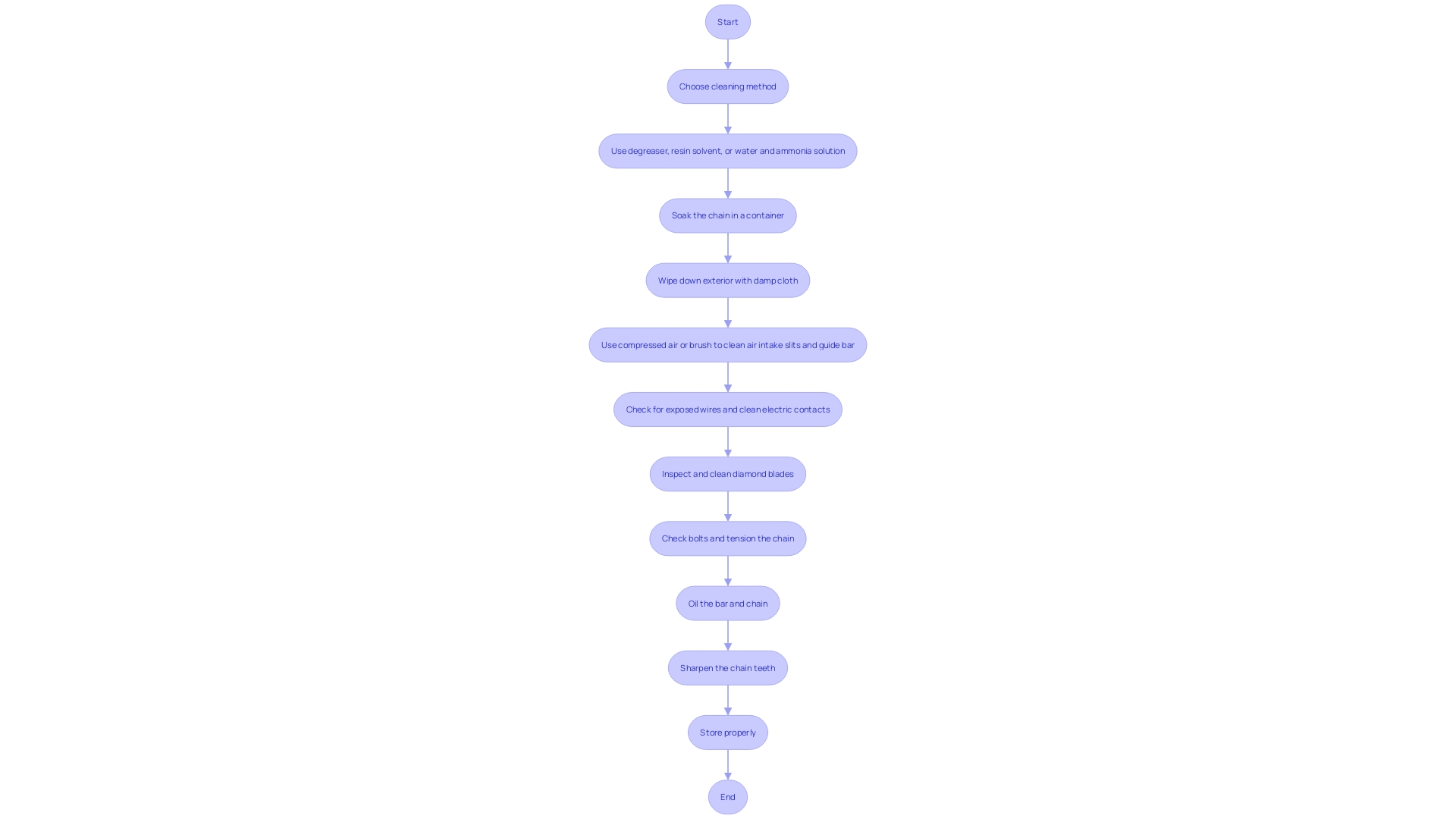

Maintenance and Care for Concrete Chainsaws

Proper upkeep of masonry chainsaws is essential for their efficient operation and durability. High upkeep costs, often ranging from USD 4.75 to USD 7.5 per foot, underscore the importance of diligent care. Operators should start by:

- Cleaning the blades after each use to remove dust and debris, which can lead to significant wear and tear.

- Regularly checking and tightening bolts and screws to maintain the tool’s structural integrity.

Inspecting the diamond blades for damage and replacing them as necessary is crucial for maintaining cutting efficiency. Following the manufacturer's guidelines for lubrication and storage is also advisable to prevent rust and degradation. Applying these optimal methods aids in reducing elevated upkeep expenses and can prolong the typical lifespan of chainsaw blades, which generally spans from 15 to 20 hours of cutting time.

Real-world examples illustrate the effectiveness of a . For example, a significant case study in the concrete cutting sector emphasizes that companies encountering high procurement and upkeep costs frequently opt for renting or buying second-hand equipment. By maintaining their tools properly, contractors can avoid these additional expenses and ensure better project outcomes, ultimately leading to improved efficiency and cost-effectiveness on their projects.

As an industry expert noted, "Regular upkeep not only extends the life of the equipment but also significantly reduces operational costs in the long run." This sentiment reflects the importance of detailed and reliable information in constructing effective business strategies, including upkeep practices.

By embracing these maintenance tips, contractors can ensure that their concrete chainsaws remain in excellent working condition, which is vital for achieving successful project outcomes.

Conclusion

The exploration of concrete chainsaws reveals their significant role in modern construction and demolition projects. With their ability to cut through tough materials like reinforced concrete with precision, these tools are essential for achieving high-quality results. The advancements in technology, such as the introduction of cordless models, not only enhance performance but also address sustainability concerns, making concrete chainsaws a valuable asset for contractors.

While the benefits are substantial, the challenges associated with high maintenance costs and rigorous safety protocols cannot be overlooked. Understanding the importance of proper maintenance practices and safety measures is crucial for maximizing the efficiency and longevity of these tools. By prioritizing regular upkeep and adhering to safety guidelines, contractors can mitigate risks and ensure a secure work environment.

Ultimately, the informed use of concrete chainsaws—whether through purchase or rental—can significantly elevate project outcomes. By embracing these powerful tools alongside effective maintenance and safety strategies, professionals can navigate the complexities of construction and demolition with confidence, leading to successful and efficient project completions.

Frequently Asked Questions

What is a solid cutting tool and what is it used for?

A solid cutting tool is designed to slice through tough materials like stone and masonry effectively. Unlike conventional saws for wood, masonry saws use diamond blades or carbide-tipped teeth for accurate cuts, making them vital in demolition and renovation projects.

How have advancements in cutting technology impacted the industry?

Recent advancements, such as Husqvarna's new cordless cutting tools, have improved performance and sustainability, making them a popular choice. These technologies enhance efficiency and safety on-site, with the solid cutting tool market projected to reach $7.51 billion by 2032.

What are concrete saws used for?

Concrete saws are essential for tasks like creating openings for windows and doors, cutting expansion joints, and performing controlled demolitions. They ensure clean cuts with minimal damage to surrounding materials, enhancing overall work quality.

What should be considered when renting solid saws?

When renting solid saws, consider the scale of the project, the type of concrete to be cut, and the rental duration. It’s also important to review rental agreements for maintenance responsibilities, damage liability, and return policies.

What safety measures should be followed when operating solid cutting tools?

Operators should wear personal protective equipment (PPE) such as safety goggles, gloves, hearing protection, and dust masks. Regular checks on the tool’s components and ensuring a clear work area are also essential for safety.

How can operators minimize risks while using cutting tools?

Operators should be well-trained in the tool's controls, maintain the equipment properly, and implement higher-order control measures to substitute hazards with safer alternatives. PPE should be a supplementary measure, not the primary solution for risk control.

What maintenance practices are important for masonry chainsaws?

Proper maintenance includes cleaning blades after use, checking and tightening bolts, inspecting diamond blades for damage, and following manufacturer guidelines for lubrication and storage. This helps prolong the lifespan of the equipment and reduce upkeep costs.

What are the typical upkeep costs associated with masonry cutting equipment?

Maintenance costs for masonry cutting equipment can range from $4.75 to $7.5 per foot, highlighting the importance of regular care to avoid high expenses and ensure effective operation.