Introduction

In the dynamic world of construction and manufacturing, the ability to efficiently prepare surfaces is paramount. Sandblasters, essential tools in this process, offer a powerful solution for removing contaminants and ensuring optimal adhesion for coatings. As industries increasingly turn to these machines to enhance productivity and achieve high-quality finishes, understanding the intricacies of sandblasting technology becomes crucial for project managers.

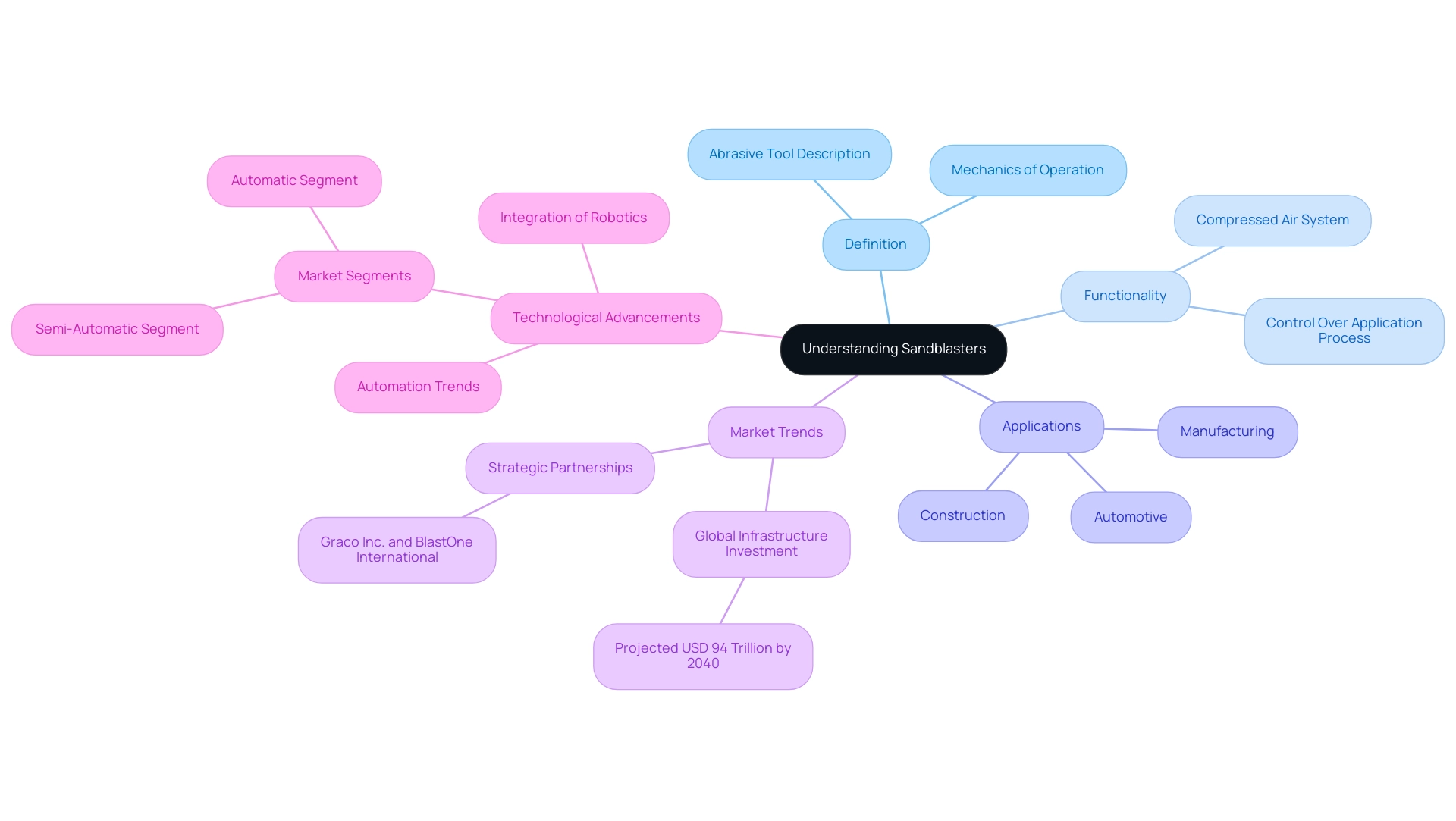

With advancements in automation and the growing market for rental equipment, professionals must navigate a landscape filled with options and considerations. This article delves into the following topics related to sandblasters:

- Definition

- Applications

- Benefits

- Cost factors

Providing a comprehensive guide to making informed decisions that drive project success.

Understanding Sandblasters: Definition and Functionality

An abrasive blaster, often referred to as an abrasive tool, is a vital piece of machinery that propels abrasive materials at high velocity to clean or prepare surfaces effectively. The operation of a sandblaster hinges on a compressed air system which forces the abrasive media through a nozzle, providing precise control over the application process. This level of precision is essential for industries such as construction, automotive, and manufacturing, where the removal of paint, rust, and other contaminants is crucial for ensuring surface integrity.

Recent statistics indicate a growing dependence on abrasive blasting methods, particularly considering projected global infrastructure investments estimated to reach USD 94 trillion by 2040. Moreover, Graco Inc., recognized for its fluid handling systems, has recently formed a strategic alliance with BlastOne International, a leading supplier of surface preparation solutions, emphasizing the significance of cooperation in enhancing surface treatment technology. Grasping the mechanics of how sandblasters function—and their diverse applications—is crucial for managers who aim to maximize efficiency and maintain optimal performance, particularly when it comes to sandblaster machine rental.

Additionally, advancements in abrasive blasting technology, including automation trends and the integration of robotics, are expected to further enhance the functionality and appeal of these systems across multiple sectors. Notably, the semi-automatic segment holds a significant market share due to its balance of efficiency and operator control, while the automatic segment is anticipated to grow the fastest, as indicated by the case study titled 'Operation Insights in Sandblasting Machines Market.' Including insights on average FOB prices and average selling prices of sandblasting equipment can also provide project managers with a more comprehensive understanding of the economic aspects of these tools.

Applications of Sandblasters: Where and How They Are Used

Sandblasters serve a multitude of essential functions across various sectors, particularly in construction and automotive applications. In construction, the sandblaster machine rental is vital for surface preparation before painting or coating, ensuring that surfaces are meticulously cleaned and primed for optimal adhesion. In the automotive industry, abrasive blasting equipment is commonly employed to strip away old paint and rust from vehicle bodies, facilitating a smooth and professional repainting process.

Statistics indicate that a significant percentage of automotive shops are now using abrasive blasters, underscoring their importance in modern repair practices. Additionally, the manufacturing sector utilizes abrasive blasting tools for cleaning molds and dies, highlighting their versatility and efficiency. As observed by industry specialists, the precision provided by sandblaster machine rental is essential for attaining high-quality finishes in various tasks.

Recent case studies have illustrated the successful application of abrasive blasting in construction projects, showcasing not only its effectiveness but also its role in enhancing productivity. The abrasive blasting market in the US has been expanding at a CAGR of 1.3% from 2019 to 2024, reflecting the increasing demand for these machines across industries. Furthermore, key manufacturers such as KENNEDY and Marco are leading the market, ensuring the availability of high-quality blasting equipment.

In July 2024, Graco Inc., known for its fluid handling systems, entered into a strategic partnership with BlastOne International, a prominent provider of surface preparation and protective coating solutions, further emphasizing the evolving landscape of the sandblasting industry.

Benefits and Considerations of Renting Sandblasters

For construction project managers, especially those tackling short-term projects or operating within tight budget constraints, a sandblaster machine rental presents a compelling solution. One of the most significant advantages is the cost savings linked to leasing; by choosing to lease rather than buy, managers can bypass the substantial upfront investment generally necessary for such specialized equipment. For context, hiring a professional abrasive blasting service averages around $3,200, making rentals a financially attractive option.

Furthermore, renting provides access to the latest models and technologies, which can enhance efficiency without the added burden of maintenance and storage responsibilities—critical factors in the fast-paced construction environment. Merem Blasting emphasizes this advantage, stating,

With quick service and rapid estimates, our mobile abrasive solutions reduce the time needed to finish your task, resulting in lower labor expenses.

Additionally, the physical demands of abrasive blasting, including frequent lifting up to 50 lbs and exposure to bright lights and dust, further underscore the practicality of renting equipment rather than relying on in-house resources.

It's also important to consider the labor costs associated with these initiatives, such as the Class B Driver position starting at $30 or more per hour. By thoroughly comprehending these factors, construction experts can make informed choices regarding sandblaster machine rental that align with their requirements, ultimately maximizing the advantages of renting abrasive blasting equipment.

Types of Sandblasting Equipment Available for Rent

When evaluating sandblasting equipment rentals, managers can choose from three primary categories:

- Portable units

- Cabinet machines

- Industrial equipment

Portable abrasive blasting machines are particularly advantageous for small to medium-sized projects due to their flexibility and ease of transport, enabling users to navigate various job sites with minimal hassle. In contrast, cabinet systems for abrasive blasting create a contained environment that facilitates precise work, making them ideal for intricate tasks where accuracy is paramount.

For larger scale operations, industrial blasting machines are the go-to option, engineered to endure heavy-duty applications with remarkable efficiency. Recognizing the distinct features and capabilities of these sandblasting tools is essential for selecting the most appropriate equipment tailored to the specific demands of each project.

As the market for sandblaster leasing continues to expand—projected to reach a valuation of USD 143.1 million by 2033, with a growth rate of 4.6%—S. N. Jha observes that this growth offers significant opportunities for investment in the leasing market. Furthermore, the construction rental sector in the Middle East and Africa is anticipated to expand by 5.8% due to large-scale endeavors, suggesting additional potential for sandblaster machine rental in these regions. Therefore, construction managers must stay informed on the best options available to maximize their investment and success.

Cost Factors for Renting Sandblasters: What to Expect

Renting a sandblaster machine rental involves various cost considerations that can significantly impact project budgets. Typically, the price for a standard sandblaster ranges from $50 to $150 per day. However, this base cost can fluctuate based on several factors, including:

- The specific type of equipment

- Duration of use

- Geographic location

Additionally, users should anticipate extra expenses for abrasive materials, such as aluminum oxide, which is priced between $2 to $2.50 per pound and is suitable for cleaning glass, granite, marble, and steel, but should never be used on soft or delicate surfaces. This adds another layer of cost, with abrasive materials ranging from $10 to $50 per bag depending on the chosen material. It's also crucial to consider potential deposits and insurance fees that leasing companies may require, which can vary widely.

Understanding the cost factors is essential for effective budgeting. The recent rise in cropland lease rates by 2.6% from 2023 may also reflect broader market trends that could influence the pricing of sandblaster machine rentals. As mentioned by S. N. Jha, Principal Consultant, the sandblaster machine rental market is expected to attain a valuation of around $143.1 million by the end of 2033, highlighting the increasing demand for such equipment and the budgeting challenges that construction managers encounter.

By being aware of these variables, construction project managers can refine their budgeting processes and minimize the risk of unexpected costs during their projects.

Conclusion

In the realm of construction and manufacturing, the significance of sandblasters cannot be overstated. These powerful tools play a crucial role in surface preparation, ensuring that surfaces are free from contaminants and primed for optimal adhesion. Understanding the definition and functionality of sandblasters equips project managers with the knowledge needed to leverage these machines effectively, particularly as advancements in technology continue to shape the industry.

The diverse applications of sandblasters across various sectors highlight their versatility and importance. From construction to automotive repair, sandblasters facilitate high-quality finishes and enhance productivity. The increasing reliance on these tools, coupled with a growing market for rental equipment, presents both opportunities and challenges for professionals. By recognizing the benefits of renting, such as cost savings and access to the latest technology, project managers can make informed decisions that align with their project needs.

As the market for sandblasting equipment expands, understanding the different types of sandblasters available for rent is essential for selecting the right tool for each specific task. With clear insights into cost factors associated with renting sandblasters, including rental prices and additional expenses for abrasive materials, project managers can navigate their budgets more effectively.

Ultimately, mastering the intricacies of sandblasting technology not only drives project success but also positions professionals to adapt to the evolving demands of the industry. By embracing the potential of sandblasters, construction and manufacturing leaders can enhance their operational efficiency and ensure high-quality outcomes in their projects.

Frequently Asked Questions

What is an abrasive blaster and how does it work?

An abrasive blaster, or sandblaster, is a machine that propels abrasive materials at high velocity to clean or prepare surfaces. It operates using a compressed air system that forces the abrasive media through a nozzle, allowing for precise control over the application process.

Why is precision important in abrasive blasting?

Precision is crucial in industries such as construction, automotive, and manufacturing for effectively removing paint, rust, and contaminants, which ensures the integrity of surfaces being treated.

What are some industries that utilize abrasive blasting?

Abrasive blasting is primarily used in construction, automotive, and manufacturing sectors for tasks such as surface preparation, paint stripping, and cleaning molds and dies.

What recent trends are shaping the abrasive blasting market?

The abrasive blasting market is experiencing growth due to projected global infrastructure investments and advancements in technology, including automation and robotics, which are enhancing functionality and appeal.

What is the significance of the partnership between Graco Inc. and BlastOne International?

The partnership emphasizes the importance of cooperation in advancing surface treatment technology and highlights the evolving landscape of the sandblasting industry.

How is sandblaster machine rental relevant in various applications?

Sandblaster machine rental is vital for ensuring surfaces are cleaned and primed before painting or coating in construction, and for stripping old paint and rust in automotive applications.

What market trends are observed in the abrasive blasting industry?

The abrasive blasting market in the US has been growing at a CAGR of 1.3% from 2019 to 2024, indicating increasing demand for these machines across various sectors.

Who are the key manufacturers in the abrasive blasting market?

Key manufacturers in the abrasive blasting market include KENNEDY and Marco, which provide high-quality blasting equipment.