Introduction

In the ever-evolving landscape of material handling, stackers have emerged as indispensable tools for businesses aiming to enhance operational efficiency. With their ability to lift and move pallets effectively, these machines cater to a variety of needs across warehouses, construction sites, and manufacturing facilities.

As organizations grapple with the challenges of optimizing workflow and managing costs, the option to rent stackers presents a compelling solution. This article delves into the nuances of stacker rentals, exploring their benefits, the critical considerations for selection, and best practices for safe operation.

By understanding the value of stackers and how they can transform material handling processes, businesses can make informed decisions that not only improve productivity but also ensure safety and cost-effectiveness in their operations.

Understanding Stacker Rentals: An Overview

Stackers denote specialized material handling tools crafted to effectively lift and transport pallets and goods, which are available for stacker rental to satisfy various functional requirements. These machines come in both manual and powered forms, catering to various applications in warehouses, construction sites, and manufacturing facilities. Their primary function is to facilitate the stacking and unstacking of materials, thereby optimizing space usage and significantly enhancing productivity.

Recent advancements in the material handling equipment sector, especially in 2024, highlight the increasing dependence on forklifts for enhancing workflow efficiency. For example, organizations utilizing equipment leases have reported a significant improvement in performance, highlighting their role in tackling the challenges of material handling. Vena, which has grown to over 500 employees, exemplifies a company that recognizes this trend.

Additionally, Vena launched a preconfigured corporate performance management solution for legal firms, developed in collaboration with Politics, which streamlines financial and operational planning—illustrating a real-world application of tools in enhancing operational efficiency. As emphasized in the article 'Leveraging Machine Learning for Sophisticated Value Predictions: A Case Study from Munich, Germany,' current trends in the industry indicate that incorporating advanced technologies can further improve the efficiency of equipment leases. As Hunter Madeley, CEO of Vena, emphasizes,

Our collective focus on the value we create for customers is strengthened by the unique skills and perspectives of each of our team members.

This sentiment reflects the critical role that loaders play in streamlining operations and highlights the need for businesses to consider their stacker rental options for improved productivity.

Exploring Different Types of Stackers: Walkie Stackers vs. Forklifts

In the realm of material handling, the choice between walkie lifts and forklifts is pivotal. Walkie vehicles are engineered for exceptional maneuverability in confined areas, enabling operators to walk alongside the equipment. This design makes them particularly effective for low to medium lifting tasks within smaller warehouses, where space constraints are a significant consideration.

Conversely, forklifts offer greater versatility, capable of managing heavier loads and reaching greater heights, making them better suited for larger operations. However, their functional footprint demands more space, which can be a challenge in compact environments. Understanding these distinctions is crucial for businesses aiming to optimize efficiency in their material handling processes.

Notably, the Elderly Care Services Market, valued at USD 1,006 Billion in 2022 and projected to reach USD 1,414 Billion by 2031, underscores the increasing demand for efficient material handling solutions in growing sectors. In 2024, walkie stackers are projected to capture an increased share of the market, reflecting their growing popularity for applications in smaller spaces. Additionally, it is important to consider that combustion engine forklifts may require costly storage solutions for safely storing LPG or diesel fuel, which contributes to the expenses of these machines.

As Adam Gavrun aptly notes,

Though the driving is power-assisted for most models, walking and standing for long periods is more fatiguing to your workforce than sitting in the driver's seat of a forklift.

This insight reinforces the importance of considering operator comfort and efficiency when choosing tools. By assessing the specific requirements of a project, managers can make informed choices, ensuring that they choose the appropriate tools to enhance operational productivity.

Cost and Capacity: What to Consider When Renting a Stacker

When leasing a lifter, two essential aspects are considered: the expense of the lease and the lifting capacity of the machinery. In 2024, average rental costs for forklifts can fluctuate significantly based on the type of equipment, the rental duration, and any additional features that enhance functionality. It's essential for businesses to assess their specific lifting requirements, such as the weight of materials to be handled and the necessary lifting height.

This evaluation not only helps in choosing the appropriate capacity for a stacker rental but also guarantees that the machinery aligns with functional requirements. By conducting a thorough evaluation, companies can make informed, cost-effective decisions that enhance their material handling efficiency while minimizing the risk of accidents linked to untrained operators or unsafe conditions. This proactive approach is essential in maintaining safety standards and integrity.

Additionally, as Dynapac commemorates its 90th anniversary in 2024, the industry reflects on advancements in machinery that influence rental decisions, such as Caterpillar Inc.'s PM800 series cold planers, known for their efficient performance and ability to customize milling widths. Moreover, the case study titled 'Solve Asphalt Cement Tank Wear' illustrates how suitable tool selection and maintenance can greatly influence functional integrity, emphasizing the significance of assessing lifting capacity and safety.

The Benefits of Renting Stackers for Your Operations

Stacker rental presents a multitude of advantages for businesses, particularly in the construction sector, where flexibility, cost savings, and operational efficiency are paramount. By choosing to rent, companies can avoid the substantial upfront costs linked to buying tools, thus freeing up capital for other critical initiatives. This financial strategy is increasingly relevant, given that the rental market for machinery is projected to grow at a compound annual rate of 4% through 2030, primarily fueled by the demand for advanced devices like crawler cranes.

Moreover, stacker rental enables businesses to utilize the latest models equipped with cutting-edge features, enhancing productivity and workplace safety. Kyle Clements, CEO of Quipli, emphasizes the significance of this trend, noting that access to modern tools can significantly impact operational effectiveness. He states,

“Partnering with independent rental companies enables businesses to run their operations more effectively and create an impactful experience for their customers.”

The flexibility that comes with renting is especially beneficial for enterprises facing fluctuating demands. Companies can easily modify their resource needs without being tied to long-term commitments, allowing for more agile responses to project requirements. Contractors should weigh the following factors when deciding whether to choose a stacker rental or buy:

- Project duration

- Machinery frequency

- Maintenance costs

- Resale value

This makes the rental option particularly appealing in dynamic environments.

This adaptability is supported by the ToolSense Asset Management Solution, which assists businesses in effectively managing rented assets. By utilizing ToolSense, companies can track maintenance and usage data, leading to enhanced operational efficiency and informed decision-making based on detailed analytics. The result of using such a solution involves prolonging the lifespan of tools and making more strategic choices based on real-time data.

In conclusion, the strategic choice of stacker rental not only streamlines material handling processes but also leads to significant cost savings, making it a compelling option for construction project managers looking to optimize their operations. Additionally, the efficiency of the rental process is highlighted by the fact that completing a lease application takes about 48 hours to receive a response, showcasing the speed of renting compared to purchasing.

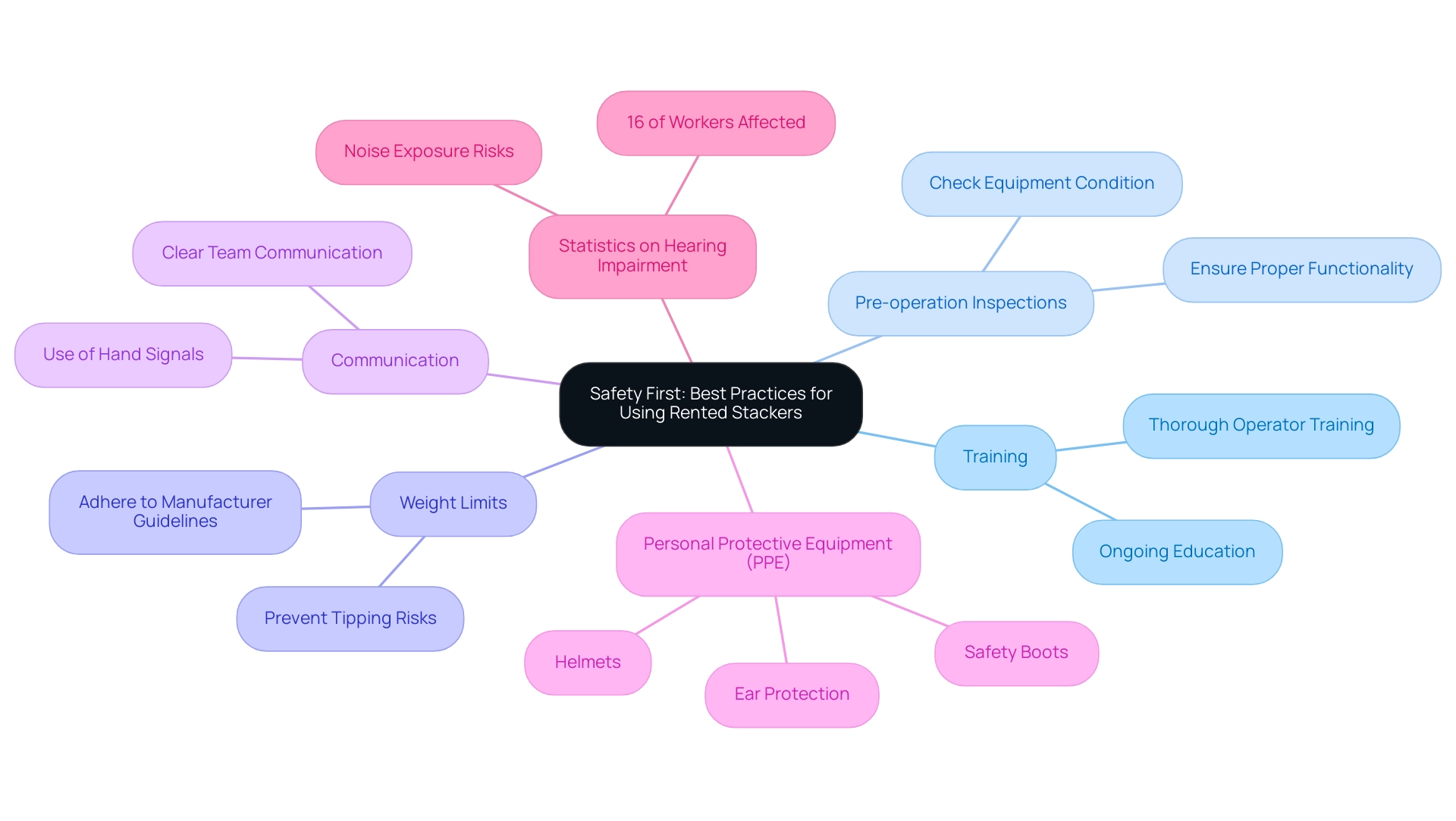

Safety First: Best Practices for Using Rented Stackers

Safety is paramount when using rented equipment, as improper operation can lead to serious injuries. It is essential that operators receive thorough training to ensure they can manage the tools safely and effectively. Key best practices include:

- Conducting pre-operation inspections to ensure that the handler is well-maintained and in good working order.

- Strictly adhering to weight limits to prevent tipping or machinery failure.

- Fostering clear communication with team members during operation.

Additionally, techniques such as maintaining three points of contact can significantly reduce the risk of falls, which are a leading cause of accidents in construction settings. The use of appropriate personal protective equipment (PPE) is crucial to mitigate injury risks. Furthermore, statistics from 2023 indicate that 16% of construction workers exposed to noise on the job experienced hearing impairment in both ears.

This emphasizes the significance of protective measures, especially in settings where operators work, as noise exposure from machinery can contribute to this issue. By rigorously following these safety protocols, businesses not only enhance the safety of their stacker rental operations but also safeguard their workforce, leading to improved outcomes in the construction industry. The emphasis on effective communication and training—akin to the recommendations outlined in the recent case study on construction safety—can significantly reduce the likelihood of accidents and promote a culture of safety within the workplace.

In the broader context, the recent stability in the U.S. Export Price Index may influence the rental services market in construction, underscoring the importance of maintaining high safety standards to protect workers and equipment.

Conclusion

The exploration of stacker rentals reveals their critical role in enhancing operational efficiency across various industries. By understanding the distinctions between different types of stackers, such as walkie stackers and forklifts, businesses can make informed choices that align with their specific operational needs. This knowledge not only aids in selecting the appropriate equipment but also ensures the optimization of space and productivity.

Cost considerations and lifting capacity are pivotal when renting stackers. A thorough evaluation of these factors allows companies to make strategic decisions that enhance material handling efficiency while prioritizing safety. The benefits of renting, particularly in terms of flexibility and access to the latest technology, underscore the financial prudence of this approach, especially in dynamic environments like construction.

Moreover, prioritizing safety through best practices is essential when operating rented stackers. Comprehensive training for operators, adherence to safety protocols, and the use of personal protective equipment can significantly mitigate risks associated with equipment use. By fostering a culture of safety, businesses not only protect their workforce but also enhance overall operational outcomes.

In conclusion, embracing stacker rentals is a proactive strategy for businesses seeking to streamline operations, reduce costs, and ensure safety. By leveraging the advantages of renting, organizations can respond agilely to changing demands, ultimately leading to improved productivity and a competitive edge in the market.

Frequently Asked Questions

What are stackers and what purpose do they serve?

Stackers are specialized material handling tools designed to lift and transport pallets and goods. They are available for rental and primarily facilitate the stacking and unstacking of materials, optimizing space usage and enhancing productivity.

What types of stackers are available?

Stackers come in both manual and powered forms, catering to various applications in warehouses, construction sites, and manufacturing facilities.

How have recent advancements in material handling equipment impacted workflow efficiency?

Recent advancements, particularly in 2024, have led to an increased reliance on forklifts to enhance workflow efficiency. Organizations that utilize equipment leases have reported significant performance improvements in material handling.

Can you provide an example of a company that has benefited from these advancements?

Vena, a company that has grown to over 500 employees, exemplifies this trend. They have launched a corporate performance management solution for legal firms, showcasing how tools can enhance operational efficiency.

How does incorporating advanced technologies affect equipment leases?

Current industry trends indicate that incorporating advanced technologies can further improve the efficiency of equipment leases, enhancing overall operational productivity.

What is the difference between walkie lifts and forklifts?

Walkie lifts are designed for maneuverability in confined spaces and are effective for low to medium lifting tasks in smaller warehouses. Forklifts, on the other hand, are more versatile, capable of handling heavier loads and reaching greater heights, but require more space.

What market trends are influencing the demand for material handling solutions?

The Elderly Care Services Market, valued at USD 1,006 Billion in 2022 and projected to reach USD 1,414 Billion by 2031, highlights the increasing demand for efficient material handling solutions. Walkie stackers are expected to capture a larger market share in 2024, particularly for applications in smaller spaces.

What considerations should businesses keep in mind when choosing material handling equipment?

Businesses should assess the specific requirements of their projects and consider factors such as operator comfort, efficiency, and the spatial constraints of their environments to make informed choices about material handling tools.