Overview

This article serves as a comprehensive guide to renting a torque wrench, outlining key rental locations in Irving, TX, including:

- EZ Equipment Rental

- AutoZone

- Home Depot

Understanding the importance of selecting the right type of wrench and ensuring proper usage is crucial. It is essential to grasp the specific force range and tool condition, along with best practices for maintenance, to ensure effective and safe application across various industries. Such knowledge is paramount for achieving project success.

In addition to identifying rental locations, the article emphasizes the reliability and quality of the tools available. By selecting a reputable rental service, you can be assured of the equipment's condition and performance. Testimonials from satisfied customers further underscore the value of choosing the right rental provider, enhancing the overall experience.

Furthermore, understanding the maintenance of tools not only prolongs their lifespan but also ensures safety during use. Implementing best practices in tool care can significantly impact the outcomes of your projects. Therefore, we encourage you to consider these factors when renting equipment.

Take action now and explore the rental options available to you in Irving, TX. By doing so, you will pave the way for successful project execution with the right tools at your disposal. Don't hesitate to reach out to these rental locations for more information on their offerings and how they can meet your specific needs.

Key Highlights:

- Torque wrenches apply specific rotational force on fasteners, crucial for automotive, construction, and machinery applications.

- Proper torque application prevents damage from over-tightening and structural failures from insufficient tightening.

- North America holds a 36.6% share of the global high-torque tool market, driven by sectors like automotive and aerospace.

- The global sensors market for rotational force is expected to grow, reflecting ongoing advancements in force measurement technology.

- Types of torque wrenches include click, beam, digital, and hydraulic, each suited for different applications.

- Key rental locations for torque wrenches in Irving, TX include EZ Equipment Rental, AutoZone, O'Reilly Auto Parts, Home Depot, and Sunbelt Rentals.

- Important considerations when renting include force range, type of tool, rental terms, tool condition, and calibration.

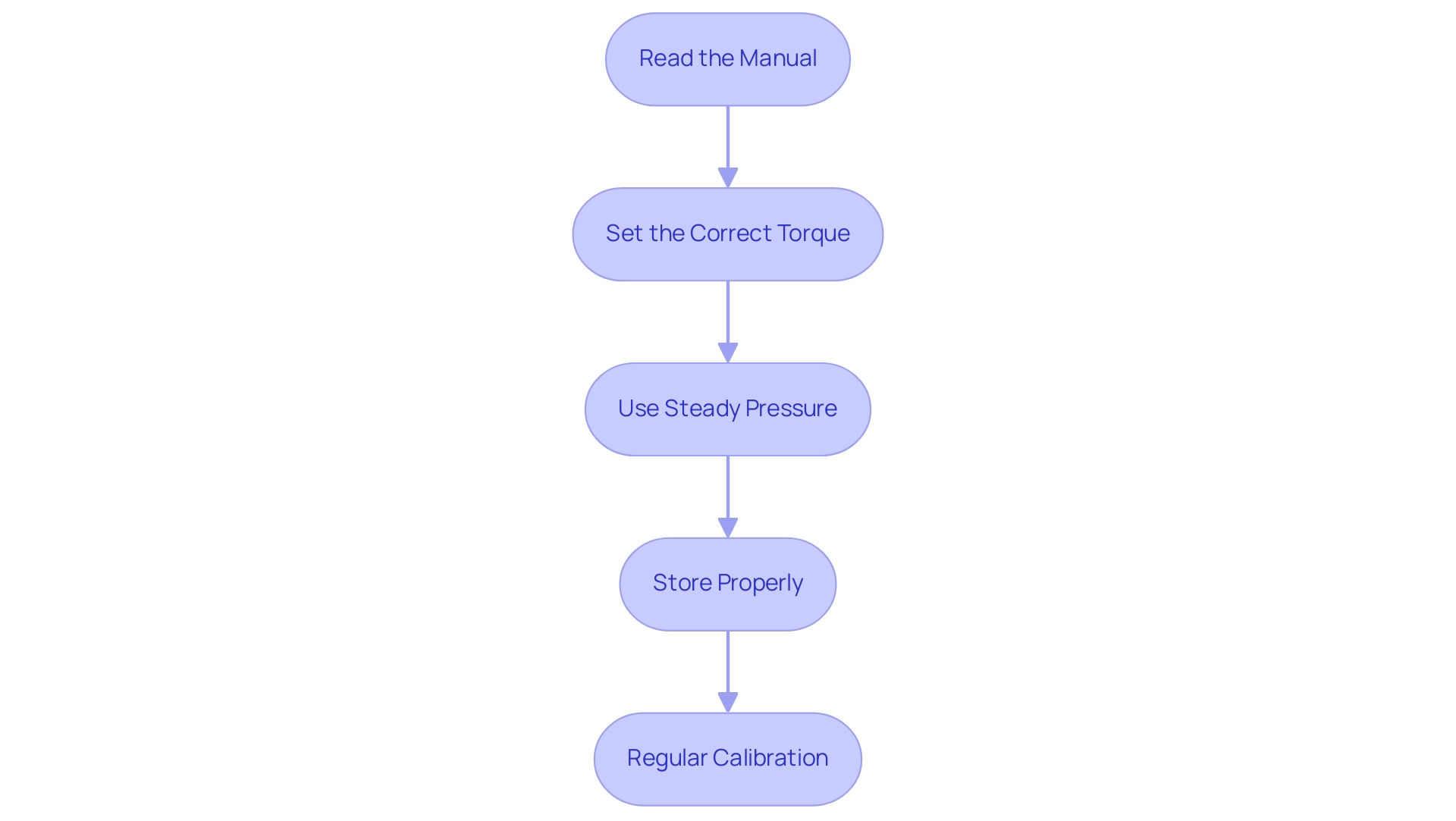

- Best practices for using torque wrenches include reading manuals, setting correct torque, applying steady pressure, proper storage, and regular calibration.

Introduction

In the construction and automotive repair industries, precision is not just important; it is essential. A torque wrench is a critical tool that ensures fasteners are tightened to the correct specifications, preventing both over-tightening and under-tightening. These missteps can lead to serious safety hazards and structural failures.

As the torque wrench market continues to grow—driven by technological advancements and rising demand across various sectors—professionals must understand the types available, rental options, and best practices for use to enhance their operational efficiency.

The evolution of the industry underscores the increasing significance of these tools, making it imperative for users to remain informed and equipped for success.

Understanding Torque Wrenches: Importance and Applications

A torque instrument is an essential device engineered to apply a specific amount of rotational force on fasteners, such as nuts and bolts. This precision is vital across various applications, including automotive repairs, construction, and machinery assembly. By utilizing a twisting tool, users can ensure that fasteners are secured according to manufacturer specifications, effectively mitigating risks associated with both excessive tightening, which can cause damage, and insufficient tightening, which may result in structural failures.

In the construction industry, the proper application of rotational force is critical for maintaining structural integrity. A recent analysis reveals that North America commands a significant 36.6% share of the global high-torque tool market, primarily driven by demand from key sectors such as automotive, aerospace, and oil & gas. This statistic underscores the indispensable nature of adjustable tools for professionals in these domains.

Furthermore, the global sensors market for rotational force is poised for substantial growth, spurred by the emergence of new applications and advancements in force measurement technology. This trend emphasizes the ongoing relevance of these tools in modern practices.

The importance of twisting tools extends into automotive applications, where they are crucial for securing lug nuts. Recent technological advancements have led to the development of models designed for high-temperature conditions and hazardous environments, particularly beneficial in the chemical sector. As the global sensor market for rotational force continues to expand, driven by innovation and new applications, the significance of force tools in both construction and automotive industries remains paramount.

However, the market does encounter challenges, including the skill requirements for utilizing high-torque tools and competition from alternative devices. Understanding these challenges, along with knowledge of where to rent a torque wrench, empowers users to achieve safe and effective outcomes in their tasks, whether assembling heavy machinery or conducting automotive repairs. The integration of these instruments into standard practices not only enhances safety but also boosts the overall efficiency and reliability of construction and automotive operations.

As Gabriele Ketterl, Director of Marketing & PR, remarked, "OpenPR is the nicest and most clearly laid out PR platform I have seen to this day," highlighting the significance of clear communication within the industry. This statement reinforces the necessity for professionals to remain informed about the resources they employ, ensuring they are equipped to meet the demands of their tasks.

Types of Torque Wrenches: Choosing the Right One for Your Needs

Torque wrenches are indispensable tools across various industries, each type meticulously designed for specific applications and user requirements. Understanding the distinctions among them can significantly influence project outcomes. Below are the primary types of torque wrenches:

- Click Torque Wrench: This widely favored option emits a distinct click sound upon reaching the preset tension, providing audible confirmation for the user. Its reliability and user-friendliness make it particularly preferred in automotive applications, where precision is paramount.

- Beam Torque Wrench: Known for its simplicity and durability, this tool employs a beam and pointer system to indicate force levels. Its straightforward design guarantees consistent performance, establishing it as a dependable choice for a variety of tasks.

- Digital Wrench: Featuring a digital display, this type offers precise rotational force readings, making it ideal for applications requiring high accuracy. The ease of reading and recording force values enhances its practicality in professional environments.

- Hydraulic Torque Tool: Engineered for heavy-duty applications, this tool utilizes hydraulic pressure to attain high rotational force levels. It is particularly suited for industrial settings where robust performance is essential.

When considering where to rent a torque wrench for your task, it is crucial to account for factors such as the required force range, the specific application, and the working conditions. High-torque tools are especially valued for their capacity to ensure accuracy and efficiency in demanding environments, making knowledge of where to rent a torque wrench vital for successful project execution. The Torque Tool Market Report 2025 indicates significant growth in the tool sector, propelled by technological advancements and rising demand in the automotive and construction industries.

However, challenges such as the necessity for skilled labor and competition from alternative fastening tools persist.

In 2025, the most sought-after tool types in construction are expected to include click and digital models, reflecting a trend towards precision and convenience. Practical applications of click tools demonstrate their effectiveness in ensuring accuracy in fastening tasks, further solidifying their market position.

As advancements in fastening technology continue to emerge, staying informed about the latest developments will aid you in selecting the best equipment for your needs. According to a Senior Research Analyst at Cognitive Market Research, "Through collaboration with cross-functional teams, I played a pivotal role in shaping business strategies rooted in robust research." This insight underscores the importance of understanding market trends and strategies when selecting tools for construction projects.

Whether overseeing a construction project or engaged in automotive repair, comprehending the nuances of adjustable tools can enhance your operational efficiency.

Where to Rent a Torque Wrench: Top Rental Locations

When seeking to rent a twisting tool, several leading rental spots in the Irving, TX region stand out for their exceptional services and customer support.

- EZ Equipment Rental: Situated at 1307 W Airport Fwy, Irving, TX 75062, EZ Equipment Rental emerges as a premier choice for adjustable tools and various equipment. They offer flexible rental terms and competitive pricing, ensuring that both personal and business needs are met efficiently. Their unwavering commitment to exceptional customer service, including timely delivery and maintenance, positions them as a reliable partner for any project. EZ Equipment Rental is the ideal destination for those inquiring about where to rent a torque wrench, along with a comprehensive range of equipment such as boom lifts, excavators, and forklifts catering to diverse construction needs. In alignment with industry trends, EZ Equipment Rental plans to invest in new equipment, echoing the 48% of rental companies intending to do so in 2025, highlighting their focus on providing cutting-edge technology and flexibility.

- AutoZone: Renowned for its Loan-A-Tool initiative, AutoZone allows clients to borrow tightening tools with a deposit. This option is particularly convenient for those with short-term needs, especially when considering where to rent a torque wrench, making it an accessible choice for quick projects.

- O'Reilly Auto Parts: Similar to AutoZone, O'Reilly offers a rental program where customers can effortlessly rent tools by placing an order online and collecting them at their nearest store. This streamlined process caters to both DIY enthusiasts and professionals, including guidance on where to rent a torque wrench.

- Home Depot: With an extensive equipment rental area, Home Depot is an excellent place to find where to rent a torque wrench, offering a variety of adjustable spanners suitable for both DIY tasks and professional applications. Their vast inventory ensures that customers can locate the right tool for their specific requirements.

- Sunbelt Rentals: Specializing in equipment rentals, Sunbelt Rentals provides hydraulic and electric fastening tools designed for more demanding applications. Their emphasis on high-quality tools positions them as a strong competitor for those needing specialized equipment.

These establishments not only present a diverse selection of adjustable tools but also reflect the growing trend in the construction sector, where 48% of rental firms plan to invest in new machinery in 2025. This shift is driven by the necessity for cost savings, access to newer technology, and the flexibility that rental services offer. As construction firms increasingly favor leasing equipment, EZ Equipment Rental distinguishes itself with positive customer feedback that underscores their outstanding service and dependability in tool rentals.

As Mark Keily, Health, Safety & Sustainability Director, remarked, while challenges persist in the industry, companies like EZ Equipment Rental are proactively pursuing practical solutions to address these issues, further solidifying their status as a leader in the equipment rental market.

Key Considerations When Renting a Torque Wrench

When renting a torque wrench, several key considerations are essential to ensure optimal performance and project success:

- Force Range: Selecting a wrench that meets the specific force specifications of your task is crucial. Different applications require varying force ranges, and using the correct range is vital for achieving precise results. For instance, construction projects in 2025 typically demand force ranges that align with the latest industry standards, reflecting an average force requirement that has evolved due to advancements in construction technology.

- Type of Tool: The type of torque tool you choose can significantly impact your work efficiency. Options include click, beam, digital, and hydraulic wrenches, each designed for specific applications. Understanding the advantages of each type will empower you to select the most suitable tool for your needs.

- Rental Terms: Thoroughly reviewing rental terms is essential. This includes the duration of the rental, pricing structures, and any potential additional fees. Awareness of these terms can prevent unexpected expenses and ensure that you remain within your budget, especially as transportation costs are expected to increase by 4% in 2025 compared to 2024. This rise in transportation expenses may influence overall budgets, making it essential to plan accordingly.

- Condition of the Tool: Prior to finalizing your rental, examine the torque tool for any visible damage or signs of wear. A well-maintained instrument is critical for precise force application, particularly in high-pressure environments such as construction, where accuracy can directly affect safety and project outcomes.

- Calibration: Ensure that the torque wrench has been calibrated recently. Proper calibration is essential for guaranteeing that the instrument operates correctly and safely, as even slight variations can lead to significant issues in construction projects.

In the words of Misha, Managing Director at Deloitte Consulting LLP, "E&C firms must adapt to evolving economic conditions, technological advancements, and changing policy landscapes to capitalize on growth opportunities in 2025." By considering these factors, you can facilitate a smooth rental experience and know exactly where to rent a torque wrench to achieve optimal results in your projects. As the construction sector continues to adjust to changing economic circumstances and technological advancements, making informed choices about equipment rentals will be crucial to seizing growth opportunities in 2025.

Furthermore, the AIA consensus 2025 forecast for Data Centers indicates a growth of +21.9%, underscoring the increasing demand for reliable instruments such as adjustable fasteners in the construction industry. Additionally, the recent case study titled "Strategic Growth through Mergers and Acquisitions" highlights how firms are optimizing their portfolios and focusing on strategic investments, which can also impact decisions regarding tool rentals.

Tips for Proper Use and Maintenance of Torque Wrenches

To maximize the effectiveness and longevity of your rented torque wrench, adhere to the following best practices:

- Read the Manual: Begin by thoroughly reviewing the manual of the tool for applying rotational force. Understanding its specific features and operational guidelines is crucial for optimal performance.

- Set the Correct Torque: Always adjust the torque tool to the specified torque value before use. This ensures that you meet the requirements of your project and prevents potential damage to fasteners.

- Use Steady Pressure: When using the tool, apply consistent and steady pressure. This technique helps avoid over-tightening, which can lead to fastener failure or damage.

- Store Properly: After use, keep the tool in a protective case. Additionally, reset it to its lowest setting to relieve tension on the internal mechanisms, which is essential for maintaining accuracy and extending tool life.

- Regular Calibration: For frequent use, consider scheduling regular calibrations. This practice is vital for ensuring the tool's accuracy, as even minor deviations can significantly impact performance.

By applying these strategies, you can improve the efficiency of your rental tool and ensure it meets the requirements of your project while also considering where to rent a torque wrench to extend its lifespan. Monitoring bolt stretch during installation is also critical, as it helps prevent exceeding maximum stretch limits, further ensuring the integrity of your work. As Mike Mavrigian aptly states, 'If in doubt, replace them,' emphasizing the significance of maintaining your equipment.

With the manual torque wrench projected to dominate the market by over 75% in 2025, understanding these best practices is more important than ever for effective tool management.

Conclusion

The significance of torque wrenches in both construction and automotive repair is paramount. These tools are essential for ensuring that fasteners are tightened to the precise specifications required for maintaining safety and structural integrity. As the market for torque wrenches expands due to technological advancements and increasing demand, it becomes crucial for professionals in these industries to understand the different types available, rental options, and best practices for use.

Choosing the right torque wrench requires recognizing the specific needs of each project, whether that be a click, beam, digital, or hydraulic wrench. Each type offers unique advantages that can significantly enhance efficiency and accuracy in application. Furthermore, renting torque wrenches from reliable sources not only provides access to high-quality tools but also reflects the industry's trend towards flexibility and cost-effectiveness.

Proper use and maintenance of torque wrenches are critical for achieving optimal performance. By adhering to best practices—such as reading manuals, ensuring correct torque settings, and maintaining regular calibration—users can extend the life of their tools while ensuring project success. As the construction and automotive sectors continue to evolve, staying informed about torque wrench innovations and best practices will empower professionals to effectively meet the challenges of their projects.

In conclusion, the continuous evolution of torque wrench technology and the growing market underscore the vital role of these tools in achieving safe and efficient operational outcomes. Understanding their applications, selecting the appropriate type, and committing to proper maintenance will not only enhance individual project results but also contribute to the overall reliability and safety standards within the industry.

Frequently Asked Questions

What is a torque instrument and why is it important?

A torque instrument is a device designed to apply a specific amount of rotational force on fasteners like nuts and bolts. It is crucial for ensuring that fasteners are tightened according to manufacturer specifications, which helps prevent damage from excessive tightening and structural failures from insufficient tightening.

In which industries are torque instruments commonly used?

Torque instruments are commonly used in various industries, including automotive repairs, construction, and machinery assembly. They are especially important in maintaining structural integrity in construction and securing components in automotive applications.

What percentage of the global high-torque tool market does North America command?

North America commands a significant 36.6% share of the global high-torque tool market, driven primarily by demand from key sectors such as automotive, aerospace, and oil & gas.

What factors are contributing to the growth of the global sensors market for rotational force?

The global sensors market for rotational force is poised for substantial growth due to the emergence of new applications and advancements in force measurement technology.

What are the different types of torque wrenches and their applications?

The primary types of torque wrenches include: 1. Click Torque Wrench: Emits a click sound at preset tension, ideal for automotive applications. 2. Beam Torque Wrench: Uses a beam and pointer system for force indication, known for its durability and simplicity. 3. Digital Wrench: Features a digital display for precise readings, suitable for high-accuracy applications. 4. Hydraulic Torque Tool: Utilizes hydraulic pressure for heavy-duty applications in industrial settings.

What challenges exist in the market for torque tools?

The market faces challenges such as the necessity for skilled labor to operate high-torque tools and competition from alternative fastening devices.

What should users consider when renting a torque wrench?

When renting a torque wrench, users should consider the required force range, specific application, and working conditions to ensure successful project execution.

What trends are expected in the torque tool market by 2025?

By 2025, the most sought-after tool types in construction are expected to include click and digital models, reflecting a trend towards precision and convenience in fastening tasks.

How do advancements in fastening technology impact the selection of tools?

Advancements in fastening technology emphasize the importance of staying informed about the latest developments, aiding users in selecting the best equipment for their needs in construction and automotive projects.