Overview

Crimping tool rental is crucial for construction managers, offering cost efficiency, access to the latest technology, and the flexibility needed to meet project demands. This structured rental process not only highlights the significance of selecting the appropriate tools based on specific project requirements but also underscores the industry's growth. By adhering to best practices for maintenance, users can ensure optimal performance of the equipment.

The benefits of utilizing rental tools are manifold. They provide a reliable solution that adapts to the evolving needs of construction projects. Moreover, employing the latest technology through rentals can significantly enhance productivity and efficiency on-site. This approach not only saves costs but also ensures that construction managers can focus on delivering high-quality results without the burden of managing extensive inventories.

In addition, selecting the right tools is paramount. Evidence from industry growth statistics supports the notion that well-maintained equipment leads to better project outcomes. Testimonials from satisfied customers further illustrate the reliability and quality of rented tools, reinforcing the importance of making informed choices.

Ultimately, crimping tool rental presents an opportunity for construction managers to optimize their operations. By engaging with a reputable rental service, they can access top-tier equipment tailored to their project needs. Now is the time to take action and explore the benefits of crimping tool rental to elevate your construction projects.

Key Highlights:

- Crimping tools are essential for securely connecting wires and cables in various construction applications.

- Types of crimping tools include manual, hydraulic, and electric, each suited for different tasks.

- Manual crimpers are popular for their ease of use and portability, while hydraulic crimpers are designed for larger jobs requiring more force.

- The North American market is expected to see increased demand for crimping tools, indicating their growing importance in construction.

- Phoenix Contact plans to invest $260 million in tools and equipment, highlighting industry growth.

- When renting crimping tools, key factors include material type, connector size, and expected work volume.

- Rental options reduce upfront costs and maintenance responsibilities, providing access to the latest technology.

- A structured rental process includes identifying needs, researching companies, comparing rates, and inspecting equipment.

- Best practices for maintaining rented crimping tools include cleaning after use, regular inspections, and following manufacturer guidelines.

- The rental market is optimistic, with many companies planning investments in new equipment, enhancing operational efficiency.

Introduction

In the dynamic world of construction, crimping tools are essential for ensuring secure connections across various applications, from electrical work to plumbing. As technology evolves, selecting the appropriate crimping tool becomes increasingly vital for construction managers focused on enhancing project efficiency and safety.

With a wide array of options available—manual, hydraulic, and electric—understanding their unique features and applications can significantly influence the success of any project. This article explores the essentials of crimping tools, providing insights into their types, the advantages of renting versus buying, and best practices for maintenance.

By empowering construction professionals with this knowledge, we enable informed decision-making for 2025 and beyond.

Understanding Crimping Tools: Essential Equipment for Construction

Crimping instruments are indispensable devices crafted to deform materials, especially wires or cables, ensuring secure connections. Their importance permeates electrical work, plumbing, and various construction applications, making them crucial for project managers. In 2025, understanding the different types of fastening instruments—manual, hydraulic, and electric—will be vital for selecting the appropriate device for specific tasks.

Manual crimpers dominate the market, favored for their ease of use, affordability, and portability, particularly for smaller jobs. Their widespread adoption across industries stems from their versatility and the advantage of not requiring a power source. In contrast, hydraulic crimpers are engineered for larger, more demanding tasks, delivering the necessary force to guarantee robust connections in high-stakes environments.

The significance of joining instruments in construction cannot be overstated. They facilitate reliable electrical connections and secure fittings, which are essential for the safety and efficiency of any project. Recent statistics indicate that North America is projected to experience the highest demand for fastening devices during the forecast period, reflecting an increasing reliance on these instruments in construction.

Furthermore, Phoenix Contact's planned investment of US$ 260.0 million in structures, machinery, and equipment underscores the industry's growth and the rising demand for high-quality connectors.

Expert opinions stress that the integration of advanced fastening devices, such as battery-powered models like the EMC3300, enhances productivity and safety during wire assembly. As noted by Jim Camillo, senior editor of ASSEMBLY, "In manufacturing, ironclad formulas for success are hard to come by, but the appropriate instruments can make a significant difference." These advancements illustrate the ongoing evolution of fastening technology, ensuring that construction professionals have access to the finest equipment available.

Practical applications of fastening implements in electrical tasks underscore their critical role in ensuring success. Case studies reveal that the effective use of these resources can significantly impact timelines and outcomes, emphasizing the necessity for managers in the field to be well-versed in their operation and selection. As the construction landscape continues to evolve, staying informed about the latest innovations in fastening devices will empower managers to make strategic decisions that enhance efficiency and safety.

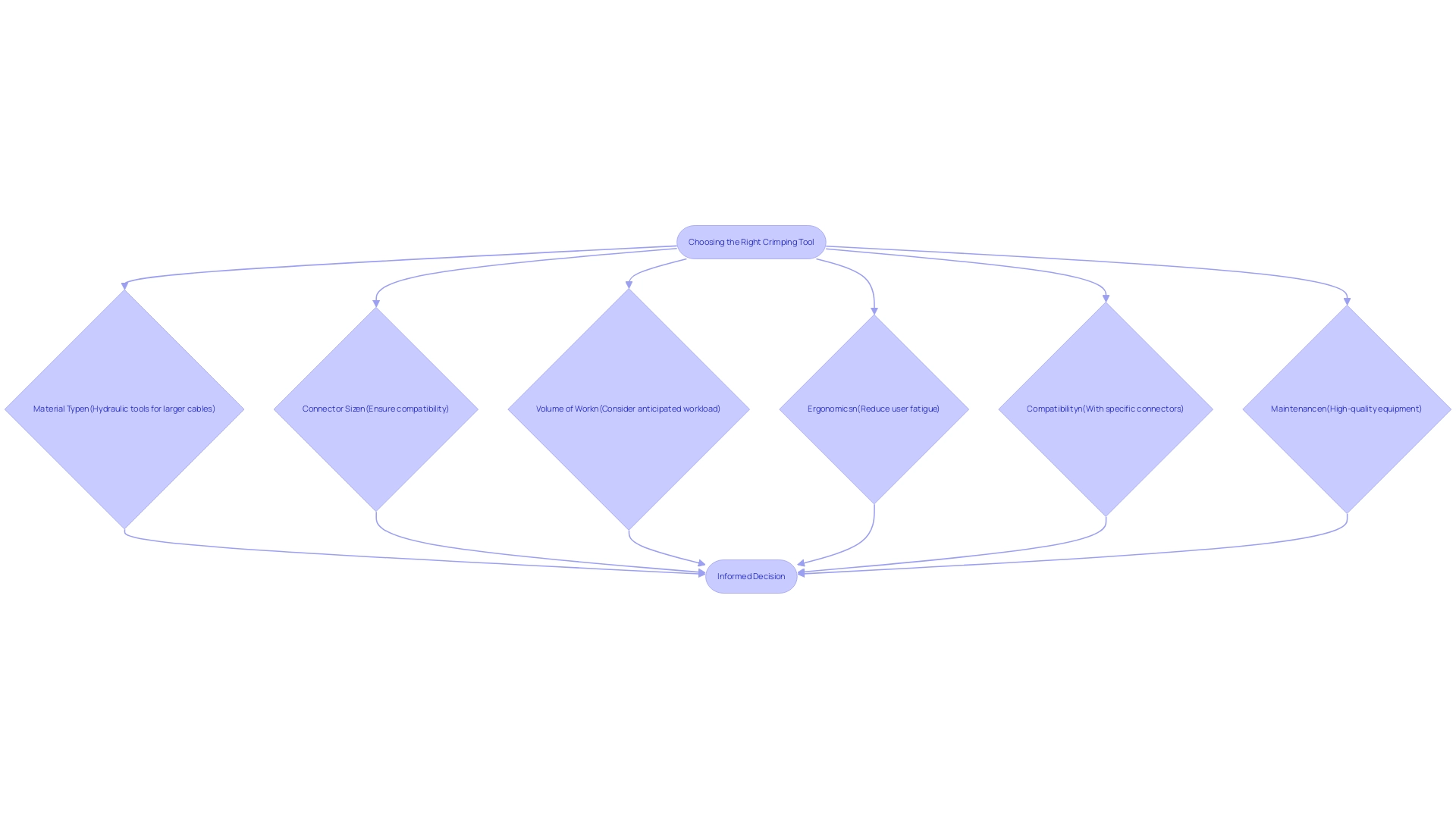

Choosing the Right Crimping Tool for Your Project Needs

Selecting the right fastening implement, such as a crimping tool rental, is crucial for the success of any construction project. Key factors to consider include:

- The type of material being crimped

- The size of the connectors

- The anticipated volume of work

For instance, when dealing with larger cables, a hydraulic pressing device is often essential to generate the necessary force for effective joining.

Ensuring compatibility between the device and the specific connectors used in your project is vital, particularly when utilizing a crimping tool rental, as this can significantly influence the quality of the crimp.

Ergonomics also play a critical role, especially for tasks that require extended use. Tools designed with ergonomic features can help minimize user fatigue, thereby enhancing productivity on the job site. In fact, ease of use is a fundamental consideration, as it directly affects the efficiency of the joining process.

Recent studies suggest that while environmental factors are considered less significant in equipment productivity, the selection and maintenance of tools remain paramount. A case study titled "Environmental Factors and Their Insignificance in Equipment Productivity" revealed that maintenance and operational aspects are more critical than environmental factors in influencing productivity. This underscores the importance of choosing high-quality equipment, including a crimping tool rental, that can withstand the rigors of construction work.

Moreover, statistics show that shot peening can improve surface and near-surface hardness rates by 8%, highlighting the importance of durability and maintenance in the selection process. Additionally, the characterization of implement I23 revealed scratches and drag zones on the crimping surface, further emphasizing the necessity for quality instruments available for crimping tool rental that can endure demanding conditions.

As we look to 2025, the average size of connectors utilized in construction projects has evolved, necessitating a careful evaluation of tool specifications to ensure compatibility. By taking these factors into account, managers can make informed decisions that lead to successful outcomes. As Ilca Dacian noted, these findings have direct engineering implications for construction, particularly in the assembly of wiring harnesses.

The Advantages of Renting Crimping Tools for Construction Projects

The benefits of crimping tool rental are clear, offering both cost efficiency and operational flexibility for your building projects. A key advantage is the significant reduction in upfront costs, allowing managers to allocate resources to other critical areas, thereby enhancing overall project viability. For instance, statistics demonstrate that construction initiatives utilizing rental equipment can achieve an impressive 734 hours of machinery usage at a total expense of $267,500, showcasing the financial effectiveness of rentals.

Moreover, choosing crimping tool rental alleviates the burdens of long-term storage and maintenance, as rental companies typically handle these responsibilities. This not only conserves valuable space but also minimizes ongoing maintenance costs that can accumulate over time with owned equipment. Additionally, crimping tool rental grants access to the latest technology and tools, ensuring that managers can utilize the most efficient and advanced equipment available.

This is particularly advantageous for short-term tasks or projects with varying equipment needs, enabling managers to adapt swiftly without incurring unnecessary costs.

A case study on equipment availability illustrates that while ownership provides immediate access, relying on rental services can effectively mitigate availability issues by offering a diverse range of machines. This adaptability is crucial in the fast-paced construction sector, where requirements can change rapidly. Furthermore, expert opinions emphasize that crimping tool rental, alongside leasing equipment such as fastening devices, not only leads to cost reductions but also enhances efficiency by ensuring that the right tools are accessible when needed.

As Randy Blount wisely states, "Don't just buy equipment because it's cool," highlighting the importance of strategic equipment acquisition.

In summary, the advantages of leasing equipment for construction projects in 2025 are evident: reduced expenses, decreased maintenance responsibilities, access to cutting-edge technology, and the flexibility to meet diverse needs. This approach not only streamlines operations but also contributes significantly to the overall success of construction efforts. For more information and to reserve equipment, contact EZ Equipment Rental at (214) 951-7800.

Step-by-Step Guide to Renting Crimping Tools

Leasing equipment for shaping effectively requires a structured method to guarantee you fulfill your needs without unnecessary complications. Follow these steps to streamline the process:

- Identify Your Needs: Start by determining the specific kind of crimping tool rental required for your task. Consider factors such as size, material, and specific application to ensure you choose the right instrument.

- Research Rental Companies: Seek out reputable rental companies in the Dallas-Fort Worth area that provide crimping tool rentals. For instance, EZ Equipment Rental is known for its extensive inventory of well-maintained equipment and flexible rental options. With a wide selection of equipment and expert guidance, EZ Equipment Rental stands out as a reliable choice for construction resources tailored to your project needs.

- Compare Rates and Terms: Once you have a list of potential rental companies, evaluate their rental rates, terms, and conditions. For 2025, average rental rates for fastening equipment in the Dallas-Fort Worth area can vary, so this comparison will assist you in identifying the most cost-effective option while ensuring you understand any additional fees or requirements.

- Check Availability: Confirm that the crimping device you need is available for your desired rental period. This step is crucial, especially during peak construction seasons when demand for equipment can be high.

- Review the Rental Agreement: Before finalizing your rental, carefully read through the rental agreement. Pay close attention to terms regarding maintenance responsibilities, liability coverage, and return policies to avoid any surprises later.

- Inspect the Equipment: Upon receiving the equipment, conduct a thorough inspection for any signs of damage or excessive wear. Ensuring that the instrument aligns with your standards is essential for both safety and efficiency.

- Return the Equipment: After finishing your assignment, return the equipment according to the rental agreement. Make sure it is clean and in good condition to prevent incurring additional fees.

By adhering to these steps, you can navigate the crimping tool rental process seamlessly, ensuring you have the appropriate equipment for your building requirements while benefiting from the reliability and assistance provided by EZ Equipment Rental, serving the DFW Metroplex. As noted by Robin Young, a Senior Researcher, "Choosing a reputable rental company is essential for ensuring project success and minimizing risks." Additionally, understanding local market dynamics, such as those highlighted in the Sherman-Denison housing market analysis, can provide insights into rental demand and availability.

Maintaining Rented Crimping Tools: Best Practices for Construction Managers

To ensure the longevity and optimal performance of rented crimping tools, construction managers must adhere to best practices that guarantee reliability and efficiency:

- Clean After Use: Removing debris or residue from the implement after each use is essential. This practice prevents buildup that can hinder performance and prolong the lifespan of the equipment.

- Inspect Regularly: Conduct thorough inspections for signs of wear or damage before and after each use. Regular checks are vital to maintain the functionality and safety of the crimping tool rental.

- Follow Manufacturer Guidelines: Always adhere to the specific maintenance instructions provided by the rental company or manufacturer. These guidelines are designed to maximize the efficiency and durability of a crimping tool rental.

- Store Properly: When not in use, keep the device in a dry, protected area. This minimizes exposure to moisture and harsh environmental conditions that could lead to deterioration.

- Report Issues Promptly: Should any problems arise during the crimping tool rental period, it is crucial to report them to the rental company immediately. Addressing issues early can prevent further complications and ensure the tool remains in good working order.

In 2025, maintaining rented equipment is more critical than ever. Statistics indicate that improper maintenance can lead to significant performance issues, impacting project timelines and costs. Notably, rental expenses are not considered liabilities, which can enhance borrowing power for companies, making renting a financially sound choice. Additionally, the rental market is optimistic, with a Confidence Index standing at 66 and 48% of rental companies planning to invest in new equipment this year.

By implementing these best practices, construction managers can enhance efficiency and reduce overhead, ultimately preparing their teams for future challenges. Furthermore, leveraging technology in equipment rental, such as accounts payable and logistics software, can streamline the maintenance process, saving time and reducing costs associated with tool management across multiple job sites. As Nathan Venables, general manager at Kennards Hire, notes, battery, solar, and hybrid power solutions are becoming more accessible and efficient, providing viable alternatives to traditional equipment options.

Conclusion

Crimping tools are not merely accessories; they are essential components that significantly influence the safety and efficiency of construction projects. Understanding the various types of crimping tools—manual, hydraulic, and electric—enables construction managers to select the right tool for specific tasks, ultimately enhancing project outcomes. The importance of ergonomics and compatibility with connectors cannot be understated, as these factors directly impact the quality of crimping and overall productivity.

Renting crimping tools offers distinct advantages, including cost savings, reduced maintenance responsibilities, and access to the latest technology. This approach allows project managers to allocate resources more effectively while adapting to fluctuating project demands. As the construction landscape evolves, the decision to rent rather than buy can streamline operations and ensure that teams are equipped with the best tools for the job.

To maximize the benefits of rented crimping tools, adhering to best maintenance practices is crucial. Regular cleaning, inspections, and following manufacturer guidelines will extend tool life and maintain optimal performance. By embracing these strategies, construction professionals can not only enhance efficiency but also prepare their teams for future challenges.

In conclusion, the informed selection and management of crimping tools play a pivotal role in the success of construction projects in 2025 and beyond. By leveraging the right tools—whether rented or owned—construction managers can significantly improve safety, efficiency, and project outcomes, paving the way for a more productive future in the industry.

Frequently Asked Questions

What are crimping instruments used for?

Crimping instruments are used to deform materials, particularly wires or cables, to ensure secure connections. They are essential in electrical work, plumbing, and various construction applications.

What are the different types of crimping tools?

The main types of crimping tools are manual, hydraulic, and electric. Manual crimpers are popular for their ease of use and portability, while hydraulic crimpers are designed for larger, more demanding tasks requiring greater force.

Why are crimping tools important in construction?

Crimping tools are crucial for creating reliable electrical connections and secure fittings, which are essential for the safety and efficiency of construction projects.

What factors should be considered when selecting a crimping tool?

Key factors include the type of material being crimped, the size of the connectors, the anticipated volume of work, and ensuring compatibility between the tool and the connectors.

How does ergonomics affect the use of crimping tools?

Ergonomics play a critical role, particularly for tasks requiring extended use. Tools designed with ergonomic features can minimize user fatigue and enhance productivity.

What is the significance of maintenance in crimping tools?

Maintenance and operational aspects are more critical than environmental factors in influencing productivity. Choosing high-quality equipment that can withstand demanding conditions is essential.

What advancements are being made in fastening technology?

The integration of advanced fastening devices, such as battery-powered models, is enhancing productivity and safety during wire assembly, reflecting ongoing evolution in fastening technology.

What is the projected demand for fastening devices in North America?

North America is expected to experience the highest demand for fastening devices during the forecast period, indicating a growing reliance on these instruments in construction.

How has the average size of connectors changed in recent years?

The average size of connectors used in construction projects has evolved, necessitating careful evaluation of tool specifications to ensure compatibility with the connectors.