Key Highlights:

- Dock plates are portable metal structures that bridge gaps between loading areas and trucks, enhancing safety and efficiency during loading and unloading.

- Different types of dock plates, such as aluminium and steel, cater to various load capacities and operational needs.

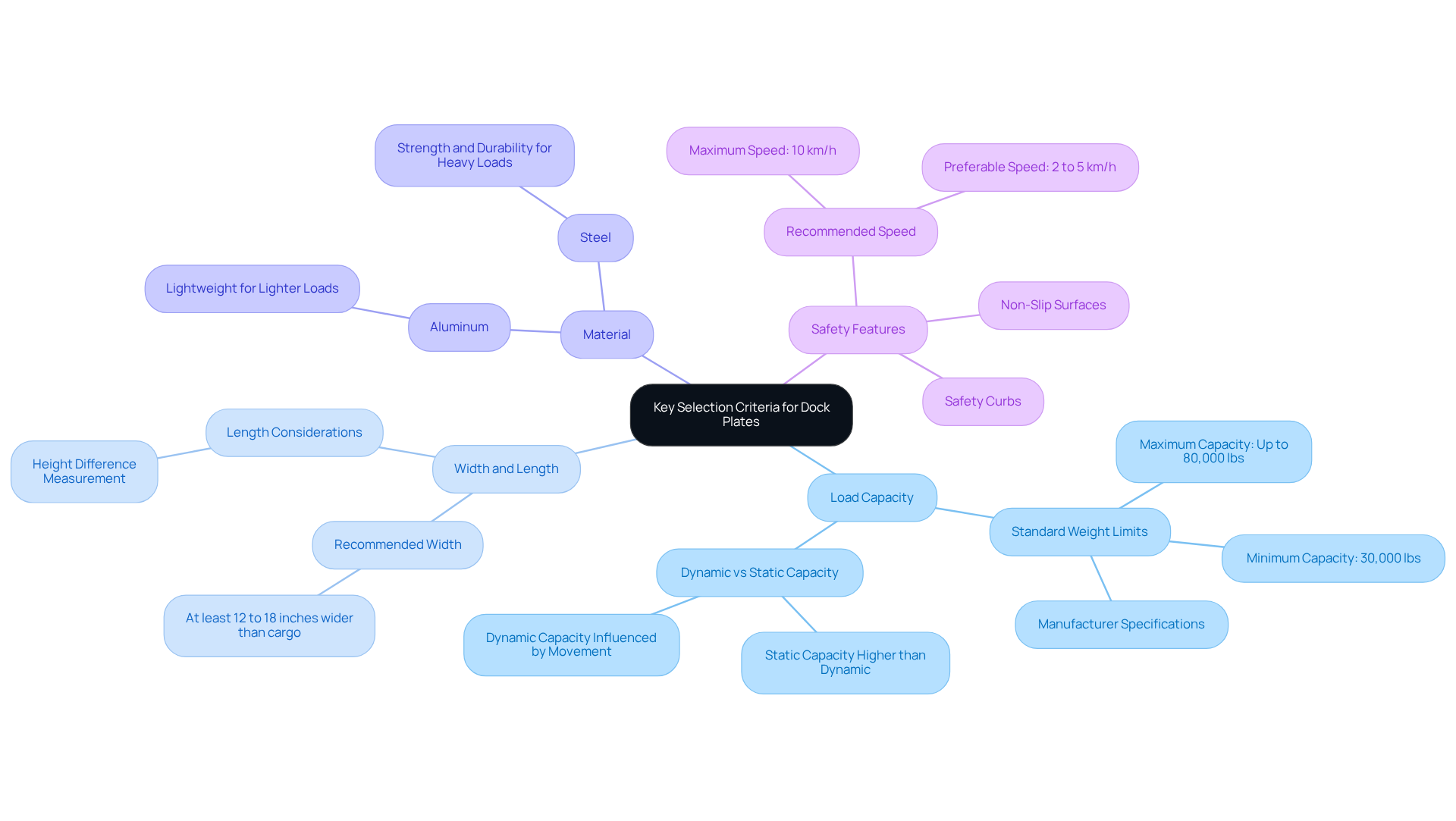

- Key selection criteria for dock plates include load capacity, dimensions (width and length), material choice, and safety features.

- Load capacity should match the maximum weight of cargo, with standard capacities ranging from 30,000 to 80,000 pounds.

- Width should be 12-18 inches wider than the cargo, while length must accommodate height differences between the platform and truck bed.

- Aluminium plates are lightweight and corrosion-resistant, suitable for lighter loads, whereas steel plates offer strength for heavier applications.

- Safety features like non-slip surfaces and curbs are essential for preventing accidents.

- To find dock plate rental services, utilise online searches, local directories, and social media, focusing on specialised leasing companies.

- Evaluate rental options based on equipment quality, pricing structure, customer support, and lease terms to ensure reliability and efficiency.

Introduction

Navigating the logistics of loading and unloading goods is no small feat, particularly when it comes to selecting the right equipment. Dock plates are essential tools that ensure safety and efficiency, effectively bridging the gap between trucks and loading areas. Understanding the significance of these devices is crucial for any operation.

This guide outlines the essential steps for successfully renting dock plates, emphasizing key selection criteria, rental options, and effective strategies to find reliable services nearby.

With numerous choices available, how can you ensure that you’re making the best decision for your specific operational needs?

Understand Dock Plates: Definition and Importance

Loading platforms are essential tools in the logistics industry, serving as flat, portable metal structures that bridge the gap between loading areas and trucks or trailers. These platforms facilitate the safe and efficient loading and unloading of goods, particularly in environments where height differences pose challenges. Their importance cannot be overstated; they significantly reduce the risk of accidents, minimize potential damage to products, and optimize operations in warehouses and distribution centers.

Understanding the various types of loading platforms available, such as aluminum and steel options, is crucial. Each type is designed to accommodate different load capacities and operational requirements, ensuring that businesses can select the right platform for their specific needs. For example, aluminum platforms are lightweight and corrosion-resistant, making them ideal for frequent use, while steel platforms offer superior strength for heavier loads.

Investing in the right loading platform not only enhances safety but also boosts overall efficiency. By preventing accidents and protecting goods, these platforms contribute to smoother operations and increased productivity. Don't underestimate the impact of choosing the right equipment; it can make all the difference in your logistics processes.

Ready to elevate your loading and unloading operations? Explore our range of loading platforms today and discover how they can transform your workflow. Contact us now to learn more about our offerings and find the perfect solution for your business needs.

Identify Key Selection Criteria for Dock Plates

When selecting a dock plate, it’s crucial to consider several key criteria that ensure safety and efficiency in your operations.

-

Load Capacity is paramount. Ensure the platform can support the maximum weight of the loads you will be managing. Standard hydraulic loading levelers typically start with a weight capacity of 30,000 pounds, with some models extending up to 80,000 pounds. Always check the manufacturer's specifications for precise weight limits to prevent structural failures during operations. Experts warn that neglecting the required load capacity can lead to serious issues, such as platform collapse due to insufficient support.

-

Next, consider the Width and Length of the loading platform. It should be at least 12 to 18 inches broader than the cargo being moved to guarantee stability. Additionally, measure the height difference between the platform and the truck bed to determine the appropriate length. This will facilitate a smooth transition and minimize the risk of accidents.

-

The Material of the dock plate is another critical factor. Choose between aluminum and steel based on the weight of the loads and the frequency of use. Aluminum loading platforms are lightweight and ideal for lighter loads, while steel platforms are renowned for their exceptional strength and durability, making them suitable for heavy-duty applications. Selecting the right material is essential for ensuring longevity and safety in your operations.

-

Lastly, prioritize Safety Features. Look for platforms equipped with non-slip surfaces and safety curbs to prevent accidents during loading and unloading. A maximum speed of 10 km/h is recommended for traveling across the leveler platform, with a preferable speed between 2 to 5 km/h to enhance operational safety, especially in busy construction environments where efficiency and worker safety are paramount.

By considering these criteria, you can ensure that your dock plate meets the demands of your operations while prioritizing safety and reliability.

Locate Dock Plate Rental Services in Your Area

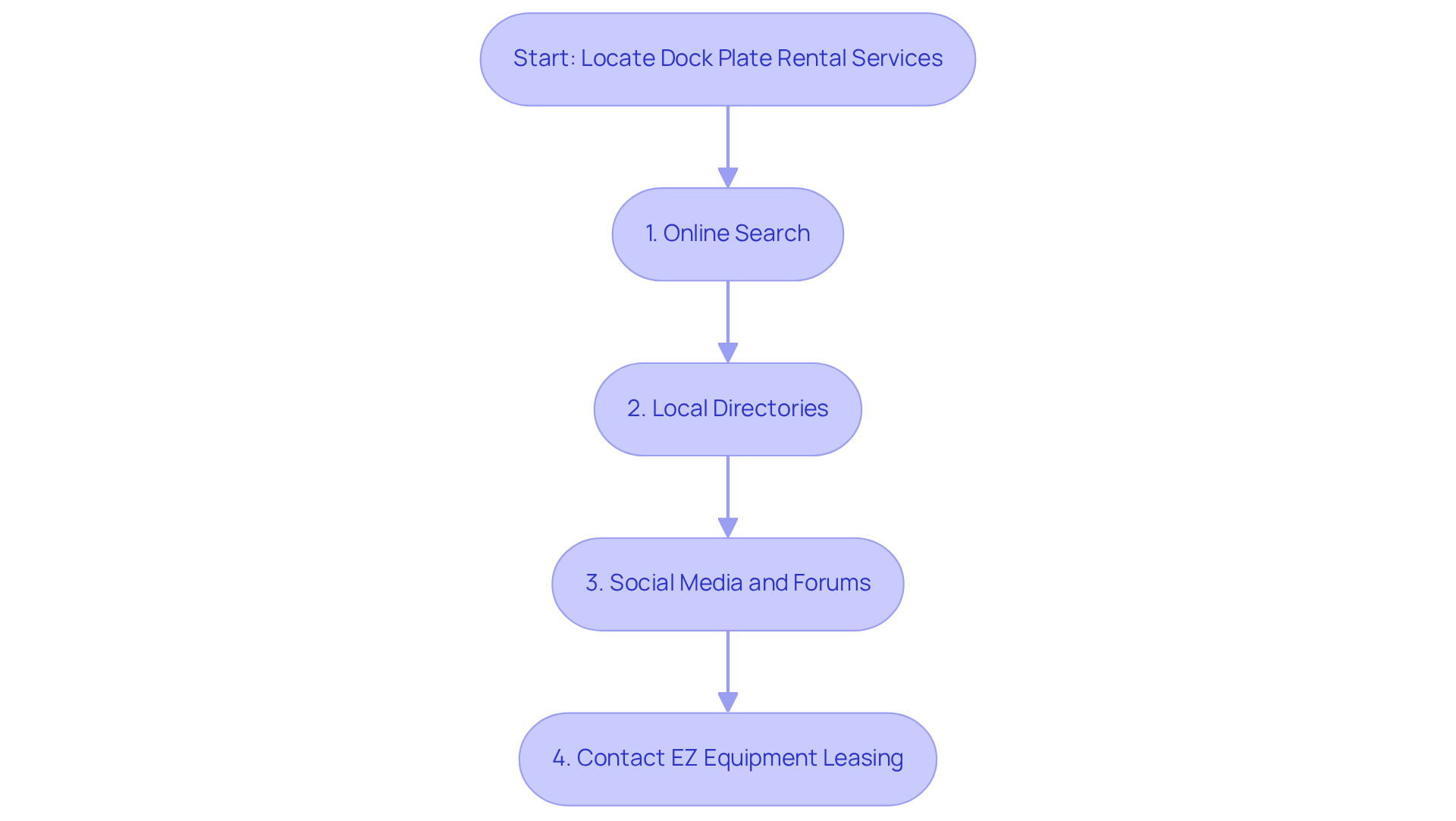

To effectively locate dock plate rental services in your area, consider these powerful strategies:

-

Online Search: Start by utilizing search engines to pinpoint equipment leasing companies nearby. By including specific keywords like 'dock plate rental near me' along with your location, you can significantly enhance your search results.

-

Local Directories: Dive into local business directories or platforms like Yelp. These resources provide customer reviews of leasing services. Focus on companies that specialize in construction or industrial tools to ensure you receive quality and reliability.

-

Social Media and Forums: Engage with local construction or machinery leasing groups on social media platforms. By interacting with community members, you can gather valuable suggestions for trustworthy leasing services.

-

Contact EZ Equipment Leasing: As a leading tool leasing provider in the Dallas-Fort Worth region, EZ Equipment Leasing provides a diverse selection of dock plate rental near me, accommodating various sizes and weight capacities to meet your project needs. With flexible leasing conditions and competitive pricing, they simplify the process of obtaining the tools you require without overspending. Don’t hesitate to reach out to them at (214) 951-7800 to check availability and pricing options.

In light of the expanding equipment leasing market in Irving, TX, which is poised for significant growth, employing these methods can greatly enhance your chances of finding the right service. Industry specialists emphasize the importance of thorough research and community engagement when selecting service providers, ensuring you make informed decisions that align with your project requirements.

Evaluate Rental Options: Quality, Pricing, and Support

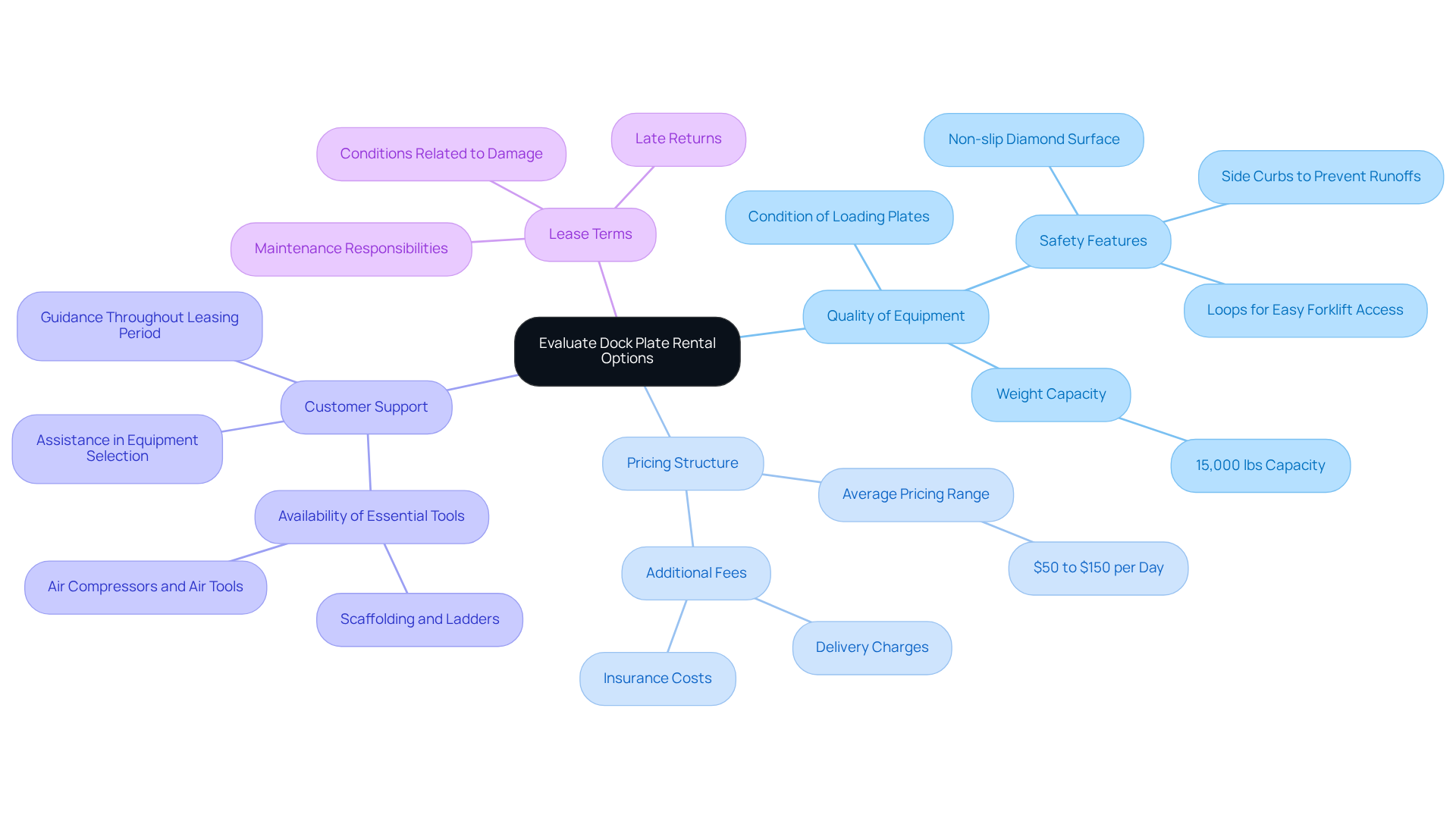

When evaluating dock plate rental near me options, it’s essential to consider several critical factors that can significantly impact your operations.

-

Quality of Equipment: The condition of loading plates is paramount. Inspect for any signs of wear and tear to ensure that the equipment meets safety standards. For example, a heavy-duty steel dock board measuring 84 inches by 72 inches can support a weight capacity of 15,000 lbs, making it ideal for loading and unloading operations. Its all-welded steel structure and non-slip diamond surface enhance safety and reliability. Additionally, features like side curbs to prevent runoffs and loops that flip up for easy forklift access further ensure efficient material handling.

-

Pricing Structure: Conduct a thorough comparison of leasing prices across various companies. In 2025, average pricing for dock plate leases typically ranges from $50 to $150 per day, depending on the model and specifications. Be mindful of additional fees that may arise, such as delivery charges or insurance costs, which can affect the overall expense. Understanding the pricing dynamics related to different models and specifications can help you make an informed decision.

-

Customer Support: Opt for a leasing service that prioritizes excellent customer support. This includes assistance in selecting the right equipment, answering questions, and providing guidance throughout the leasing period. A knowledgeable team can significantly enhance your leasing experience, ensuring you have the right tools for your project. It’s also beneficial to consider the availability of other essential tools, such as scaffolding and ladders, which are crucial for construction projects.

-

Lease Terms: Carefully review the lease agreement to understand the conditions related to damage, late returns, and maintenance responsibilities. A clear comprehension of these terms can help you avoid unexpected charges and ensure a smooth rental process. By paying attention to these critical factors, you can make a confident choice in your dock plate rental near me, ensuring reliability and efficiency in your operations.

Conclusion

Selecting the right dock plate for rental is crucial in optimizing logistics operations. This guide has illuminated the various aspects of dock plates, underscoring their essential role in ensuring safe and efficient loading and unloading processes. By grasping the key criteria for selection, businesses can make informed decisions that enhance both safety and productivity.

The article explored vital factors such as:

- Load capacity

- Dimensions

- Material selection

- Safety features

All of which significantly influence the best dock plate for specific operational needs. Furthermore, strategies for locating reliable rental services were discussed, highlighting the importance of thorough research and community engagement. Evaluating rental options based on:

- Equipment quality

- Pricing

- Customer support

- Lease terms

Empowers businesses to confidently choose the right solutions for their projects.

Ultimately, leveraging this knowledge streamlines operations and promotes a safer work environment. By prioritizing the right dock plate rental services, businesses can enhance their logistics processes, reduce risks, and achieve greater operational efficiency. Taking the time to explore local options and assess them against the outlined criteria will lead to successful outcomes in any loading and unloading scenario.

Frequently Asked Questions

What are dock plates and what is their purpose?

Dock plates are flat, portable metal structures that bridge the gap between loading areas and trucks or trailers, facilitating the safe and efficient loading and unloading of goods.

Why are dock plates important in the logistics industry?

Dock plates are crucial as they significantly reduce the risk of accidents, minimize potential damage to products, and optimize operations in warehouses and distribution centers.

What types of loading platforms are available?

The main types of loading platforms available are aluminum and steel options, each designed to accommodate different load capacities and operational requirements.

What are the advantages of aluminum loading platforms?

Aluminum platforms are lightweight and corrosion-resistant, making them ideal for frequent use.

What benefits do steel loading platforms offer?

Steel platforms provide superior strength, making them suitable for handling heavier loads.

How does investing in the right loading platform impact operations?

Investing in the right loading platform enhances safety, boosts overall efficiency, prevents accidents, and protects goods, contributing to smoother operations and increased productivity.

How can businesses find the right loading platform for their needs?

Businesses should explore various loading platform options to discover solutions that can transform their workflow and meet their specific requirements.