Key Highlights:

- Forklifts are essential for material handling, with various types designed for specific tasks.

- Counterbalance forklifts are versatile for lifting heavy loads in warehouses and outdoor settings.

- Reach trucks are ideal for accessing items stored deep on shelves in tight spaces.

- Pallet jacks are compact devices for moving pallets over short distances, useful in retail and warehouses.

- Rough terrain vehicles are built for outdoor applications on uneven surfaces, crucial for construction.

- Telehandlers combine lift truck and crane capabilities, beneficial in construction and agriculture.

- Key factors for selecting a forklift include load capacity, lift height, terrain suitability, fuel type, and manoeuvrability.

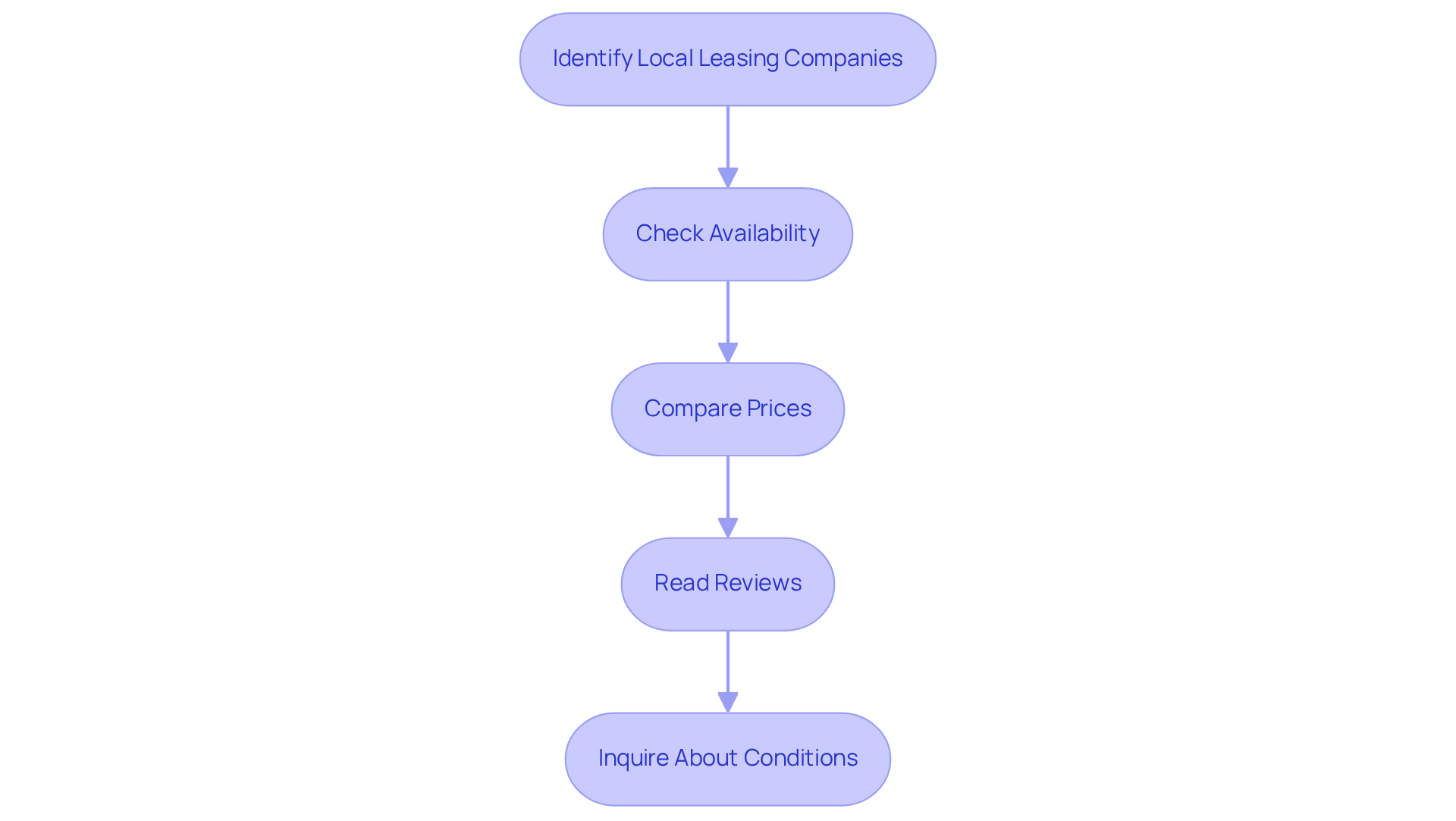

- Researching rental options in Omaha involves identifying local companies, checking availability, comparing prices, reading reviews, and understanding leasing conditions.

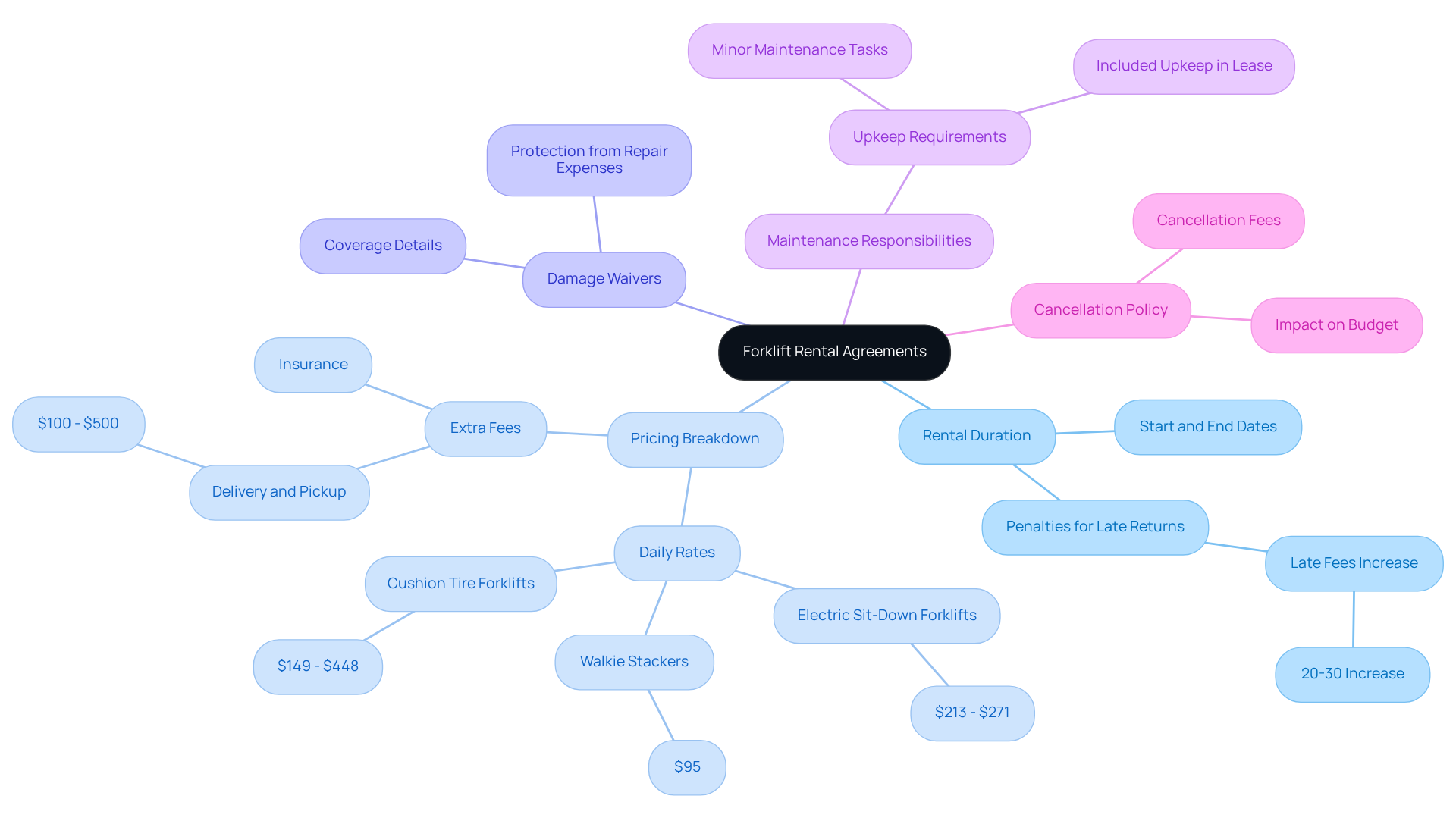

- Reviewing rental agreements should cover rental duration, pricing breakdown, damage waivers, maintenance responsibilities, and cancellation policies.

Introduction

Navigating the forklift rental landscape can feel overwhelming, especially with the vast array of options available in Omaha. It's essential to grasp the different types of forklifts and their specific applications to make informed decisions that boost safety and efficiency on the job site.

With numerous factors to weigh - from load capacity to rental agreements - how can you ensure you select the right equipment without overspending or encountering unexpected issues?

This guide simplifies the forklift rental process, offering vital insights and practical steps to help you secure the best rental options tailored to your unique project needs.

Understand Different Types of Forklifts and Their Uses

Forklifts are indispensable tools in material handling, with various types specifically designed for distinct tasks and environments. Let’s explore some of the most common types:

-

Counterbalance Forklifts: As the most prevalent type, counterbalance forklifts excel at lifting heavy loads in both warehouses and outdoor settings. Equipped with a counterweight at the back, they effectively distribute weight, making them versatile for applications ranging from loading docks to construction sites.

-

Reach Trucks: Perfect for navigating tight corridors, reach trucks extend their prongs to access items stored deep on shelves. This capability significantly enhances storage efficiency, making them invaluable in high-density warehouse environments.

-

Pallet Jacks: These compact devices, available in both manual and electric versions, are designed for moving pallets over short distances. Particularly useful in retail and warehouse settings, they streamline low-level material handling tasks.

-

Rough Terrain Vehicles: Built to handle uneven surfaces, rough terrain vehicles are essential for outdoor applications, especially in construction. Their large tires and robust design enable them to manage substantial weights on challenging terrains, ensuring efficient material transport. EZ Equipment Rental in Dallas offers a range of well-maintained rough terrain lifting machines, providing the right tools for your specific project needs.

-

Telehandlers: Combining the capabilities of a lift truck and a crane, telehandlers are adaptable machines that can raise and position loads at impressive heights. They are particularly beneficial in construction and agricultural settings, where lifting capabilities are crucial.

Understanding these types of lift trucks and their specific applications will empower you to select the right equipment for your project needs, enhancing both safety and efficiency. Don't hesitate to reach out to us for expert advice and top-quality equipment that meets your requirements.

Evaluate Key Factors for Selecting the Right Forklift

When selecting a forklift, several key factors must be considered to ensure optimal performance and safety on the job site.

-

Load Capacity: Determining the maximum weight the forklift needs to lift is essential. A pallet truck rated at 5,000 lbs at a standard 24-inch center may only handle 4,000 lbs at maximum height due to stability issues. Ensure the chosen model can comfortably handle the required weight, factoring in any attachments that may reduce capacity.

-

Lift Height: Assess the required lift height for your operations. Different types of lifting machines offer varying maximum heights; for instance, counterbalance models typically lift loads between 10 to 20 feet, while reach trucks can extend up to 30 feet. Understanding these specifications is crucial for selecting the right equipment for your tasks.

-

Terrain: Evaluate the surroundings where the lifting vehicle will function. Rough terrain lift trucks are designed for outdoor, uneven surfaces, making them ideal for construction sites. In contrast, electric pallet trucks are better suited for indoor use, particularly in warehouses where emissions and noise are concerns.

-

Fuel Type: Choose between electric, diesel, or propane-powered lifting machines based on your operational needs and environmental considerations. Electric models are gaining popularity due to their lower maintenance costs and up to 80% fuel savings compared to internal combustion engine units.

-

Maneuverability: Consider the available space for operation. Narrow aisle vehicles excel in tight spaces, allowing for efficient navigation in congested areas, while larger models are more effective in open environments.

By thoroughly assessing these factors, you can choose a lifting machine that not only boosts productivity but also emphasizes safety on your job site. As one construction project manager noted, "Understanding the lift height and load capacity is critical for ensuring that the equipment meets the demands of the project while maintaining safety standards." This approach will help you make informed decisions that align with your specific operational requirements.

Research and Compare Forklift Rental Options in Omaha

To secure the best forklift rental options in Omaha, follow these essential steps:

-

Identify local leasing companies by looking for forklift rental Omaha. Notable providers include BigRentz, Honeyman Rent-All, and RAKA Rentals, which offer extensive listings of available equipment.

-

Check Availability: After compiling a list of companies, verify their inventory online or contact them directly to confirm the availability of the specific forklift type you require. Availability can vary significantly between providers, so it's crucial to be proactive. A representative from The Herc-U-Lift team emphasizes, "Demand surges during construction season and end-of-the-year warehouse rushes often raise leasing costs," highlighting the importance of checking availability during peak periods.

-

Compare Prices: Gather quotes from various leasing firms. Inquire about daily, weekly, and monthly rates, and be sure to ask about any additional fees for delivery, fuel, or insurance. For instance, prices for a 5,000 lbs cushion tire warehouse lift generally range from $150 to $269 each day, while a 15,000 lbs pneumatic lift may cost around $754 daily. It's also essential to recognize that forklift leasing costs can vary from $1,500 to $4,000 per month for those considering extended leasing periods.

-

Read Reviews: Investigate customer reviews and ratings on platforms like Yelp or Google. This feedback can provide valuable insights into the reliability and service quality of each leasing company, helping you make an informed decision.

-

Inquire About Conditions: Contact the leasing firms to clarify their leasing terms, including maintenance policies, damage waivers, and cancellation policies. Understanding these specifics is crucial, as they can significantly influence your overall leasing experience and expenses. Be mindful of potential hidden costs associated with lease agreements, such as delivery fees or additional charges for attachments, to budget more accurately.

By conducting thorough research and making informed comparisons, you can select a company for forklift rental Omaha that aligns with your project needs and budget, ensuring a smooth and efficient process.

Review Rental Agreements and Understand Pricing Structures

Before finalizing your forklift rental omaha, it’s essential to thoroughly review the rental agreement and pricing structure to avoid any misunderstandings. Understanding these key elements can significantly impact your rental experience and budget.

Rental Duration: Clearly grasp the rental period, including start and end dates, and be aware of any penalties for late returns. Late fees can dramatically increase your overall expenses, potentially raising your final bill by 20-30% due to damage charges and excessive wear fees. Adhering to the agreed timeline is crucial to avoid these unexpected costs.

Pricing Breakdown: Look for a detailed analysis of expenses, which typically includes daily rates ranging from $150 to $500. For instance, Electric Sit-Down Forklifts are priced between $213 and $271 per day, while Cushion Tire Forklifts range from $149 to $448 per day. Additionally, inquire about any extra fees for delivery, pickup, or insurance, as these can accumulate quickly and affect your budget.

Damage Waivers: Check if the lease includes a damage waiver and understand what it covers. This can protect you from unforeseen repair expenses that may arise from regular wear and tear or accidental damage during the leasing period, ensuring peace of mind.

Maintenance Responsibilities: Clarify who is responsible for upkeep during the lease. Some companies may require you to manage minor maintenance tasks, while others may include upkeep in the lease agreement. Understanding what is included in the lease is essential to prevent unexpected obligations that could disrupt your project.

Cancellation Policy: Familiarize yourself with the terms for canceling your booking. Some companies impose fees for cancellations made within a specific timeframe, which can impact your budget if plans change. Insights from industry experts suggest that understanding these fees is vital for effective budget management.

By carefully reviewing the forklift rental omaha agreement and understanding the pricing structures, you can ensure a smooth rental experience. Make informed decisions that align with your project needs and engage with your rental provider confidently.

Conclusion

Selecting the right forklift for rental in Omaha is crucial for maximizing efficiency and ensuring safety in your operations. Understanding the various types of forklifts and their specific applications empowers you to make informed decisions that align perfectly with your project needs. This guide provides essential insights into evaluating different models, assessing key selection factors, and navigating the rental process with confidence.

Key considerations include:

- Understanding load capacities

- Lift heights

- Terrain suitability

When choosing a forklift, further research is necessary:

- Researching local rental options

- Comparing prices

- Reviewing rental agreements

These are vital steps to guarantee a seamless experience. By taking these factors into account, you can avoid unexpected costs and ensure that the equipment meets your operational requirements.

In conclusion, being well-informed about the forklift rental process not only boosts productivity but also enhances safety on the job site. Whether you're managing a construction project or overseeing warehouse logistics, having the right equipment is essential. Take action now by exploring rental options and engaging with local providers to find the best forklift rental in Omaha that fits your needs and budget.

Frequently Asked Questions

What are the main types of forklifts mentioned in the article?

The main types of forklifts mentioned are counterbalance forklifts, reach trucks, pallet jacks, rough terrain vehicles, and telehandlers.

What is the primary use of counterbalance forklifts?

Counterbalance forklifts are primarily used for lifting heavy loads in both warehouses and outdoor settings, making them versatile for various applications like loading docks and construction sites.

How do reach trucks enhance storage efficiency?

Reach trucks enhance storage efficiency by extending their prongs to access items stored deep on shelves, making them ideal for navigating tight corridors in high-density warehouse environments.

What are pallet jacks designed for?

Pallet jacks are designed for moving pallets over short distances and are particularly useful in retail and warehouse settings for low-level material handling tasks.

What features make rough terrain vehicles suitable for outdoor applications?

Rough terrain vehicles are built with large tires and a robust design to handle uneven surfaces, enabling them to manage substantial weights on challenging terrains, especially in construction.

What is a telehandler, and where is it commonly used?

A telehandler is a versatile machine that combines the capabilities of a lift truck and a crane, commonly used in construction and agricultural settings for raising and positioning loads at impressive heights.

How can understanding different types of forklifts benefit project planning?

Understanding different types of forklifts and their specific applications helps in selecting the right equipment for project needs, enhancing both safety and efficiency.