Overview

The primary focus of this article is to delineate the essential features of scissor lifts that construction project managers must be cognizant of. It elaborates on critical aspects such as:

- Safety mechanisms

- Load capacities

- Power sources

- Maintenance requirements

Understanding these features is not merely beneficial; it is crucial for enhancing safety and efficiency on construction sites. By familiarizing themselves with these elements, project managers can significantly mitigate risks and optimize operational performance.

Key Highlights:

- EZ Equipment Rental offers a diverse range of scissor lifts with essential features for construction tasks, emphasizing reliability and quality service.

- Key features include hydraulic systems for smooth operation, various platform sizes, and safety mechanisms such as guardrails and emergency stop buttons.

- Scissor lifts are available in electric and diesel models, catering to both indoor and outdoor applications, with load capacities ranging from 500 lbs to over 2,500 lbs.

- Platform height must be carefully considered, factoring in working height, project requirements, and site conditions to ensure safety and compliance.

- Different types of scissor lifts include electric, diesel, rough terrain, compact, and pneumatic models, each suited for specific environments and tasks.

- Safety features like guardrails, load indicators, and stability systems are crucial to prevent accidents and enhance operational security.

- Proper maintenance practices, including regular inspections and battery care, are essential for ensuring the longevity and safe operation of scissor lifts.

- Flexible rental options, including short-term and long-term rentals, allow for cost-effective access to equipment based on project needs.

- Key specifications to consider when selecting a scissor lift include platform height, load capacity, overall dimensions, and protective features.

Introduction

In the dynamic world of construction, scissor lifts have emerged as indispensable tools, providing unparalleled versatility and efficiency across a broad spectrum of projects. Their myriad features are meticulously designed to enhance safety and performance, making it essential for project managers and operators to grasp the nuances of these machines.

This comprehensive overview explores the critical attributes, platform capacities, and various types of scissor lifts available, offering invaluable insights into selecting the right equipment tailored to specific project needs.

Furthermore, by evaluating power sources and ensuring compliance with safety standards, this article empowers readers with the knowledge required to navigate the complexities of scissor lift selection and maintenance. Ultimately, this guidance promotes a safer and more productive work environment.

EZ Equipment Rental: Comprehensive Overview of 35 Scissor Lift Features

presents an extensive selection of elevating platforms, each equipped with essential features tailored for construction tasks. This commitment to dependability and quality service is evident in our offerings. Key attributes include:

- Hydraulic Systems: These systems ensure smooth raising and lowering, significantly enhancing operational efficiency and reliability.

- Safety Mechanisms: With guardrails and emergency stop buttons, these devices prioritize user safety, reflecting EZ Equipment Rental's dedication to exceptional customer service.

- Platform Size Options: A variety of dimensions are available to accommodate diverse tasks, ensuring versatility on the job site.

- Mobility Features: Designed for both indoor and outdoor applications, many models possess rough terrain capabilities, making them suitable for various environments.

- Power Source Variability: Users can choose between electric and diesel models, allowing for optimal fit based on their specific requirements.

- Load Capacity: Capable of handling loads from 500 lbs to over 2,500 lbs, these machines cater to a range of demands.

- Height Range: Models are available from 19 ft to 70 ft, addressing various height requirements for construction tasks.

- User-Friendly Controls: Simplified operation enhances efficiency and safety, facilitating easier management for operators.

- Maintenance Alerts: Integrated systems notify users of necessary maintenance, ensuring optimal performance and safety.

- Compact Designs: Engineered for easy maneuverability in tight spaces, these machines are ideal for urban construction sites.

In addition to these features, the economic advantages of renting equipment like these machines cannot be overlooked. For instance, engine hoists typically achieve ROI within 25-30 rental days, underscoring the cost-effectiveness of rental options for managers. Furthermore, advancements in aerial platform technology, such as the curved linkage design noted by Genie, reduce machine weight and lower replacement component costs, thereby enhancing the efficiency of these devices. With these advanced features and insights into market trends, EZ Equipment Rental's elevating platforms are expertly designed to meet the evolving demands of construction projects, significantly improving efficiency and security.

Platform Height: Key Considerations for Scissor Lift Usage

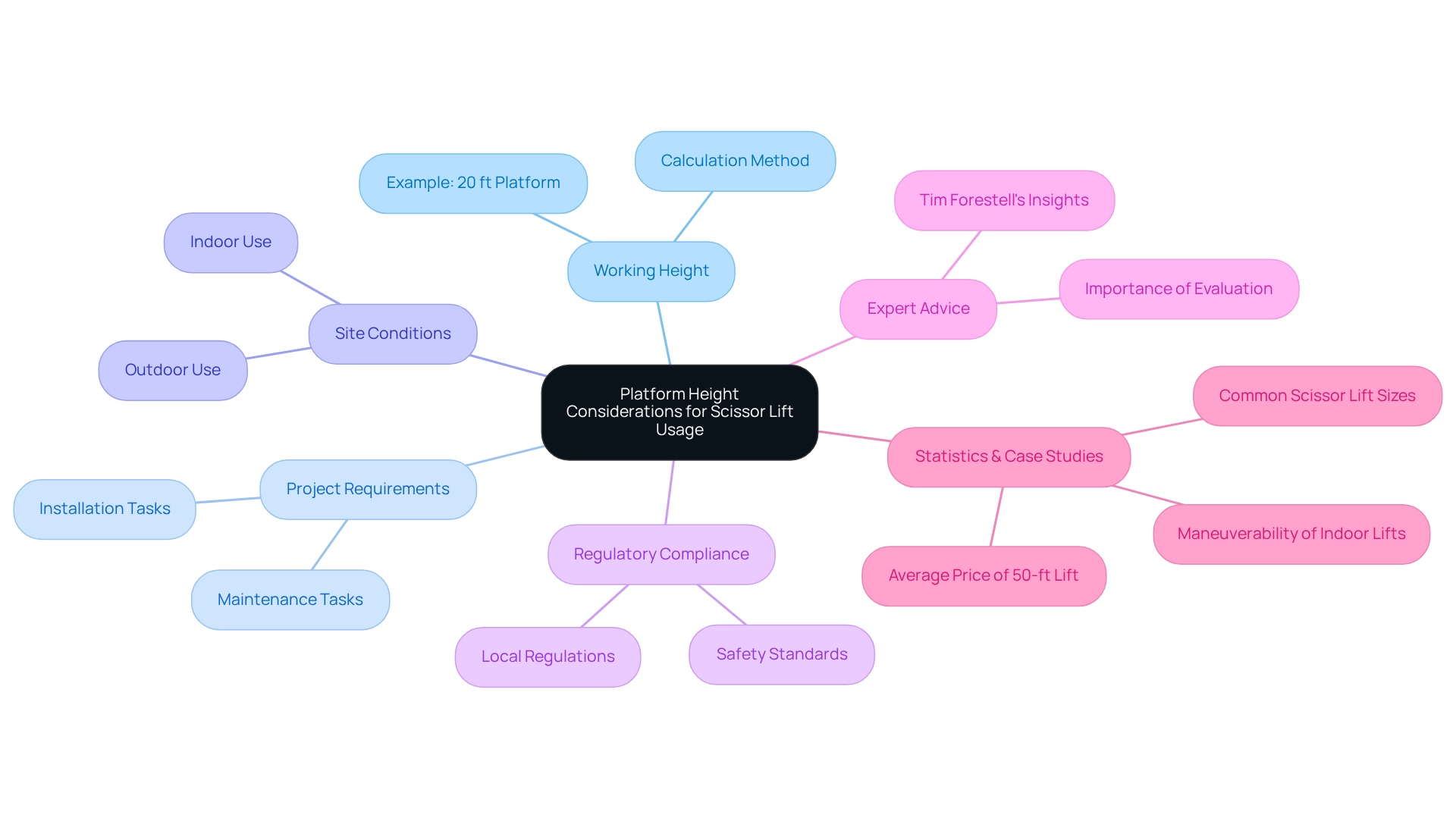

When selecting a 35 scissor lift, several key factors regarding platform height must be considered.

- Working Height: The working height is crucial for safety and efficiency. It is calculated as the platform height plus an additional 6 feet to account for the operator's reach. For instance, if a scissor mechanism has a platform height of 20 feet, the effective working height would be 26 feet.

- Project Requirements: Different tasks necessitate varying elevation heights. Installation work on elevated ceilings may require equipment that reaches 30 feet or more, while maintenance tasks might only need a device with a 15-foot reach. Understanding the specific needs of the project is essential for choosing the suitable 35 scissor lift for elevation.

- Site Conditions: The surroundings where the hoist will be utilized play a significant role in height selection. The 35 scissor lift platforms designed for indoor use are lightweight and narrow, making them ideal for confined spaces, while outdoor models are bulkier and can handle rough terrain. Ensuring that the elevator can safely reach the required height without compromising stability is paramount.

- Regulatory Compliance: Adhering to local regulations concerning maximum working heights is essential for protection. These regulations often determine the maximum height a lift can function at, ensuring that standards are upheld. Remaining aware of these regulations can help avoid expensive penalties and enhance workplace security.

- Expert Advice: Construction safety specialists stress the importance of selecting the appropriate platform height according to the specific requirements of the task. Tim Forestell, co-founder and CCO, states, "Collaborating with DOZR renters daily allows me to glimpse the evolution of various initiatives and hear stories about endeavors being developed from beginning to end." This emphasizes the necessity for thorough evaluation of the work environment and tasks to identify the most efficient elevation height for using a 35 scissor lift.

- Statistics on Requirements: In 2025, specifications for elevating platforms have advanced, with numerous initiatives now requiring devices that can reach heights of 30 feet or higher, indicating the growing complexity of construction tasks. Furthermore, the typical cost of a 50-ft. elevating platform varies from $55,000 to $70,000, which is a crucial factor for managers concerning budget limitations.

- Case Studies: A recent analysis highlighted the maneuverability of indoor platform elevating devices, which are intended for confined areas, illustrating that choosing the appropriate kind of apparatus based on the work environment is essential for optimal performance and security. Another study on typical elevating platform dimensions indicated that selecting the suitable size according to particular height and capacity needs ensures efficient performance for maintenance, installation, and construction activities.

By thoughtfully evaluating these elements, construction managers can ensure they choose the appropriate elevating device, like a 35 scissor lift, for their specific requirements, enhancing both safety and efficiency on the work site.

Platform Capacity: Understanding Load Limits for Safety and Efficiency

Platform capacity is crucial for ensuring safe operations with elevating platforms. Understanding is vital for effective project management. Each aerial platform typically has a designated maximum load capacity ranging from 500 lbs to 2,500 lbs, with models such as the Snorkel S9070RT-HC boasting a maximum platform capacity of 2,000 lbs.

Weight distribution significantly impacts stability. It is essential to ensure that weight is evenly distributed across the platform to prevent tipping or accidents. Adhering to personnel limits is equally critical; exceeding the recommended number of individuals on the platform can lead to hazardous situations. As highlighted by Hy-Brid Lifts, the PS-1430 and PS-1930 models have maximum weights of 700 lbs and 650 lbs, respectively, emphasizing the importance of understanding each model's specifications.

When utilizing platform elevating devices, consider the weight of tools and materials being handled. Overloading the platform not only risks equipment failure but also jeopardizes safety. For instance, typical weight ranges for these elevating platforms vary by height: a 19-foot model weighs between 2,580 and 2,690 lbs, while a 50-foot version can weigh approximately 17,000 lbs or more. Real-world applications demonstrate that selecting the appropriate size of a 35 scissor lift is essential for meeting specific job requirements. Case studies, such as 'Common Scissor Lift Sizes and Their Applications,' illustrate that using the right platform enhances security and efficiency, particularly in construction settings. As of 2025, adhering to load capacity regulations is vital to ensure compliance and protect personnel.

In summary, grasping platform capacity and load limits is fundamental for safe and efficient operations with a 35 scissor lift. Proper weight distribution, compliance with personnel limits, and thoughtful consideration of material handling are key factors in maximizing safety on the job site. For inquiries and bookings, contact EZ Equipment Rental at (214) 951-7800 to ensure you have the right equipment for your task.

Types of Scissor Lifts: Choosing the Right Model for Your Project

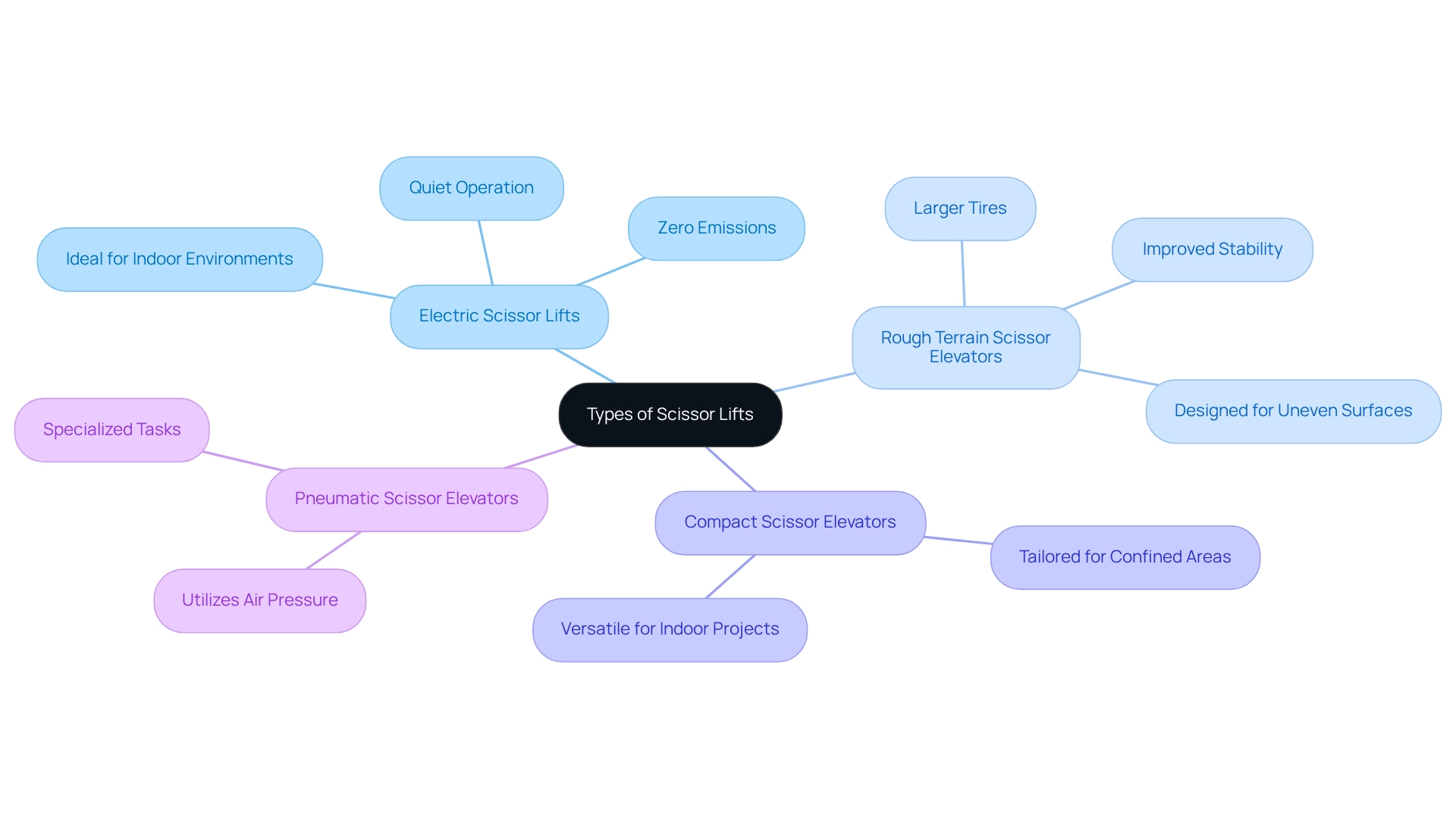

When selecting a 35 scissor lift for construction projects, it is essential to understand the various types available. The primary categories include:

- : Ideal for indoor environments, these lifts offer quiet operation and zero emissions, making them perfect for tasks in confined spaces. The 35 scissor lift, specifically diesel models, is designed for outdoor use and delivers superior power and mobility, particularly on rough terrain, making it suitable for construction sites. Notably, some diesel models feature four-wheel drive for enhanced traction on uneven surfaces.

- Rough Terrain Scissor Elevators: Equipped with larger tires and improved stability, these devices are built to navigate uneven surfaces, ensuring safety and efficiency in challenging outdoor conditions.

- Compact Scissor Elevators: Tailored for confined areas, compact models excel in indoor projects where access is restricted, providing versatility across various applications.

- Pneumatic Scissor Elevators: Utilizing air pressure for operation, these devices are often employed in specialized tasks, showcasing their unique capabilities in specific settings.

As the market evolves in 2025, the demand for electric aerial platforms continues to rise, particularly in indoor environments where their advantages—such as reduced noise and emissions—are vital. In contrast, diesel models remain preferred for their robust performance outdoors. According to industry specialists, "Electric aerial platforms are becoming more favored for indoor uses because of their ecological advantages, whereas diesel equipment is crucial for outdoor jobs needing strength and mobility." Understanding these differences is crucial for managers aiming to optimize equipment selection, particularly when considering a 35 scissor lift for their specific needs. For example, a recent case study highlighted how a construction company enhanced efficiency by selecting the appropriate type of elevating platform for their project, underscoring the importance of informed decision-making.

Safety Features: Essential Elements for Scissor Lift Operations

Key safety features to prioritize in scissor lifts include:

- Guardrails: Essential for preventing falls from the platform, guardrails serve as a fundamental safety measure that significantly reduces the risk of accidents. Their presence is crucial, especially given that an average of 20-25 fatalities occur annually while operating mobile elevating work platforms (MEWPs) and similar equipment.

- Emergency Stop Buttons: These buttons empower operators to promptly shut down the elevator in case of an emergency, ensuring a quick response to potential hazards.

- Non-Slip Surfaces: Non-slip surfaces are vital for maintaining secure footing for operators, thereby minimizing the risk of slips and falls during operation.

- Load Indicators: These indicators alert operators when approaching weight limits, helping to prevent overloading and potential equipment failure.

- Stability Systems: Designed to prevent tipping during operation, stability systems are essential for maintaining security, particularly on uneven terrain.

- Protection Interlocks: Protection interlocks ensure that the lift cannot be operated unless all operational conditions are satisfied, providing an extra layer of security for operators.

In 2025, the emphasis on these crucial protective features is more pronounced than ever, with innovations continuously enhancing their effectiveness. For example, recent advancements in protective technology have led to improved guardrail designs and more responsive emergency stop systems. As highlighted by industry specialists, the 35 scissor lift, a modest yet effective tool, has become a crucial component of various sectors, underscoring the necessity for robust protective measures.

Furthermore, the case study titled '' illustrates how regulations are implemented in real-world scenarios, showcasing the significance of these features. Regular maintenance and operator training are also critical to ensure these features function correctly, as emphasized by the quote from Forklift Inventory: "Let's work together to create a safer, more productive workplace." This collaborative approach reinforces the importance of ongoing safety practices, further enhancing workplace safety and productivity.

Engine Type: Evaluating Power Sources for Scissor Lifts

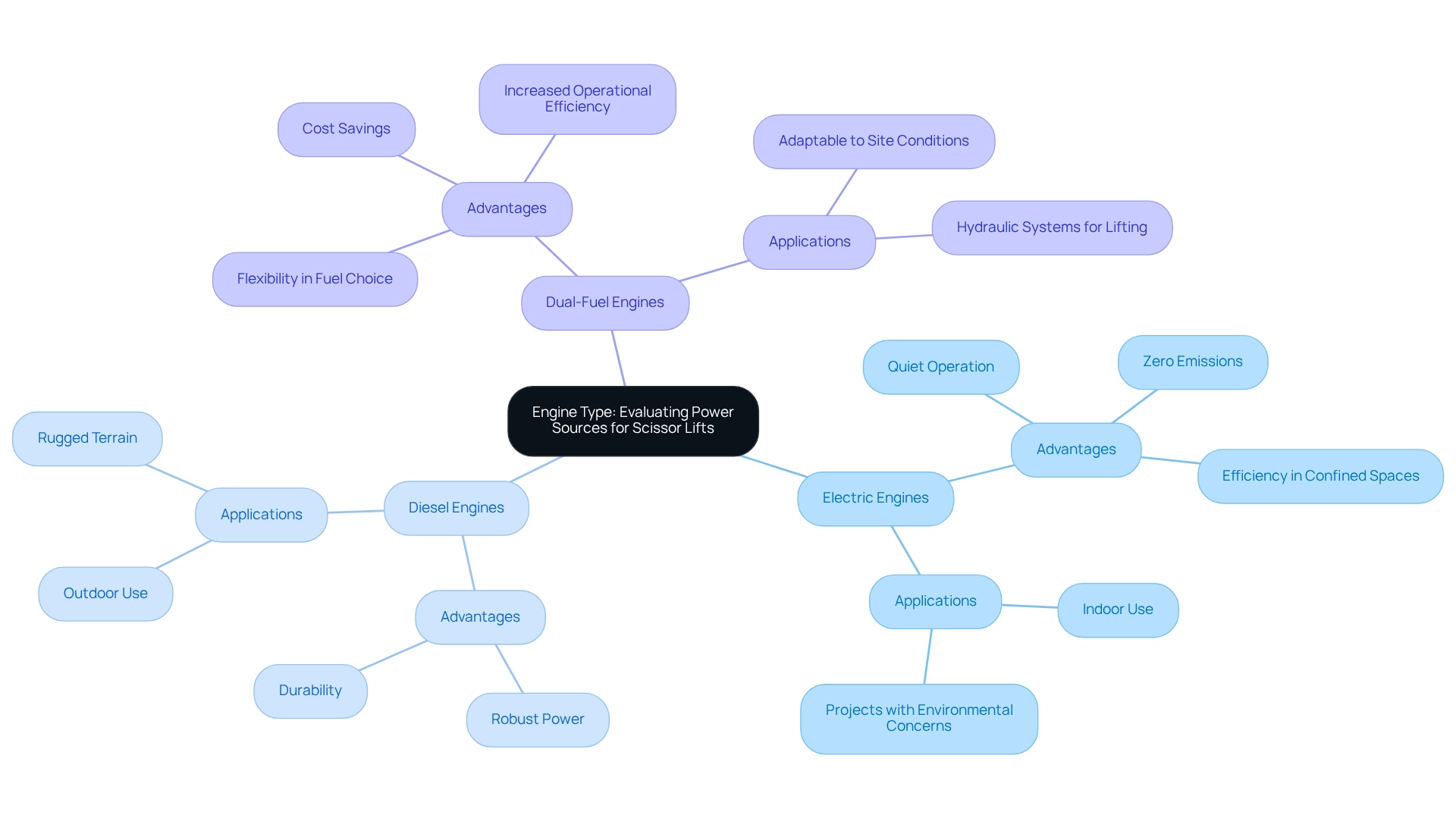

Elevating platforms can be powered by various engine types, each tailored for specific applications and environments:

- Electric Engines: Ideal for indoor use, electric models operate quietly and produce zero emissions, making them a sustainable choice for projects that require minimal environmental impact. Their efficiency is particularly advantageous in confined spaces where noise and air quality are concerns. Furthermore, electric aerial work platforms can be adjusted to different heights within their maximum reach, enhancing their adaptability on the job site.

- Diesel Engines: These engines deliver robust power, making them perfect for outdoor applications and rugged terrain. Diesel-powered elevating platforms excel in construction sites where heavy lifting and durability are critical, providing the necessary strength to navigate challenging conditions.

- Dual-Fuel Engines: By combining gasoline and propane, dual-fuel engines offer flexibility in fuel choice, allowing operators to adapt to varying site conditions and fuel availability. This versatility can lead to cost savings and increased operational efficiency in the 35 scissor lift, where hydraulic systems are commonly utilized to ensure smooth and reliable lifting operations. Their design allows for precise control, enhancing safety and performance during use.

As the industry evolves, the adoption of electric engines is rising, driven by a growing emphasis on sustainability and reduced operational costs. Recent trends indicate that are gaining popularity, reflecting a shift towards more adaptable and environmentally friendly solutions. Understanding these engine types and their applications is essential for construction project managers seeking to optimize equipment selection and enhance project efficiency. Additionally, comprehending site conditions for safe man-lift operation is crucial, ensuring that the chosen equipment meets the specific demands of the job. The future of technology in the 35 scissor lift machinery sector is intertwined with advancements, market needs, and an increasing focus on sustainability, as emphasized by industry experts. Recent discussions, such as Nitin Gadkari's proposal to utilize electric vehicles in construction, underscore the industry's transition towards greener solutions.

Machine Dimensions: Planning for Space and Accessibility

When planning for machine dimensions, several key factors must be considered to ensure optimal functionality and safety.

- Overall Height: It is crucial to verify that the lift can fit within the workspace, particularly in indoor environments where ceiling heights may be limited. This consideration is vital for maintaining safety and efficiency during operations.

- Width and Length: Evaluating the dimensions of the elevation device is essential for maneuvering through doorways and confined areas. A platform that is too wide or long may hinder movement and accessibility on the job site.

- Platform Size: Selecting an appropriately sized platform is important to accommodate the number of workers and materials required for the task. A larger platform can enhance productivity by allowing more personnel and equipment to operate simultaneously.

- Stowed Dimensions: Consider the compactness of the apparatus when it is not in use. Smaller stowed dimensions facilitate easier storage and transport, which is particularly beneficial for projects with limited space.

As develops, improvements in technology and safety regulations are influencing the design of these machines. Accessibility remains a critical focus, with manufacturers increasingly prioritizing features that enhance usability in various environments. For example, the latest trends highlight the significance of creating elevators that can easily navigate in restricted areas while offering sufficient platform size for several users. According to Autoquip, "The newest trends in elevating platform design are influencing the future of material handling."

In 2025, accessibility issues remain a major concern, with statistics showing that inadequate planning for machine dimensions can result in operational inefficiencies and risks. Professional guidance emphasizes the importance of detailed planning for scissor dimensions, ensuring that managers can effectively tackle the specific needs of each construction site. Real-world instances demonstrate how overall height factors directly affect equipment choice, influencing both safety and productivity on the job. Furthermore, a case study on Powerscreen's expansion in South Africa highlights the growing demand for equipment in the construction sector, reinforcing the importance of understanding machine dimensions in meeting project needs.

Maintenance Requirements: Keeping Your Scissor Lift in Optimal Condition

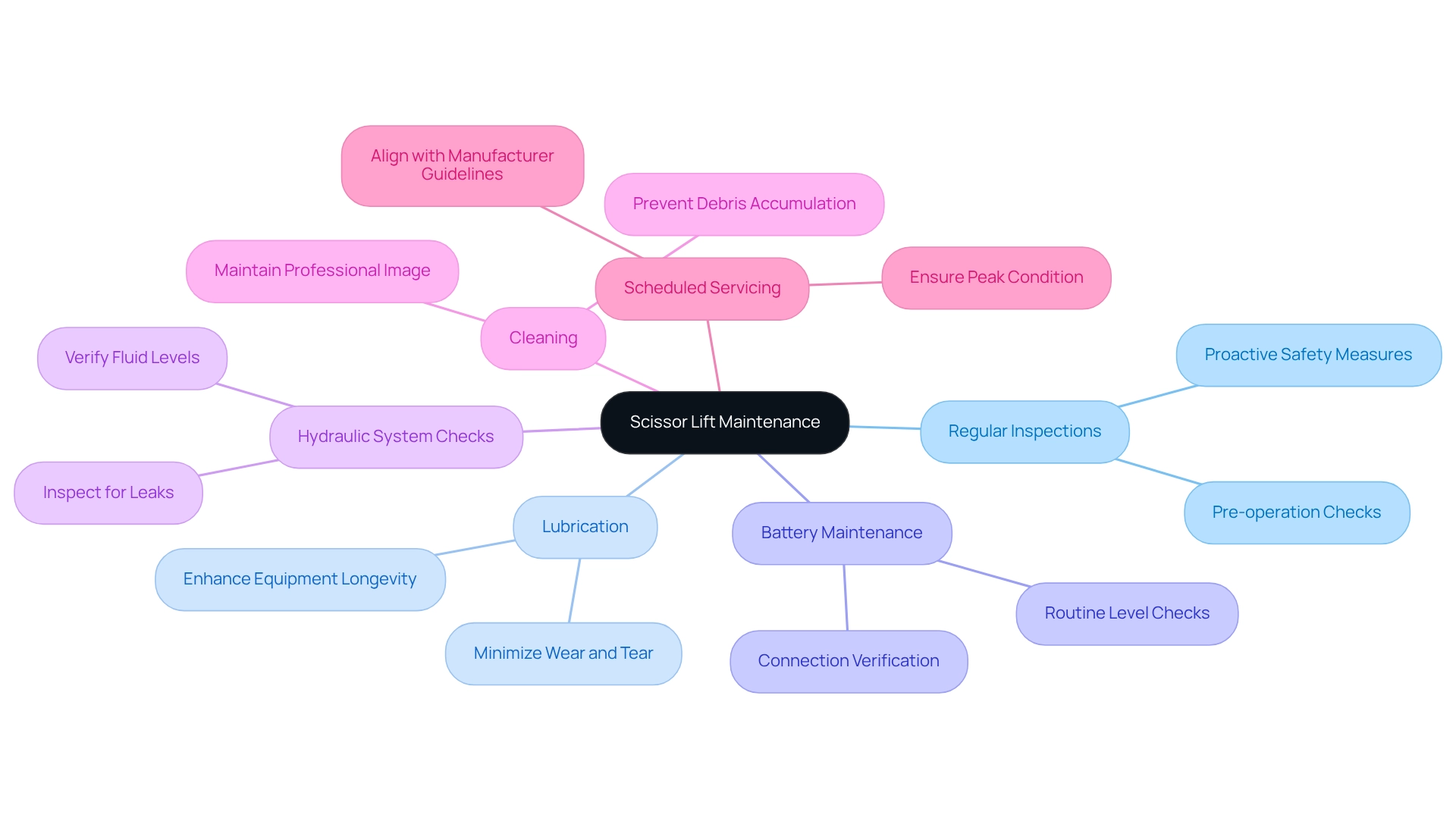

To maintain aerial work platforms in optimal condition, it is crucial to adhere to essential maintenance practices that ensure safety and reliability.

[Regular Inspections](https://ezequipmentrental.com/category/products/air-compressor-tools/equipment-rentals) are paramount. Conduct thorough pre-operation checks to identify potential issues before use. This proactive approach is essential for guaranteeing security and operational efficiency. By fostering a culture of safety, organizations can significantly reduce workplace injuries, making regular inspections even more vital.

Lubrication is another critical aspect. Properly lubricate all moving parts to minimize wear and tear, thereby enhancing the longevity of the equipment. This simple yet effective practice can prevent costly repairs and extend the life of your machinery.

Battery Maintenance is essential for electric lifts. Routinely check battery levels and connections to ensure reliable performance and prevent unexpected downtime. A well-maintained battery system is key to uninterrupted operations.

Hydraulic System Checks should not be overlooked. Regularly inspect the hydraulic system for leaks and verify that fluid levels are adequate, as these measures are crucial for safe operation. Neglecting this can lead to serious malfunctions.

Cleaning the lift is also important. Keeping the equipment clean prevents debris accumulation, which can interfere with functionality and safety. A clean lift not only operates better but also presents a more professional image.

Scheduled Servicing must align with the manufacturer’s guidelines for routine servicing and repairs, ensuring that the equipment remains in peak condition. Following these guidelines is essential for maintaining optimal performance, as implementing these best practices enhances the security and reliability of the 35 scissor lift while aligning with industry standards that emphasize the importance of regular inspections and maintenance. Statistics indicate that effective maintenance practices can lead to a significant reduction in operational risks. A culture of safety, supported by regular maintenance initiatives, can greatly decrease workplace injuries and enhance overall outcomes. For instance, underscores the importance of compliance and safety in maintenance practices, illustrating the severe consequences of neglecting these aspects.

Rental Options: Flexible Solutions for Scissor Lift Access

EZ Equipment Rental presents a diverse array of flexible rental choices for the 35 scissor lift, designed to meet various requirements:

- Short-Term Rentals: Ideal for one-time tasks or temporary needs, these rentals provide immediate access without the burden of long-term obligations. Particularly advantageous for projects with tight deadlines, they empower teams to enhance efficiency and minimize costs.

- Long-Term Rentals: A cost-effective solution for extended assignments that require consistent equipment availability, ensuring teams can maintain productivity without incurring unnecessary expenses. This option is perfect for ongoing construction efforts or maintenance tasks spanning several months.

- Flexible Terms: Customers enjoy the ability to adjust rental periods in response to shifting timelines, accommodating any changes in project scope or duration. This adaptability is crucial in the fast-paced construction environment, particularly with the use of the 35 scissor lift, which streamlines logistics and enhances operational efficiency. This growth is driven by industries that prioritize safety, efficiency, and productivity, making flexible rental options increasingly essential. Notably, the electric aerial platform rental market alone is anticipated to generate a total opportunity of USD 1,409.9 million by 2033.

Real-world instances underscore the benefits of short-term rentals, particularly in high-altitude operations where hydraulic platforms are favored for their ease of use. For instance, a recent project at a high-rise building site demonstrated how a temporary rental of hydraulic platform equipment allowed the team to efficiently complete tasks at elevated heights without the pressure of long-term commitments.

To discover more about , contact us today! Additionally, explore our latest posts on how renting trailers and extension ladders can further optimize your efficiency in various tasks.

Specifications Overview: Making Informed Decisions for Scissor Lift Use

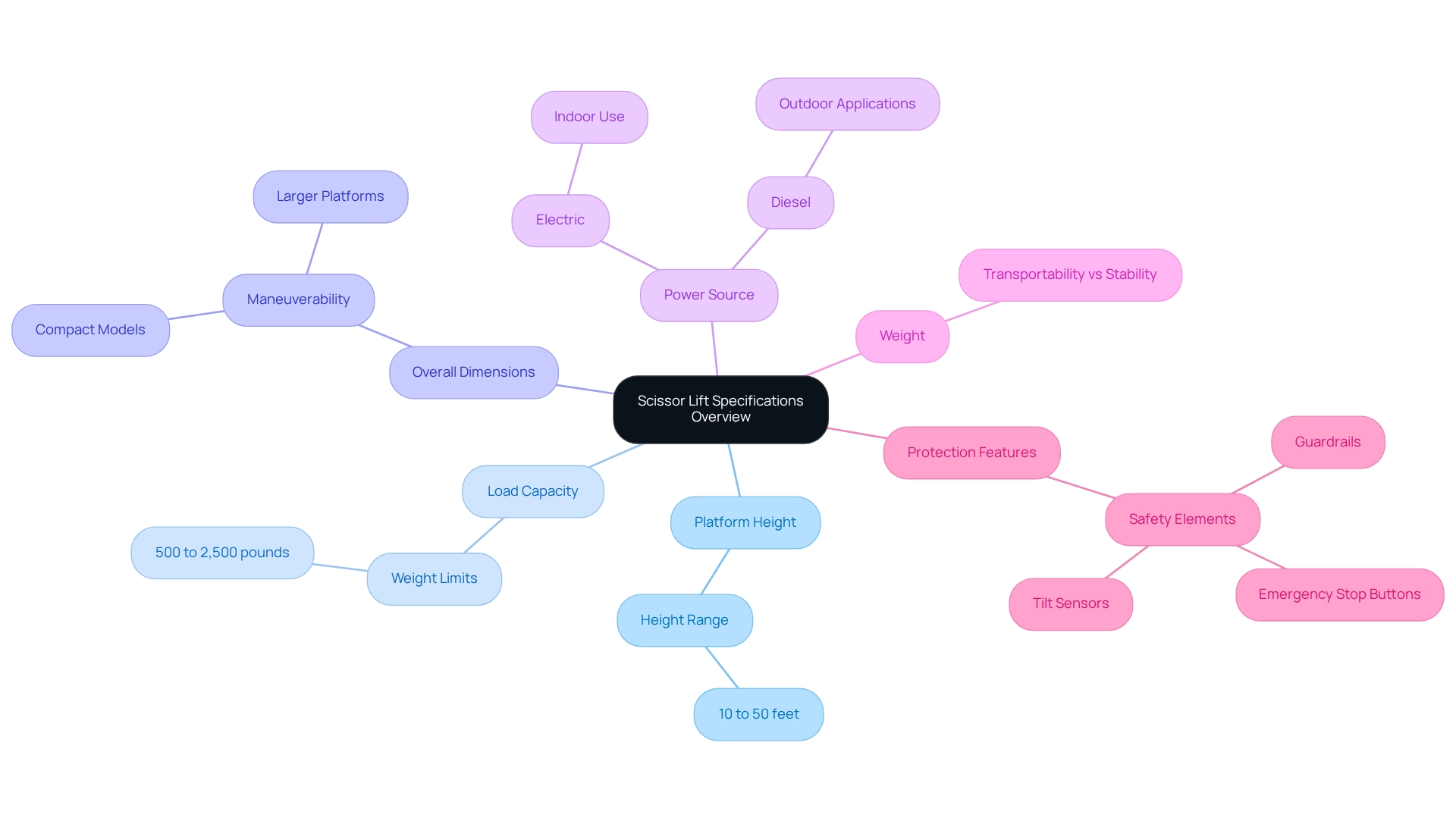

When selecting a 35 scissor lift, several key specifications must be considered to ensure optimal performance and safety on construction sites.

- Platform Height: This refers to the maximum height the lift can reach, which is crucial for accessing elevated work areas. Elevating platforms generally provide heights from 10 to 50 feet, accommodating diverse requirements.

- Load Capacity: Understanding the maximum weight the mechanism can safely manage is essential. possess load capacities ranging from 500 to 2,500 pounds, making it crucial to select a model that can meet the particular needs of your task.

- Overall Dimensions: The dimensions of the hoist, both when stored and in use, influence maneuverability in confined areas. Compact models are available for projects with limited access, while larger platforms offer greater reach.

- Power Source: Scissor platforms are available in electric and diesel options. Electric elevators are ideal for indoor use due to their quiet operation and zero emissions, while diesel models are suited for outdoor applications where power and durability are paramount.

- Weight: The overall weight of the lift impacts transportability and stability. Heavier models may offer increased stability but can be more challenging to transport.

- Protection Features: Essential protective elements, such as guardrails, emergency stop buttons, and tilt sensors, ensure secure operation and compliance with industry standards.

Informed choices concerning these specifications not only improve operational efficiency but also aid in the safety and success of construction endeavors. As Tim Forestell, co-founder and CCO of DOZR, emphasizes, "Working with renters daily provides me a glimpse into the evolution of various initiatives and listening to stories about endeavors being developed from beginning to end." This underscores the significance of comprehending equipment specifications in the context of development. Furthermore, as illustrated in the case study of EZ Equipment Rental's sales of new tools, understanding the characteristics of elevating platforms can greatly influence buying choices. Staying updated on the latest specifications and innovations in 35 scissor lift technology is crucial for project managers aiming to optimize their equipment choices.

Conclusion

Understanding the intricacies of scissor lifts is vital for successful construction project management. This comprehensive overview highlights essential features, including hydraulic systems, safety mechanisms, and platform capacities, which are integral to selecting the right equipment. Each type of scissor lift—be it electric, diesel, or rough terrain—offers unique advantages tailored to specific project needs, emphasizing the importance of informed decision-making.

Furthermore, safety cannot be overstated. Key safety features such as guardrails, emergency stop buttons, and load indicators are critical for ensuring operator protection and equipment reliability. Adhering to maintenance requirements and understanding the implications of platform height and load capacity further enhance operational efficiency and safety on job sites.

As the construction industry continues to evolve, so does the technology behind scissor lifts. Embracing advancements in power sources and machine dimensions equips project managers with the tools necessary to navigate the complexities of modern construction. Ultimately, prioritizing the right equipment selection and maintenance practices boosts productivity and fosters a safer working environment for all involved.

Frequently Asked Questions

What types of elevating platforms does EZ Equipment Rental offer?

EZ Equipment Rental provides a diverse selection of elevating platforms equipped with essential features tailored for construction tasks, including hydraulic systems, safety mechanisms, various platform sizes, mobility features, and different power sources.

What safety features are included in the elevating platforms?

The elevating platforms are designed with safety mechanisms such as guardrails and emergency stop buttons to prioritize user safety.

How do the platform sizes accommodate different construction tasks?

EZ Equipment Rental offers a variety of platform dimensions to ensure versatility on job sites, allowing users to choose the size that best fits their specific tasks.

Are the elevating platforms suitable for both indoor and outdoor use?

Yes, many models are designed for both indoor and outdoor applications, with capabilities to handle rough terrain.

What power sources are available for the elevating platforms?

Users can choose between electric and diesel models, allowing for optimal fit based on their specific requirements.

What is the load capacity range of the elevating platforms?

The platforms can handle loads ranging from 500 lbs to over 2,500 lbs, catering to a variety of demands.

What is the height range of the elevating platforms offered?

Models are available with height ranges from 19 ft to 70 ft, addressing various height requirements for construction tasks.

How user-friendly are the controls on these elevating platforms?

The elevating platforms feature simplified controls that enhance efficiency and safety, making them easier for operators to manage.

What maintenance features do the elevating platforms have?

Integrated systems in the platforms notify users of necessary maintenance, ensuring optimal performance and safety.

How do the designs of the elevating platforms facilitate maneuverability?

The platforms are engineered with compact designs, making them easy to maneuver in tight spaces, which is ideal for urban construction sites.

What are the economic advantages of renting elevating platforms?

Renting equipment like elevating platforms can be cost-effective, with engine hoists typically achieving ROI within 25-30 rental days, making it a financially viable option for managers.

How has technology advanced in aerial platforms?

Advancements in aerial platform technology, such as the curved linkage design, have reduced machine weight and lowered replacement component costs, thereby enhancing the efficiency of these devices.

What should be considered when selecting a 35 scissor lift?

Key factors include working height, project requirements, site conditions, regulatory compliance, and expert advice to ensure the right choice for safety and efficiency.

What is the importance of platform capacity and load limits?

Understanding maximum load limits is vital for safe operations, as exceeding these limits can lead to equipment failure and jeopardize safety. Proper weight distribution and compliance with personnel limits are also crucial.