Key Highlights:

- Conduct thorough market research to identify needed tools and evaluate their market value using online resources and industry reports.

- In Texas, average prices for used construction equipment are expected to rise by 2026, particularly for reliable brands.

- Comparing prices across dealers is essential for securing competitive rates and enhancing negotiation power.

- Perform detailed inspections on critical components like the engine and hydraulic systems to avoid unforeseen repair costs.

- Request maintenance records from sellers to assess the equipment's history and care.

- Explore financing options, such as loans or leases, to spread costs over time and compare terms for the best fit.

- Consider warranties for used equipment to cover repairs and maintenance, providing added security.

- Establish relationships with reliable suppliers to ensure quality support and insights for future purchases.

- Building trust with dealers can lead to better deals and a more efficient purchasing process.

Introduction

Navigating the landscape of used construction equipment presents a significant challenge, particularly given the constantly shifting market dynamics and the vast array of options available. For contractors and businesses, grasping the best practices for purchasing these assets is essential to guarantee both value and reliability. This article explores key strategies designed to enhance decision-making, empowering buyers to secure high-quality equipment at competitive prices. Yet, amid these opportunities, a critical question arises: how can one effectively balance cost, quality, and long-term support in a market filled with both risks and rewards?

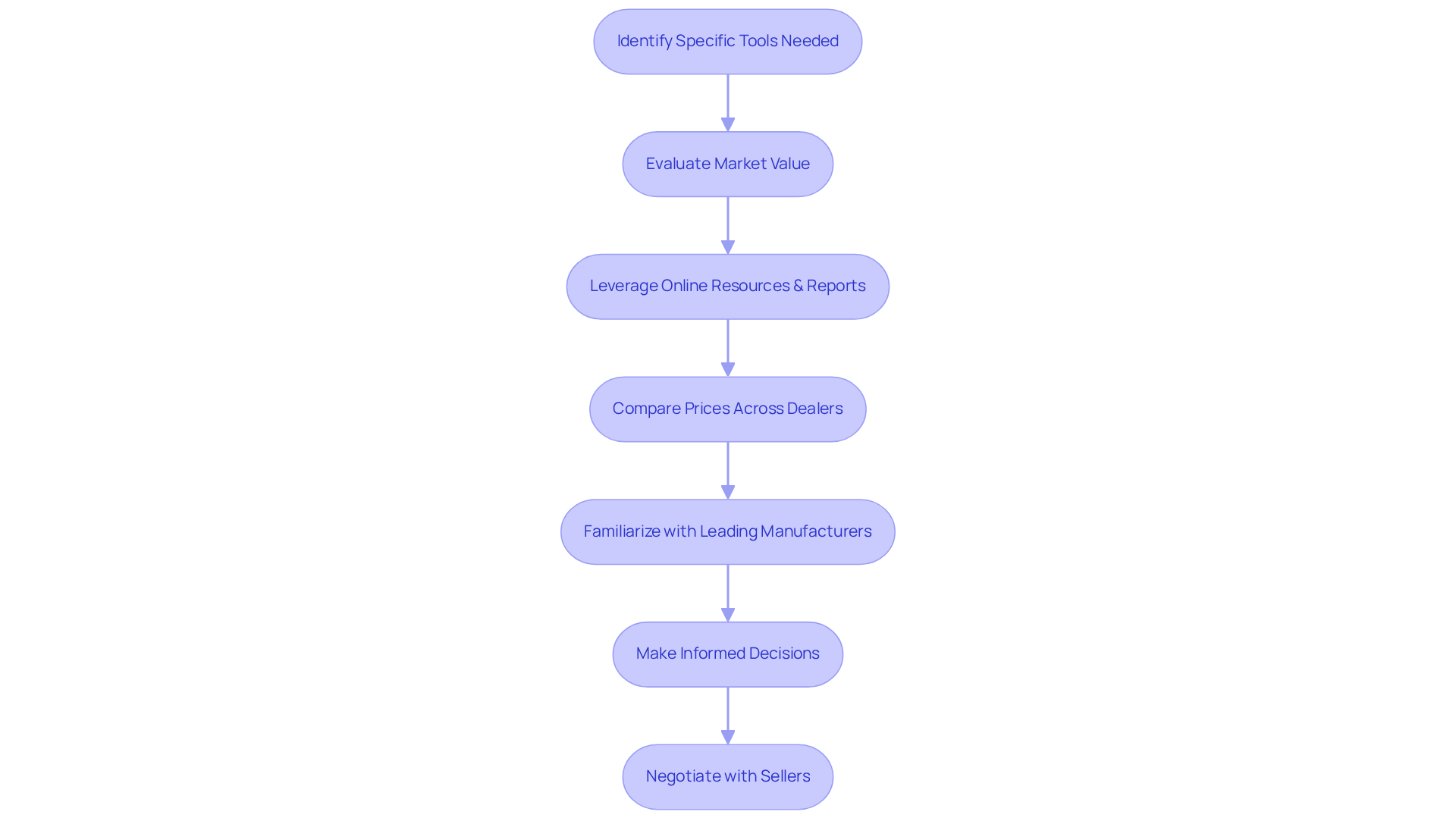

Conduct Comprehensive Market Research

Conducting a thorough industry analysis is crucial before acquiring used construction equipment. Start by pinpointing the specific tools you need and evaluating their market value. Leverage online resources, industry reports, and valuation tools to gather insights on pricing trends and availability. In Texas, the average prices for used construction equipment in 2026 are expected to rise, particularly for reliable brands known for their resale value. As Bella Williams wisely noted, "Without data, you're just another person with an opinion," underscoring the necessity of data in making informed decisions.

Comparing prices across various dealers and platforms is essential to secure a competitive rate. Familiarizing yourself with leading manufacturers can significantly enhance your purchasing strategy, as certain brands consistently uphold higher resale values. For example, a contractor who conducted extensive market research successfully identified a well-maintained excavator at a competitive price, ultimately saving thousands compared to market averages. This foundational knowledge not only empowers you to make informed decisions but also equips you to negotiate effectively with sellers, paving the way for a more successful acquisition process.

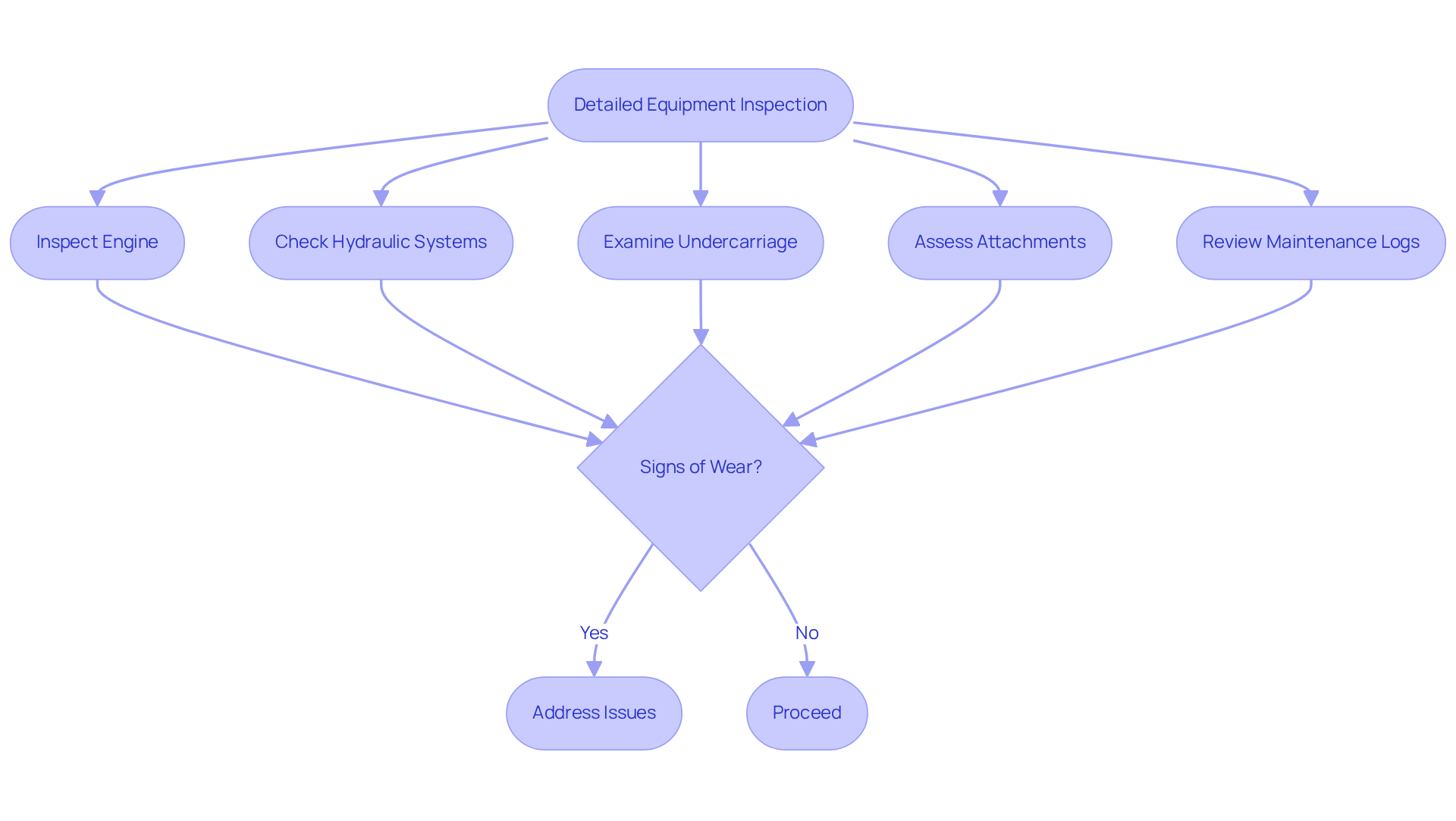

Perform Detailed Equipment Inspections

A detailed inspection is absolutely essential when it comes to used construction equipment. Focus on critical components like the engine, hydraulic systems, undercarriage, and attachments. Look for signs of wear, rust, or damage that may indicate a history of inadequate care. Industry data shows that systematic maintenance can lead to a remarkable 55% reduction in maintenance costs, underscoring the necessity of thorough inspections. If possible, enlist a qualified mechanic to conduct the inspection, providing an expert assessment of the machinery's condition. As Thompson Tractor states, "Providing quality assurance is another way we support the market."

Additionally, request upkeep records from the seller to understand how well the equipment has been maintained. Common pitfalls include overlooking these records or missing subtle signs of wear. To ensure a comprehensive inspection, consider this checklist:

- Inspect the engine for leaks and performance issues

- Check hydraulic systems for signs of wear or leaks

- Examine the undercarriage for uneven wear

- Assess attachments for functionality

- Review maintenance logs for consistency

This proactive strategy not only protects you from unforeseen repair expenses but also guarantees that the machinery meets your operational needs.

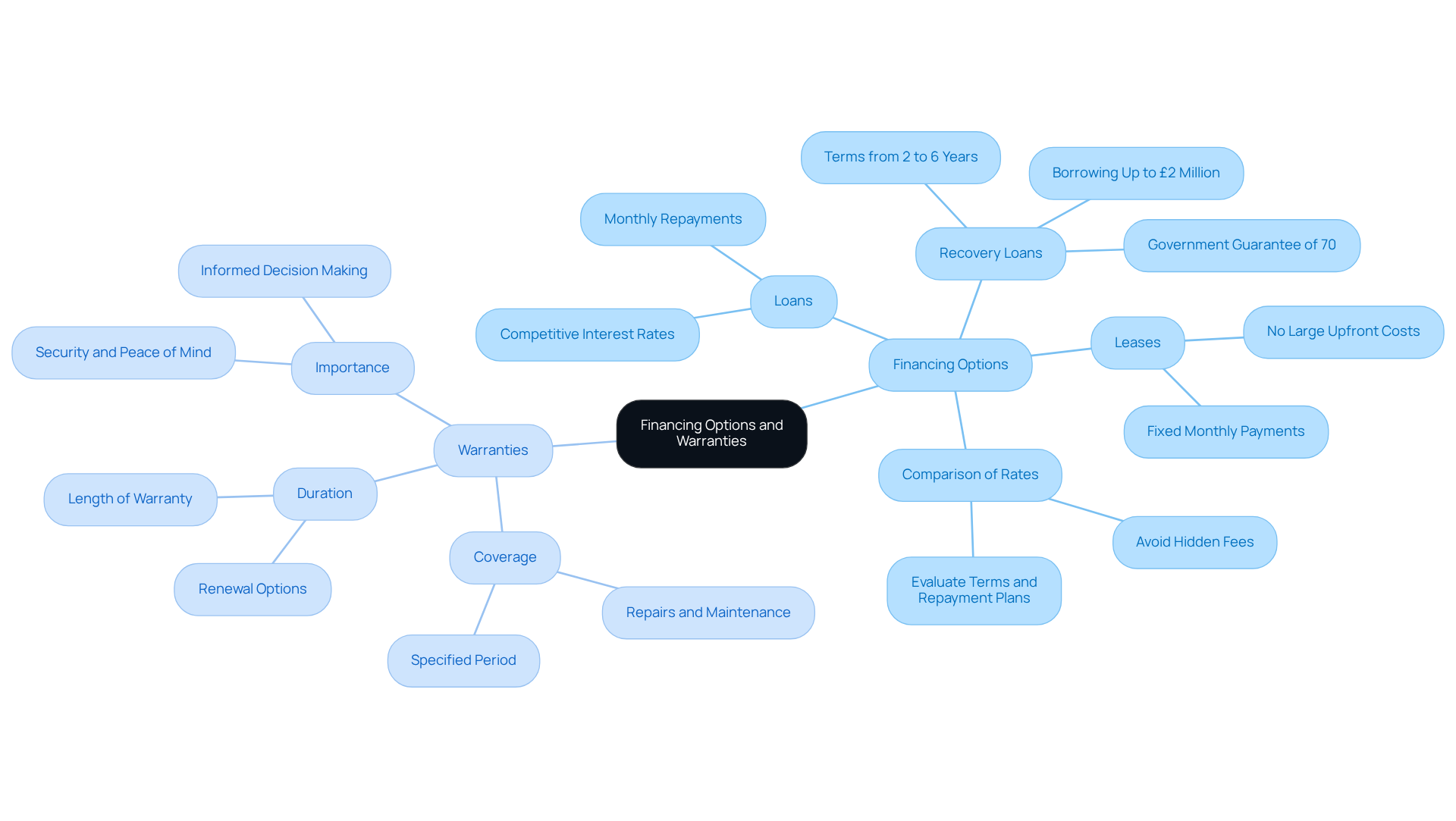

Explore Financing Options and Warranties

Before making a purchase, it’s crucial to explore the various financing options available for used construction equipment. Many lenders provide loans or leases specifically designed for asset acquisitions, allowing you to spread the cost over time. In Texas, competitive interest rates for machinery loans are anticipated in 2026, with options like Recovery Loans enabling businesses to borrow up to £2 million on terms ranging from 2 to 6 years. Comparing rates, terms, and repayment plans is essential to find the best fit for your budget.

Additionally, consider the availability of warranties with your tools. A strong warranty can cover repairs and maintenance for a specified period, giving you added security and peace of mind. As Andrew D. White, Director of Marketing at Bill Good Marketing, aptly puts it, "A good financial advisor doesn’t just help clients grow their wealth. They help them understand what wealth is really for." By grasping these financial aspects and steering clear of common pitfalls - like hidden fees or insufficient warranty coverage - you can make a purchase that is both feasible and beneficial in the long run.

For instance, a building firm that utilized a sale-and-lease-back arrangement successfully freed up cash for other operational needs while maintaining access to essential tools. This approach not only highlights the flexibility of financing options for used construction equipment but also underscores the importance of making informed decisions in your investments.

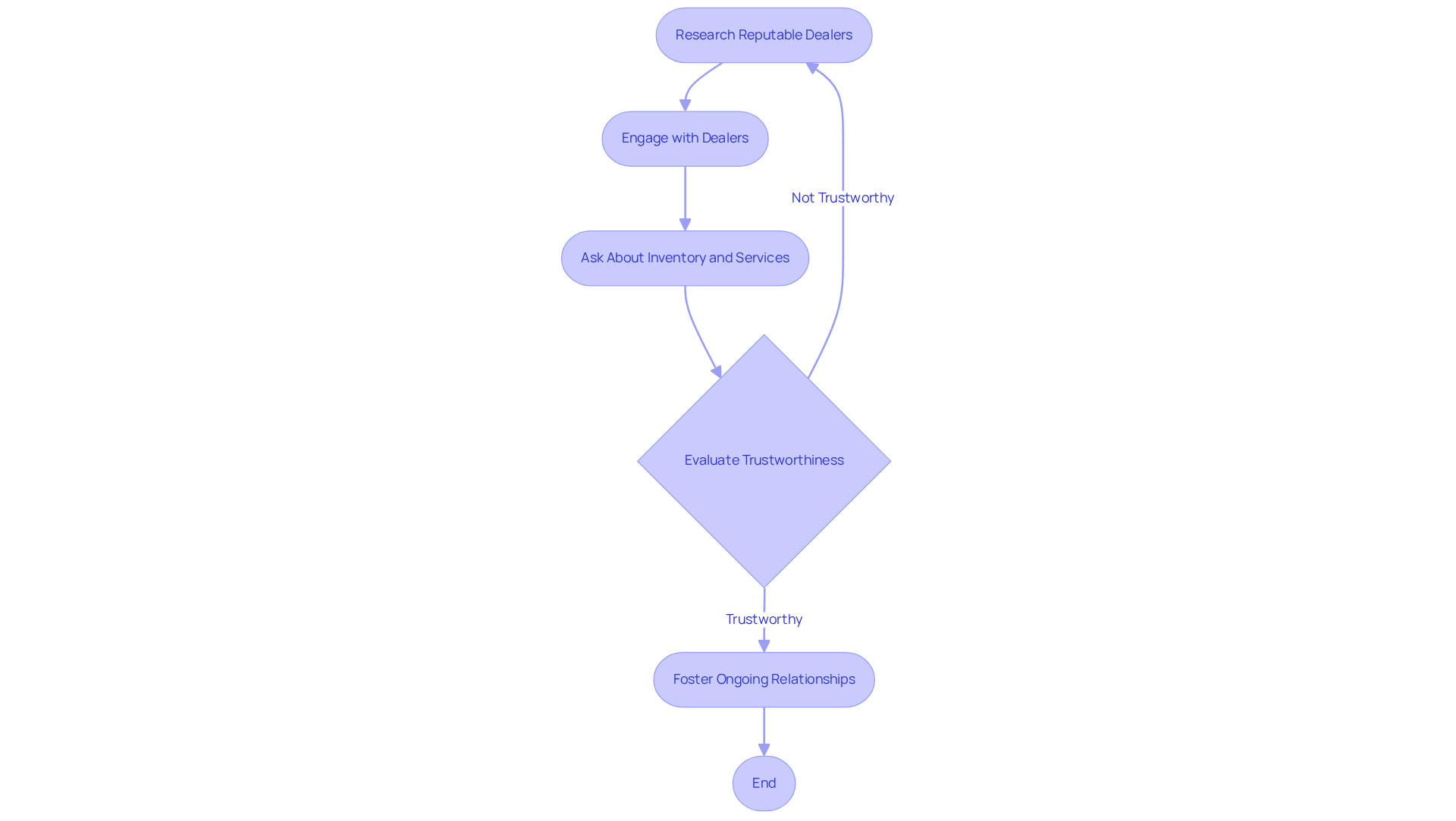

Establish Relationships with Trusted Dealers

Establishing strong connections with reliable suppliers is essential for achieving long-term success in acquiring used construction equipment. Start by thoroughly researching reputable dealers in your area, focusing on those with positive reviews and a solid track record of customer satisfaction. Actively engage with these dealers by asking about their inventory, warranties, and available services. A trustworthy seller not only provides quality tools but also offers ongoing support, maintenance services, and valuable insights for future purchases. Such partnerships can lead to better deals and a more efficient purchasing process, ensuring you have a dependable ally for all your equipment needs.

As Jeremy Renner wisely stated, 'Building is about getting around the obstacles that are presented to you.' This highlights the critical role of having trustworthy partners in the construction industry. By fostering these relationships, you can navigate challenges more effectively and secure the best resources for your projects. Don't underestimate the power of collaboration; it can significantly enhance your operational efficiency and overall success.

Conclusion

Thorough preparation and informed decision-making are essential when purchasing used construction equipment. By conducting comprehensive market research, performing detailed inspections, exploring financing options, and establishing relationships with trusted dealers, buyers can significantly enhance their acquisition process. These practices not only ensure sound investments but also empower buyers to navigate the complexities of the used equipment market with confidence.

Key insights emphasize the importance of data-driven decisions, meticulous evaluations of equipment condition, and exploring financial avenues that suit individual needs. Understanding market trends and leveraging relationships with reputable dealers can lead to better deals and ongoing support, ultimately fostering a more successful purchasing experience. These strategies are crucial for anyone looking to maximize their investment in used construction equipment.

As the landscape of used construction equipment continues to evolve, adopting these best practices will be vital for buyers aiming to thrive in the industry. Embracing a proactive approach mitigates risks and positions buyers to seize opportunities that align with their operational goals. By prioritizing informed choices and building lasting partnerships, the path to successful equipment acquisition becomes clearer and more attainable.

Frequently Asked Questions

Why is conducting market research important before acquiring used construction equipment?

Conducting market research is crucial because it allows you to pinpoint specific tools needed, evaluate their market value, and gather insights on pricing trends and availability, ensuring informed purchasing decisions.

What resources can be used for market research on used construction equipment?

You can leverage online resources, industry reports, and valuation tools to gather insights on pricing trends and availability.

What is the expected trend for used construction equipment prices in Texas for 2026?

The average prices for used construction equipment in Texas are expected to rise in 2026, particularly for reliable brands known for their resale value.

How can comparing prices help in the acquisition of used construction equipment?

Comparing prices across various dealers and platforms is essential to secure a competitive rate, which can lead to significant savings.

Why is it beneficial to familiarize yourself with leading manufacturers?

Familiarizing yourself with leading manufacturers enhances your purchasing strategy, as certain brands consistently uphold higher resale values, which can influence your buying decisions.

Can you provide an example of how market research can lead to savings?

Yes, a contractor who conducted extensive market research successfully identified a well-maintained excavator at a competitive price, ultimately saving thousands compared to market averages.

How does market knowledge empower negotiation with sellers?

Having foundational knowledge from market research equips you to negotiate effectively with sellers, paving the way for a more successful acquisition process.