Key Highlights:

- Implement comprehensive safety protocols to protect personnel and enhance operational efficiency in material lift rental.

- Conduct daily safety checks to identify potential issues before use, ensuring a safer work environment.

- Enforce the use of Personal Protective Equipment (PPE) such as hard hats and harnesses to reduce injury risks.

- Display load limits on hoists and ensure operators are trained to adhere to these limits to prevent accidents.

- Establish clear emergency procedures and conduct regular drills to ensure team familiarity with protocols.

- Select the right material lift by assessing project requirements, site conditions, load capacity, and ease of use.

- Provide hands-on training for operators, covering pre-operational checks, safety guidelines, and regulatory compliance.

- Implement a system for operator assessment and certification to ensure qualified personnel are in charge of equipment.

- Conduct daily inspections and establish a routine maintenance schedule to ensure lifts are safe and operational.

- Engage certified technicians for professional inspections to identify issues that may not be visible during daily checks.

Introduction

Ensuring safety in construction is paramount, particularly regarding material lifts, which play a crucial role in transporting heavy loads at heights. By adopting best practices for material lift rental, construction teams can protect their workforce and significantly enhance operational efficiency. However, the challenge persists: how can companies effectively implement these safety measures while navigating the complexities of equipment selection, operator training, and maintenance?

This article explores four critical best practices that can transform material lift operations into a safer, more reliable aspect of construction projects. In addition, these practices not only safeguard workers but also streamline processes, ultimately leading to improved project outcomes. By focusing on reliability and quality, construction teams can ensure that their material lifts contribute positively to their overall safety culture.

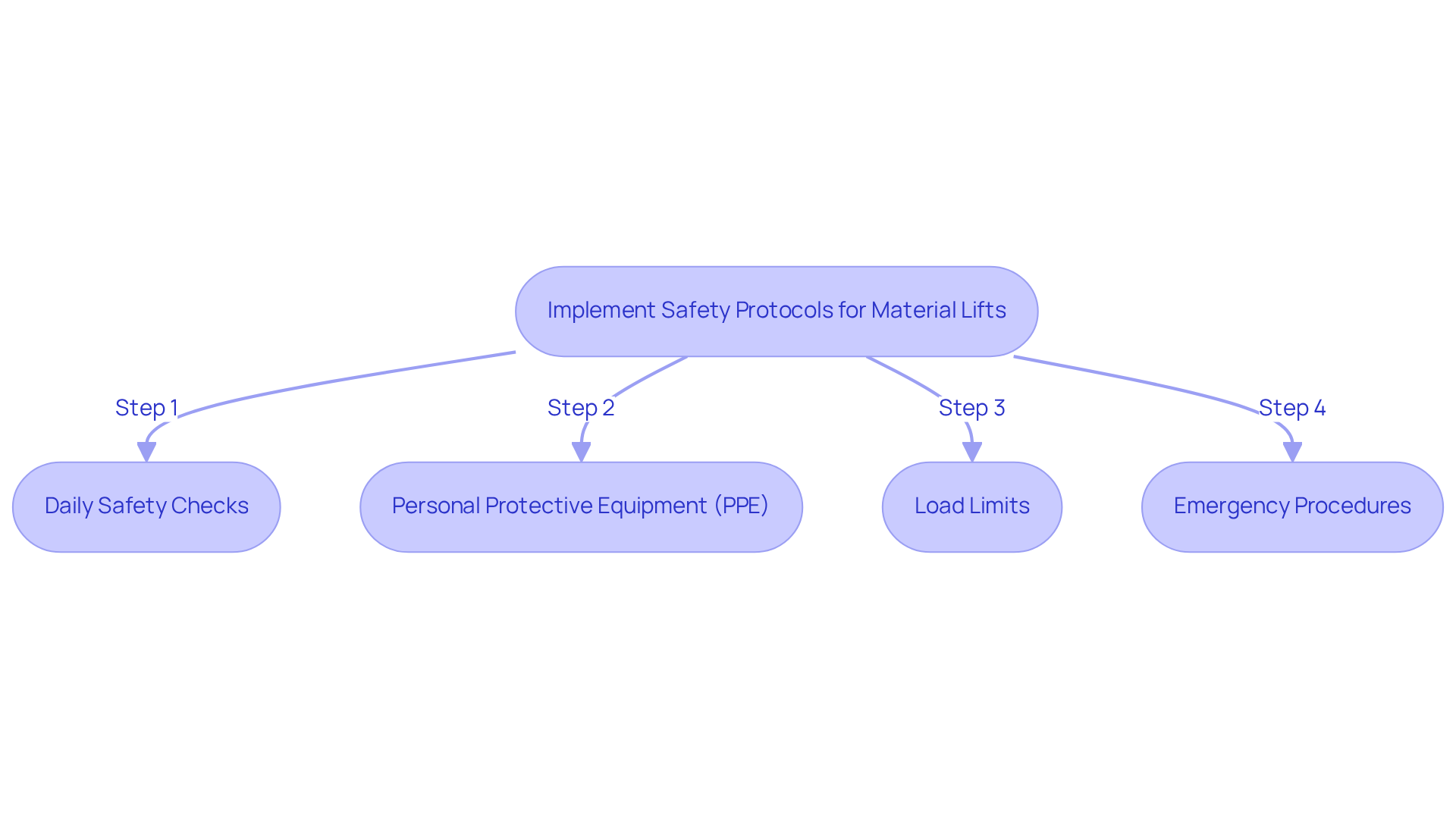

Implement Safety Protocols for Material Lifts

To ensure the secure operation of material lift rental, it is essential to implement comprehensive precautionary measures. These protocols not only safeguard personnel but also enhance overall operational efficiency.

Daily Safety Checks are non-negotiable. Conduct thorough inspections of the lift before each use, checking for visible damage, loose parts, or malfunctioning components. This proactive approach helps identify potential issues before they escalate into accidents, ensuring a safer work environment.

Personal Protective Equipment (PPE) is vital. Enforce the use of appropriate PPE, such as hard hats, safety goggles, and harnesses, to protect all personnel in the vicinity of the hoist. By prioritizing safety gear, you significantly reduce the risk of injury.

Load Limits must be clearly displayed on the hoist. Ensure that operators are well-trained to adhere to these limits, preventing overloading that could lead to tipping or mechanical failure. This practice not only protects equipment but also enhances operational reliability.

Emergency Procedures are crucial for effective risk management. Establish and communicate clear protocols for elevator operation, detailing responses to equipment failure or accidents. Regular drills will ensure that all team members are familiar with these procedures, fostering a culture of safety.

By implementing these safety measures, construction crews can dramatically reduce the risk of accidents and injuries related to material lift rental equipment handling. Take action now to prioritize safety and ensure a secure working environment.

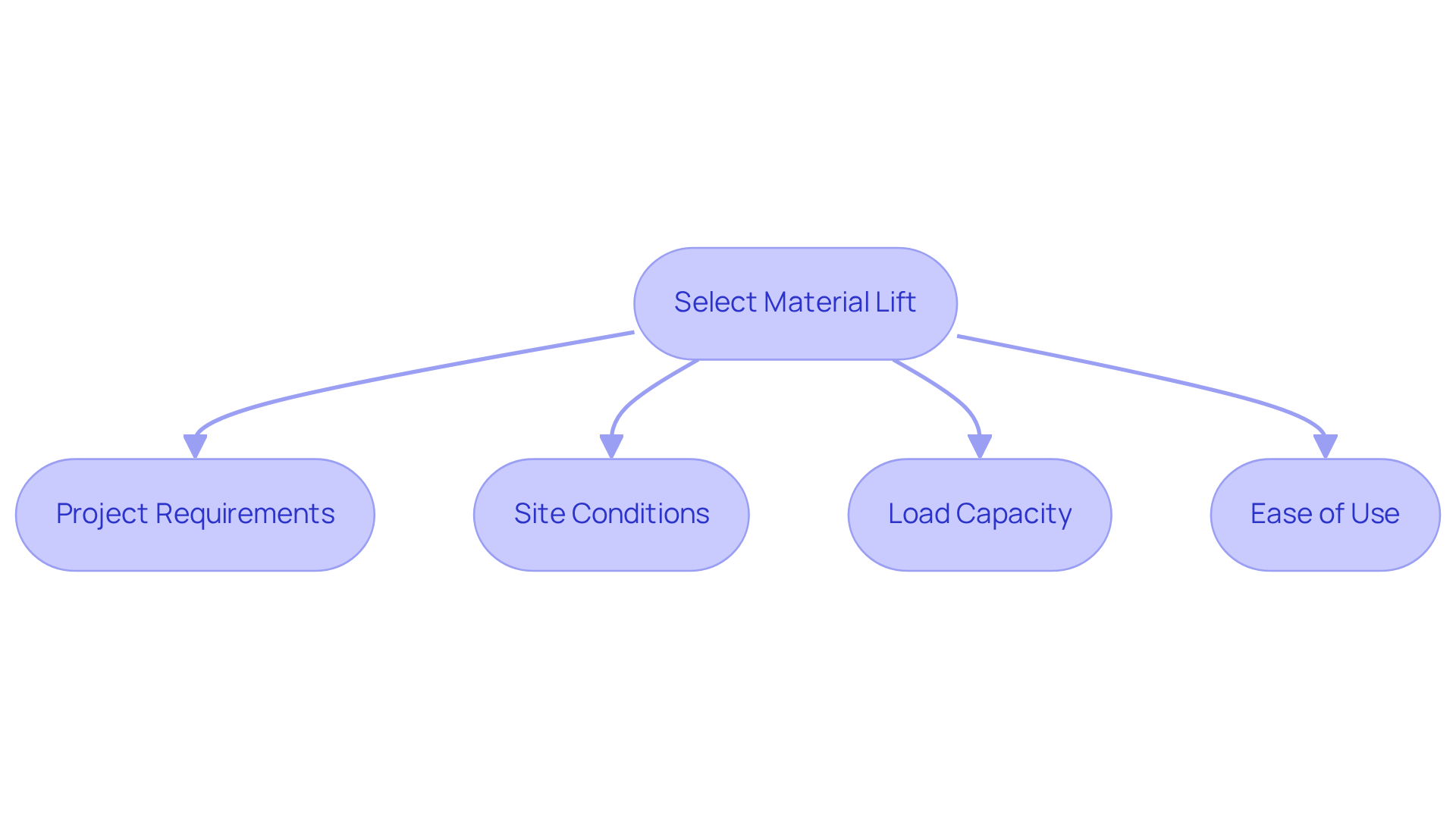

Choose the Right Material Lift for Your Project

Selecting the right material lift rental for your construction project is crucial. It requires careful consideration of several key factors that can significantly impact your project's success.

Project Requirements: Start by clearly defining the specific needs of your project. Consider the height and weight of materials to be lifted. For instance, boom platforms excel at moving heavy materials to considerable heights, allowing workers to reach elevated areas and navigate around barriers with ease. This capability is essential for tasks like painting, repairs, and construction activities, ensuring that project deadlines are met without compromising safety or budget.

Site Conditions: Next, assess the worksite conditions, including ground stability and space constraints. In environments with uneven ground, vehicles equipped with pneumatic tires are recommended for their shock-absorbing features, which enhance stability and safety. A thorough evaluation of mobility requirements ensures that the chosen equipment can operate effectively in restricted spaces.

Load Capacity: It's vital to confirm that the device can handle the maximum load you expect to raise. Heavy-duty forklifts, for example, can manage loads up to 36,000 pounds, while scissor platforms typically accommodate lighter weights. Always consult the manufacturer's specifications to avoid overloading. Using the wrong equipment can lead to serious safety incidents; OSHA reports that falls from heights accounted for 39% of construction fatalities in 2023.

Ease of Use: Finally, opt for equipment that is user-friendly and can be set up quickly. Scissor platforms, for instance, can often be relocated in minutes, significantly reducing setup time and minimizing the risk of accidents during operation.

By thoroughly assessing these elements, you can select a material lift rental that enhances productivity while also prioritizing safety on the job site. With the ongoing expansion of urban development in Dallas, the equipment rental market is projected to grow at a 3.6% CAGR between 2025 and 2035. This underscores the importance of making informed decisions in this evolving market.

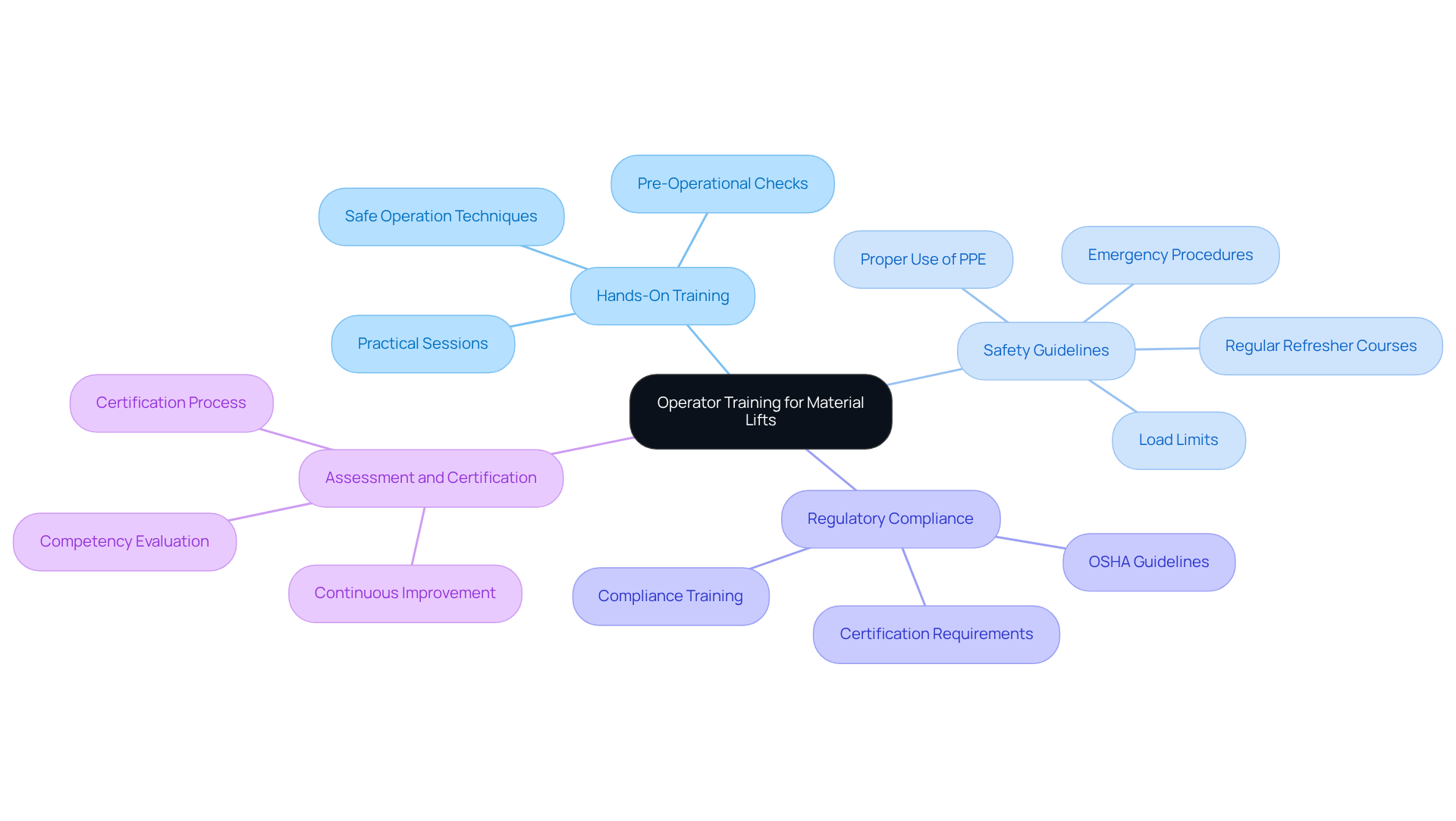

Train Operators for Safe and Efficient Use

Enhancing safety and efficiency when utilizing a material lift rental starts with comprehensive training for users. Hands-On Training is essential; operators must engage in practical sessions to familiarize themselves with the equipment. This includes learning how to perform pre-operational checks and operate the lift safely.

Safety Guidelines are another critical component. Users need to be well-versed in protocols, such as load limits, emergency procedures, and the proper use of PPE. Regular refresher courses reinforce these protocols, ensuring that safety remains a priority.

Furthermore, Regulatory Compliance is non-negotiable. Training personnel on pertinent regulations and standards, including OSHA guidelines, fosters a culture of security on the job site. It’s mandatory for every forklift driver to be certified before operating the machine. Alarmingly, approximately 70% of forklift incidents could have been prevented with better safety strategies, underscoring the importance of adhering to these regulations.

Implementing a system for Assessment and Certification is vital. Evaluating personnel competency and providing certification upon successful completion of training guarantees that operators are qualified. This not only instills confidence in their abilities but also enhances overall safety.

By investing in comprehensive training programs, construction companies can significantly boost safety and operational efficiency, particularly in the context of material lift rental, leading to successful project outcomes. Notably, nearly 25% of workplace fatalities stem from falling loads and forklifts tipping over, highlighting the urgent need for well-trained operators who can effectively navigate potential hazards.

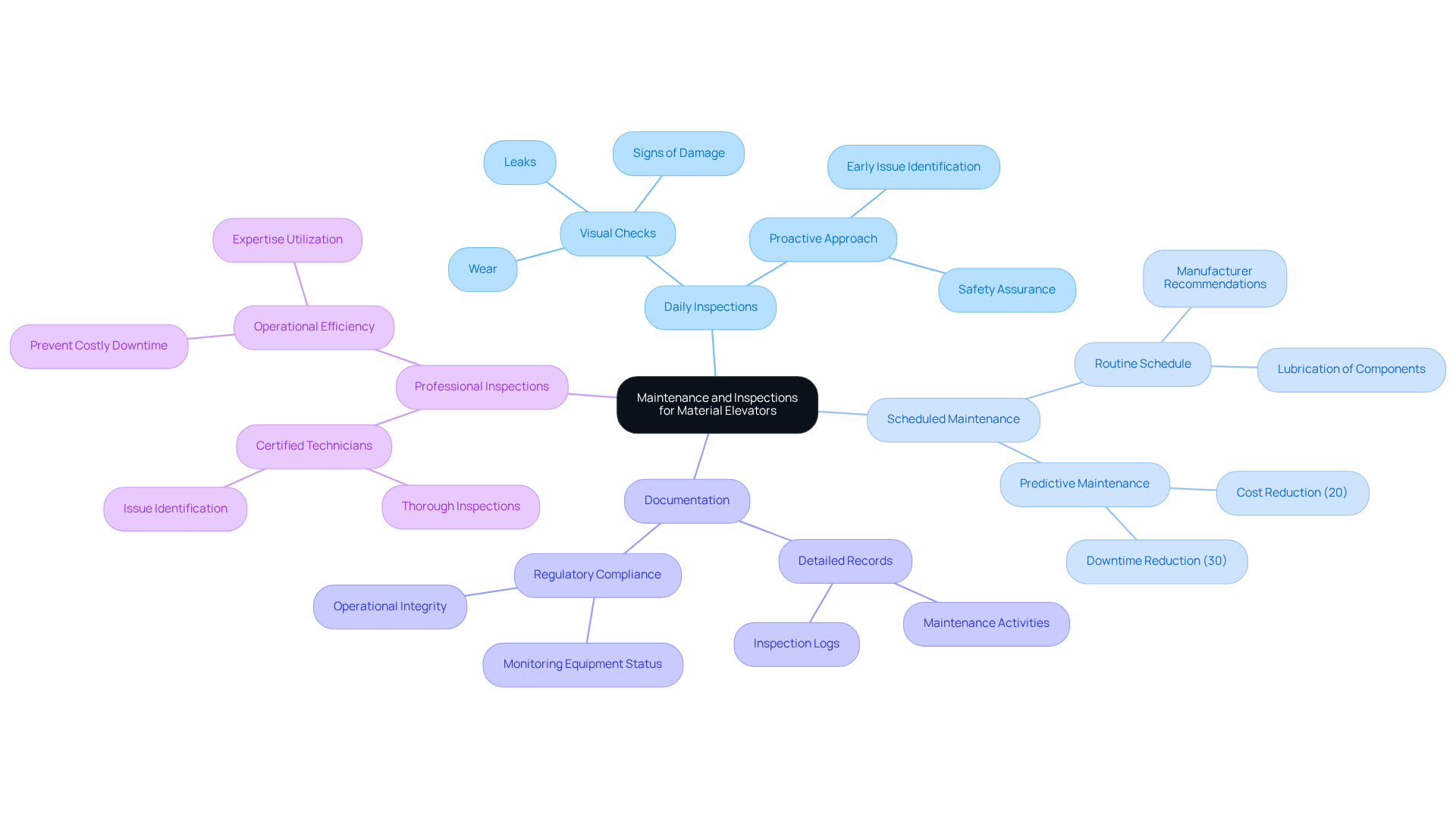

Conduct Regular Maintenance and Inspections

To ensure the safe and efficient operation of material elevators, conducting regular maintenance and inspections is essential. Daily Inspections are a must; operators should perform visual checks before each use, looking for any signs of damage, leaks, or wear. This proactive approach helps identify potential issues early, ensuring the lift is safe to operate. Remember, an hour of equipment downtime can cost businesses an average of $260,000, making these inspections vital.

Scheduled Maintenance is equally important. Establish a routine maintenance schedule based on the manufacturer's recommendations. This should include tasks like lubricating moving components, checking fluid levels, and testing protective features. Predictive maintenance can reduce costs by 20% and cut equipment downtime by up to 30%, underscoring the importance of sticking to this schedule.

Documentation plays a crucial role as well. Keeping detailed records of all inspections and maintenance activities assists in monitoring the equipment's status over time and ensures compliance with regulations, which is essential for operational integrity.

Professional Inspections should not be overlooked. Engaging certified technicians for thorough inspections at regular intervals allows for the identification of issues that may not be apparent during daily checks. As noted by Iron Mechanical, "Our expert predictive maintenance services are designed to improve operational efficiency and prevent costly downtime across all aspects of your commercial construction projects."

By prioritizing these maintenance and inspection practices, construction teams can significantly enhance the safety and reliability of material lift rentals, ultimately contributing to the successful execution of projects. Neglecting these practices can lead to costly breakdowns and project delays, highlighting the necessity of a proactive maintenance strategy.

Conclusion

Implementing effective practices for material lift rental is crucial for ensuring safety and efficiency on construction sites. By prioritizing safety protocols, selecting the right equipment, training operators, and conducting regular maintenance, construction teams can create a secure working environment. Adhering to these practices significantly mitigates risks associated with material handling, leading to successful project outcomes.

The importance of comprehensive safety measures cannot be overstated. Daily inspections, the use of personal protective equipment, and clear communication of emergency procedures are essential. Furthermore, selecting the right material lift based on project requirements and site conditions is vital for operational effectiveness. Training operators in safety guidelines and regulatory compliance enhances safety and reduces the likelihood of accidents.

Given the potential hazards associated with material lifts, construction companies must take proactive steps in implementing these best practices. Investing in safety not only protects personnel but also boosts productivity and project timelines. By fostering a culture of safety and efficiency, construction teams can navigate the complexities of modern construction projects with confidence and assurance.

Frequently Asked Questions

What are the essential safety protocols for material lifts?

The essential safety protocols for material lifts include conducting daily safety checks, enforcing the use of personal protective equipment (PPE), clearly displaying load limits, and establishing emergency procedures.

Why are daily safety checks important?

Daily safety checks are important because they involve thorough inspections of the lift before each use, helping to identify visible damage, loose parts, or malfunctioning components. This proactive approach prevents potential issues from escalating into accidents, ensuring a safer work environment.

What type of personal protective equipment (PPE) should be used around material lifts?

Appropriate PPE includes hard hats, safety goggles, and harnesses. Enforcing the use of this safety gear helps protect all personnel in the vicinity of the hoist and significantly reduces the risk of injury.

Why is it important to display load limits on the hoist?

Displaying load limits on the hoist is important to ensure that operators are well-trained to adhere to these limits, preventing overloading that could lead to tipping or mechanical failure. This practice protects equipment and enhances operational reliability.

What should be included in emergency procedures for material lifts?

Emergency procedures should include clear protocols for elevator operation, detailing responses to equipment failure or accidents. Regular drills should be conducted to ensure that all team members are familiar with these procedures, fostering a culture of safety.

How can implementing safety measures impact construction crews?

Implementing safety measures can dramatically reduce the risk of accidents and injuries related to material lift rental equipment handling, creating a more secure working environment for construction crews.