Overview

Effective excavation rentals depend on four essential practices:

- Evaluating project requirements

- Understanding various equipment types

- Comparing rental options and pricing strategies

- Implementing best operational practices

By thoroughly assessing project needs and selecting the right machinery, project efficiency and cost savings can be significantly enhanced. Furthermore, adhering to safety protocols not only boosts operational effectiveness but also reduces risks associated with excavation work.

Key Highlights:

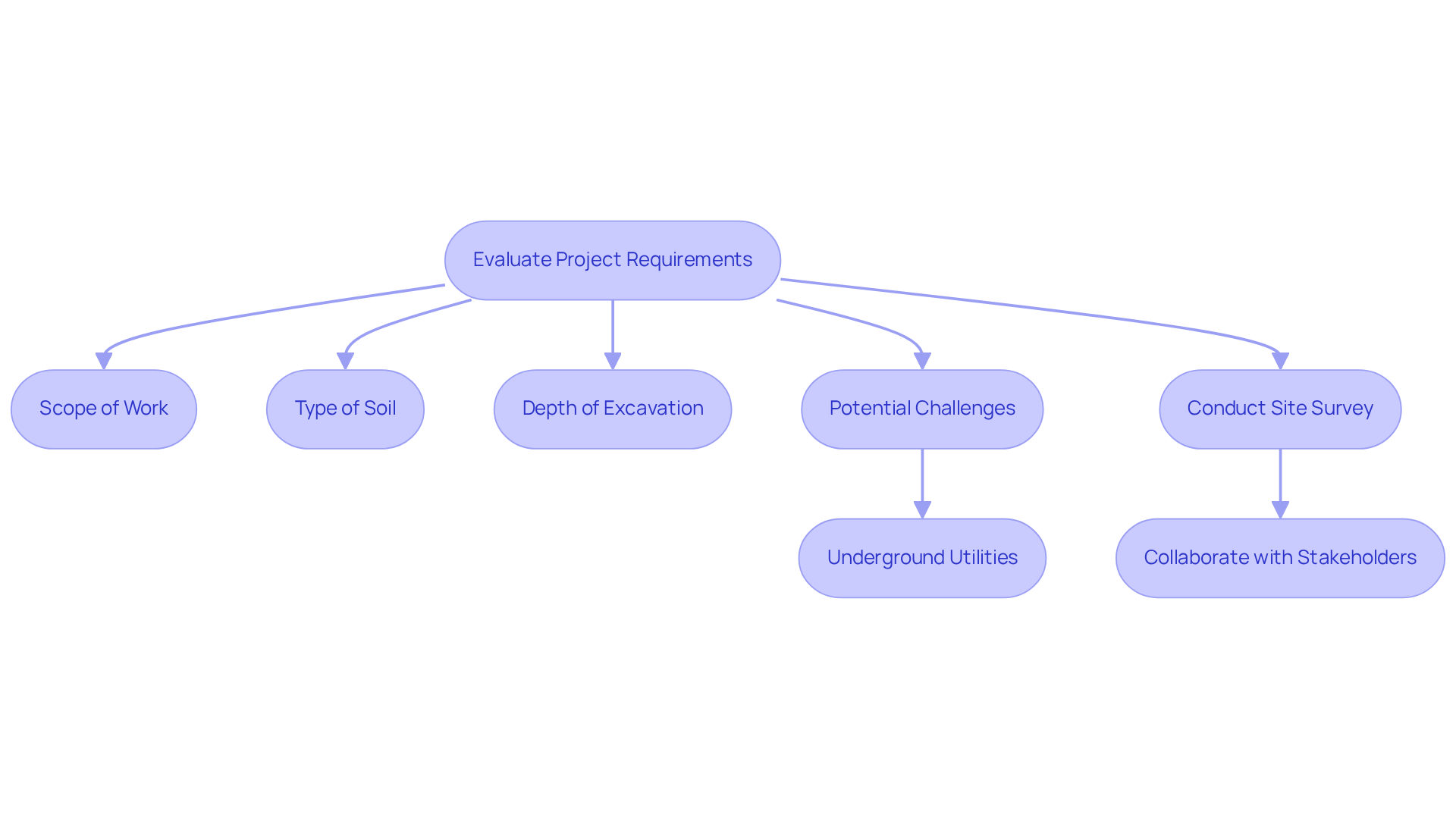

- Evaluating project requirements involves understanding the scope, soil type, excavation depth, and potential challenges like underground utilities.

- Conducting a site survey is crucial for identifying specific needs related to excavation.

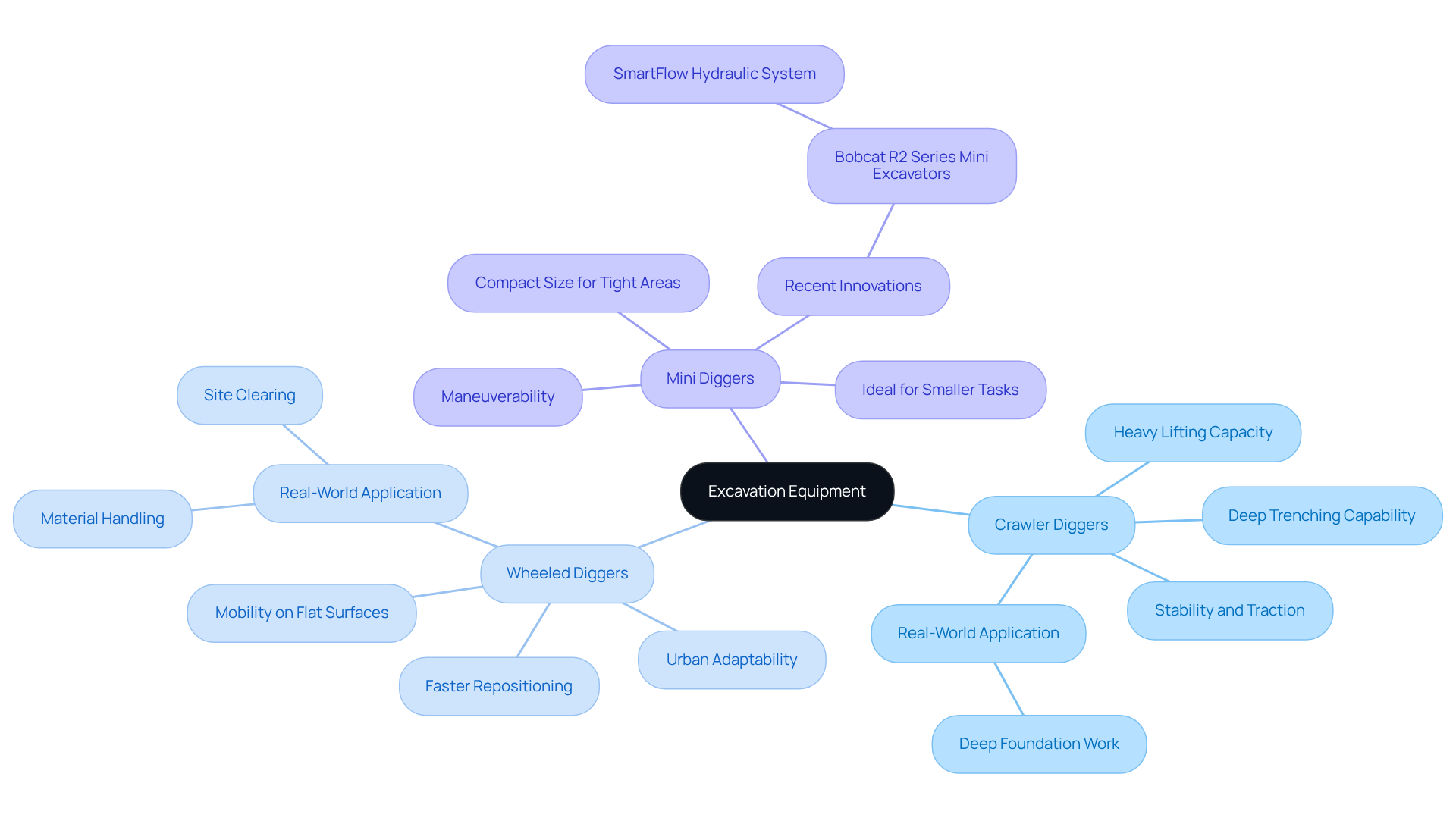

- Different types of excavation equipment include crawler diggers (for rough terrain), wheeled diggers (for urban settings), and mini diggers (for tight spaces).

- Choosing the right excavator affects project timelines and costs, with newer models emphasising electrification and automation.

- Comparing rental options and pricing strategies is essential; renting can save 30-50% compared to purchasing equipment.

- Flexible rental terms can lead to savings of up to 20% for long-term projects, but hidden fees must be considered.

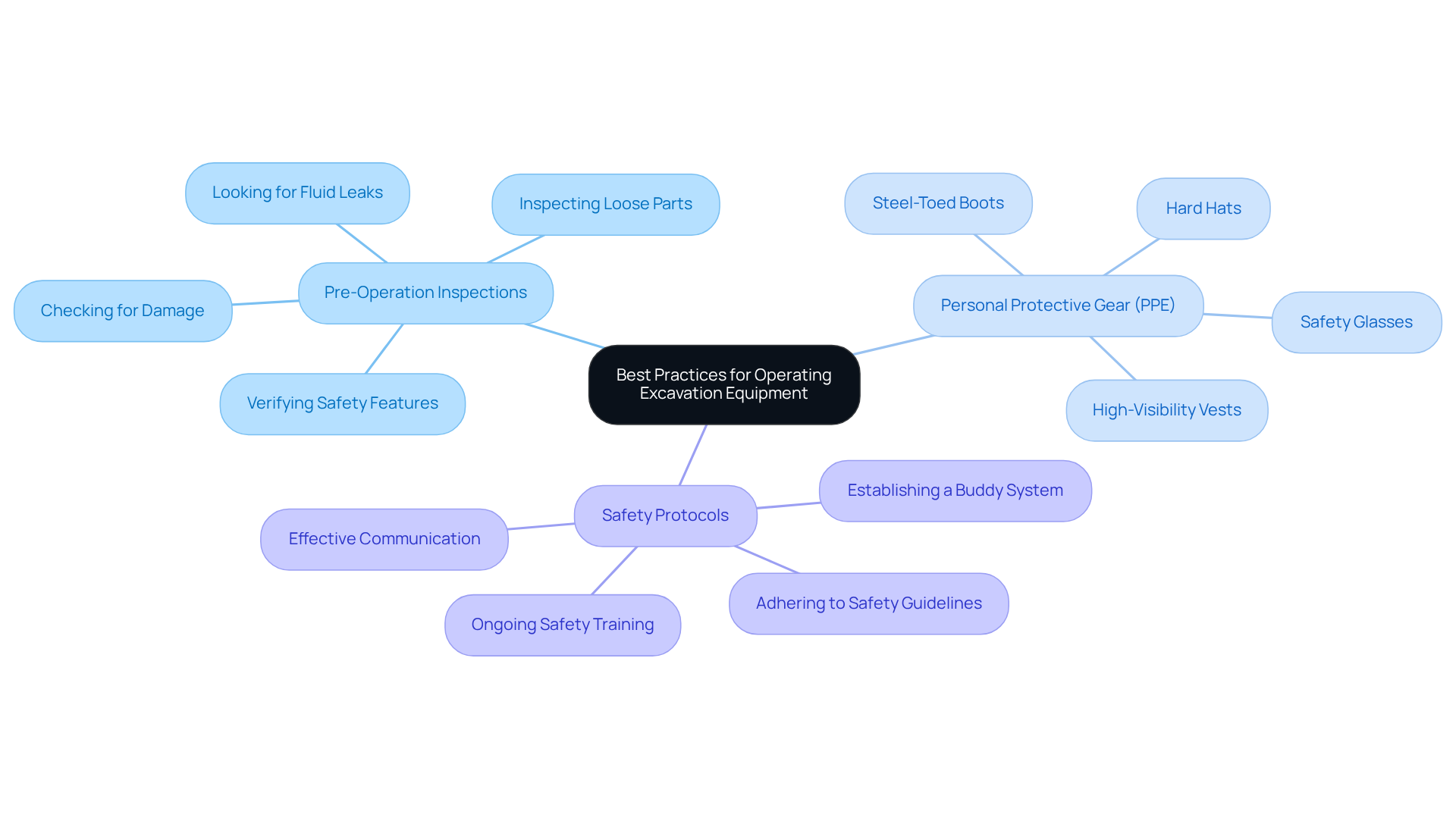

- Best practises for operating excavation equipment include pre-operation inspections, using PPE, and adhering to safety protocols to reduce accidents.

- Fostering a culture of safety through training and communication enhances operational efficiency and safety.

Introduction

Navigating the complexities of excavation rentals can be a daunting task for construction managers, particularly given the diverse range of equipment and pricing options available. Understanding the intricacies of project requirements, equipment types, and rental strategies is crucial for optimizing both efficiency and budget. With numerous variables at play, how can one ensure they are making the best choices for their specific needs? This article delves into four essential practices that can transform the excavation rental process, streamlining operations and enhancing project outcomes.

Evaluate Project Requirements for Excavation Rentals

Before considering excavation rentals, it is essential to evaluate the specific needs of your project. This involves understanding the scope of work, the type of soil, the depth of excavation required, and any potential challenges, such as underground utilities. Conducting a site survey is crucial for identifying these factors.

For instance, if your project entails digging in rocky terrain, a more robust excavator may be necessary. Additionally, collaborating with stakeholders can provide valuable insights into unique considerations that demand attention, ensuring that the right tools are selected from the outset.

Understand Different Types of Excavation Equipment

Excavation rentals encompass a variety of equipment types, each tailored for distinct tasks within construction projects. The main types consist of:

- Crawler diggers

- Wheeled diggers

- Mini diggers

Crawler diggers excel in rough terrain, providing superior stability and traction, making them perfect for deep trenching and heavy lifting. In contrast, wheeled diggers offer improved mobility on flat surfaces, enabling faster repositioning and adaptability in urban settings. Mini diggers, with their compact size, are ideal for smaller tasks or tight areas, where maneuverability is essential.

Understanding the differences in capabilities—such as digging depth, lifting capacity, and operational speed—is vital for selecting the right excavation rentals. For instance, a crawler digger typically boasts a greater digging depth and lifting capacity compared to a mini digger, making it the preferred choice for extensive excavation rentals. Real-world applications demonstrate this: in a recent infrastructure undertaking, a crawler machine was used for deep foundation work, while wheeled machines were employed for site clearing and material handling on level ground. This tactical choice of tools not only improved performance but also boosted efficiency of the initiative.

Furthermore, recent developments in digging machinery, including Bobcat's new R2 Series mini models and Caterpillar's 330 UHD Ultra High Demolition Hydraulic Machine, emphasize the sector's transition towards electrification and automation. These innovations not only improve operational efficiency but also address environmental concerns. As highlighted by industry specialists, selecting the appropriate excavator for excavation rentals can greatly affect timelines and expenses, making it crucial to evaluate the latest models and their features. By understanding these differences and advancements, construction managers can make informed choices that improve outcomes.

Compare Rental Options and Pricing Strategies

When assessing excavation rentals, contrasting different leasing firms and their pricing strategies is essential. EZ Equipment Rental in Dallas stands out with competitive pricing options, making quality forklifts accessible and affordable for businesses of all sizes. Look for companies that provide excavation rentals with flexible leasing terms—daily, weekly, or monthly rates tailored to your project's timeline. Inquire about potential hidden fees, such as delivery charges or insurance costs, as these can significantly impact your overall budget.

According to a case study, companies that utilize excavation rentals can save approximately 30-50% compared to outright purchases, highlighting the financial benefits of renting. Furthermore, numerous businesses provide price reductions for prolonged excavation rentals, leading to significant savings. For example, a study from the construction leasing sector suggests that excavation rentals with adaptable leasing conditions can result in savings of up to 20% for endeavors necessitating extended equipment usage. Always examine the rental agreement to fully understand the terms and conditions, ensuring you avoid unforeseen expenses that could hinder your plans.

Additionally, failing to account for site conditions, such as ground type and environmental factors, can lead to additional costs and project delays. This consideration is essential when evaluating your options, as it can greatly influence your project's success.

Implement Best Practices for Operating Excavation Equipment

To ensure the safe and efficient operation of excavation machinery, operators must adhere to best practices. This includes:

- Conducting thorough pre-operation inspections

- Utilizing appropriate personal protective gear (PPE)

- Strictly complying with safety protocols

Key inspection tasks involve:

- Checking for damage

- Inspecting loose parts

- Looking for fluid leaks

- Verifying the functionality of safety features

Additionally, operators must ensure the work area is free of obstacles before commencing operations. Statistics reveal that the construction industry has one of the highest rates of work-related fatalities, underscoring the critical role of proper pre-operation inspections in significantly reducing the risk of accidents.

Furthermore, fostering a culture of safety through ongoing training and effective communication among team members is crucial. For example, establishing a buddy system, where operators check one another's gear setup, can enhance both safety and operational efficiency. As Johann Wolfgang von Goethe wisely stated, 'Precaution is better than cure.' This collaborative approach not only reinforces safety practices but also promotes a shared responsibility for maintaining a safe work environment.

In addition, EZ Equipment Rental offers flexible rental terms and competitive pricing, making it easier for construction project managers to access reliable equipment while prioritizing safety. By choosing EZ Equipment Rental, you can ensure that your team is equipped with the best tools and excavation rentals to operate safely and efficiently.

Conclusion

Evaluating excavation rentals effectively necessitates a comprehensive understanding of project needs, equipment types, and rental strategies. By concentrating on these essential practices, construction managers can optimize their operations and ensure they select the most suitable tools for their specific tasks. This article underscores the importance of assessing project requirements, comprehending the various types of excavation equipment available, comparing rental options and pricing, and implementing best practices for safe operation.

Key arguments presented highlight the necessity of:

- Conducting thorough site evaluations

- Recognizing the capabilities of different equipment types

- Understanding the financial advantages of renting rather than purchasing machinery outright

Furthermore, adhering to safety protocols and fostering a culture of safety among team members is paramount to mitigating risks associated with excavation work. These insights collectively emphasize the significance of informed decision-making in the excavation rental process.

In conclusion, embracing these best practices not only enhances project efficiency but also contributes to a safer work environment. As the excavation rental landscape continues to evolve, staying informed about the latest equipment advancements and pricing strategies will empower construction managers to make choices that drive success. Prioritizing thorough evaluations and safety measures will ultimately lead to improved project outcomes, ensuring that excavation efforts meet both budgetary and operational goals.

Frequently Asked Questions

Why is it important to evaluate project requirements before renting excavation equipment?

Evaluating project requirements is essential to understand the scope of work, type of soil, depth of excavation, and any potential challenges, such as underground utilities, which ensures the right tools are selected for the job.

What factors should be considered when assessing excavation needs?

Factors to consider include the scope of work, type of soil, depth of excavation required, and potential challenges like underground utilities.

How can a site survey assist in the excavation rental process?

A site survey helps identify specific factors related to the project, such as soil type and terrain challenges, which are crucial for selecting the appropriate excavation equipment.

What should be done if the project involves digging in rocky terrain?

If the project involves rocky terrain, a more robust excavator may be necessary to handle the challenging conditions.

Why is collaboration with stakeholders important in the excavation planning process?

Collaborating with stakeholders provides valuable insights into unique project considerations that need attention, helping ensure the right tools and equipment are selected from the outset.