Overview

To achieve success in diamond floor grinder rental, four key strategies must be embraced.

- First, it is essential to understand the various types of grinders available. Each type serves specific applications, making it crucial to select the right equipment for your project.

- Second, adequate preparation before rental cannot be overstated; it lays the foundation for a smooth rental experience.

- Third, implementing safety protocols during operation is vital to minimize workplace injuries—ensuring that all operators are well-informed about the equipment's safe usage.

- Finally, evaluating costs is necessary for securing cost-effective rentals, allowing you to maximize your budget while maintaining quality.

These strategies are supported by detailed insights into the specific applications of different grinder types. For example, knowing whether to choose a planetary grinder or a single-disc grinder can significantly impact your project's efficiency. Furthermore, outlining essential preparation steps helps ensure that all necessary tools and resources are at hand before the rental begins. Emphasizing the importance of safety measures not only protects workers but also enhances productivity by fostering a secure working environment.

Additionally, providing strategies for comparing costs is instrumental in maximizing efficiency. By analyzing rental agreements and understanding the total cost of ownership, you can make informed decisions that benefit your bottom line. This comprehensive approach to diamond floor grinder rentals not only enhances your operational capabilities but also positions you for long-term success in your projects. Engage with us today to explore our extensive range of rental options and experience the reliability and quality that our equipment offers.

Key Highlights:

- Diamond floor grinders are categorised into three types: single-disc, dual-disc, and four-disc, each designed for specific applications.

- Single-disc grinders are lightweight and ideal for small jobs, projected to hold a 25% market share by 2025.

- Dual-disc machines enhance productivity for medium-sized projects, reducing grinding time by up to 30% compared to single-disc grinders.

- Four-disc machines are suited for large-scale operations, expected to capture 50% of the market share by 2025 due to their efficiency.

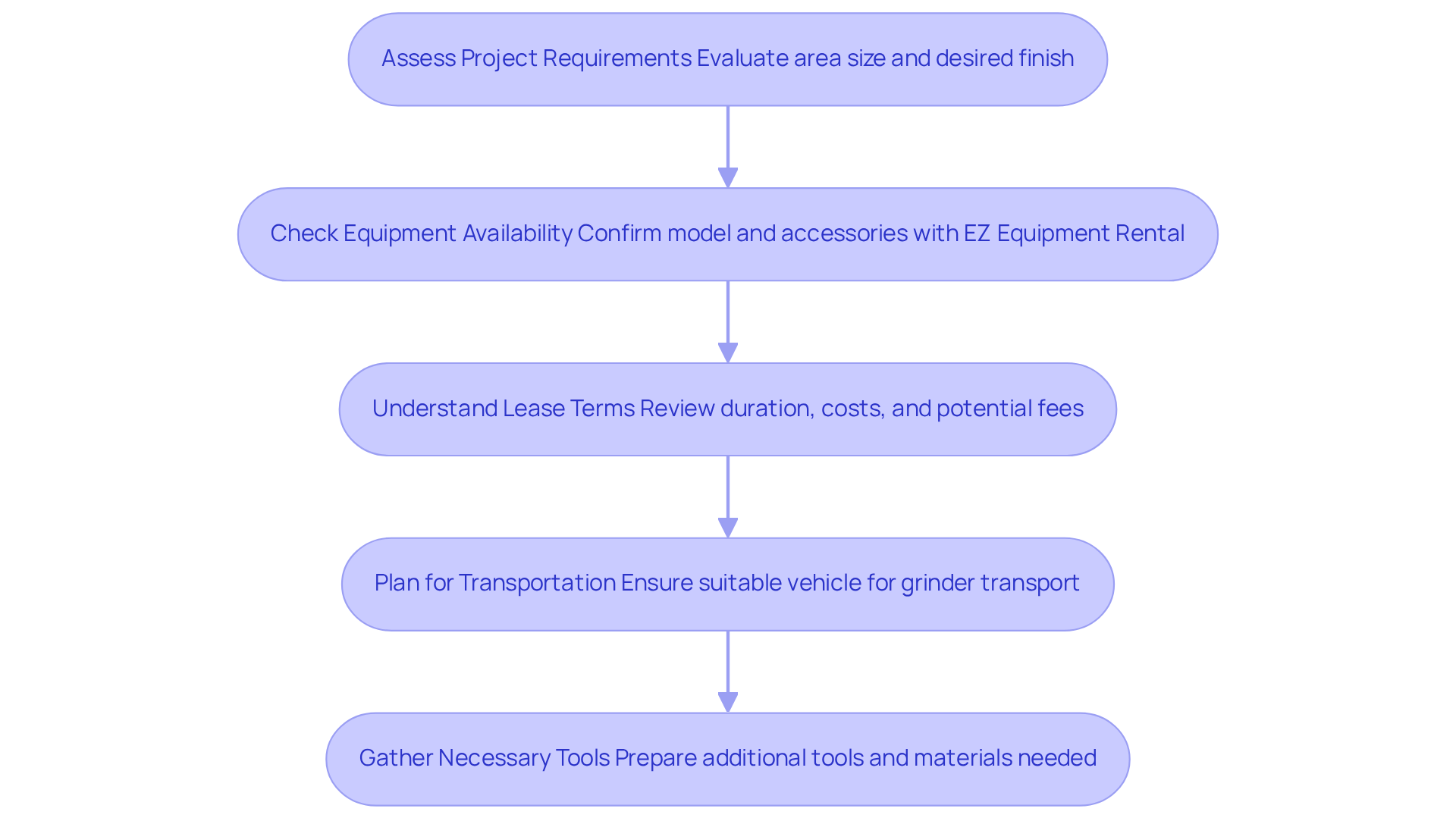

- Proper preparation before renting includes assessing project requirements, checking equipment availability, understanding lease terms, planning for transportation, and gathering necessary tools.

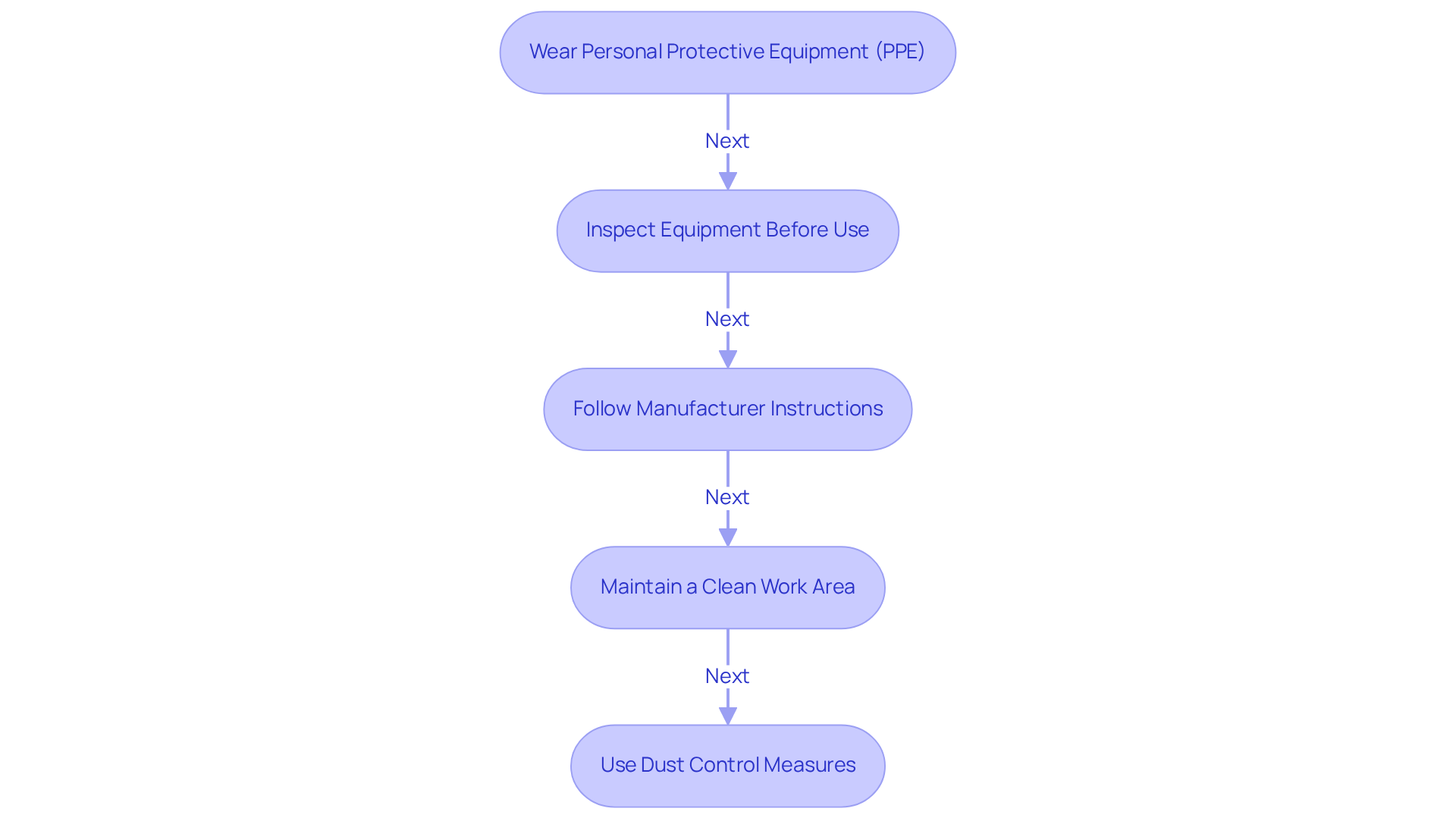

- Safety protocols for operating diamond floor grinders include wearing PPE, inspecting equipment, following manufacturer instructions, maintaining a clean work area, and using dust control measures.

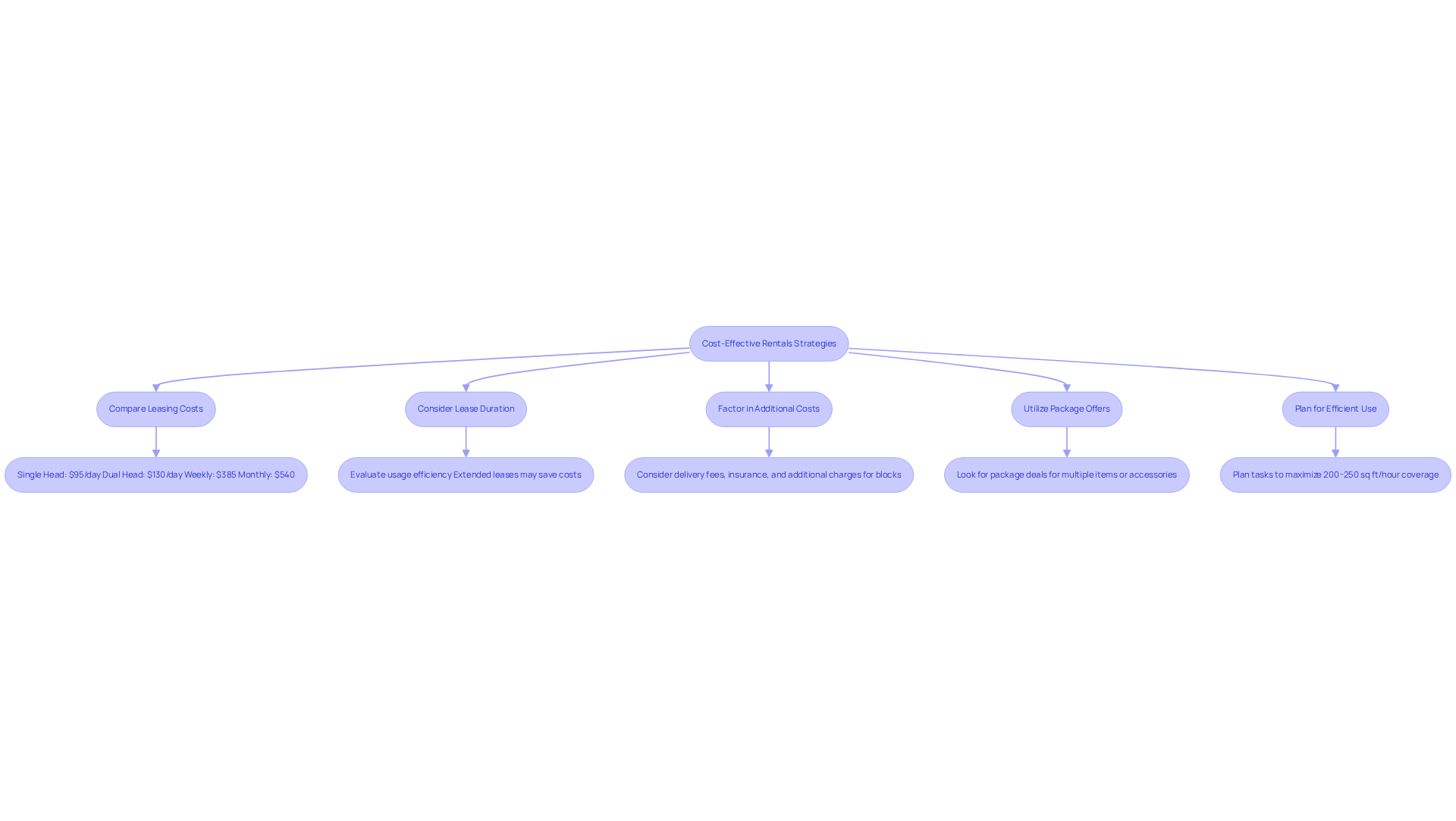

- Cost-effective rental strategies involve comparing leasing costs, considering lease duration, factoring in additional costs, utilising package offers, and planning for efficient use of rented equipment.

Introduction

Understanding the intricacies of diamond floor grinder rentals is essential for construction professionals who aim to enhance their project outcomes. With a variety of grinder types available, each tailored for specific applications, selecting the right equipment can significantly influence both efficiency and quality.

However, navigating the rental process presents challenges, from assessing project needs to ensuring that safety protocols are adhered to. What strategies can be employed to ensure a successful rental experience while maximizing both safety and cost-effectiveness?

Understand Diamond Floor Grinders: Types and Applications

Diamond floor tools are indispensable instruments in the construction industry, each type meticulously designed for specific applications. The primary categories include:

-

Single-Disc Grinders: Lightweight and maneuverable, these machines are perfect for small jobs and residential applications. They excel in polishing and grinding confined spaces, such as edges and corners. In 2025, single-disc tools are projected to hold a market share of approximately 25%, underscoring their popularity among DIY enthusiasts and small contractors.

-

Dual-Disc Machines: With increased power and efficiency, dual-disc machines are ideal for medium-sized projects. They shine in surface preparation and concrete polishing, making them a favored choice for contractors aiming to enhance productivity without compromising quality. Industry specialists note that dual-disc machines can reduce grinding duration by up to 30% compared to single-disc variants, marking them as a budget-friendly option for various projects.

-

Four-Disc Machines: Tailored for large-scale operations, four-disc machines deliver exceptional productivity by covering extensive surface areas swiftly. Their robust design is preferred in commercial settings, where high output and efficiency are crucial. Market analysis indicates that four-disc tools are expected to capture approximately 50% of the market share by 2025, driven by their effectiveness in large-scale applications.

The choice of milling equipment significantly impacts project outcomes, whether for surface preparation, polishing, or coating removal. Understanding the specific applications of each type empowers users to select the most suitable equipment, ensuring optimal results and efficiency in their projects. As the market for diamond floor polishing machines evolves, advancements in technology—such as improved diamond tooling and enhanced motor efficiency—are elevating performance, making these tools essential in modern construction. Furthermore, common mistakes include selecting the incorrect type of mill for the task or neglecting maintenance, which can lead to subpar results. By recognizing these factors, users can maximize the effectiveness of their grinding operations.

Prepare for Rental: Essential Steps Before Renting

Before renting a diamond floor grinder, it is crucial to follow these essential steps to ensure a successful rental experience:

-

Assess Project Requirements: Begin by evaluating the size of the area to be worked on and the desired finish. This assessment is vital for selecting the appropriate type of mill, as different projects may require varying levels of power and precision. Notably, the construction machinery rental market is projected to expand to $137.69 billion by 2029, underscoring the growing demand for specialized tools.

-

Check Equipment Availability: Next, reach out to EZ Equipment Rental to confirm the availability of the specific grinder model and any necessary accessories. Given the rising need for specialized devices, timely communication is essential to securing the right tools for your project. As Josh Nickell, Vice President of the American Rental Association, states, effective planning and analytics are crucial in forecasting equipment needs.

-

Understand Lease Terms: It is imperative to carefully review the lease agreement, paying close attention to the duration, costs, and any potential fees for damages or late returns. Understanding these terms can help prevent unforeseen costs and ensure a seamless leasing process. The anticipated increase in fleet spending emphasizes the importance of being informed about rental agreements.

-

Plan for Transportation: Ensure you have a suitable vehicle for transporting the grinder to and from the job site, considering its weight and size. Proper planning in this area can prevent delays and logistical challenges, particularly in a market where flexibility is increasingly valued.

-

Gather Necessary Tools: Finally, prepare any additional tools or materials needed for the job, such as dust collection systems or protective equipment. Having everything ready will streamline the workflow and enhance safety on site. The focus on quality and reliability in tool rental is crucial, as it directly impacts project outcomes.

By diligently following these steps, construction project managers can effectively prepare for a diamond floor grinder rental, ensuring they have the right equipment to meet their project needs.

Implement Safety Protocols: Best Practices for Operation

To ensure the safe operation of the diamond floor grinder rental, adhering to best practices is essential.

-

Wear Personal Protective Equipment (PPE): Always don appropriate PPE, including goggles, gloves, and dust masks, to shield against debris and harmful dust. Research shows that appropriate PPE utilization can result in a 70% decrease in workplace injuries, highlighting its essential function in protection, particularly when using equipment such as a diamond floor grinder rental. Phil Clark emphasizes, "Many firms talk about security, we embody it," underscoring the necessity of adhering to security protocols.

-

Inspect Equipment Before Use: Conduct a comprehensive inspection of the grinder prior to operation, checking for any signs of wear or damage. Ensure that all protective guards are securely in place to prevent accidents, fostering a safer work environment.

-

Follow Manufacturer Instructions: Strictly adhere to the manufacturer's guidelines for operation, including recommended settings, maintenance procedures, and instructions regarding diamond floor grinder rental. This compliance is crucial for both security and equipment longevity, ensuring reliable performance over time.

-

Maintain a Clean Work Area: Keep the work area clear of obstacles and debris to prevent tripping hazards and ensure safe maneuverability. A neat work environment plays a crucial role in overall security, enhancing operational efficiency.

-

Use Dust Control Measures: Implement effective dust control measures, such as utilizing a vacuum attachment, to minimize airborne particles and maintain a safe breathing environment. This is particularly important as 51% of construction workers report high exposure to hazardous noise, which can lead to long-term health issues.

In real-world applications, construction sites that prioritize PPE compliance have seen a marked increase in worker confidence and productivity, with effective training programs leading to a 20% boost in these areas. Despite this, statistics show that a substantial portion of construction workers still do not consistently use PPE while operating cutting tools, emphasizing the necessity for continuous education and enforcement of safety protocols.

Evaluate Costs: Strategies for Cost-Effective Rentals

To ensure cost-effective rentals of diamond floor grinders, consider the following strategies:

-

Compare Leasing Costs: Conduct thorough research to compare leasing costs from various providers, including EZ Equipment Rental. For instance, a single head floor-diamond grinder is available for $95 per day, while a dual head option costs $130 per day. Additionally, consider the weekly charge of $385 and the monthly price of $540. This comparison helps identify the best deal without sacrificing quality.

-

Consider Lease Duration: Carefully evaluate the lease duration. Although extended leasing durations might provide savings, confirm that the tools will be used efficiently during that period to optimize worth.

-

Factor in additional costs associated with your diamond floor grinder rental, such as delivery fees, insurance, or charges for diamond grinding blocks and scraper blocks. These can significantly impact your overall budget, so it's essential to account for them in your planning.

-

Utilize Package Offers: Seek package offers that may encompass multiple items or essential accessories at a lower price. This method can offer improved value and simplify your leasing process.

-

Plan for Efficient Use: Maximize the efficiency of the rented equipment by planning your work schedule effectively. The grinder can cover approximately 200-250 square feet per hour at a depth of 1/32 inch, so organizing tasks to align with this capability can help avoid unnecessary rental time and costs.

Conclusion

In conclusion, understanding the intricacies of diamond floor grinder rentals is essential for achieving successful project outcomes. Familiarizing oneself with the various types of grinders and their specific applications empowers users to make informed choices that enhance efficiency and effectiveness on the job site. The strategies outlined here serve as a comprehensive guide for ensuring a seamless rental experience, covering preparation, operation, and cost management.

Key insights emphasize the importance of:

- Assessing project requirements

- Verifying equipment availability

- Adhering to safety protocols

Furthermore, evaluating costs through careful comparison and planning can significantly impact the overall budget. By implementing these best practices, construction professionals can optimize their rental experience and elevate the quality of their work.

Ultimately, prioritizing preparation, safety, and cost-effectiveness in diamond floor grinder rentals is vital in today’s competitive construction landscape. Embracing these strategies not only leads to immediate project success but also fosters long-term relationships with rental providers and enhances overall operational efficiency. Taking the time to understand and apply these principles can make all the difference in achieving project goals and ensuring safety in the workplace.

Frequently Asked Questions

What are the main types of diamond floor grinders?

The main types of diamond floor grinders include Single-Disc Grinders, Dual-Disc Machines, and Four-Disc Machines, each designed for specific applications in the construction industry.

What are Single-Disc Grinders used for?

Single-Disc Grinders are lightweight and maneuverable, making them ideal for small jobs and residential applications. They excel in polishing and grinding confined spaces, such as edges and corners.

What is the market share projection for Single-Disc Grinders by 2025?

Single-Disc Grinders are projected to hold a market share of approximately 25% by 2025.

What advantages do Dual-Disc Machines offer?

Dual-Disc Machines provide increased power and efficiency, making them suitable for medium-sized projects. They are particularly effective in surface preparation and concrete polishing, and can reduce grinding duration by up to 30% compared to single-disc variants.

How do Four-Disc Machines perform in large-scale operations?

Four-Disc Machines are designed for large-scale operations, delivering exceptional productivity by covering extensive surface areas efficiently. They are preferred in commercial settings where high output is crucial.

What is the expected market share for Four-Disc Machines by 2025?

Four-Disc Machines are expected to capture approximately 50% of the market share by 2025.

Why is it important to choose the correct type of diamond floor grinder?

Choosing the correct type of milling equipment significantly impacts project outcomes, whether for surface preparation, polishing, or coating removal. Selecting the most suitable equipment ensures optimal results and efficiency.

What common mistakes should users avoid when using diamond floor grinders?

Common mistakes include selecting the incorrect type of mill for the task and neglecting maintenance, both of which can lead to subpar results.

How is technology evolving in the diamond floor polishing machine market?

Advancements in technology, such as improved diamond tooling and enhanced motor efficiency, are elevating the performance of diamond floor polishing machines, making them essential in modern construction.