Overview

The article delineates four pivotal strategies for effectively renting small tunnel boring machines (TBMs). It underscores the significance of:

- Selecting the appropriate machine

- Grasping rental terms

- Engaging with providers

- Managing costs

These strategies are bolstered by meticulous considerations, including:

- Assessing project specifications

- Negotiating leasing rates

- Establishing clear expectations

Such measures are essential for enhancing project efficiency and minimizing misunderstandings, ultimately fostering a smoother rental experience.

Key Highlights:

- Assess project specifications including tunnel diameter, length, and geological conditions to choose the right TBM.

- Evaluate the TBM's power, speed, and efficiency to ensure it meets project demands.

- Consider the reputation of manufacturers for reliability and customer support in TBM selection.

- Review leasing proposals for flexibility and budget alignment to enhance workflow efficiency.

- Understand rental agreement terms, including lease duration, maintenance responsibilities, and insurance requirements.

- Establish clear expectations with rental providers to minimise misunderstandings and improve project outcomes.

- Utilise technology for effective communication and regular updates with rental providers.

- Implement thorough financial planning and real-time expense tracking to manage costs effectively.

- Negotiate leasing rates to achieve cost savings, especially when renting multiple TBMs.

- Regularly evaluate the cost-effectiveness of the rental to ensure it aligns with budget and performance expectations.

Introduction

The construction industry is currently experiencing a significant surge in the demand for small tunnel boring machines (TBMs), a trend driven by the urgent need for efficient underground solutions. Selecting the appropriate TBM for a project not only enhances operational efficiency but also plays a critical role in effectively managing costs and timelines. However, navigating the complexities of rental agreements and ensuring effective communication with providers can present considerable challenges. To address these issues, construction managers must employ key strategies to streamline the rental process and maximize the benefits of small tunnel boring machines.

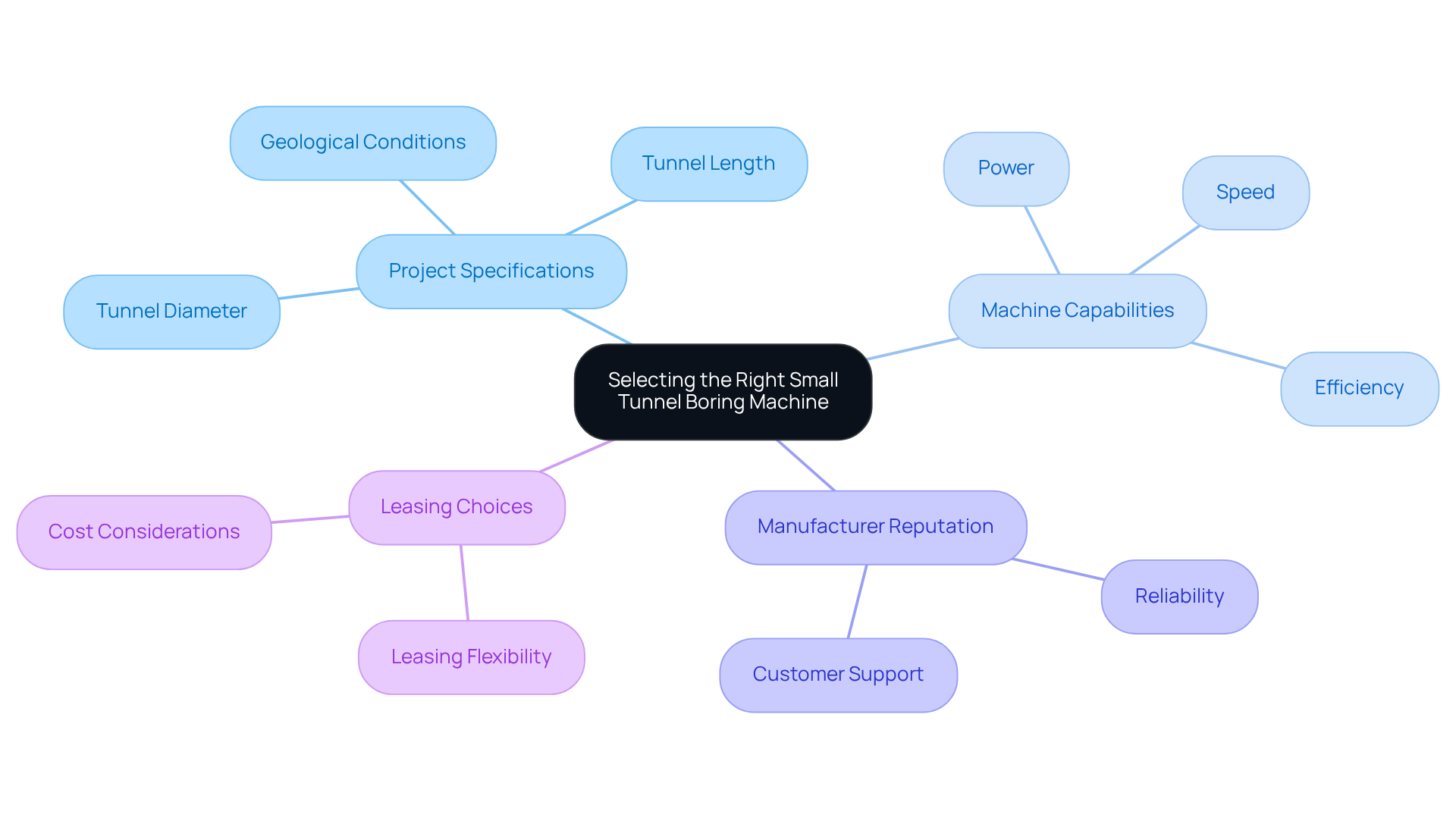

Select the Right Small Tunnel Boring Machine

Selecting the right small tunnel boring machine rental for your construction project requires a meticulous evaluation of several key factors.

Project Specifications: Start by assessing the diameter and length of the tunnel, along with the geological conditions. Different TBMs are engineered for specific soil types and tunnel dimensions, making this assessment essential for optimal performance.

Machine Capabilities: Next, evaluate the TBM's power, speed, and efficiency. It is crucial to ensure that the machine can handle the anticipated workload and environmental challenges, as these factors directly influence timelines and expenses. Recent market analysis indicates that the global tunnel boring machine market was valued at USD 7.50 billion in 2024 and is expected to grow at a CAGR of 6.5% from 2025 to 2032, underscoring the increasing demand for efficient tunneling solutions.

Manufacturer Reputation: Investigate the manufacturers and their historical performance. Opting for machines from reputable companies known for their reliability and customer support can significantly mitigate risks associated with equipment failure. As one construction manager noted, "Choosing a TBM from a reliable manufacturer not only guarantees quality but also offers reassurance during vital phases of the endeavor."

Leasing Choices: Finally, assess leasing proposals from various suppliers to identify the best fit for your needs and budget. Flexibility in leasing conditions, particularly in small tunnel boring machine rental, is vital to accommodate any potential alterations, which is crucial for maintaining workflow efficiency. A case study on successful projects utilizing small tunnel boring machine rental under specific geological conditions revealed that having adaptable leasing agreements can lead to smoother execution and reduced downtime.

By carefully considering these factors, you can select a TBM that not only enhances project efficiency but also minimizes downtime, ultimately contributing to the success of your construction endeavors.

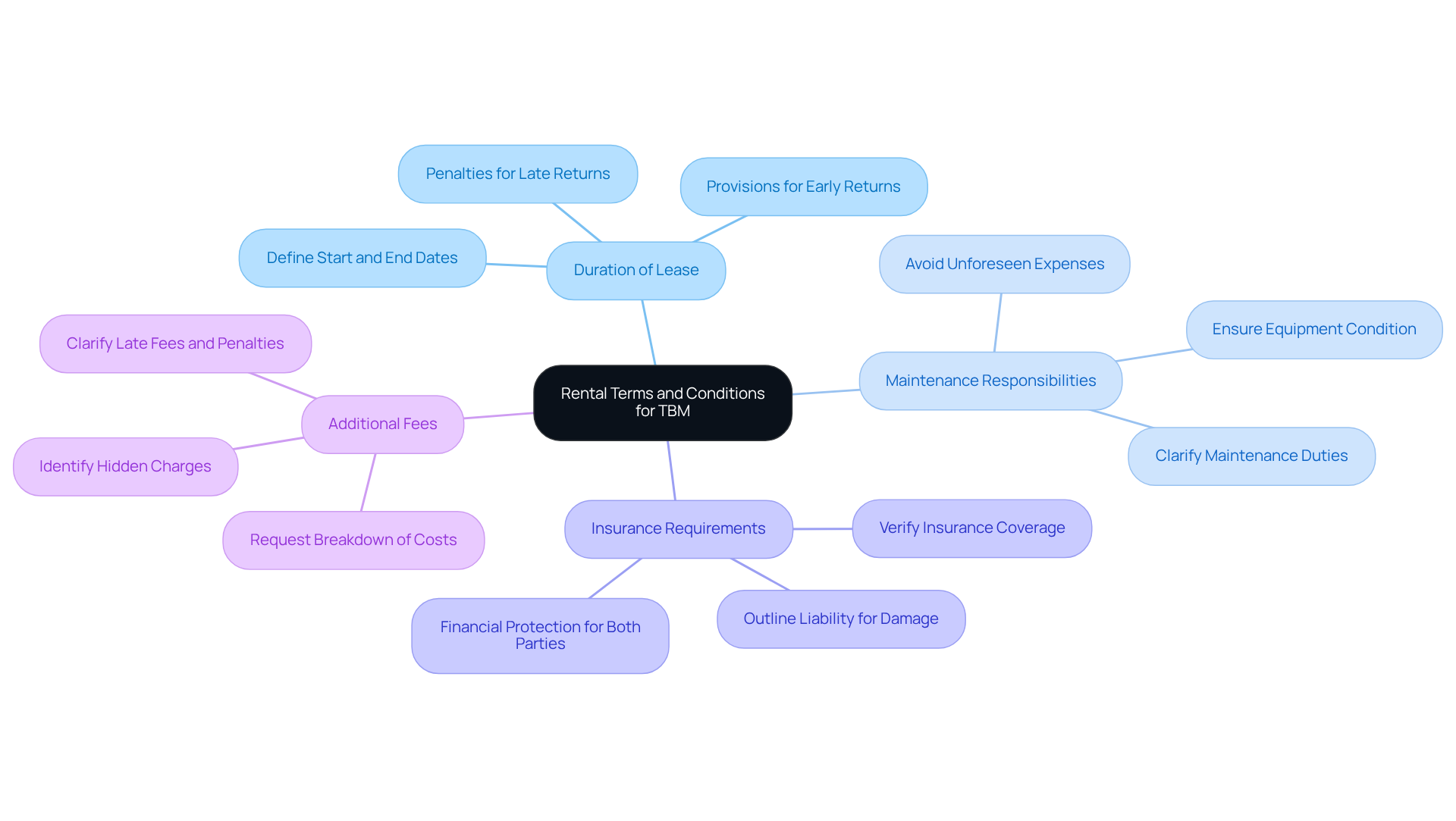

Understand Rental Terms and Conditions

When finalizing a rental agreement for a small tunnel boring machine (TBM), it is essential to pay close attention to the following key terms:

- Duration of Lease: Clearly define the leasing period, including start and end dates. Comprehending the timeline is crucial to synchronize with your schedule and prevent penalties for late returns, which can significantly impact budgets.

- Maintenance Responsibilities: Specify who is responsible for maintenance and repairs during the lease period. This clarity can help avoid unforeseen expenses and ensure that the equipment remains in peak condition throughout the project.

- Insurance Requirements: Verify whether the rental company mandates insurance coverage for the equipment. Understanding these requirements protects both parties in the event of damage or loss, ensuring financial security.

- Additional Fees: Be vigilant about potential hidden charges, such as transportation expenses, late fees, or penalties for exceeding usage limits. Requesting a comprehensive breakdown of all possible costs is vital to avoid surprises that could derail your budget.

By thoroughly understanding these terms, you can mitigate risks and facilitate a seamless experience with small tunnel boring machine rental, ultimately contributing to the success of your project.

As the U.S. construction equipment leasing market is projected to grow to USD 54.17 billion by 2029, comprehending these agreements becomes increasingly vital. Josh Nickell, Vice President of the American Rental Association, emphasizes the significance of planning and analytics in equipment leasing, stating, "You can’t just assume that there’s a piece of equipment on your lot or hope one will be back in time; you have got to do a lot more planning, and use analytics to forecast what your needs are going to be." By being aware of common pitfalls, such as misunderstandings regarding maintenance duties or concealed charges, managers can navigate the leasing process more effectively.

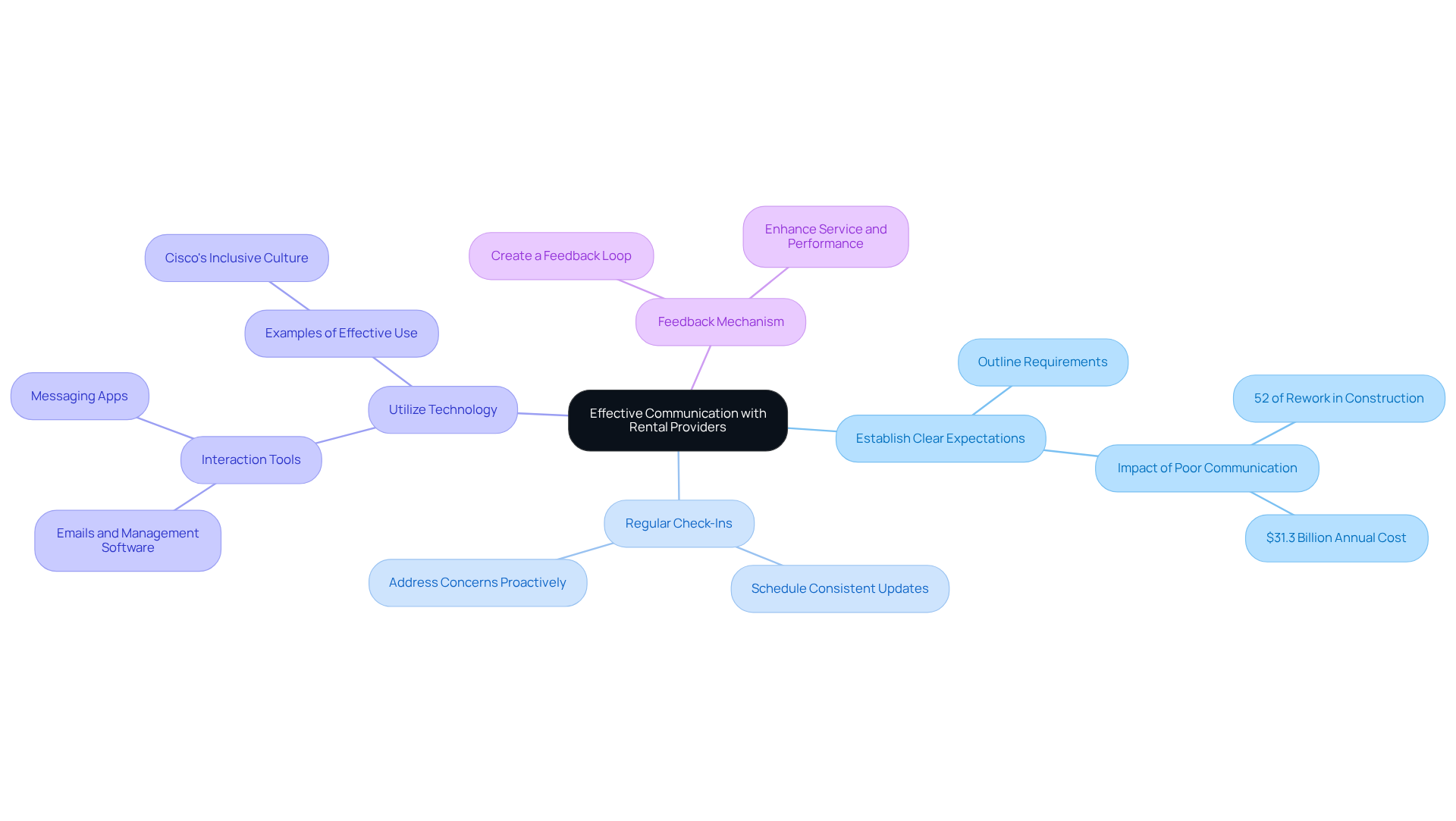

Communicate Effectively with Rental Providers

To foster effective communication with your rental provider, consider these strategies:

- Establish Clear Expectations: Clearly outline your requirements, including timelines, equipment specifications, and any special needs. This clarity helps the provider understand your expectations and aligns their services with your project goals. Notably, poor communication causes 52% of rework in construction, costing the industry $31.3 billion annually, underscoring the importance of clear expectations.

- Regular Check-Ins: Schedule consistent updates with the rental provider to discuss progress, address concerns, and make necessary adjustments to the rental agreement. This proactive approach minimizes misunderstandings and keeps the initiative on track.

- Utilize Technology: Leverage interaction tools such as emails, management software, or messaging apps to maintain open lines of dialogue. This ensures that all parties are informed and engaged, facilitating timely decision-making. Organizations like Cisco exemplify inclusive culture and open dialogue practices, serving as a model for effective interaction in your projects.

- Feedback Mechanism: Create a feedback loop where both parties can share insights and suggestions. This cooperative method can lead to enhancements in service and equipment performance, improving the overall experience. Dr. Jeremy Pollack emphasizes that addressing interaction obstacles is crucial for enhancing collaboration and preventing disputes in the construction sector.

By applying these interaction strategies, you can establish a strong partnership with your provider of small tunnel boring machine rental, resulting in a more successful project. Effective communication not only streamlines operations but also fosters trust and collaboration—essential elements in the construction industry.

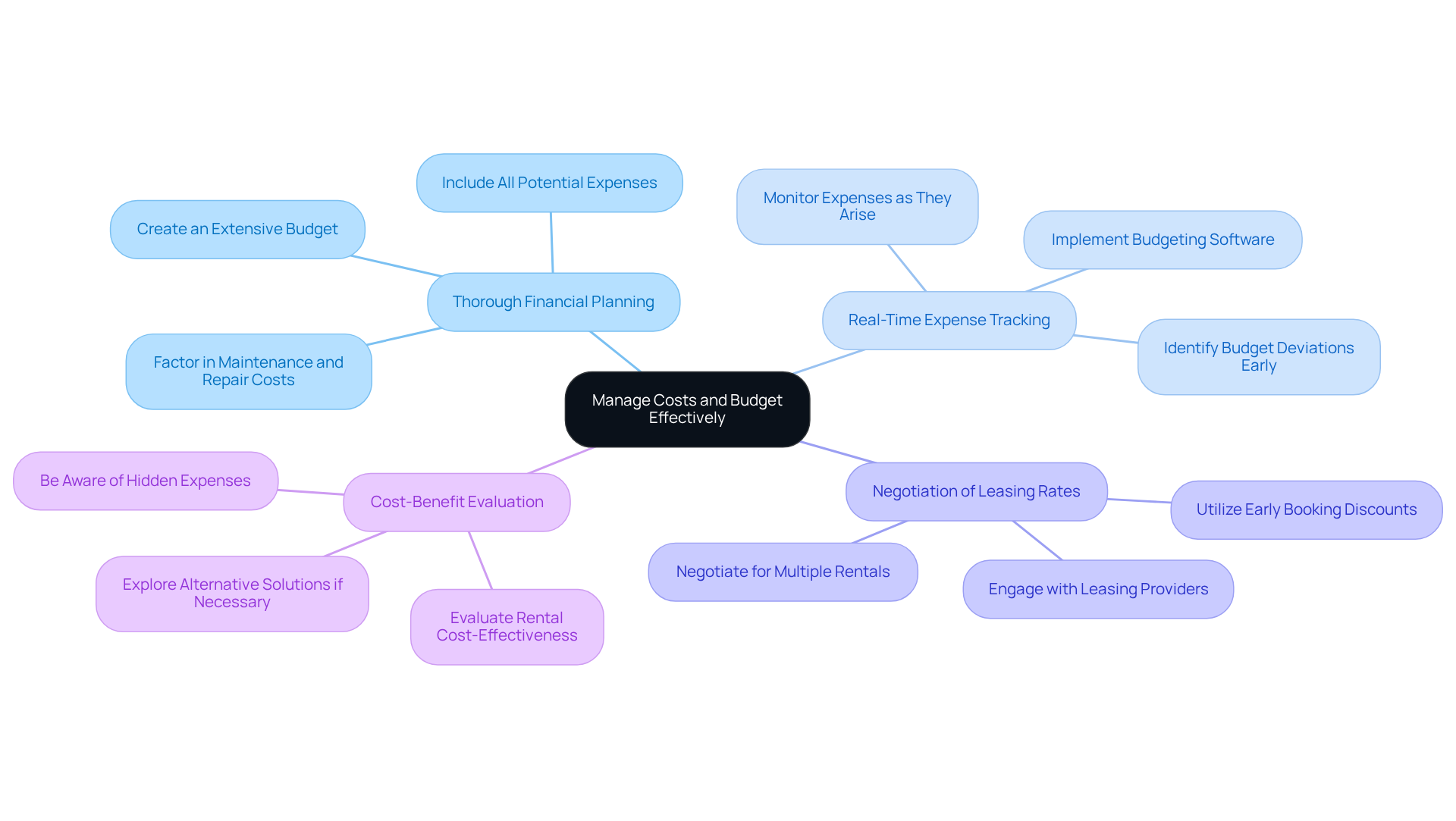

Manage Costs and Budget Effectively

To manage costs effectively when utilizing small tunnel boring machine rental, it is essential to adopt robust budgeting strategies.

- Thorough Financial Planning: Begin by creating an extensive budget that encompasses all potential expenses related to the lease, including transportation, maintenance, and insurance. According to the American Rental Association, maintenance and repair costs typically account for about 10-15% of revenues, underscoring the importance of incorporating these expenses into your financial plan.

- Real-Time Expense Tracking: Implement budgeting software or spreadsheets to monitor expenses as they arise. This proactive approach facilitates the early identification of any budget deviations, allowing for timely adjustments. As noted by Fernando de Querol Cumbrera, effective tracking can avert unexpected financial burdens, ensuring that your project remains on track.

- Negotiation of Leasing Rates: Engage in discussions with leasing providers to negotiate favorable rates, particularly for small tunnel boring machine rental when renting multiple pieces of equipment. Many companies are open to pricing negotiations, which can result in substantial savings. For example, United Rentals successfully executed an early booking discount strategy, leading to a remarkable 40% increase in pre-booked transactions.

- Cost-Benefit Evaluation: Regularly evaluate the cost-effectiveness of the rental. If the machine is underperforming or expenses surpass initial projections, it may be prudent to explore alternative solutions. Be vigilant about common pitfalls, such as overlooking hidden expenses or failing to adjust the budget based on actual usage.

By implementing these financial management strategies, you can maintain your initiative within budget while effectively achieving its objectives. Remember, proficient budgeting not only aids in controlling costs but also significantly enhances overall project success.

Conclusion

Selecting a small tunnel boring machine (TBM) for rental is a pivotal decision that can greatly influence the success of construction projects. This process requires meticulous consideration of various factors, including:

- Project specifications

- Machine capabilities

- Manufacturer reputation

- Leasing options

By prioritizing these elements, project managers can optimize performance and reduce downtime, ensuring that the construction endeavor advances seamlessly.

Key insights presented throughout this article highlight the necessity of comprehending rental terms and conditions, fostering effective communication with rental providers, and implementing robust cost management strategies. Establishing clear expectations, conducting regular check-ins, and utilizing feedback mechanisms cultivate strong partnerships that enhance project collaboration. Furthermore, thorough financial planning and real-time expense tracking are vital for maintaining budgets and avoiding unforeseen costs.

Ultimately, the successful rental of a small tunnel boring machine relies on informed decision-making and proactive management. By applying the strategies outlined, construction professionals can not only improve operational efficiency but also contribute to the overarching success of their projects. Embracing these best practices will facilitate smoother operations, generate cost savings, and ensure more effective resource utilization in the construction industry.

Frequently Asked Questions

What factors should be evaluated when selecting a small tunnel boring machine (TBM) rental?

Key factors include project specifications (diameter and length of the tunnel, geological conditions), machine capabilities (power, speed, efficiency), manufacturer reputation, and leasing choices.

Why is it important to assess project specifications before selecting a TBM?

Assessing project specifications is essential because different TBMs are designed for specific soil types and tunnel dimensions, which directly affects their performance.

What machine capabilities should be considered when choosing a TBM?

Important machine capabilities to evaluate include the TBM's power, speed, and efficiency, ensuring it can handle the expected workload and environmental challenges.

How does the reputation of the manufacturer influence the selection of a TBM?

Choosing a TBM from a reputable manufacturer can significantly reduce risks associated with equipment failure, as these companies are known for their reliability and customer support.

What should be considered regarding leasing proposals for TBMs?

It's important to assess leasing proposals from various suppliers to find the best fit for your needs and budget, with a focus on flexibility in leasing conditions to accommodate potential changes.

How can adaptable leasing agreements impact construction projects?

Adaptable leasing agreements can lead to smoother execution and reduced downtime, contributing to overall project efficiency and success.