Overview

Choosing the right straight boom lift with jib is crucial for project success. Key criteria to evaluate include:

- Height requirements

- Weight capacity

- Operational environment, which encompasses terrain and space constraints

Understanding how these factors impact safety and efficiency on job sites is essential. Selecting equipment that meets specific project needs and adheres to safety standards not only ensures compliance but also enhances overall productivity.

Key Highlights:

- Straight boom lifts with jib extend both vertically and horizontally, enhancing access to elevated work areas.

- The jib feature improves manoeuvrability, making it ideal for tasks like electrical work and construction.

- Key selection criteria include height requirements, weight capacity, and horizontal reach for optimal performance.

- Assessing the operational environment involves evaluating terrain, indoor vs. outdoor use, space constraints, and access points.

- Safety features such as stability systems, emergency controls, and operator training are critical for safe operation.

- Compliance with safety standards, including OSHA regulations, is necessary to minimise risks and ensure legal adherence.

Introduction

Choosing the right straight boom lift with jib is crucial for the success of construction and maintenance projects. Yet, many overlook essential features that enhance both performance and safety. These versatile machines offer unparalleled access to elevated work areas, making them invaluable for tasks that demand precision.

With a myriad of options available, how can you ensure that the selected equipment meets specific project needs while adhering to safety standards? This guide explores the critical steps for making an informed choice, ensuring both efficiency and security on the job site.

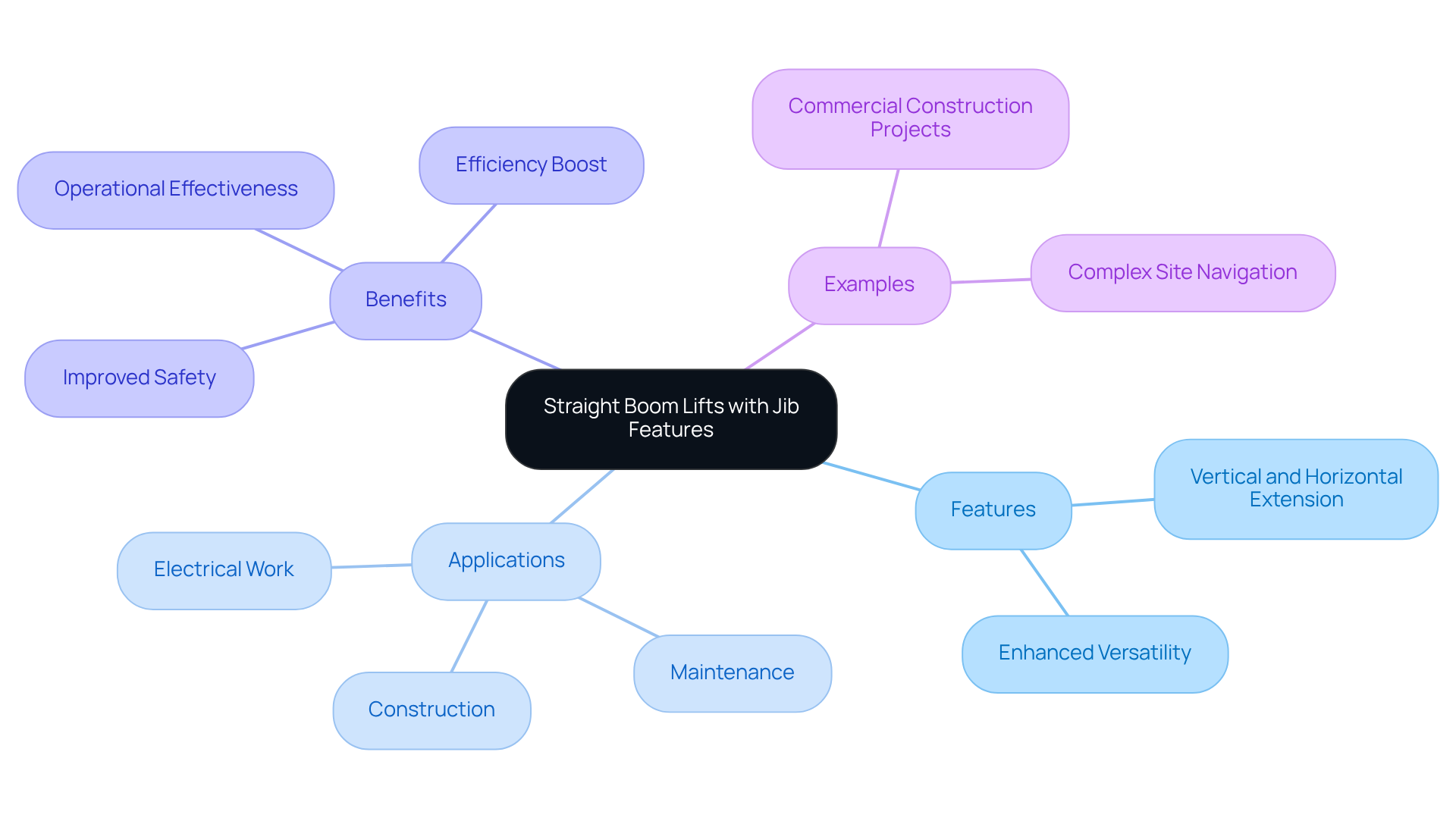

Understand Straight Boom Lifts and Their Jib Features

Telescopic boom apparatuses, known as straight boom lift with jib devices, are engineered to extend both vertically and horizontally, allowing precise access to elevated work areas. The straight boom lift with jib mechanism, which serves as an additional rotating arm, significantly enhances the versatility of the hoist, facilitating optimal placement of workers and materials. This capability proves particularly beneficial for tasks such as electrical work, maintenance, and construction projects that require accurate positioning at height. The jib feature allows for improved reach and maneuverability, streamlining operations and boosting efficiency on the job site.

For instance, in a recent commercial construction project, the deployment of straight aerial platforms equipped with arm capabilities enabled teams to navigate complex site designs effectively, thereby enhancing both safety and productivity. Industry specialists emphasize that using a straight boom lift with jib can lead to substantial improvements in operational effectiveness, as it provides access to hard-to-reach locations without compromising safety. Understanding these advanced features is essential for selecting the right equipment tailored to your specific project needs, as they can significantly impact both efficiency and safety on the job site.

Evaluate Key Selection Criteria for Your Project

When selecting a straight boom lift with jib, several key criteria must be carefully evaluated to ensure optimal performance and safety.

-

Height Requirements: Establish the maximum height necessary for your project. Straight aerial platforms can achieve impressive elevations, with some models, such as Genie's ZX-135, reaching up to 135 feet with a 600 lb capacity, and the SX-180 reaching 180 feet with a 750 lb capacity. Ensure the selected model meets or exceeds your project's height specifications to facilitate safe and efficient operations.

-

Weight Capacity: It is crucial to assess the combined weight of materials and personnel that will be lifted. Each boom hoist has a specified weight capacity, usually varying from 440 lbs to 1,000 lbs. Surpassing this limit can present considerable hazards, making it essential to select an elevator that meets your particular load needs. Proper evaluation of weight capacity not only ensures compliance with safety regulations but also enhances operational efficiency.

-

Reach: Consider the horizontal extension of the equipment, which is vital for projects requiring access to areas not directly beneath it. Many straight boom lifts with jib provide significant horizontal outreach, enhancing their versatility in various applications.

For projects demanding precise positioning, opt for a straight boom lift with jib. This feature allows for additional maneuverability, enabling operators to place materials accurately, which is particularly beneficial in tasks such as installation and maintenance.

In the construction industry, understanding these selection criteria is paramount. Initiatives that necessitate considerable vertical reach must prioritize equipment with sufficient height capabilities, while those involving heavy materials must choose models with suitable weight limits to avert accidents and guarantee worker safety. Significantly, most elevation accidents are caused by falling, highlighting the importance of following these criteria during the selection process. Furthermore, using an aerial platform can greatly improve efficiency, enabling workers to accomplish tasks quickly and aid in prompt project completion. Contemporary aerial platforms are designed with improved safety features, ensuring secure operations in elevated work environments.

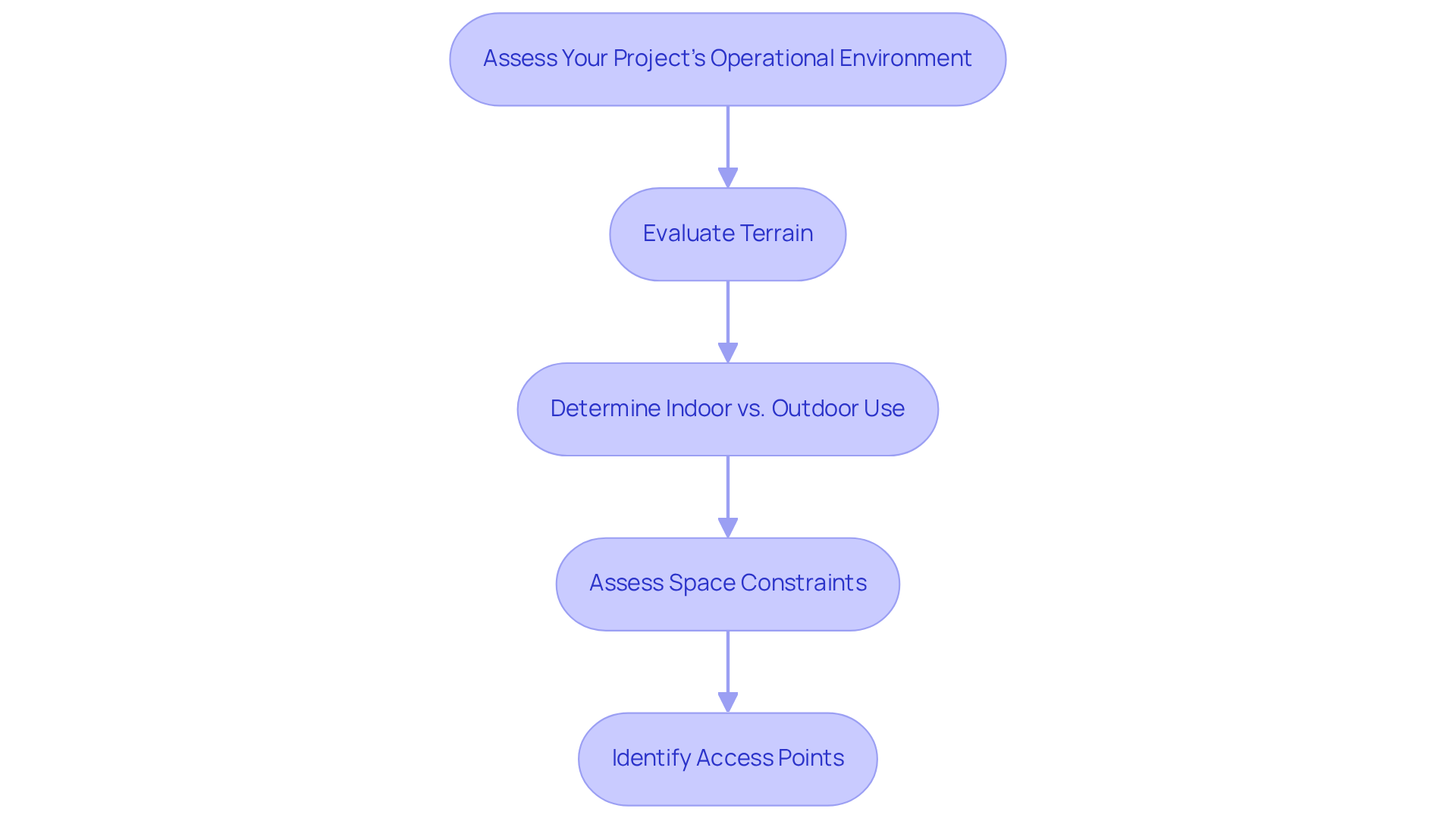

Assess Your Project's Operational Environment

Before finalizing your choice of a straight boom lift, it is crucial to assess the operational environment to ensure optimal performance and safety.

Terrain: Begin by evaluating whether the apparatus will be utilized on flat surfaces, uneven ground, or slopes. Models designed for rough terrain often feature enhanced stability and traction, making them suitable for challenging conditions. For example, articulating boom devices are particularly effective in navigating obstacles and tight spaces, while telescopic boom equipment excels in providing extended reach on flat terrains. Notably, industry statistics reveal that around 20-30% of construction accidents are associated with heavy machinery such as aerial platforms, underscoring the significance of selecting the appropriate model for the terrain.

Indoor vs. Outdoor Use: Next, determine the primary usage environment. Indoor elevators typically require a more compact design and lower noise levels to comply with regulations and minimize disruption. Conversely, outdoor elevators must be robust enough to withstand various weather conditions, with engine-powered models often preferred for their reliability in demanding environments. Recent statistics indicate that electric boom platforms represented approximately 35% of the boom platforms market revenue in 2023, showcasing their increasing popularity for indoor applications.

Space Constraints: Additionally, evaluate the available area for maneuvering the hoist. It is essential to ensure that the elevator can function without obstructions and has sufficient space for setup and operation. For instance, compact aerial work platforms are perfect for tight areas, whereas larger versions might be required for expansive outdoor locations. Construction professionals often recommend assessing the specific dimensions of the work area to avoid operational delays.

Access Points: Finally, determine how the elevator will reach the work area. Consider door widths, overhead clearances, and any potential obstacles that may hinder movement. Proper planning in this area can prevent delays and ensure efficient operation. Experts in the field emphasize that awareness of overhead power lines is critical to prevent electrocutions and serious injuries when using equipment near live electrical wires.

Integrating these factors not only enhances security but also optimizes the effectiveness of aerial platform operations, adhering to industry best practices and minimizing the risk of incidents.

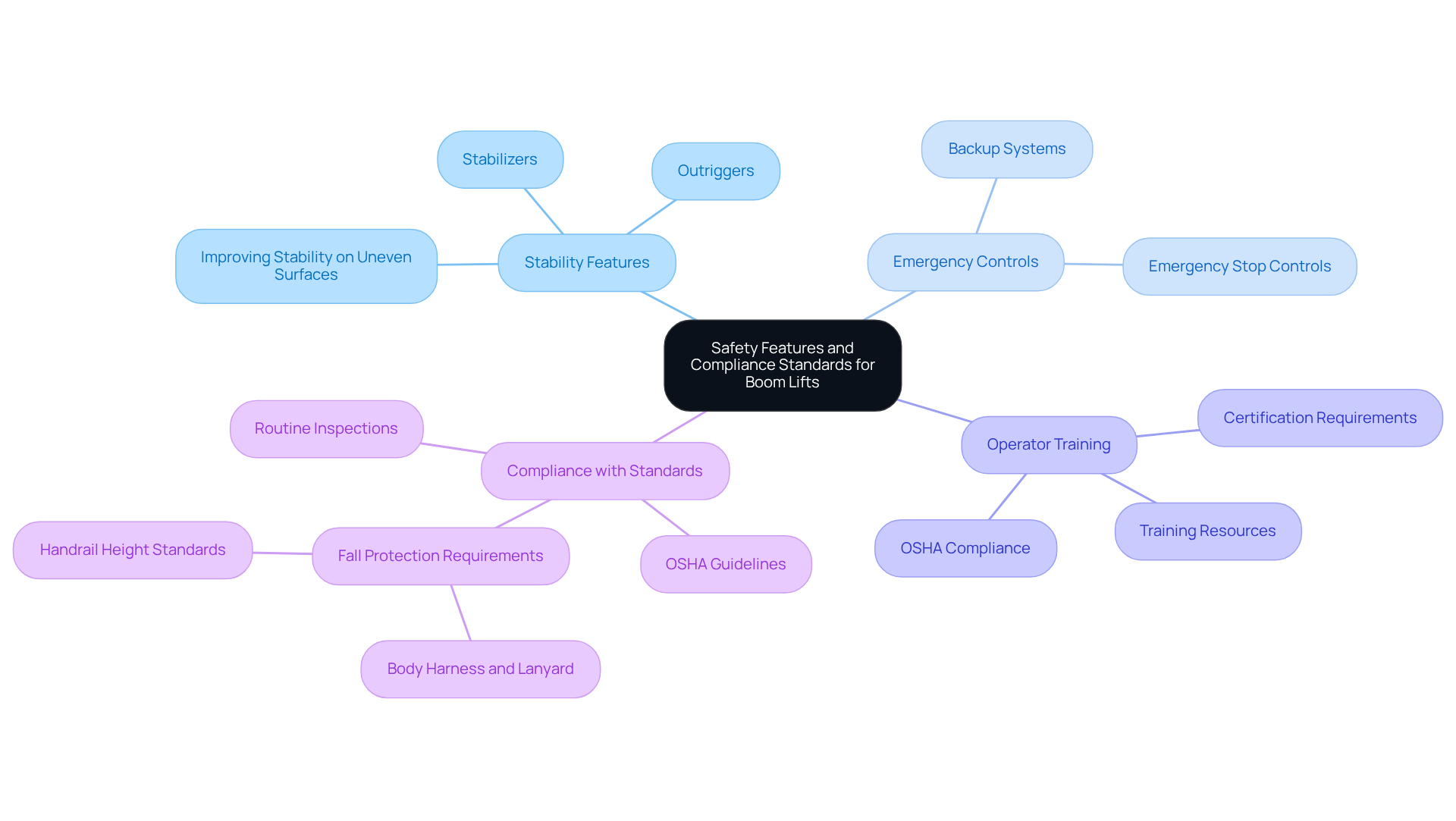

Prioritize Safety Features and Compliance Standards

Safety is paramount when selecting a straight boom lift with jib for residential construction projects in Dallas. It is crucial to consider key safety features and compliance standards that ensure both efficiency and protection on the job site.

-

Stability Features: Elevators equipped with stabilizers or outriggers are essential for improving stability during operation, particularly on uneven surfaces. Instability can lead to accidents, especially in construction settings where a straight boom lift with jib plays a vital role in safeguarding workers and facilitating effective task completion.

-

Emergency Controls: It is imperative that the elevator includes emergency stop controls and backup systems. These features are critical for managing unexpected situations, significantly mitigating the risk of accidents on the job site.

-

Operator Training: Ensure that operators are properly trained and certified to safely use the equipment. Many manufacturers provide comprehensive training resources, which are vital for compliance with OSHA regulations and for minimizing workplace accidents. Companies that neglect to train their workers may incur costly OSHA fines, underscoring the importance of thorough training in residential construction.

-

Compliance with Standards: Confirm that the apparatus meets local and national regulations, including OSHA guidelines. Adherence not only guarantees the equipment's security but also fulfills legal obligations, protecting both employees and the organization from potential liabilities. Routine examinations of aerial equipment are essential for maintaining compliance and ensuring a safe work environment. Furthermore, OSHA mandates the use of a body harness and lanyard for boom-supported equipment to limit operator movement, while fall protection requirements for handrail systems specify a minimum height of 42 inches. Educating operators about climbing hazards is also crucial to reducing fatalities. This reinforces the significance of renting a straight boom lift with jib from EZ Equipment Rental, which supports compliance and safety through its services.

Conclusion

Choosing the right straight boom lift with jib is a crucial decision that can significantly impact the efficiency and safety of construction projects. By comprehensively understanding the unique features of these lifts—particularly their vertical and horizontal reach capabilities—one can ensure that the selected equipment meets the specific demands of the job. The jib function enhances versatility, allowing for precise positioning that is essential in many elevated tasks.

Throughout this discussion, key selection criteria such as height requirements, weight capacity, reach, and the operational environment have been thoroughly examined. Evaluating these factors not only ensures compliance with safety regulations but also enhances overall operational effectiveness. Furthermore, prioritizing safety features and compliance standards is paramount, as they play a crucial role in preventing accidents and ensuring a secure work environment.

In conclusion, selecting the appropriate straight boom lift with jib is not merely a matter of convenience; it is a vital step toward achieving successful project outcomes. By carefully considering the discussed criteria and emphasizing safety, operators can optimize their work processes while minimizing risks. It is essential to approach this decision with diligence, as the right equipment can lead to improved productivity and a safer workplace, ultimately reinforcing the importance of informed choices in construction operations.

Frequently Asked Questions

What is a straight boom lift with jib?

A straight boom lift with jib is a telescopic boom apparatus designed to extend both vertically and horizontally, allowing precise access to elevated work areas. The jib mechanism acts as an additional rotating arm to enhance the versatility of the lift.

What advantages does the jib feature provide?

The jib feature improves reach and maneuverability, allowing for optimal placement of workers and materials. This is particularly beneficial for tasks that require accurate positioning at height, such as electrical work, maintenance, and construction projects.

How does the use of a straight boom lift with jib impact safety and productivity?

Using a straight boom lift with jib can enhance safety and productivity by providing access to hard-to-reach locations without compromising safety. This capability allows teams to navigate complex site designs more effectively.

Why is it important to understand the features of straight boom lifts with jib?

Understanding these advanced features is essential for selecting the right equipment tailored to specific project needs, as they can significantly impact both efficiency and safety on the job site.

Can you provide an example of where straight boom lifts with jib have been beneficial?

In a recent commercial construction project, the deployment of straight aerial platforms equipped with arm capabilities enabled teams to effectively navigate complex site designs, thereby enhancing both safety and productivity.