Key Highlights:

- The 6k telehandler has a maximum load capacity of 6,000 lbs, with capacity decreasing as the boom extends.

- Understanding the load capacity chart is essential to prevent accidents and equipment damage.

- The telehandler can lift to a maximum height of approximately 42 feet and reach forward up to 30 feet.

- Proper operator training is crucial for safe operation and effective use of the telehandler's capabilities.

- The telehandler's four-wheel drive and multiple steering modes enhance its manoeuvrability on various terrains.

- Versatile attachments like forks and buckets improve operational efficiency and reduce the need for multiple machines.

- Stability features, such as a low centre of gravity, are vital for preventing tipping during operations.

- Operator comfort is enhanced through ergonomic seating, intuitive controls, and climate control systems, which improve productivity.

Introduction

The construction industry consistently seeks innovative solutions to boost productivity and safety on job sites. Among these solutions, the 6k telehandler emerges as a versatile piece of equipment, offering project managers a variety of features tailored to address the challenges of modern construction. However, with its remarkable capabilities comes the necessity of comprehending its specifications, including load capacity, reach, maneuverability, and operator comfort.

How can project managers fully leverage the potential of the 6k telehandler while ensuring safety and efficiency? This article explores six key features essential for maximizing the effectiveness of this powerful machine.

Understand Load Capacity of the 6k Telehandler

The 6k telehandler features a maximum load capacity of 6,000 lbs, which is crucial for lifting heavy materials on construction sites. Understanding the load capacity chart is essential, as it outlines the maximum weight that can be lifted at various heights and reaches. Importantly, as the boom extends, the load capacity decreases. Therefore, project managers must ensure that operators are well-trained in interpreting these charts accurately. Misunderstanding load limits can result in overloading, a frequent cause of accidents and equipment damage.

For instance, a telescopic handler's load capacity chart typically includes a grid that displays secure lifting capacities at different boom angles and extensions. This highlights the importance of meticulous planning and adherence to regulations. Regular training and pre-operation inspections are vital for maintaining safety and efficiency on the job site.

Evaluate Reach and Height Capabilities of the 6k Telehandler

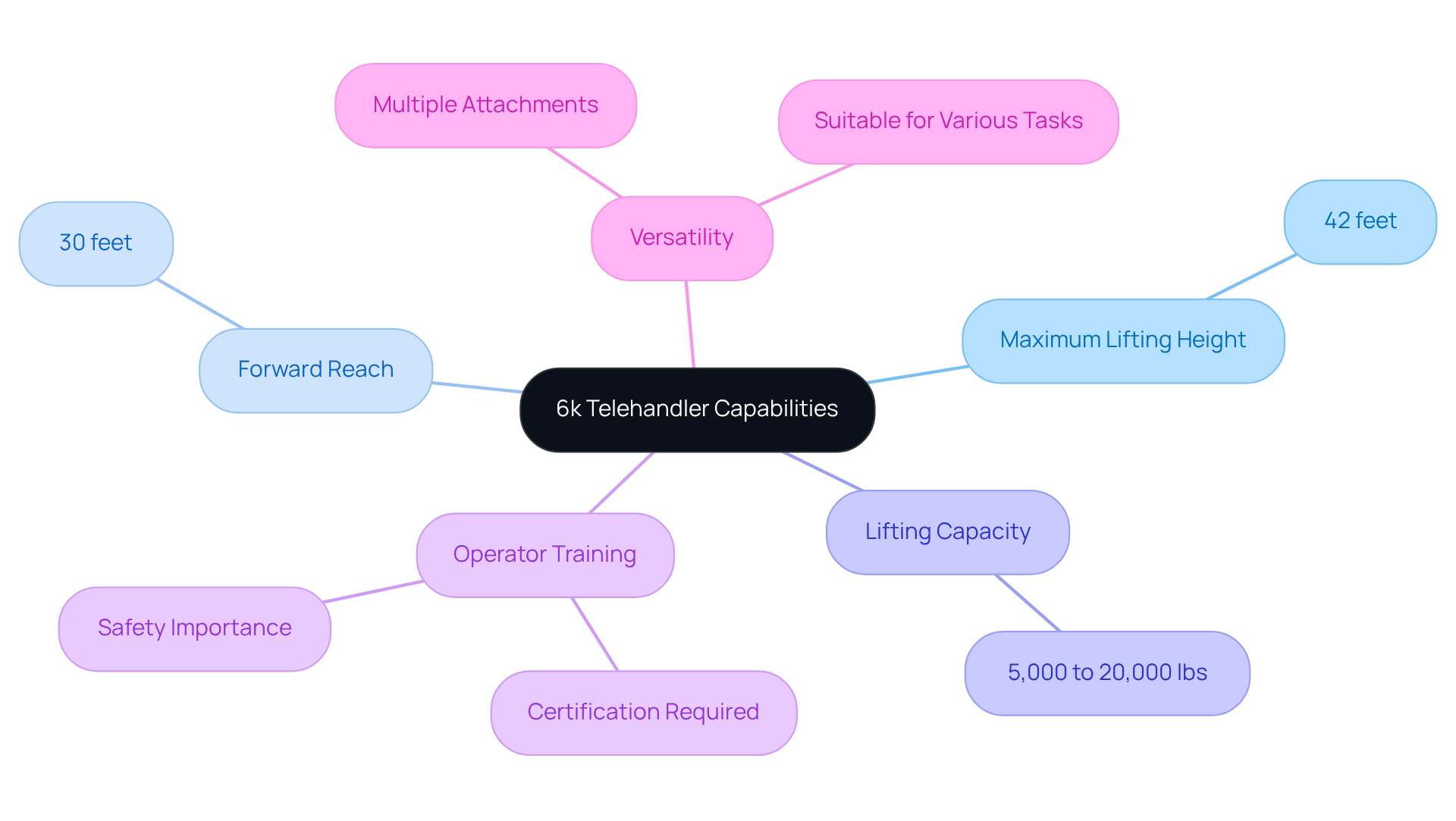

The 6k telehandler is designed to achieve a maximum lifting height of approximately 42 feet and a forward reach of around 30 feet, making it an essential tool for various construction tasks. These specifications empower project managers to efficiently position materials on elevated structures or maneuver through tight spaces with ease.

Telehandlers can lift between 5,000 and over 20,000 lbs, offering a significant advantage compared to skid steers, which primarily focus on digging or grading tasks. For instance, when lifting materials to the upper levels of a multi-story building, the height capability of the lifting equipment is a critical factor in machinery selection.

As one construction expert noted, 'Choosing the appropriate 6k telehandler for high-rise projects depends on understanding its reach and lift height; it’s vital for ensuring safety and productivity on site.'

Furthermore, boom lifts, which provide excellent vertical and horizontal reach, enhance safety by allowing workers to access elevated areas securely, making them a valuable asset on any construction site.

Telehandlers necessitate operator training and certification for safe operation, highlighting the importance of proper handling. Therefore, assessing the specific needs of each project is crucial to ensure that the equipment's capabilities align with operational demands, ultimately enhancing productivity and safety.

EZ Equipment Rental in Dallas offers a diverse fleet of specialized equipment, including electric forklifts and rough terrain forklifts, ensuring that project managers have access to the right tools tailored to their requirements.

Assess Maneuverability of the 6k Telehandler

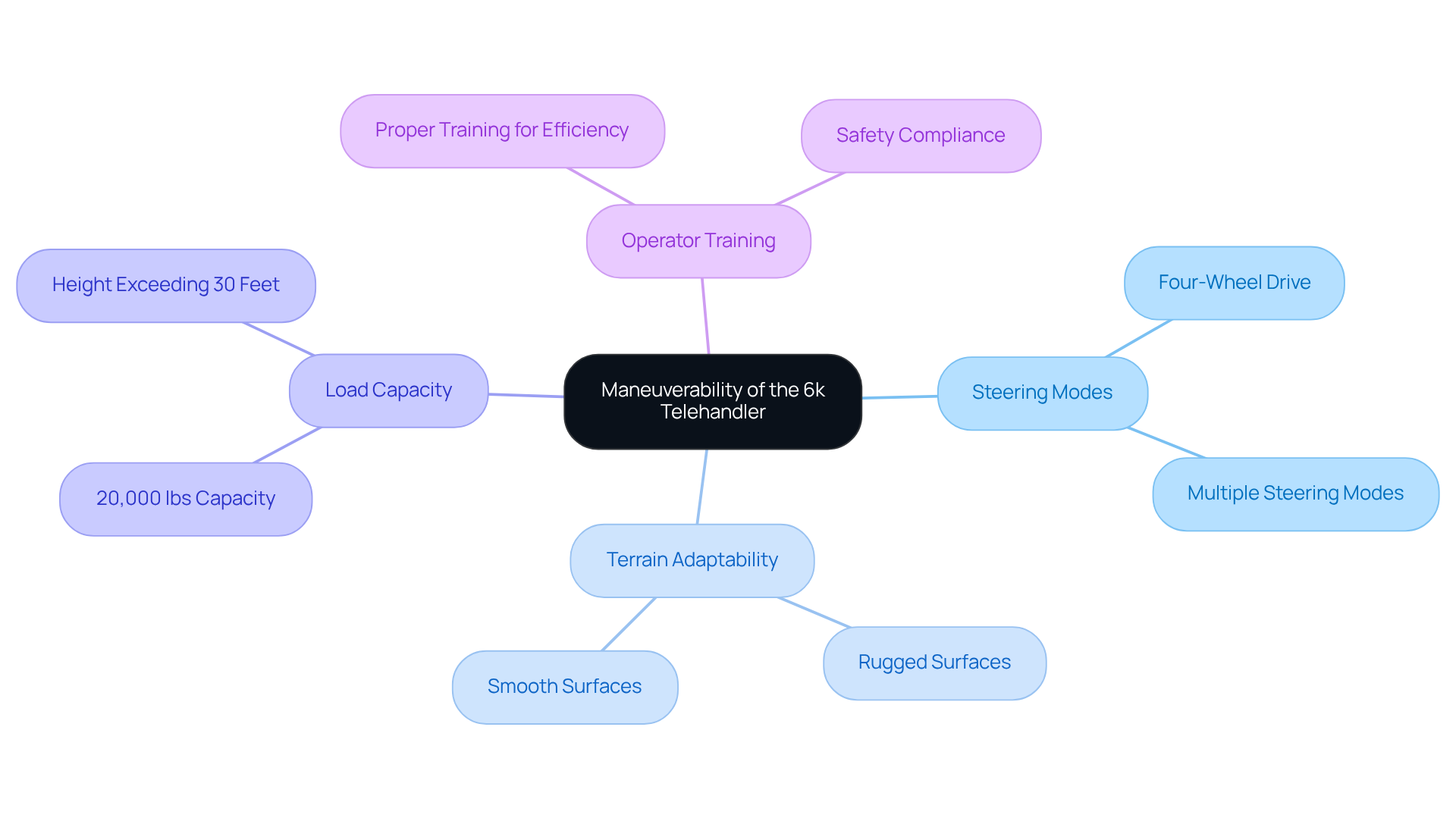

The 6k telehandler is engineered for exceptional maneuverability, featuring four-wheel drive and multiple steering modes that allow it to traverse rough terrain and tight workspaces with ease. Telehandlers are capable of operating on both rugged and smooth surfaces, making them versatile assets for a range of applications.

Project managers should meticulously evaluate their worksite layout; in environments with narrow pathways or uneven ground, a machine with enhanced maneuverability is vital for sustaining operational efficiency. Furthermore, a 6k telehandler can lift loads up to 20,000 lbs and reach heights exceeding 30 feet, which is crucial for overcoming obstacles on construction sites.

It is also imperative for operators to receive proper training to effectively utilize these features, thereby improving the machine's performance and ensuring safe, efficient operations. With the material handling equipment market projected to reach USD 2.3 billion by 2025, recognizing the importance of selecting the right machinery is essential for project managers.

Explore Versatile Attachments for the 6k Telehandler

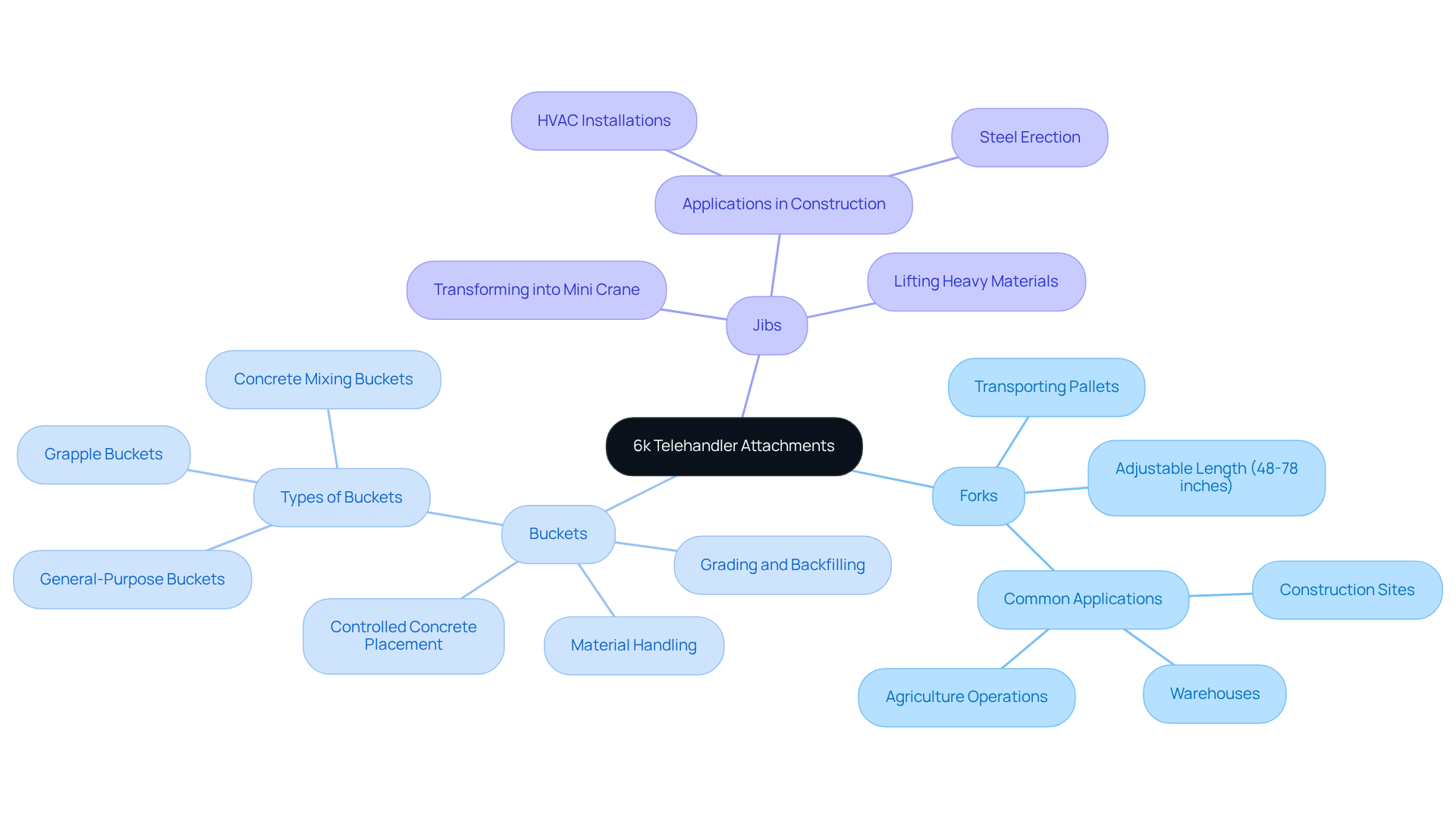

The versatility of the 6k telehandler is greatly enhanced by its ability to accommodate various attachments, such as forks, buckets, and jibs. For example, a bucket attachment is particularly effective for efficient material handling, while forks are designed for transporting pallets across job sites. Standard pallet forks typically range from 48 to 78 inches in length, making them suitable for a variety of load sizes. Project managers should evaluate the specific tasks at hand and select the most appropriate attachments to optimize the machine's operational efficiency. This adaptability streamlines processes and reduces the need for multiple pieces of equipment, ultimately saving both time and costs.

Case studies have shown that projects utilizing adaptable equipment attachments, like the Pallet Fork Attachment, experience significant improvements in productivity and safety. For instance, jibs allow for the precise lifting of heavy materials to elevated locations, effectively transforming the equipment into a mini crane, which is essential in construction settings. Experts stress the importance of selecting the right attachment; it must align with the weight, height, and terrain of the job to ensure optimal performance. Additionally, operators should inspect attachments for damage and verify compatibility with the hydraulic system of the lifting equipment to maintain safety. By fully leveraging the potential of equipment attachments, project managers can enhance their operational capabilities and achieve greater efficiency on site.

Prioritize Stability Features of the 6k Telehandler

The stability characteristics of the 6k telehandler, such as a low center of gravity and a wide wheelbase, are essential for safe operations. These design features are critical in preventing tipping during lifting tasks, especially on uneven surfaces. In 2018, telehandler accidents were prevalent, with 20% resulting from loss of control over the machine, objects, or animals. This statistic highlights the urgent need for proper training in stability management. Furthermore, a tip-over can incur repair costs ranging from $8,000 to $20,000, along with potential downtime and liability risks, underscoring the economic implications of stability issues.

Understanding the stability triangle - which includes the load, the machine's center of gravity, and the ground - is vital for operators. Implementing automatic correction systems and load limiters can enhance safety by ensuring adherence to operational parameters. Regular maintenance, such as checking tire pressure, is also crucial for optimal lifting stability. By prioritizing personnel education on these stability concepts, project managers can significantly improve site safety and operational efficiency, ultimately fostering a more secure working environment.

Recognize Operator Comfort and Control Features of the 6k Telehandler

The 6k telehandler emphasizes user comfort by incorporating ergonomic seating, intuitive controls, and excellent visibility. These design elements help minimize fatigue and enhance concentration during tasks. As noted by Kubota Construction Equipment, "A comfortable worker is a productive worker," emphasizing the vital link between comfort and productivity. Therefore, project managers should prioritize equipment that incorporates these comfort features, as they can significantly boost productivity and ensure safer operations.

Moreover, providing training on the use of controls can further enhance user efficiency, ensuring tasks are completed effectively and safely. For example, the R13100 model has a capacity of 13,200 lbs and a maximum lift height of 97 ft, illustrating how ergonomic design contributes to operational effectiveness. Additionally, advanced safety mechanisms, such as Automatic Attachment Recognition and Load Management Information System, play a crucial role in enhancing operational security by providing essential information and alerts to users.

Climate control systems are also vital for maintaining operator comfort in harsh weather conditions, further supporting productivity and safety on the job site. By investing in telehandlers that emphasize ergonomic design, project managers can enhance overall productivity and foster a safer work environment.

Conclusion

The 6k telehandler is an essential tool for project managers, offering a remarkable combination of load capacity, reach, and versatility, all while incorporating vital safety features. Its design facilitates efficient lifting and transporting of materials on construction sites, prioritizing operator comfort and control. This makes it a comprehensive solution tailored to meet various project demands.

Key features of the 6k telehandler include:

- A maximum load capacity of 6,000 lbs

- An impressive reach of 42 feet

- Superior maneuverability across diverse terrains

Selecting appropriate attachments to enhance functionality is crucial, as is ensuring stability for safe operations. Additionally, the ergonomic design and user-friendly controls significantly boost operator productivity and safety, reinforcing the telehandler's value in construction environments.

In summary, investing in a 6k telehandler equipped with the right features not only enhances operational efficiency but also improves safety and productivity on the job site. Project managers should prioritize these key specifications when selecting equipment to meet the unique demands of their projects. By doing so, they can optimize workflow, minimize risks, and ultimately achieve greater success in their construction endeavors.

Frequently Asked Questions

What is the maximum load capacity of the 6k telehandler?

The maximum load capacity of the 6k telehandler is 6,000 lbs.

Why is understanding the load capacity chart important?

Understanding the load capacity chart is crucial because it outlines the maximum weight that can be lifted at various heights and reaches. Misunderstanding load limits can lead to overloading, which is a frequent cause of accidents and equipment damage.

How does the boom extension affect load capacity?

As the boom extends, the load capacity decreases, which is why it is important for operators to be well-trained in interpreting load capacity charts.

What factors are included in a telehandler's load capacity chart?

A telehandler's load capacity chart typically includes a grid displaying secure lifting capacities at different boom angles and extensions.

What is the maximum lifting height and forward reach of the 6k telehandler?

The 6k telehandler can achieve a maximum lifting height of approximately 42 feet and a forward reach of around 30 feet.

How does the lifting capability of telehandlers compare to skid steers?

Telehandlers can lift between 5,000 and over 20,000 lbs, offering a significant advantage over skid steers, which primarily focus on digging or grading tasks.

Why is operator training and certification important for telehandlers?

Operator training and certification are vital for safe operation, ensuring that operators can handle the equipment properly and adhere to safety regulations.

What should project managers consider when selecting a telehandler for high-rise projects?

Project managers should consider the telehandler's reach and lift height to ensure safety and productivity on site.

What types of equipment does EZ Equipment Rental in Dallas offer?

EZ Equipment Rental in Dallas offers a diverse fleet of specialized equipment, including electric forklifts and rough terrain forklifts, tailored to project managers' requirements.

List of Sources

- Understand Load Capacity of the 6k Telehandler

- The Ultimate Telehandler Spec Guide and Size Charts (https://dozr.com/blog/telehandler-spec-guide-and-size-charts)

- Telehandler Safety Tips Every Operator Must Know (https://yashequipments.com/post/telehandler-safety-tips)

- How to Read A Telehandler Load Capacity Chart | JLG (https://jlg.com/en/directaccess/understanding-a-telehandler-load-capacity-chart)

- How much can a telehandler lift? A JCB telehandler for every project (https://jcb.com/en-GB/explore/knowledge/faqs/telehandlers/how-much-can-a-telehandler-lift)

- Evaluate Reach and Height Capabilities of the 6k Telehandler

- Telehandler Guide for Construction: How It Works & Choosing the Right Type - SANY Group (https://sanyglobal.com/blog/telehandler-guide-for-construction)

- The Ultimate Telehandler Spec Guide and Size Charts (https://dozr.com/blog/telehandler-spec-guide-and-size-charts)

- How much can a telehandler lift? A JCB telehandler for every project (https://jcb.com/en-GB/explore/knowledge/faqs/telehandlers/how-much-can-a-telehandler-lift)

- Choosing the Right Telehandler Size for Your Job | Gregory Poole (https://gregorypoole.com/choosing-telehandler-size)

- How Does a Telehandler Move Loads to Height? Expert Insights (https://telescro.com/how-does-a-telehandler-move-loads)

- Assess Maneuverability of the 6k Telehandler

- Telehandler Guide for Construction: How It Works & Choosing the Right Type - SANY Group (https://sanyglobal.com/blog/telehandler-guide-for-construction)

- Improving Concrete Operations with Telehandlers (https://forconstructionpros.com/equipment/attachments/lifting-material-handling/article/22914612/jlg-industries-inc-improving-concrete-operations-with-telehandlers)

- JLG to show new tracked telehandler (https://powerprogress.com/news/jlg-to-show-new-tracked-telehandler/8112058.article)

- Telehandler Market to Reach a value of USD 12.2 bn by 2034 (https://dimensionmarketresearch.com/report/telehandler-market)

- Explore Versatile Attachments for the 6k Telehandler

- Analyzing Telehandler Attachments Market Growth and Revenue Trends with a Forecasted 4.3% CAGR from 2026 to 2033 (https://linkedin.com/pulse/analyzing-telehandler-attachments-market-growth-revenue-trends-n5see)

- Complete Guide To Telehandler Attachments And Their Use Cases (https://herculift.com/complete-guide-to-telehandler-attachments-and-their-use-cases)

- Making Sense of Telehandler Attachments (https://genielift.com/en/aerialpros/telehandler-attachments)

- Telehandler: A Material Handling Expert (https://jcb.com/en-IN/explore/insight/blogs/2024/10/telehandler-a-material-handling-expert)

- Prioritize Stability Features of the 6k Telehandler

- Telehandler Stability When Lifting: Avoid Tipping Mistakes (https://telescro.com/telehandler-stability-when-lifting)

- The importance of stability in telehandlers - Merlo | United States of America (https://merlo.com/usa/en/the-importance-of-stability-in-telehandlers)

- Most common risks when working with a telehandler | TVH (https://tvh.com/learning-hub/most-common-risks-when-working-with-a-telehandler)

- Telehandler Stability | D2000 Safety (https://d2000safety.com/telehandler-stability)

- Recognize Operator Comfort and Control Features of the 6k Telehandler

- A Comfortable Operator is a Productive Operator: A Guide to Comfort-Enhancing Features - Texoma Utility (https://texomautility.com/blog/a-comfortable-operator-is-a-productive-operator-a-guide-to-comfort-enhancing-features)

- JLG Updates Its Rotating Telehandler Line, Introduces New R13100 Model (https://jlg.com/en/press-releases/jlg-updates-its-rotating-telehandler-line---introduces-new-r13100-model)

- A Comfortable Operator is a Productive Operator: A Guide to Comfort-Enhancing Features - Wowco Equipment Co. (https://wowco.com/blog/a-comfortable-operator-is-a-productive-operator-a-guide-to-comfort-enhancing-features)