Overview

The best practices for using a 15 ton carry deck crane focus on enhancing safety and operational efficiency through comprehensive training, pre-operation inspections, and effective lift planning. The article supports this by emphasizing the importance of clear communication, proper load distribution, and scheduling operations during off-peak hours to minimize risks and streamline workflow, alongside statistics highlighting the critical need for strict safety protocols in the lifting equipment industry.

Key Highlights:

- The 15 ton carry deck crane is designed for lifting and transporting materials in confined spaces, ideal for urban construction projects.

- Key features include a rotating boom for precise material placement and a low-profile design for enhanced stability.

- The IC 280 lift vehicle, launched by Broderson Construction Corporation, exemplifies advancements in lifting technology.

- The crane enhances operational efficiency by minimizing downtime and labor costs through its compact design and ease of use.

- Common applications include lifting heavy materials like steel beams and precast concrete, as well as landscaping tasks.

- Safety practices include comprehensive operator training, pre-operation inspections, and clear communication among team members.

- Between 2011 and 2017, 154 fatalities were recorded involving lifting equipment, emphasizing the importance of strict safety protocols.

- Best practices for efficiency include effective lift planning, proper load distribution, and scheduling operations during off-peak hours.

Introduction

In the dynamic world of construction, efficiency and adaptability are paramount. Enter the 15-ton carry deck crane, a versatile powerhouse designed to tackle the unique challenges of modern job sites. With its compact footprint and impressive lifting capabilities, this crane excels in tight urban environments where space is often at a premium. From facilitating the seamless movement of heavy materials to enhancing safety protocols, the 15-ton carry deck crane is revolutionizing construction practices. As the industry evolves, understanding its features, applications, and best practices becomes essential for project managers aiming to optimize workflows and ensure successful project outcomes.

Understanding the 15 Ton Carry Deck Crane: Features and Applications

stands out as a highly adaptable piece of equipment, expertly engineered for lifting and transporting materials on building sites. Its compact design allows for exceptional maneuverability in confined spaces, making it particularly suited for urban development projects where space is at a premium. Key features of this device include:

- A rotating boom that offers a broad range of motion, allowing for precise placement of materials

- A low-profile design that enhances stability even when handling heavy loads

Significantly, Broderson Construction Corporation launched the IC 280 lift vehicle with a capacity of 20 USt in February 2021, highlighting advancements in equipment technology that enhance development operations. By facilitating operations in tight environments, these machines not only optimize space but also significantly bolster operational efficiency, paralleling the crucial role forklifts play in enhancing safety and productivity on construction sites.

For instance, case studies have demonstrated how the IC 280 has been effectively utilized in various urban projects, improving project timelines and reducing labor costs.

As Manitowoc states, 'This strategic partnership demonstrates how business units can enhance productivity, market expansion, and customer satisfaction in the competitive environment of the global lifting equipment market.' For project managers, comprehending the functionalities of the 15 ton carry deck crane, along with other machinery like forklifts and boom lifts, becomes essential for fulfilling specific project requirements and ensuring smooth execution.

The competitive environment of the lifting equipment market is defined by innovation, as demonstrated in case studies showcasing key participants concentrating on technological advancements and customer support, making these machines essential for contemporary building practices.

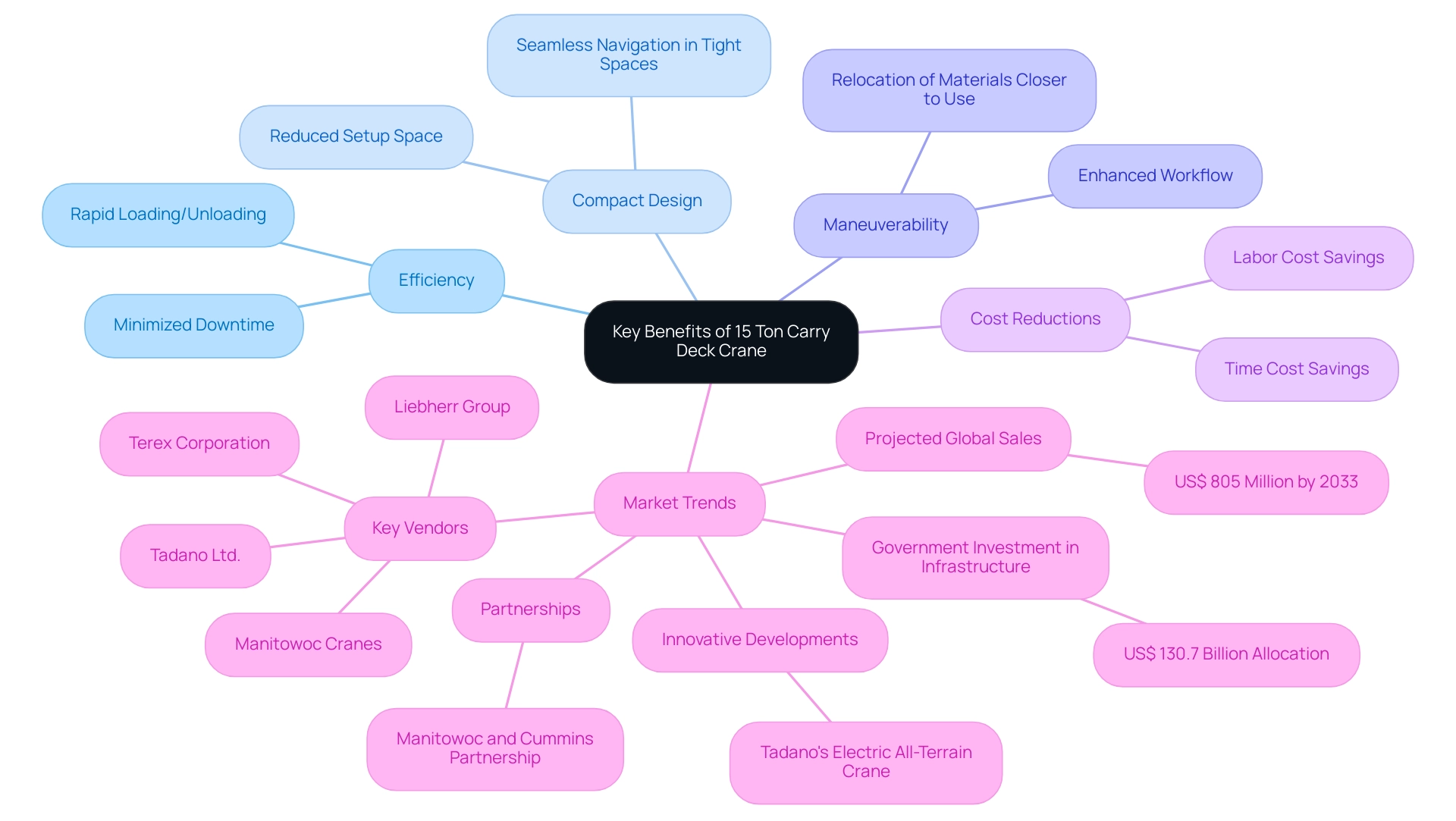

Key Benefits of Utilizing a 15 Ton Carry Deck Crane in Construction

The adoption of provides a myriad of benefits tailored for construction projects. These machines are designed for optimal efficiency, facilitating rapid loading and unloading of materials, which can drastically minimize downtime on the job site. Their compact design enables seamless navigation in tight spaces, a significant advantage over larger machines that often necessitate extensive setup and room.

This enhanced maneuverability not only streamlines workflow but also boosts productivity, enabling materials to be relocated closer to their point of use. Moreover, the operational ease of a 15 ton carry deck crane, which generally does not need complex rigging arrangements, leads to significant labor and time cost reductions. As noted by S. N. Jha, Principal Consultant, the lifting equipment market is evolving, with global sales projected to reach US$ 805 million by 2033, indicating a robust demand for efficient solutions in the construction sector.

The Indian government's allocation of US$ 130.7 billion for infrastructure development further emphasizes the increasing demand for dependable machinery such as mobile hoists in current projects. Key vendors such as:

- Manitowoc Cranes

- Terex Corporation

- Tadano Ltd.

- Liebherr Group

are leading the charge in providing these innovative solutions. Additionally, the partnership between Manitowoc and Cummins exemplifies how collaboration in the industry enhances productivity and market expansion.

Investing in a lifting system is, consequently, a tactical decision for enhancing operational effectiveness and promoting project success.

Common Applications of 15 Ton Carry Deck Cranes in Construction Projects

The adaptability of a 15 ton carry deck crane in building work is remarkable, making it an invaluable asset for a variety of applications. These machines are primarily utilized for lifting and placing heavy materials such as steel beams and precast concrete panels, which are essential in both new builds and renovations. Their compact design allows them to operate efficiently in confined spaces typical of urban construction sites, where maneuverability is crucial.

For instance, during recent urban renovation projects, these machines have facilitated the seamless integration of heavy materials, enhancing workflow and safety compliance. Moreover, they are increasingly employed in landscaping endeavors, where their capability to transport large boulders and trees proves beneficial. Their flexibility enables project managers to utilize across commercial and residential projects alike, ensuring maximum utility and return on investment.

Significantly, the material handling sector represented approximately 40% of the lifting equipment market in 2023, highlighting the significance of these machines in meeting the changing requirements of building. As Manitowoc Company highlights, their dedication to preserving competitiveness in the lifting equipment market depends on ongoing innovation and sustainability efforts, positioning these machines as essential instruments in contemporary project management. Moreover, the competitive environment of the lifting equipment market demonstrates that the capacity to fulfill particular customer demands is vital for producers to secure market share, emphasizing the importance of these devices in modern construction methods.

Essential Safety Practices for Operating a 15 Ton Carry Deck Crane

Operating a 15 ton carry deck crane mandates strict adherence to established safety protocols. It's essential for operators to undergo comprehensive training and certification to fully grasp the machine's capabilities and limitations. A thorough inspection of the lifting device is critical prior to operation, ensuring that any mechanical issues or wear are identified and addressed.

Clear communication signals among team members are vital for coordinating safe movements, especially in crowded job sites. Awareness of the surroundings is paramount, as operators of the 15 ton carry deck crane must ensure that the load being lifted remains within the machine's capacity. Notably, difficult lifts above 80% of the machine's capacity require a comprehensive safety plan and constant monitoring to mitigate risks effectively.

These safety practices are not merely recommendations but crucial steps for mitigating risks; a notable 15% of fatal injuries involving lifting equipment have occurred among , emphasizing the urgent need for vigilance. Between 2011 and 2017, 154 fatalities were recorded due to incidents involving lifting equipment, where workers were struck by objects or the machinery itself, according to the U.S. Bureau of Labor Statistics, which states that '154 fatalities involving lifting equipment occurred between 2011 and 2017 after employees were struck by an object or the machinery.' Additionally, the five states with the highest reports of fatal injuries involving lifting equipment during this period—Texas, Florida, New York, California, and Illinois—underscore the geographical risks associated with these operations.

By implementing robust safety protocols, we can significantly reduce the likelihood of accidents and injuries on the job site.

Best Practices for Efficient Use of a 15 Ton Carry Deck Crane

To maximize efficiency when operating , project managers should adhere to several key best practices. Effective lift planning is paramount, encompassing critical factors such as the load's weight, lift height, and path of movement. Incorporating forklifts, known for their load capacity and maneuverability, and boom lifts, which provide elevated access and safety features, into the operations can further enhance construction efficiency by optimizing the transport of materials and equipment on site.

Planning access routes for the machinery and equipment is essential for smooth operations, while achieving proper load distribution is vital for maintaining stability during operations, thereby enhancing safety. Scheduling equipment usage during off-peak hours can significantly alleviate job site congestion, facilitating smoother operations and improving overall workflow. Furthermore, consistent maintenance is crucial to ensure the machinery operates at its highest performance level.

Investing in thorough training and certification programs for crane operators enhances efficiency and minimizes accident risks, making it a critical consideration for project managers. As Bob Kirkpatrick, a pioneer in wire rope pressure, emphasizes,

Our unmatched reputation and field expertise set us apart from competitors who have since attempted to replicate our success.

A real-world example of the importance of proper site preparation and positioning can be seen in the case study that highlights how adequate lighting, signage, and organized pathways, supported by the maneuverability of forklifts and the stability of boom lifts, contribute to worker safety and operational efficiency.

By implementing these best practices and leveraging the essential role of forklifts and boom lifts, construction teams can reduce delays and ensure successful project completions, ultimately enhancing worker safety and operational efficiency.

Conclusion

The 15-ton carry deck crane represents a significant advancement in construction technology, offering a blend of efficiency, adaptability, and safety that is essential for modern job sites. Its compact design and impressive lifting capabilities make it a valuable asset, particularly in urban environments where space is often limited. The crane's ability to facilitate the rapid movement of heavy materials not only enhances productivity but also contributes to overall project success by reducing downtime and labor costs.

Moreover, the versatility of the 15-ton carry deck crane extends across various applications, from lifting steel beams to transporting large landscaping materials. As the construction industry continues to evolve, these cranes are becoming indispensable in meeting the growing demands for reliable and efficient equipment. The emphasis on safety practices, including thorough training and adherence to protocols, further underscores the importance of responsible operation to mitigate risks and protect workers on the job site.

In conclusion, investing in a 15-ton carry deck crane is not merely a choice but a strategic decision that can lead to improved operational efficiency and enhanced project outcomes. As the market for carry deck cranes expands, driven by innovation and collaborative efforts among industry leaders, project managers must recognize the value of these cranes in optimizing workflows and ensuring safety. Embracing this technology will undoubtedly pave the way for more successful and sustainable construction practices in the future.

Frequently Asked Questions

What is a 15 ton carry deck crane?

A 15 ton carry deck crane is a highly adaptable piece of equipment designed for lifting and transporting materials on construction sites. Its compact design allows for exceptional maneuverability in confined spaces, making it ideal for urban development projects.

What are the key features of the 15 ton carry deck crane?

Key features include a rotating boom for a broad range of motion, allowing for precise placement of materials, and a low-profile design that enhances stability when handling heavy loads.

What advancements were made with the launch of the IC 280 lift vehicle?

The IC 280 lift vehicle, launched by Broderson Construction Corporation in February 2021, has a capacity of 20 USt and represents advancements in equipment technology that enhance development operations, particularly in tight environments.

How does the 15 ton carry deck crane improve operational efficiency?

The crane facilitates rapid loading and unloading of materials, minimizing downtime. Its compact design allows for seamless navigation in tight spaces, streamlining workflow and boosting productivity by relocating materials closer to their point of use.

What impact does the operational ease of a 15 ton carry deck crane have on costs?

The operational ease of the crane, which typically does not require complex rigging arrangements, leads to significant reductions in labor and time costs.

What is the projected growth of the lifting equipment market?

Global sales in the lifting equipment market are projected to reach US$ 805 million by 2033, indicating robust demand for efficient solutions in the construction sector.

What is the significance of the Indian government's allocation for infrastructure development?

The Indian government's allocation of US$ 130.7 billion for infrastructure development highlights the increasing demand for reliable machinery, such as mobile hoists, in current projects.

Who are the key vendors in the lifting equipment market?

Key vendors include Manitowoc Cranes, Terex Corporation, Tadano Ltd., and Liebherr Group, all of which are leading the charge in providing innovative solutions in the market.

How does collaboration in the industry enhance productivity?

Partnerships, such as that between Manitowoc and Cummins, exemplify how collaboration in the lifting equipment industry can enhance productivity and market expansion.

Why is investing in a lifting system considered a tactical decision?

Investing in a lifting system is seen as a tactical decision to enhance operational effectiveness and promote project success in construction projects.