Introduction

In the world of construction, the success of driveway projects often hinges on the choice of boring techniques. With methods like auger boring and directional boring at their disposal, project managers face the critical task of selecting the right approach tailored to specific soil conditions and project requirements.

As the industry evolves, understanding the intricacies of these techniques becomes paramount—not only to ensure efficiency but also to mitigate risks associated with unexpected challenges.

This comprehensive guide delves into best practices, safety considerations, and the nuances of renting boring tools, providing essential insights that empower professionals to navigate the complexities of driveway boring with confidence and precision.

Exploring Effective Boring Techniques for Driveways

When considering dull techniques for driveway projects, two prominent methods stand out: auger drilling and directional drilling. Auger drilling utilizes a rotating helical screw equipped with a standard cutter head or lead auger with carbide teeth, effectively excavating and removing soil, which is particularly beneficial in softer ground conditions. This method allows for efficient ground excavation and is widely recognized for its reliability.

On the other hand, directional drilling is designed for more intricate scenarios, allowing for precise utility placement while minimizing surface disruption. This approach proves advantageous, especially in areas where maintaining the integrity of the surface is critical.

Understanding the characteristics of the soil will significantly influence your choice of technique. For example, in rocky soil conditions, directional drilling often demonstrates greater efficiency, despite potentially higher costs.

Recent advancements in both auger and directional drilling techniques further enhance their effectiveness, particularly in challenging environments. The forecast duration for the Auger Drilling Market from 2024 to 2032 emphasizes the continuous advancements in this area, highlighting the significance of remaining updated on the newest progress.

Knowledge of these techniques, combined with perspectives from industry experts, will enable managers to choose the most appropriate drilling method customized to their specific driveway needs under driveway boring tool rental. As noted by ORACLE, 'MarkWide Research is a trusted partner that provides us with the market insights we need to make informed decisions. Their reports are thorough, accurate, and delivered on time.

We appreciate their professionalism and expertise, and would highly recommend their services to other companies looking for reliable market research.' Their insights can be instrumental in navigating these choices effectively.

Best Practices for Utilizing Boring Tools Successfully

Efficient use of drilling instruments starts with careful planning of the endeavor. One of the best practices for successful drilling operations in 2024 is to measure and mark the precise locations where drilling will take place. This step is crucial for preventing costly errors, as it ensures that the work aligns with project specifications.

Furthermore, prior to starting any tedious work, it is essential to clearly mark all utilities in the area. Doing so mitigates the risk of damaging existing infrastructure, which can lead to significant delays and expenses. As a guideline, aim for at least 4x the bar diameter for stick-out to enhance instrument performance.

In a case study titled "Enhancing the Process Capability of Machining Process of Boring Tool Holder," the study aimed to identify causes for the high rejection rates of Boring Tool Holders (BTH) due to variations in key size and bore size dimensions. By adopting a DMAIC approach, the team implemented corrective actions that led to the process being in statistical control, achieving process capability indices of 1.09 and 1.15 for key size and bore size respectively. This demonstrates the importance of adhering to best practices in boring equipment operations.

During equipment operation, maintaining a steady pace is vital. Closely monitor the equipment for any signs of strain or malfunction, as this can be indicative of potential issues that require immediate attention. Regular inspections of the cutting head and auger for wear and tear are equally important; replacing worn parts promptly is key to sustaining optimal performance.

As mentioned by a construction specialist, "Even if you don’t have a design bone in your body, you can use one of the Visme templates and modify it," highlighting the importance of planning and preparation in achieving successful results. By following these best practices, you can greatly improve the efficiency of your mundane instruments, resulting in smoother execution and better results.

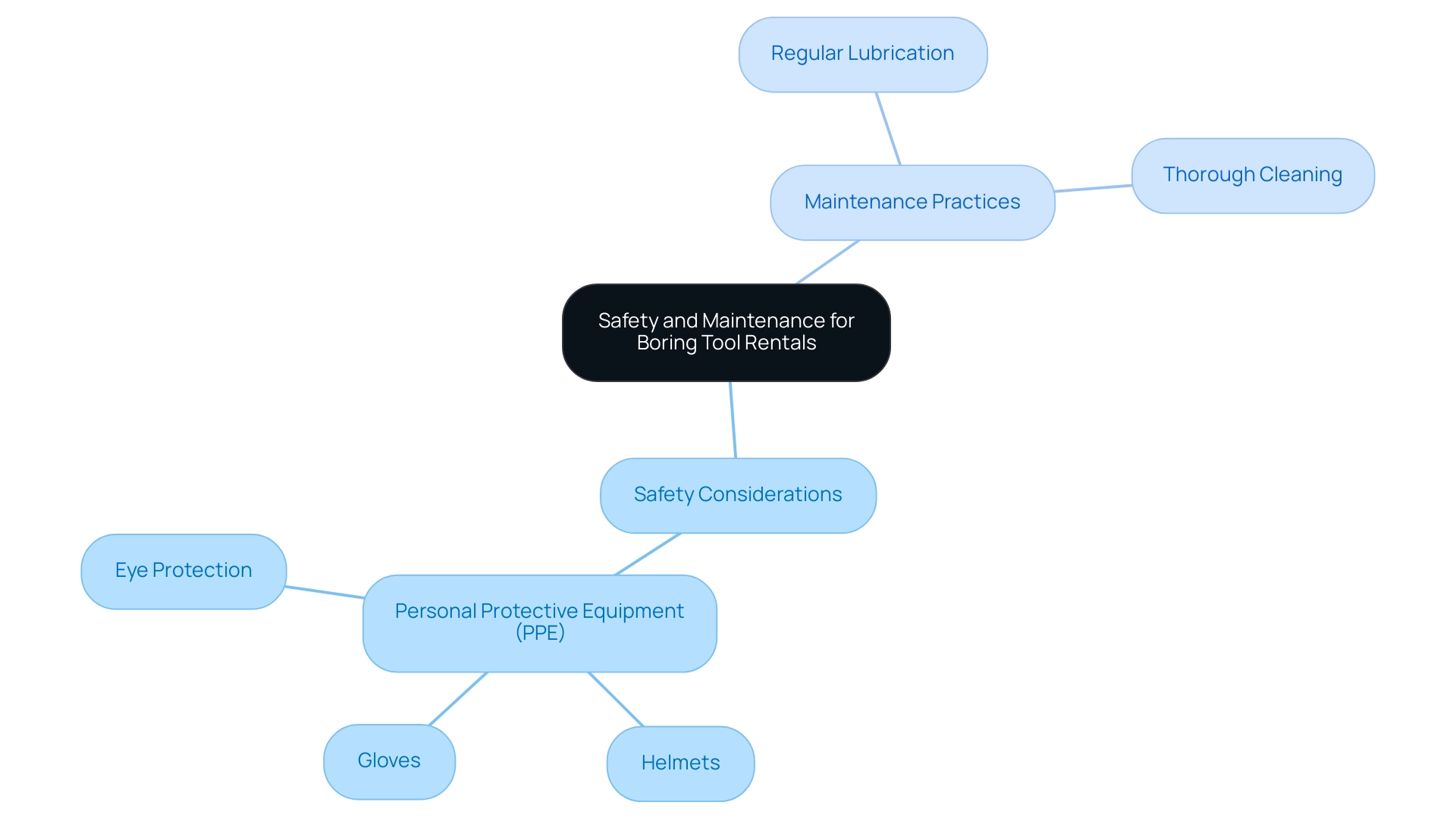

Safety and Maintenance: Key Considerations for Boring Tool Rentals

Emphasizing protection is essential when utilizing an under driveway boring tool rental for your driveway tasks. Equip yourself and your team with the necessary personal protective equipment (PPE), including:

- Helmets

- Gloves

- Eye protection

to minimize injury risks. Before using any rented equipment, perform a thorough inspection to identify any damaged components and ensure that all protective features are fully operational.

Maintenance practices should not be overlooked; adhere to the manufacturer's maintenance guidelines, which typically include:

- Regular lubrication of moving parts

- Thorough cleaning after each use

This proactive strategy for protection and upkeep not only reduces risks but also guarantees that your rented tools stay in optimal working order during the entire length of your task. In 2023, there were a total of 5,283 fatal work injuries reported, reflecting a 3.7% decrease from the previous year, underscoring the importance of maintaining high protective standards.

For example, the recent conclusion of the I-76 undertaking by Flatiron demonstrates the application of strong precautions in construction. Additionally, the Minnesota Dot's initiative to improve traffic flow at a critical junction emphasizes the significance of safety inspections and maintenance in enhancing both safety and operational efficiency. Implementing these measures can significantly contribute to a safer work environment and enhance overall efficiency.

Navigating the Boring Tool Rental Process

Navigating the tedious equipment rental process requires careful consideration and research to identify reputable companies specializing in construction machinery. Start by examining customer reviews and ratings, as these insights can provide a clear picture of a rental company's reliability. For instance, a typical 4-hour rental from providers like Lowe’s, Sunbelt Rentals, or The Home Depot averages around $70, making it essential to weigh the cost against the value offered.

When choosing an instrument, prioritize your assignment's specific needs, including the required bore diameter and depth. It's crucial to inquire about the maintenance history of the equipment and any warranties available, as these factors significantly influence performance. Additionally, training and certification programs are available for various instruments and equipment across rental services, which can enhance your team's competency and ensure safe operation.

Lewis Tyler, an industry expert, emphasizes the importance of assessing rental equipment reliability, stating, 'It's essential to choose equipment that has been well-maintained and is backed by a reliable rental company.' Furthermore, consider the delivery options and rental terms to prevent unexpected issues. A case study titled 'Advantages of Tool Rental Services' highlights how these services provide knowledgeable staff and rigorous maintenance protocols, helping contractors expand their capabilities without the need for costly purchases.

By meticulously following these steps, you can ensure that you select the optimal tools to meet your requirements effectively while maximizing your budget and time.

Overcoming Challenges in Driveway Boring Projects

Driveway boring tasks frequently face a range of challenges, notably unexpected soil conditions and utility conflicts. A comprehensive site assessment is essential before commencing work, as it allows managers to identify potential obstacles that could impact timelines and costs. Recent advancements in trenchless technology, as observed in Columbia, Missouri's $9.2 million sewer rehabilitation initiative, demonstrate the effectiveness of such assessments.

Moreover, statistics reveal that 43.9 percent of downhole tooling is purchased from OEMs, underscoring the reliance on quality equipment in the industry. If teams encounter challenging soil or rock formations, employing advanced boring techniques or specialized tools can be pivotal. Industry experts highlight that understanding geotechnical conditions can significantly enhance the success of horizontal directional drilling (HDD) operations.

As Robert Carpenter, Editor-in-Chief, aptly stated,

We’re definitely in it for the long haul,

reflecting the need for resilience in management. Additionally, it is crucial to acknowledge that most damages involving HDD are attributed to facility operators damaging each other and themselves, primarily due to locating and excavation practice root causes. Having a well-thought-out contingency plan for utility conflicts is vital; knowing how to reroute utilities can save invaluable time and resources.

Furthermore, Ariaratnam identifies three challenging worksite conditions for HDD:

- Unsupportive geotechnical conditions

- Insufficient layout area for pipes

- Time restrictions in urban settings

By proactively addressing these challenges through meticulous planning and strategic decision-making, construction managers can keep their projects on track and minimize disruptions.

Conclusion

Selecting the right boring technique for driveway projects is essential for ensuring efficiency and minimizing risks. By understanding the distinctions between auger boring and directional boring, project managers can make informed decisions based on soil conditions and project requirements. Each method has its advantages, with auger boring excelling in softer ground and directional boring providing precision in intricate scenarios.

Implementing best practices in utilizing boring tools cannot be overstated. From meticulous project planning to regular equipment inspections, these strategies are vital for optimizing performance and preventing costly errors. Ensuring safety through proper equipment maintenance and the use of personal protective gear further enhances project effectiveness and protects workers.

Navigating the tool rental process requires thorough research and consideration of specific project needs. By selecting reliable rental companies and understanding the equipment's maintenance history, project managers can secure the best tools for their projects. Addressing challenges such as unexpected soil conditions and utility conflicts through careful site assessments and contingency planning is crucial for maintaining project timelines and budgets.

Ultimately, a comprehensive approach to driveway boring that incorporates informed technique selection, best operational practices, and proactive problem-solving will lead to successful project outcomes. By prioritizing these elements, construction professionals can navigate the complexities of driveway projects with confidence and achieve lasting results.

Frequently Asked Questions

What are the two prominent dull techniques for driveway projects?

The two prominent techniques are auger drilling and directional drilling.

How does auger drilling work?

Auger drilling utilizes a rotating helical screw equipped with a cutter head or lead auger with carbide teeth to excavate and remove soil, making it effective in softer ground conditions.

What are the advantages of directional drilling?

Directional drilling allows for precise utility placement while minimizing surface disruption, making it advantageous in areas where surface integrity is critical.

How does soil type affect the choice of drilling technique?

Understanding the characteristics of the soil is crucial; for instance, directional drilling is often more efficient in rocky soil conditions, despite potentially higher costs.

What advancements have been made in drilling techniques?

Recent advancements in both auger and directional drilling techniques enhance their effectiveness, particularly in challenging environments.

Why is it important to stay updated on drilling techniques?

Staying updated on advancements is significant for making informed decisions regarding the most appropriate drilling method for specific driveway needs.

What is a best practice for successful drilling operations?

One best practice is to measure and mark the precise locations for drilling to prevent costly errors and ensure alignment with project specifications.

Why is it important to mark utilities before drilling?

Clearly marking utilities mitigates the risk of damaging existing infrastructure, which can lead to significant delays and expenses.

What should be monitored during equipment operation?

It's vital to maintain a steady pace and monitor the equipment for any signs of strain or malfunction, as well as regularly inspect the cutting head and auger for wear and tear.

What is the significance of the case study on boring tool holders?

The case study demonstrates the importance of adhering to best practices in boring equipment operations, which can lead to improved process capability and reduced rejection rates.