Overview

To choose and rent a 30,000 lb excavator effectively, one must assess specific project requirements, budget constraints, and the type of excavator best suited for the tasks at hand, whether crawler or wheeled. The article outlines a comprehensive guide that includes evaluating site conditions, understanding rental terms, and adhering to best practices for operation and maintenance, ensuring that decisions are informed and aligned with project needs.

Key Highlights:

- Identify specific tasks requiring a 30,000 lb excavator, such as digging, grading, or demolition.

- Consider site dimensions, soil characteristics, and the need for specialized attachments.

- Document project parameters for discussions with local rental companies in Irving, TX.

- Assess project timeline and budget; monthly rental fees for a 30,000 lb excavator range from $6,000 to $22,000.

- Evaluate crawler vs. wheeled excavators based on project needs; crawlers excel in rugged terrains, while wheeled models offer better mobility.

- Key features to assess include hydraulic systems, bucket size/type, operator comfort, stability features, and maintenance accessibility.

- Research reputable leasing companies and request quotes tailored to project specifications.

- Inspect equipment before leasing to ensure it meets project requirements and is in good condition.

- Review lease agreements for terms related to insurance, maintenance responsibilities, and fuel charges.

- Implement best practices such as pre-operation checks, operator training, strategic planning, safety adherence, and regular communication.

Introduction

In the bustling landscape of the DFW Metroplex, the successful execution of construction projects hinges on the careful selection and effective use of heavy machinery, particularly 30,000 lb excavators. With a myriad of tasks ranging from digging to demolition, understanding the nuances of project requirements is paramount.

This article delves into the essential considerations for assessing project needs, exploring various types of excavators, and navigating the rental process. It highlights:

- Key features to look for

- The intricacies of rental terms

- Best practices for optimizing excavator performance

By equipping project managers and contractors with the knowledge to make informed decisions, this guide aims to streamline operations and enhance productivity in the competitive construction industry.

Assessing Your Project Requirements for a 30,000 lb Excavator

To effectively evaluate the scope of your project in , start by identifying the specific tasks at hand, including those that may require a 30,000 lb excavator for digging, grading, or demolition. It's essential to consider the dimensions of the area where the machinery will operate, along with the characteristics of the soil or materials involved. Additionally, ascertain whether you will need specialized attachments, such as those for trenching or lifting, to optimize your operations with a 30,000 lb excavator.

Documenting these parameters will provide a clear framework for discussions with local rental companies in Irving, TX, where a wide variety of equipment—including boom lifts, diggers, forklifts, scissor lifts, air compressors, and more—is readily available. As the IMARC Team emphasizes, 'The depth of analysis, accuracy of data, and actionable recommendations have greatly enhanced our strategic decision-making.' This reinforces the importance of thorough evaluation in your planning process.

Next, assess your project's timeline and budgetary constraints.

Understanding the duration for which you will need the machinery, alongside your financial limits, will help streamline your options. Recent trends indicate that monthly fees for a 30,000 lb excavator typically range from $6,000 to $22,000, which is essential to factor into your planning. Additionally, consider the financial implications of excavation work; for instance, jackhammered rock excavation costs can range from $50 to $200+ per cubic yard, which should be included in your budget considerations.

Collaborate with your team to collect varied perspectives, ensuring that all possible requirements are thoroughly evaluated before proceeding with the leasing process. Moreover, examining case studies focusing on essential issues regarding the construction machinery leasing market can offer significant insights into project scope assessment and assist in guiding your choices. For additional details, reach out to us at (214) 951-7800 or stop by our site at 1307 W Airport Fwy, Irving, TX 75062, to discover our wide variety of equipment offered for hire throughout the DFW Metroplex.

Exploring Different Types of 30,000 lb Excavators

When considering the rental of a 30,000 lb excavator, two primary types dominate the market: crawler models and wheeled models. Crawler machines, recognized for their stability and traction, excel in challenging terrain and large-scale endeavors. Their design provides superior digging power and enables effective maneuvering in confined spaces, making them a preferred choice for challenging environments.

As highlighted in industry reports, the demand for crawler machinery is anticipated to increase, especially as infrastructure growth persists in Australia, with a CAGR of 6.1% expected from 2024 to 2030. According to Deloitte, "MarkWide Research is a trusted partner that provides us with we need to make informed decisions. Their reports are thorough, accurate, and delivered on time.

We appreciate their professionalism and expertise, and would highly recommend their services to other companies looking for reliable market research."

On the other hand, wheeled machines provide improved mobility, making them appropriate for tasks that require frequent relocation. Their speed on paved surfaces allows for efficient movement in urban settings, where quick transitions between job sites are essential. Construction specialists frequently recommend that the selection between crawler and wheeled machinery should be guided by the particular operational needs of an undertaking.

For instance, while crawler machines provide the robustness needed for rugged terrains, wheeled models can optimize productivity in smoother environments. Understanding these differences is crucial for making informed decisions that align with both project goals and market conditions. Additionally, the current decline of 17.4% in the non-residential sector in France could impact the overall demand for construction machinery, including crawler machines, as seen in the case study on the declining real estate industry, which highlights how economic factors can influence equipment selection.

Key Features to Look for in a 30,000 lb Excavator

When choosing a 30,000 lb excavator, it is essential to evaluate several key features to maximize both performance and efficiency:

- Hydraulic System: The hydraulic system is crucial for enhancing digging and lifting capabilities. Choose machinery equipped with adjustable hydraulic flow, which allows for optimization based on varied task requirements. Innovations in hydraulic technology, including advanced pressure sensors and variable displacement pumps, have recently improved operational efficiency and responsiveness. Notably, CASE has introduced seven new models of , which incorporate these advancements, ensuring better performance in various applications.

- Bucket Size and Type: Choosing the appropriate bucket size is crucial to success. Larger buckets can transport more material, making them ideal for extensive excavation; however, they may compromise efficiency in confined spaces. It’s important to match the bucket type to your specific requirements, considering both size and functionality.

- Operator Comfort: Comfort directly impacts productivity. Look for models featuring ergonomic cabins with adjustable seating and integrated climate control systems. These enhancements not only increase operator efficiency but also lessen fatigue over extended workdays, ultimately resulting in improved outcomes. This focus on operator comfort aligns with Case's commitment to increasing productivity and reducing operating costs.

- Stability Features: Stability is paramount, particularly when working on uneven terrain. Ensure the machine is designed with features such as wide tracks or stabilizers. These elements provide greater balance and safety during operation, which is vital for achieving precise results without compromising on safety.

- Maintenance Accessibility: Downtime can significantly impact timelines and costs. Therefore, consider machinery that offers easy access to maintenance points. Models with strategically placed service doors and simplified maintenance protocols can lead to reduced downtime, enhancing overall productivity. This is particularly relevant in the context of the case study titled "Construction Industrial Machinery Procurement - Essential Guide," which emphasizes the importance of strategic vendor management and technology integration for optimizing machinery selection and maintenance processes.

By focusing on these features and integrating the insights from CASE's latest innovations and strategic practices, project managers can make informed decisions that enhance the functionality and efficiency of their excavation operations, especially when using a 30,000 lb excavator.

Navigating the Excavator Rental Process

To navigate the leasing process effectively for excavators, follow these essential steps:

- Research Leasing Companies: Begin by investigating reputable firms that specialize in heavy equipment. Look for online reviews and ratings to gauge reliability and customer service quality. As the construction leasing sector is expected to increase by 5.8% in the Middle East and Africa because of large-scale initiatives, it's essential to collaborate with established suppliers. Notably, CES Power LLC's acquisition of a Bird Limited and Apex Generators highlights the trend of consolidation in the industry, emphasizing the importance of choosing well-established companies.

- Request Quotes: Reach out to several companies to request quotes tailored to your project specifications. This enables a comparison of prices, equipment availability, and leasing terms, ensuring you receive the best value.

- Inspect Equipment: Prior to completing any lease, thoroughly examine the 30,000 lb excavator for signs of wear or damage. Confirm that the equipment, specifically the 30,000 lb excavator, meets your project requirements and is in optimal working condition, as this can prevent unexpected delays and costs down the line.

- Review Lease Agreement: Carefully scrutinize the lease agreement, focusing on critical terms related to insurance coverage, liability, and maintenance responsibilities. As Mike Watts, founder of a successful leasing company, emphasizes, building relationships based on honesty and integrity is essential in this process. Understanding these elements can protect your endeavor against unforeseen issues.

- Schedule Delivery: Work closely with the leasing company to coordinate that align seamlessly with your project timeline. Confirm all logistical details to avoid potential delays, ensuring the timely availability of equipment when you need it. For example, the situation of Florida Coast Equipment purchasing Polk Tractor Co. demonstrates how such collaborations can improve service offerings, emphasizing the significance of selecting trustworthy leasing firms.

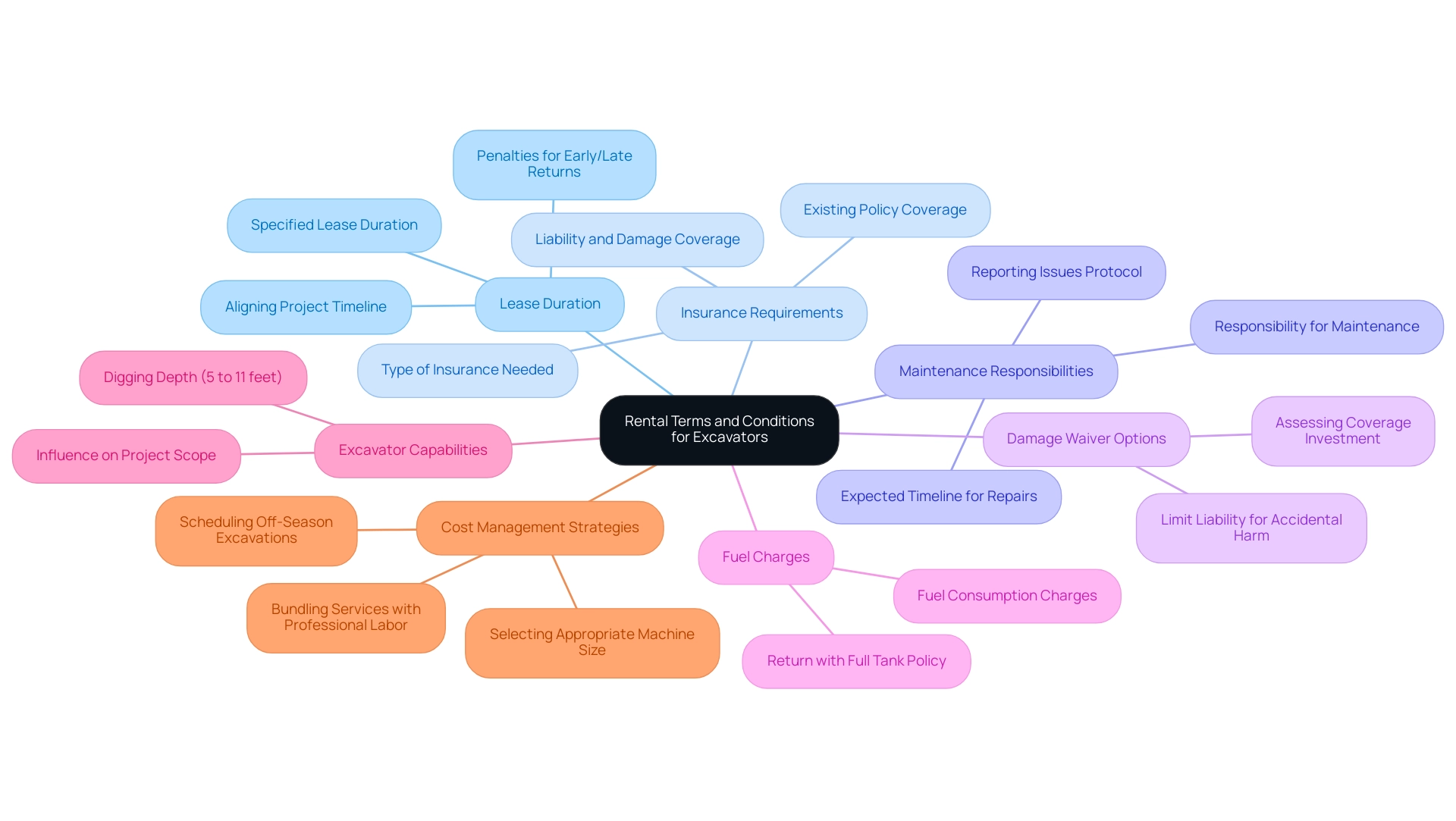

Understanding Rental Terms and Conditions for Excavators

When leasing a 30,000 lb excavator, it is crucial to carefully examine the following terms and conditions.

- Lease Duration: Understand the specified lease duration and be aware of any penalties for early or late returns. Aligning your project timeline with the leasing period is essential to avoid unexpected charges.

- Insurance Requirements: Most leasing firms require insurance coverage for the machinery. Ensure you verify the type of insurance needed and check if your existing policy extends to cover the lease. Acquainting yourself with the latest insurance requirements for , such as liability and damage coverage, will assist in compliance and risk management.

- Maintenance Responsibilities: Clearly define who is responsible for maintenance and repairs during the rental period. Establish the protocol for reporting issues and the expected timeline for repairs to avoid delays in the work.

- Damage Waiver Options: Explore damage waiver options that can limit your liability in the event of accidental harm to the apparatus. Assess whether investing in such coverage is prudent based on the specific risks associated with your project. As noted by Josh Nickell, vice president of machinery leasing at the American Rental Association, those companies that excel in customer service and data-driven decisions will provide better solutions for contractors.

- Fuel Charges: Be mindful of fuel policies, as some companies charge for fuel consumed during the usage period, while others may require the equipment to be returned with a full tank. Understanding these policies can help you avoid unexpected costs and ensure a smoother rental experience.

- Excavator Capabilities: It's important to note that a 30,000 lb excavator can dig between 5 and 11 feet deep, depending on the model. This capability can influence your scope and timeline, so ensure that the equipment you select fulfills your excavation needs.

- Cost Management Strategies: Implementing strategies from case studies, such as scheduling off-season excavations, selecting the appropriate machine size, and bundling services with professional labor, can significantly reduce rental costs. These practical tips can help you manage your budget effectively while ensuring project success.

Best Practices for Using Your Rented 30,000 lb Excavator

To optimize the performance of your rented 30,000 lb machine, adhering to the following best practices is essential:

- Conduct Thorough Pre-Operation Checks: Before operating the machinery, perform comprehensive pre-operation checks that include assessing fluid levels, verifying brake functionality, and inspecting all safety features. According to industry statistics, approximately 30% of mechanical failures can be attributed to inadequate pre-operation checks. Such diligence ensures the machine is fully prepared for use and mitigates the risk of mechanical issues during operation.

- Prioritize Operator Training: It is essential that operators receive training customized to the specific model of machinery being utilized. Proper training not only enhances safety but also significantly boosts operational efficiency, allowing the team to work effectively and confidently. This aligns with broader industry standards that emphasize the importance of skilled labor in maintaining compliance and worker welfare on construction sites.

- Plan Work Strategically: Formulate a detailed work plan that outlines the tasks to be completed with the 30,000 lb excavator, accompanied by realistic timelines. An organized approach minimizes downtime and maximizes productivity on-site. For instance, a recent case study showed that a well-planned excavation project achieved a record of 158,601 tickets processed in one month, demonstrating the impact of strategic planning on productivity.

- Adhere to Safety Protocols: Strictly follow all relevant safety protocols, including the use of personal protective equipment (PPE) and compliance with site-specific safety guidelines. Ensuring a safe working environment is paramount to preventing accidents and safeguarding worker health.

- Foster Regular Communication: Establish a consistent communication flow among team members regarding the excavator's operation and any emerging issues. Effective communication fosters teamwork, keeps everyone informed about site conditions, and enables prompt responses to any challenges that arise.

As aptly states,

Maintaining efficient and effective communication within the workplace is essential to preserving the health, safety and welfare of workers as well as to increasing production rates.

These practices not only enhance operational efficiency but also contribute to overall project success.

Conclusion

Understanding the intricacies of renting and operating a 30,000 lb excavator is crucial for successful project management in the DFW Metroplex. By thoroughly assessing project requirements, including specific tasks, budget constraints, and equipment specifications, project managers can make informed decisions that align with their operational needs. Recognizing the differences between crawler and wheeled excavators further enhances the ability to select the right equipment for the job, ensuring optimal performance in various environments.

Crucial features such as:

- Hydraulic systems

- Bucket size

- Operator comfort

- Stability

- Maintenance accessibility

must not be overlooked. These elements significantly impact the efficiency and productivity of excavation work. Moreover, navigating the rental process involves careful research, equipment inspection, and a solid understanding of rental terms and conditions. By adhering to best practices, including:

- Pre-operation checks

- Operator training

teams can maximize the effectiveness of their rented excavators while maintaining a safe working environment.

Ultimately, the ability to strategically assess project needs and optimize equipment use not only streamlines operations but also enhances overall productivity in the competitive construction landscape. By leveraging the insights provided in this guide, project managers and contractors can confidently navigate the complexities of excavator rentals and operations, setting the stage for successful project outcomes in the DFW Metroplex.

Frequently Asked Questions

What should I consider when evaluating the scope of my project in the DFW Metroplex?

Start by identifying specific tasks that may require a 30,000 lb excavator, such as digging, grading, or demolition. Consider the dimensions of the operating area and the characteristics of the soil or materials involved. Additionally, determine if specialized attachments, like those for trenching or lifting, are necessary.

Why is documenting project parameters important?

Documenting parameters provides a clear framework for discussions with local rental companies, helping to ensure that all aspects of the project are considered and that the right equipment is selected.

What are the typical monthly rental fees for a 30,000 lb excavator?

Monthly fees for a 30,000 lb excavator typically range from $6,000 to $22,000, which should be factored into your project planning.

What are the financial implications of excavation work?

Costs for jackhammered rock excavation can range from $50 to $200+ per cubic yard, which should be included in your budget considerations.

How can collaboration improve the evaluation process?

Collaborating with your team allows for the collection of varied perspectives, ensuring that all possible requirements are thoroughly evaluated before proceeding with the leasing process.

What types of excavators are available for rental, and what are their characteristics?

The two primary types of excavators available for rental are crawler models and wheeled models. Crawler models offer stability and traction for challenging terrains, while wheeled models provide improved mobility for tasks requiring frequent relocation.

When should I choose a crawler model over a wheeled model?

Crawler models are preferred for rugged terrains due to their digging power and maneuverability in confined spaces, while wheeled models are better suited for smoother environments where quick transitions between job sites are essential.

How does economic demand affect the construction machinery market?

Economic factors, such as the current decline in the non-residential sector in France, can impact the overall demand for construction machinery, including crawler machines, influencing equipment selection based on market conditions.