Overview

This article serves as a comprehensive guide for construction managers seeking to rent a cherry picker crane. It emphasizes critical factors, including safety protocols, equipment selection, and essential rental considerations. By detailing necessary steps such as conducting pre-operation safety checks, understanding the various types of cherry pickers available, and evaluating rental firms, it ensures that efficiency and safety are prioritized on construction sites.

In addition to outlining these steps, the article highlights the benefits of each tool and equipment type, showcasing how they contribute to successful project outcomes. For example, reliable cherry pickers enhance productivity while ensuring worker safety. Furthermore, testimonials from satisfied customers reinforce the claims of reliability and quality, making the case for choosing the right equipment provider.

To encourage immediate engagement, the article concludes with strong calls to action, urging readers to assess their equipment needs and connect with reputable rental firms. By following this guide, construction managers can make informed decisions that lead to safer and more efficient construction site operations.

Key Highlights:

- Cherry pickers, or aerial work platforms, are vital for construction and maintenance, allowing safe access to high areas.

- Advancements in 2025 include enhanced safety features and improved maneuverability, which increase efficiency on construction sites.

- Aerial lifts are safer alternatives to ladders and scaffolding, offering greater reach and reducing labor costs.

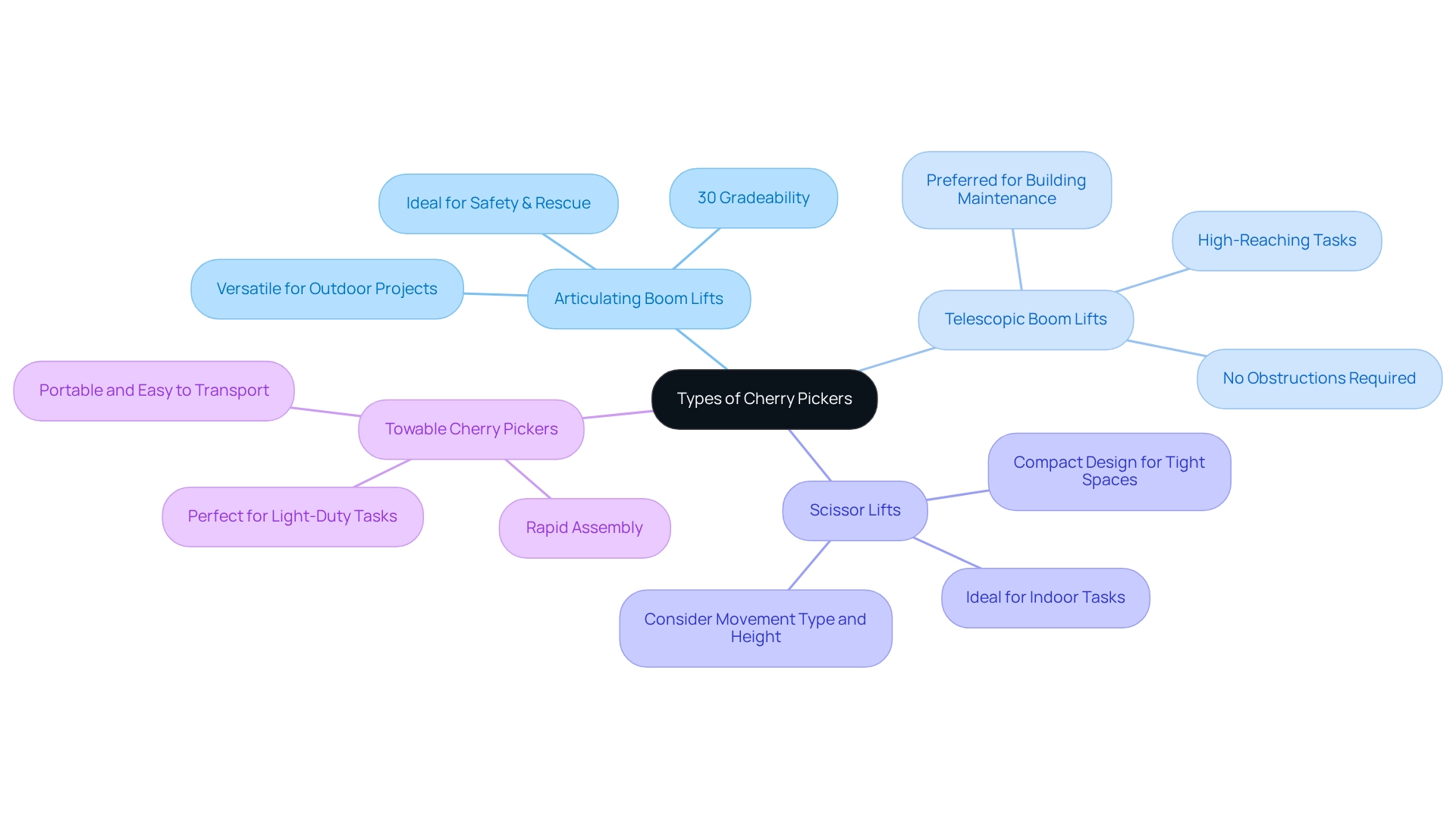

- Different types of cherry pickers include articulating boom lifts for obstacles, telescopic boom lifts for height, scissor lifts for compact spaces, and towable cherry pickers for mobility.

- Key components to consider when renting include boom length, weight capacity, stabilizers, control systems, and safety features.

- Personal Protective Equipment (PPE) is essential for operator safety, significantly reducing accident rates.

- Pre-operation safety checks are critical for ensuring equipment readiness and preventing accidents.

- When renting, consider factors like rental firm reputation, terms, availability, support services, and insurance coverage.

- Regular inspections during the rental period are necessary to maintain safety and functionality.

- Effective communication with rental companies and prioritizing operator training enhance the overall rental experience.

Introduction

In the realm of construction and maintenance, cherry pickers—commonly referred to as aerial work platforms—are essential tools that elevate both workers and productivity to unprecedented heights. These machines are meticulously engineered to traverse challenging terrains and access hard-to-reach areas, rendering them vital for a myriad of tasks, from electrical installations to tree trimming.

As the industry progresses, innovations in cherry picker technology significantly enhance safety and efficiency, empowering teams to undertake high-altitude work with increased confidence. With an array of models available, comprehending the unique features and applications of cherry pickers becomes imperative for construction managers seeking to optimize their projects.

This article explores the fundamental aspects of cherry pickers, encompassing their various types, key components, safety protocols, and rental considerations, ensuring that operators are thoroughly equipped to address any task safely and effectively.

Understanding Cherry Pickers: What They Are and Their Uses

Cherry harvesters, often referred to as , serve as essential tools in the construction and maintenance sectors, designed to safely elevate workers to significant heights. These machines are crucial for accessing difficult areas such as rooftops, utility poles, and high ceilings, making them indispensable for various tasks, including painting, electrical installations, and tree trimming.

In 2025, advancements in aerial work platforms have introduced enhanced safety features and improved maneuverability, facilitating more efficient operations on construction sites. The latest models come equipped with advanced stabilization systems and user-friendly controls, which significantly mitigate the risk of accidents and boost overall productivity.

The benefits of utilizing aerial lifts in construction projects are extensive. They not only offer a safer alternative to ladders and scaffolding but also provide greater reach and flexibility. For instance, construction supervisors have noted that aerial lifts enable teams to complete tasks more swiftly and with fewer personnel, ultimately reducing labor costs.

As one construction manager stated, "Cherry lifters have transformed how we approach high-altitude work; they make it safer and more efficient."

Beyond construction, the real-world applications of aerial lifts are vast. They are frequently employed in maintenance and repair tasks, such as fixing streetlights and power lines, where their capability to provide adequate vertical elevation is vital. Recent news highlights how aerial lifts and boom lifts are utilized to service telephone poles and conduct essential repairs quickly and securely, demonstrating their versatility across various sectors.

Recent data indicates a growing reliance on aerial work platforms in construction, with usage rates increasing as more firms recognize their advantages. This trend underscores the importance of understanding the specific applications of aerial lifts to ensure that construction managers select the appropriate tools for their projects, ultimately leading to safer and more efficient work environments. Case studies, such as 'Versatility of Aerial Lifts,' illustrate that the adaptability of these machines not only enhances productivity but also plays a critical role in maintaining safety standards on job sites.

As Steve remarked, "Contact Steve at 0404 070 585 to organize a complimentary, no commitment site evaluation and estimate," underscoring the significance of expert insights in selecting the right equipment, such as cherry lifts.

Exploring Different Types of Cherry Pickers: Choosing the Right One for Your Project

Cherry pickers, essential tools in construction projects, are readily available through cherry picker crane rental services, and they come in various types, each tailored for specific applications. Understanding these options is crucial for selecting the right equipment for your needs in 2025.

- Articulating Boom Lifts: These lifts feature joints that allow the boom to bend, enabling access to hard-to-reach areas with obstacles. Their versatility makes them ideal for outdoor projects with complex layouts, where navigating around structures is necessary. Notably, offers an impressive 30% gradeability, making it suitable for sloped surfaces. Articulating boom lifts are often favored in safety and rescue operations, as they provide quick access to high-rise buildings during emergencies, demonstrating their critical role in ensuring swift and safe responses.

- Telescopic Boom Lifts: Characterized by a straight arm that extends vertically, telescopic boom lifts excel in high-reaching tasks where there are no obstructions. Their ability to reach significant heights makes them a preferred choice for tasks such as building maintenance and construction work on tall structures. When comparing articulating and telescopic boom lifts, it's important to consider specific project requirements, such as the presence of obstacles and the height needed.

- Scissor Lifts: Although not conventional aerial work platforms, scissor lifts offer vertical access and are frequently utilized in indoor construction tasks where space is restricted. Their compact design allows for maneuverability in tight areas, making them ideal for tasks like electrical work or ceiling installations. When choosing between a scissor lift and a boom lift, consider factors such as the type of movement needed, height requirements, weight capacity, budget constraints, and the project location.

- Towable Cherry Pickers: These portable units can be towed to job sites, making them perfect for light-duty tasks. Their ease of transport and rapid assembly render them a practical choice for projects that demand mobility and adaptability.

When selecting the appropriate aerial lift, a cherry picker crane rental should be considered, taking into account the necessary height, weight capacity, and the landscape of the work site. In 2025, understanding the market share and specific use cases of articulating versus telescopic boom lifts will further inform your decision-making process. By assessing these elements, construction supervisors can efficiently select the most suitable lift for their projects, ensuring improved efficiency and cost-effectiveness in their operations.

Key Components of Cherry Pickers: What to Look For

When assessing lift equipment for your construction projects, it is crucial to consider the following key components:

- Boom Length and Reach: Evaluate the boom's capacity to extend to the required height and reach for your specific project needs. Typically, the average boom length in the market ranges from 30 to 60 feet, with some models providing even greater reach. This capability is essential for tasks such as overhead work or accessing hard-to-reach areas.

- Weight Capacity: Verify the maximum load that the lift can safely handle. This encompasses not only the weight of the operator but also any tools or materials being lifted. Many fruit harvesters have weight limits varying from 300 to 1,000 pounds. Selecting a model that meets your project's demands without compromising safety is vital. Claims regarding weight capacity must be substantiated to avoid misleading practices, as noted in industry discussions.

- Stabilizers: These components are essential for maintaining balance, especially on uneven surfaces. Ensure that the stabilizers are functional and well-maintained, as they play a critical role in preventing tipping and ensuring safe operation.

- Control System: Familiarize yourself with the control arrangement of the lifting platform. An intuitive control system can significantly enhance operational efficiency, enabling operators to maneuver the equipment smoothly and safely.

- Protection Features: Prioritize cherry pickers equipped with vital protection features, such as emergency stop buttons, guardrails, and harness attachment points. These features are crucial for ensuring the safety of operators and workers on the job site. As Jennifer Faulkner, Director of Communications, emphasizes, clear communication regarding tool specifications is essential for both safety and efficiency.

Including these factors in your cherry picker crane rental choice will not only enhance operational efficiency but also ensure a safer working environment. The versatility and power of , akin to the SANY ST230V skid steer, can significantly impact job sites. Therefore, it is essential for construction managers to understand the specifications and capabilities of cherry picker crane rentals for successful project execution. Furthermore, ethical considerations in apparatus rental agreements, such as avoiding confidentiality language that restricts customer collaboration with regulatory authorities, should be kept in mind.

Finally, establishing due diligence programs is essential for confirming equipment specifications and protective features, ensuring a responsible rental process.

Safety First: Essential Equipment and Protocols for Cherry Picker Operation

To ensure the safe operation of a cherry picker, it is essential to follow these key protocols. Personal Protective Equipment (PPE) is crucial; operators must wear suitable PPE, including a hard hat, protective glasses, gloves, and steel-toe boots. Additionally, a safety harness is vital when working at heights, as it significantly reduces the risk of falls, a leading cause of injuries in construction. Statistics indicate that workplaces with strict PPE policies encounter up to 40% fewer accidents associated with aerial lift operations, underscoring the importance of appropriate PPE utilization.

Pre-Operation Safety Checks are imperative. Before using the cherry picker, conduct a comprehensive inspection to identify any mechanical issues or signs of damage. This includes checking the hydraulic systems, controls, and safety features to ensure everything is functioning correctly. Regular upkeep can prevent accidents and enhance machinery reliability. Real-world examples demonstrate that companies prioritizing these practices see a marked decrease in incidents.

Site Assessment is another critical step. A thorough evaluation of the work area is vital; look for potential hazards such as overhead power lines, uneven surfaces, and nearby traffic. Understanding the environment aids in planning safe operations and mitigating risks.

Training is essential for all operators. They must be adequately trained and certified in cherry picker operation, familiarizing themselves with the equipment's controls, protective features, and emergency procedures. Adequate training not only boosts security but also enhances operational efficiency. This aligns with recent news from EZ Equipment Rental, which invites individuals to join their talent community, emphasizing the demand for skilled operators in the industry.

Emergency Procedures must be well understood by operators. They should be familiar with protocols for safely lowering the platform in the event of a power failure. Having a clear strategy can save lives and prevent injuries during unforeseen circumstances. In 2025, revisions to aerial lift protocols will highlight the significance of PPE, with evidence showing that appropriate usage can greatly decrease accident rates. For instance, studies reveal that workplaces with experience up to 40% fewer accidents related to cherry picker operations. Real-world examples further emphasize the effectiveness of pre-operation safety checks, illustrating that companies prioritizing these practices see a marked decrease in incidents.

Furthermore, the significance of quality in equipment operation is demonstrated by a recent case study on a Quality Assurance Technician role, which highlights the necessity for problem-solving abilities and attention to detail in upholding high standards. By adhering to these crucial security protocols, construction managers can ensure a more secure working environment for their teams.

Step-by-Step Guide to Operating a Cherry Picker Safely and Effectively

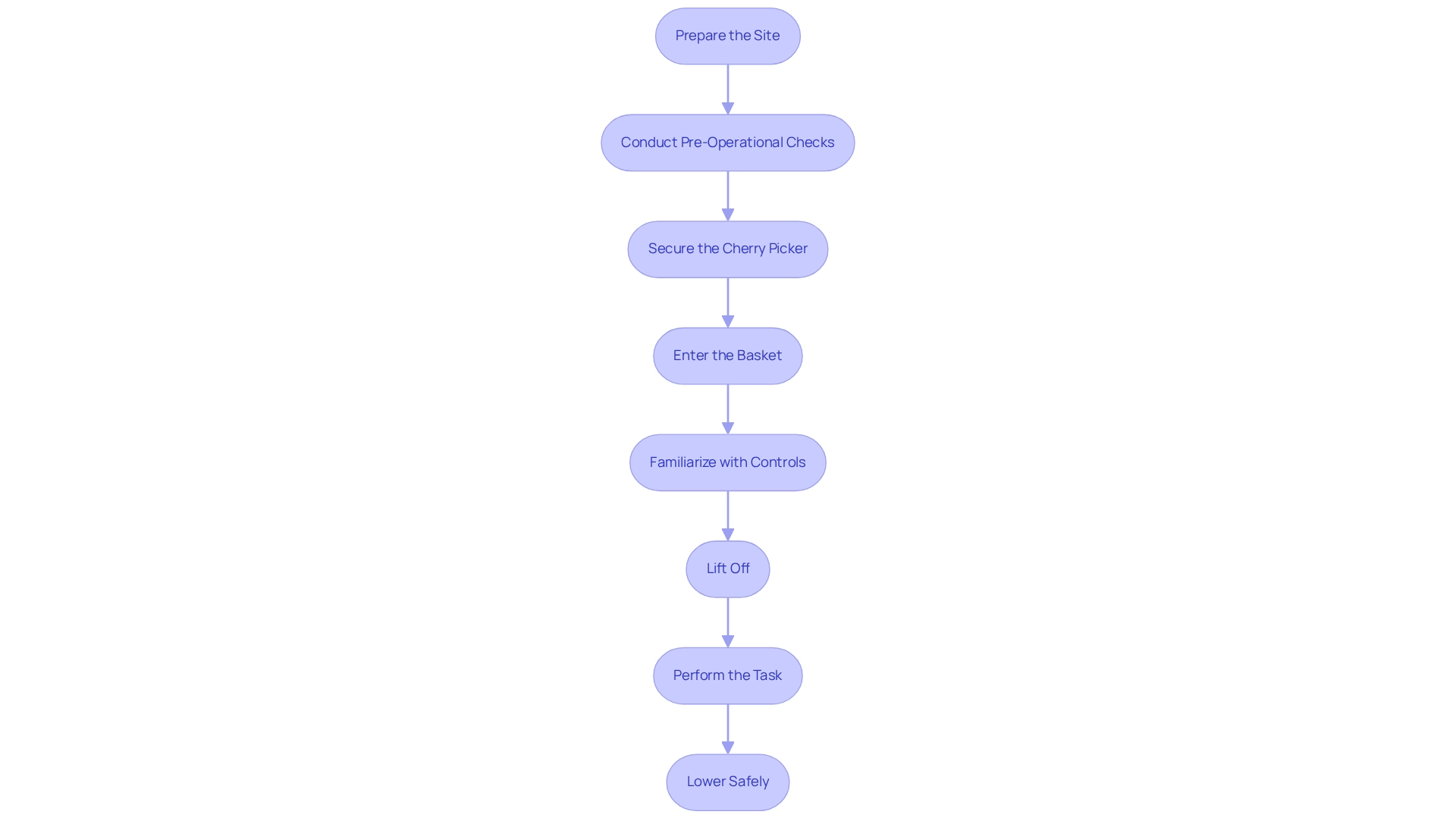

To operate a lift safely and effectively, adhere to the following steps:

- Prepare the Site: Clear the area of obstacles and hazards. Set up warning signs to alert others of the ongoing operation, ensuring a safe working environment. Compliance with OSHA regulations requires that the work area is free from potential dangers.

- Conduct Pre-Operational Checks: Inspect the cherry picker crane rental for visible damage, check fluid levels, and confirm that all protective features are operational. This step is vital as comprehensive ground evaluations and frequent device inspections greatly lower the chances of accidents. According to a case study on safety protocols and training, operator certification and maintenance checks are essential for safe operation.

- Secure the Cherry Picker: Position the machine on stable ground and deploy stabilizers if available. This ensures the equipment remains steady during operation, minimizing risks associated with instability, which is a key OSHA requirement.

- Enter the Basket: Use three points of contact when entering the basket and secure your harness. This practice is essential for preventing falls, which are a common hazard associated with cherry picker crane rental. Remember, being trapped at height can expose workers to extreme temperatures, increasing the risk of dehydration or hypothermia.

- Familiarize with Controls: Understand the control layout before operating. If possible, test the controls at ground level to ensure familiarity and confidence in operation. This preparation aligns with OSHA guidelines for operator training.

- Lift Off: Gradually raise the platform while maintaining awareness of your surroundings. Avoid sudden movements to prevent loss of control, which can lead to accidents. Following security protocols is essential to meet OSHA standards.

- Perform the Task: Work efficiently while following health guidelines. Maintain communication with ground personnel to ensure coordinated efforts and improve security. Neglecting to adhere to these protocols can result in legal consequences, as there are strict time limits for submitting claims related to incidents, as mentioned by Spagnoletti Law Firm.

- Lower Safely: When finished, lower the platform slowly and ensure the area is clear before exiting the basket. This last phase is essential to prevent incidents during dismounting, emphasizing the significance of adhering to OSHA regulations.

By implementing these optimal practices, operators can greatly improve security and efficiency when utilizing aerial lifts, conforming to compliance standards from organizations such as OSHA.

Pre-Operation Safety Checks: Ensuring Equipment Readiness

Before using a lift, it is crucial to perform comprehensive inspections to guarantee both functionality and security. Here are the critical steps to follow:

- Visual Inspection: Examine the lift for any visible damage, including cracks in the boom or leaks in hydraulic lines. This initial check can prevent potential failures during operation.

- Functionality Check: Test all operational controls to confirm they respond correctly. Pay special attention to the emergency stop button and safety alarms, as these are vital for immediate response in case of an emergency.

- Stabilizers and Outriggers: Verify that stabilizers are operational and can be deployed correctly. Proper stabilization is crucial for maintaining balance and preventing tipping during use.

- Tires and Ground Conditions: Inspect the tires for adequate inflation and assess the ground conditions where the cherry picker crane rental will be utilized. Avoid using the apparatus on soft or uneven surfaces, as this can compromise stability.

- Weight Limits: Ensure that the total weight in the basket, including personnel and equipment, does not exceed the manufacturer's specified limits. Adhering to these limits is critical to prevent mechanical failures, which have seen a concerning increase in incidents, with fatalities from mechanical failures rising by 400% in 2023 compared to the previous year.

Emphasizing protection is essential for both seasoned and novice cherry picker operators to avoid accidents. As Brian Parker, Head of Safety and Technical, stated, "We're not just launching a Global Campaign for Security; we're reaching out to the individuals who stand on the front lines of protection every day—the MEWP operators and rescue personnel." This highlights the significance of thorough inspections.

Furthermore, emphasizes the legal implications of accidents due to negligence, underscoring the need for timely legal action and the importance of understanding legal rights for individuals affected by workplace accidents. By adhering to these precautionary measures, operators can greatly minimize the risk of incidents and ensure that the cherry picker crane rental is prepared for secure operation. The importance of equipment readiness cannot be overstated, especially in the construction industry, where safety is paramount.

Renting a Cherry Picker: Where to Find and What to Consider

When renting a lifting device, it is essential to consider several key factors to ensure a smooth and efficient rental experience.

Rental Firms: Selecting trustworthy rental firms is crucial. stands out with its wide range of aerial work platforms, boom lifts, excavators, and forklifts, along with a commitment to customer satisfaction in the DFW Metroplex. Their knowledgeable team can assist you in choosing the right tools for your specific needs. According to Fortune Business Insights, major players in the rental market constitute approximately 45%-50% of the overall market share, underscoring the importance of selecting a trusted provider.

Rental Terms: Carefully reviewing the rental agreement is vital. Pay close attention to the duration of the rental, total costs, and any additional fees that may apply for delivery or pickup. Understanding these terms upfront can help avoid unexpected expenses. EZ Equipment Rental offers competitive pricing and flexible rental durations to accommodate various project needs.

Availability: Confirming the availability of the specific cherry picker crane rental you require is essential within your project timeline. Given the increasing demand for construction equipment, as highlighted in a recent case study on the commercial segment growth in equipment rental, timely reservations are crucial to securing the right machinery.

Support Services: Inquire whether EZ Equipment Rental provides support services, such as operator training or maintenance during the rental period. Creating an inviting work culture and being flexible with benefits are strategies employed by rental operators to retain employees, enhancing safety and efficiency on the job site, ensuring your team is well-prepared to operate the equipment.

Insurance and Liability: Verifying the insurance coverage included in the rental agreement is a critical step. It is recommended to evaluate if extra coverage is required to safeguard against possible damages or liabilities during the rental duration.

By factoring in these aspects, construction managers can make informed choices when opting for cherry picker crane rentals from EZ Equipment Rental, ultimately aiding the success of their projects. Moreover, staying updated on current market trends in aerial lift rentals can offer valuable insights that correspond with the latest industry advancements. For more information or to make a reservation, contact EZ Equipment Rental today.

Final Thoughts: Making the Most of Your Cherry Picker Rental Experience

To enhance , consider the following strategies:

- Plan Ahead: Start by assessing your project requirements well in advance. This proactive approach ensures you secure the appropriate lift for your specific tasks, preventing last-minute challenges. Renting equipment such as aerial lifts, trailers, and portable dock ramps from EZ Equipment Rental, along with cherry picker crane rental, significantly improves your logistics and project execution.

- Communicate with the Rental Company: Establish and maintain open lines of communication with your rental provider. This dialogue is essential for addressing any concerns or questions that may arise, ensuring a smoother rental process. As emphasized by The Editorial Team, management and supervisors should continue to support 'Stop the Job' with their teams, reinforcing the importance of effective communication.

- Prioritize Training: Equip your team by prioritizing training for all operators who will be using the cherry picker crane rental. Understanding the equipment not only boosts operational efficiency but also significantly enhances safety on the job site. The IPAF has launched targeted [safety campaigns focusing on critical issues such as falls from height](https://ipaf.org/en-us/gsr2024), highlighting the necessity of proper training and awareness.

- Conduct Regular Inspections: Throughout the rental period, implement a routine for regular inspections of the cherry picker. These checks are vital to ensure the equipment remains in safe working condition, thus reducing the risk of accidents. Notably, incidents involving entrapment have been reported in the UK and the Republic of Korea, underscoring the necessity of stringent safety measures for cherry picker crane rental operations.

- Evaluate Performance: After completing your project, take the time to evaluate both the performance of the cherry picker and your overall rental experience. This assessment will provide valuable insights that can guide your decisions for future rentals, ensuring continuous improvement in your project planning and execution.

For your rental needs, including cherry picker crane rental, portable dock ramps, and trailers, contact EZ Rental at (214) 951-7800 to learn more and reserve the necessary items. Additionally, explore our latest posts on how renting trailers can save you time and money, along with the advantages of plumbing equipment rentals in Dallas.

Conclusion

Cherry pickers are essential in the construction and maintenance industries, providing elevated access to hard-to-reach areas while significantly enhancing safety and efficiency. By understanding the diverse types of cherry pickers—articulating boom lifts, telescopic boom lifts, scissor lifts, and towable cherry pickers—construction managers can make informed decisions tailored to their project needs. Each type serves specific applications, enabling teams to optimize operations while prioritizing worker safety.

Safety is a critical concern when operating cherry pickers. Implementing stringent safety protocols, conducting thorough pre-operation checks, and ensuring comprehensive training for operators can substantially mitigate the risk of accidents. It is vital to emphasize the significance of personal protective equipment, site assessments, and emergency procedures to foster a secure working environment.

When considering renting cherry pickers, it is crucial to carefully evaluate rental companies, terms, availability, and support services to ensure a seamless experience. By planning ahead and maintaining open communication with rental providers, construction managers can secure the right equipment for their projects, avoiding unexpected complications.

Ultimately, leveraging the benefits of cherry pickers not only boosts productivity but also cultivates a culture of safety on job sites. By adhering to best practices and prioritizing safety and efficiency, teams can elevate their performance and achieve greater success in their construction endeavors.

Frequently Asked Questions

What are cherry harvesters and their primary function?

Cherry harvesters, also known as aerial work platforms, are essential tools in the construction and maintenance sectors designed to safely elevate workers to significant heights for tasks such as painting, electrical installations, and tree trimming.

What advancements have been made in aerial work platforms by 2025?

By 2025, aerial work platforms have seen enhanced safety features and improved maneuverability, including advanced stabilization systems and user-friendly controls, which help reduce the risk of accidents and increase overall productivity.

What are the benefits of using aerial lifts in construction projects?

Aerial lifts provide a safer alternative to ladders and scaffolding, offering greater reach and flexibility. They enable teams to complete tasks more quickly and with fewer personnel, ultimately reducing labor costs.

How are aerial lifts utilized outside of construction?

Aerial lifts are frequently used in maintenance and repair tasks, such as fixing streetlights and power lines, where vertical elevation is critical. They are also employed for servicing telephone poles and conducting essential repairs.

What is the trend regarding the use of aerial work platforms in construction?

There is a growing reliance on aerial work platforms in construction, with increasing usage rates as more firms recognize their advantages, leading to safer and more efficient work environments.

What types of cherry pickers are available for different applications?

The main types of cherry pickers include: - Articulating Boom Lifts: Ideal for accessing hard-to-reach areas with obstacles. - Telescopic Boom Lifts: Best for high-reaching tasks without obstructions. - Scissor Lifts: Used for indoor tasks where space is restricted. - Towable Cherry Pickers: Portable units suitable for light-duty tasks and easy transport.

What should be considered when selecting an aerial lift?

When selecting an aerial lift, consider factors such as the necessary height, weight capacity, project requirements, landscape of the work site, and the specific type of lift needed (articulating or telescopic boom lifts, scissor lifts, etc.).

Why is it important to understand the specific applications of aerial lifts?

Understanding the specific applications of aerial lifts helps construction managers select the appropriate tools for their projects, leading to improved efficiency, cost-effectiveness, and enhanced safety standards on job sites.