Introduction

In the realm of construction and renovation, the right tools can make all the difference in achieving a successful project outcome. Floor scraper machines, in particular, come in various types, each tailored to specific tasks and project scales. Understanding these options is essential for project managers aiming to optimize efficiency and productivity.

From manual scrapers for small jobs to high-powered ride-on machines for expansive areas, selecting the appropriate equipment can significantly impact workflow and team morale. This article delves into the diverse types of floor scraper machines available for rent, along with practical steps for renting, preparing, and utilizing them effectively, ensuring that every project runs smoothly from start to finish.

Exploring Different Types of Floor Scraper Machines for Rent

When selecting a floor scraper machine for rent, it is crucial to assess the various types available, each designed for specific tasks and project scales:

- Manual Floor Scrapers: These machines excel in small jobs or confined spaces, requiring physical effort to operate. They are cost-effective and easily maneuverable, making them a practical choice for minor renovations.

- Electric Floor Scrapers: Ideal for medium to large tasks, electric scrapers efficiently handle the removal of various flooring materials, including tile, carpet, and vinyl. Their quieter operation and reduced vibration compared to manual scrapers enhance comfort during use, which can significantly contribute to better team morale on-site. Keeping teams motivated during challenges is essential, and utilizing efficient tools can help maintain productivity.

- Propane-Powered Floor Scrapers: These high-powered devices are best suited for extensive, heavy-duty tasks. They excel at removing glued-down carpets or thick vinyl flooring, making them essential for large-scale tasks that demand significant lifting power.

- Ride-On Floor Scrapers: For expansive areas, ride-on machines greatly enhance productivity by allowing operators to sit while working. This ergonomic design is especially advantageous in large commercial areas or warehouses, where efficiency is crucial to meet deadlines. As noted in the quote, improving warehouse efficiency through training and technology can lead to better outcomes.

- Walk-Behind Floor Scrapers: Offering a compromise between manual and ride-on options, walk-behind scrapers provide substantial power while maintaining ease of maneuverability for various flooring types.

By understanding the unique benefits of each kind of scraper, including floor scraper machine rental near me, construction managers can make informed choices that align with the size of the task, type of surface, and the abilities of their team. Additionally, citing the case study titled "Motivating Teams Through Project Challenges" demonstrates how breaking down goals and encouraging positivity can be applied in the context of selecting and using scraping tools effectively. As the leasing market changes, staying informed about the newest developments in surface scraping technology will enhance task execution and team performance.

Step-by-Step Guide to Renting a Floor Scraper Machine

To effectively rent a scraper apparatus for your project, follow these structured steps:

-

Research Leasing Companies: Begin by identifying local leasing companies in Irving, TX, that offer floor scraper machine rental near me, as well as boom lifts and forklifts. Websites such as alliedrental.com and sunbeltrentals.com, along with local providers like RentalHosting, offer comprehensive listings of available equipment, including their pricing details.

- Compare Options: Investigate customer feedback and satisfaction ratings to assess the reliability of each leasing service. Seek feedback on the kinds of devices they provide, ensuring they have options that satisfy your particular needs. Customer feedback can often be found on the leasing companies' websites, providing valuable insights.

- Check Availability: Contact the leasing company to confirm that your desired machine is available for the dates you require it. It’s advisable to secure your lease in advance, particularly during peak construction periods when demand is high.

- Understand Rental Terms: Before finalizing your rental, clarify all terms and conditions, including the rental duration, pricing structure, deposit requirements, and any additional fees associated with late returns or equipment damage.

-

Inspect the Machine: Upon pickup, conduct a thorough inspection of the floor scraper to identify any pre-existing damage or maintenance issues. Ensuring that the equipment is in optimal working condition is crucial for a successful project.

-

Follow Usage Instructions: Take the time to familiarize yourself with the device's operation, including safety protocols and maintenance guidelines. Many leasing companies provide a brief tutorial or an operation manual to assist you.

-

Return the Machine: After finishing your flooring task, return the machine as per the lease agreement. Clean the equipment and check for any potential damages to avoid incurring extra charges.

By adhering to these steps, you can navigate the rental process smoothly. Furthermore, local suppliers in the DFW Metroplex provide a comprehensive range of machinery, including options for a floor scraper machine rental near me, such as the National Flooring Equipment 7700 High-Speed Ride-On Scraper and the National Flooring Equipment 2900 High-Speed Ride-On Scraper, valued at $38,080.00, guaranteeing you have access to the appropriate tools for your flooring removal tasks. Don't forget to explore other options available, including boom lifts and forklifts, to complete your task efficiently.

Preparing for Your Floor Scraping Project

Effective preparation is crucial for the success of your scraping project, particularly if you are looking for a floor scraper machine rental near me. Here’s a step-by-step guide to ensure you are ready:

-

Clear the Area: Begin by removing all furniture, rugs, and other items from the work area.

This will create a safe and spacious environment for operating the machinery without obstructions.

-

Assess the Flooring: Take time to identify the type of flooring that needs removal. Different materials, such as vinyl, tile, or hardwood, require specific tools and techniques.

Understanding these distinctions will aid in selecting the appropriate method and the right floor scraper machine rental near me.

-

Gather Safety Gear: Safety should always be a priority. Equip yourself with essential safety gear, which includes gloves, goggles, and a dust mask.

Given that surface scraping generates dust and debris, proper protection is necessary to prevent injury. Statistics indicate that wearing appropriate safety gear can significantly reduce the risk of accidents on construction sites. In fact, the NIOSH Mini-Baghouse Retrofit Assembly has effectively reduced concentrations of respirable dust and respirable crystalline silica, underscoring the importance of using effective safety measures during surface scraping.

-

Plan for Disposal: Before you start scraping, make arrangements for disposing of the old flooring materials. Check local regulations for disposal methods, and consider renting a dumpster if you anticipate a large volume of waste.

Proper disposal is not only a legal requirement but also promotes environmental responsibility.

-

Review the Machine Manual: Familiarize yourself with the operation manual of the floor scraper machine rental near me. Understanding its features and guidelines will not only enhance your efficiency but also ensure your safety during the scraping process.

The Safety Scraper, for example, is crafted with a locking blade sleeve for enhanced security, demonstrating how contemporary tools emphasize user safety.

By adhering to these preparatory steps, you can create the conditions for a successful and safe scraping endeavor. As an expert in the field noted,

Improve warehouse efficiency by training your team on Lean principles, using technology, and holding regular sessions.

Moreover, with Europe's market expansion for automatic surface cleaners propelled by an emphasis on sustainability and energy-efficient solutions, it’s crucial to remain updated on current trends that can enhance your initiative.

Emphasizing preparation and safety gear will ultimately lead to better project outcomes.

Tips for Using a Floor Scraper Machine Effectively

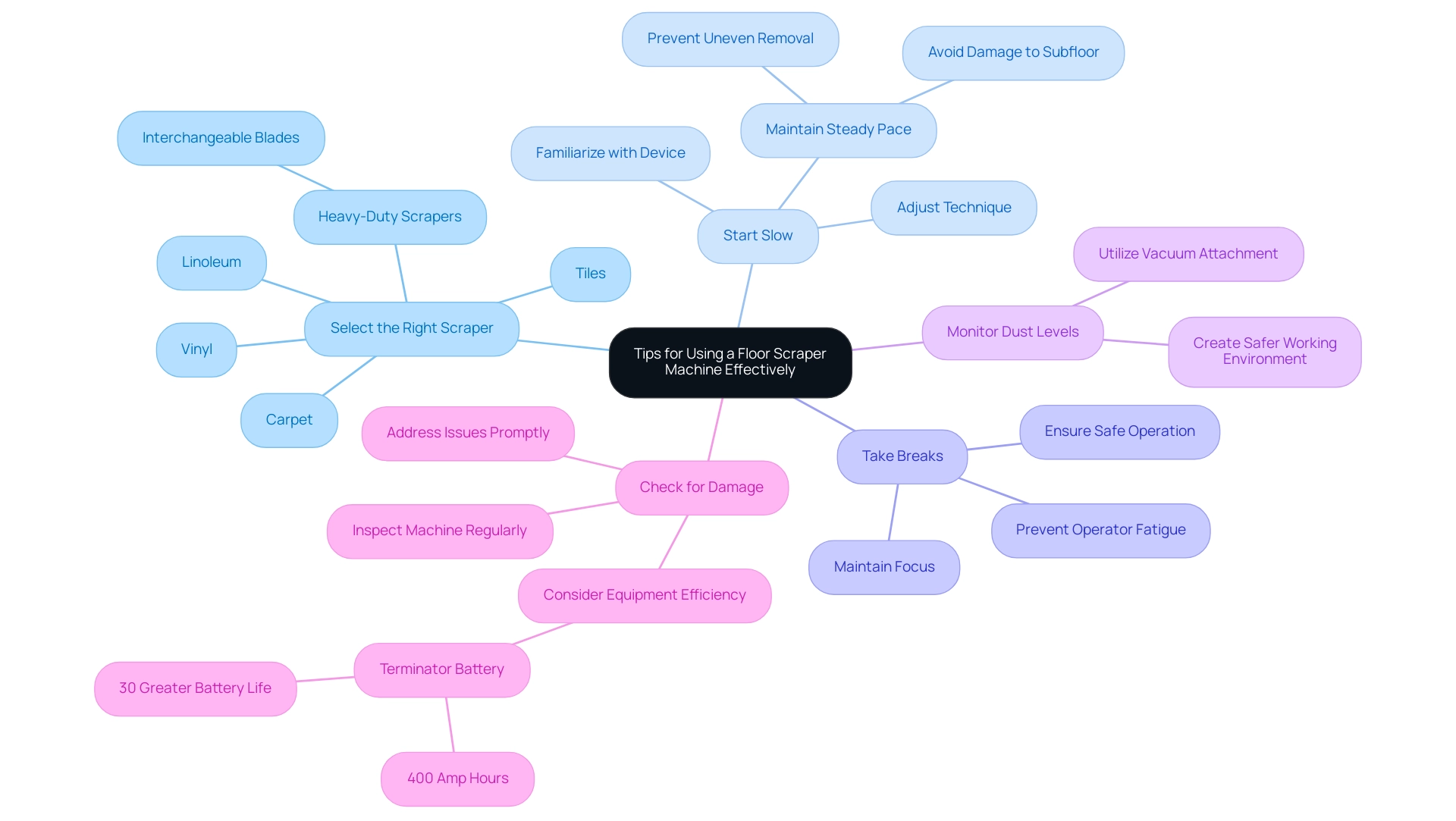

When using a scraper device, consider these essential tips to enhance efficiency and effectiveness:

-

Select the Right Scraper: Choosing the appropriate floor scraper is crucial and depends on the type of flooring being removed. For instance, specialized scrapers are necessary for materials like tiles, while a floor scraper machine rental near me, which includes versatile heavy-duty scrapers with interchangeable blades, is better suited for vinyl, carpet, or linoleum. This selection process ensures that you are using the right tool for the job, optimizing efficiency from the start.

-

Start Slow: Initiate your scraping by focusing on a small section. This approach allows you to familiarize yourself with the device's operation and the required pressure. Adjust your technique according to the specific flooring type and the equipment's responsiveness.

Maintain a Steady Pace: Consistency is key. Operating the equipment at a steady speed ensures even scraping, which prevents uneven removal and potential damage to the subfloor. As Dave Bigham, global director of training at National Flooring Equipment, notes,

Depending on the issue, production can grind to a halt entirely, taking a few days to rectify the issue.

Therefore, a deliberate pace is crucial.

-

Take Breaks: Tackling large areas can lead to operator fatigue, which significantly impacts scraping efficiency. Schedule regular breaks to maintain focus and ensure safe operation of the machine.

-

Monitor Dust Levels: Be vigilant about dust accumulation, particularly when removing materials such as tile or carpet. Utilizing a vacuum attachment when available can minimize dust exposure and create a safer working environment.

-

Check for Damage: Regularly inspect the machine for any signs of wear or damage during use. Promptly addressing these issues can prevent further complications and ensure smooth operation. Furthermore, consider the equipment's efficiency; for instance, a Terminator battery holds 400 amp hours, offering over 30% greater battery life than rivals, which can improve your operational abilities.

By implementing these best practices and recognizing the significance of choosing the appropriate tools and methods, such as a floor scraper machine rental near me, you'll optimize your scraping process and attain exceptional results, minimizing the risk of downtime and increasing overall effectiveness.

Post-Project Cleanup and Maintenance

After finishing your scraping task, applying a systematic method to post-task cleanup is crucial for guaranteeing a smooth transition and maintaining your connection with the floor scraper machine rental near me. Here are key steps to follow:

- Clean the Area: Start by thoroughly removing any debris and dust from your workspace. Sweeping or vacuuming will help ensure that the area is free of leftover materials that could hinder subsequent projects.

- Return the Machine: Adhere to the rental company’s guidelines for cleaning the rented floor scraper. It is crucial to return the equipment, such as a floor scraper machine rental near me, in a condition free from dust and debris to avoid incurring additional cleaning fees, which can average around $880 for cleaning large areas of 9,000-10,000 square feet. This financial context underscores the importance of proper cleanup and the return of equipment, such as the floor scraper machine rental near me.

- Inspect for Damage: Conduct a thorough inspection of the machine before returning it. Look for any signs of damage that may have occurred during use and document these issues. Informing the leasing company in advance can help avoid disputes and facilitate a smoother return process.

- Follow Up with the Leasing Company: Confirm the return process with the leasing company, including any final checks or documentation that may be required. This proactive step ensures that you fulfill all obligations, enabling you to address any concerns promptly.

- Provide Feedback: After your experience with the lease, consider sharing your insights with the company. Whether your experience was positive or highlighted areas for improvement, your feedback can contribute to enhancing their services for future renters. As Brian Boucher suggests, "Check out Mynd's income calculator to estimate your returns and cash flows," which can provide valuable insight into the financial aspects of your projects.

By diligently following these steps, you not only ensure a smooth transition post-project but also foster a positive relationship with the leasing company. The common practice of charging cleaning fees, as illustrated in the case study on vacation rental cleaning fees, highlights the necessity of maintaining equipment and adhering to rental guidelines, ensuring a well-maintained rental while aiding in your booking decisions. This proactive approach paves the way for future collaborations.

Conclusion

Selecting the right floor scraper machine is a pivotal step in ensuring the success of any construction or renovation project. The article outlines various types of machines available for rent, each designed to meet specific needs and project scales. From manual scrapers for small jobs to powerful ride-on machines for larger areas, understanding these options allows project managers to optimize efficiency and enhance team morale.

Moreover, following a structured approach to renting, preparing, and utilizing these machines can significantly impact project outcomes. Thorough research on rental companies, careful comparison of options, and a clear understanding of rental terms are essential for a smooth rental process. Effective preparation, including clearing the area and gathering safety gear, sets the stage for a successful scraping project.

Finally, utilizing best practices during operation and maintaining a diligent post-project cleanup routine ensures not only the integrity of the rented equipment but also fosters positive relationships with rental providers. By prioritizing the right tools and thorough preparation, project managers can navigate challenges more effectively, ultimately leading to enhanced productivity and successful project completion.

Frequently Asked Questions

What types of floor scraper machines are available for rent?

There are several types of floor scraper machines available for rent: 1. Manual Floor Scrapers - ideal for small jobs and confined spaces. 2. Electric Floor Scrapers - suitable for medium to large tasks, efficient on various flooring materials. 3. Propane-Powered Floor Scrapers - designed for heavy-duty tasks, especially glued-down carpets and thick vinyl. 4. Ride-On Floor Scrapers - enhance productivity for large areas, allowing operators to sit while working. 5. Walk-Behind Floor Scrapers - provide substantial power while being easy to maneuver.

What are the advantages of using electric floor scrapers?

Electric floor scrapers are quieter and produce less vibration compared to manual scrapers, enhancing comfort during use. This can contribute to better team morale and productivity on-site.

When should I consider renting a propane-powered floor scraper?

A propane-powered floor scraper is best suited for extensive, heavy-duty tasks, particularly when removing glued-down carpets or thick vinyl flooring.

What is the benefit of using ride-on floor scrapers?

Ride-on floor scrapers are advantageous for expansive areas as they allow operators to sit while working, significantly enhancing productivity and efficiency in large commercial spaces or warehouses.

How can construction managers make informed choices about floor scraper rentals?

Construction managers can make informed choices by understanding the unique benefits of each type of scraper and aligning the selection with the size of the task, the type of surface, and the team's capabilities.

What steps should I follow to rent a floor scraper machine?

To rent a floor scraper machine, follow these steps: 1. Research local leasing companies and compare options. 2. Check the availability of the desired machine. 3. Understand the rental terms and conditions. 4. Inspect the machine upon pickup. 5. Familiarize yourself with the usage instructions. 6. Return the machine as per the lease agreement.

Why is it important to inspect the machine before renting it?

Inspecting the machine before renting is crucial to identify any pre-existing damage or maintenance issues, ensuring that the equipment is in optimal working condition for your project.

What should I do before returning the rented machine?

Before returning the rented machine, clean it and check for any potential damages to avoid incurring extra charges.