Overview

The article offers a comprehensive guide on effectively utilizing a gravel tamper rental, highlighting the crucial role of selecting the appropriate tool based on project size, material type, and maneuverability. It elaborates on the key features of tampers, providing step-by-step operational instructions and troubleshooting tips. This ensures users are well-equipped to achieve optimal compaction results in their construction projects. By understanding the right equipment, readers can enhance their project outcomes significantly.

Key Highlights:

- Gravel tampers are crucial for compressing and leveling loose materials like gravel, soil, and sand.

- Weight and size of tampers affect their compaction power; heavier tampers are suited for larger areas.

- Plate design impacts efficiency; wider plates cover more ground while smaller plates are better for tight spaces.

- Vibration mechanisms in tampers enhance compaction by allowing deeper penetration into materials.

- Ergonomically designed handles improve user comfort and control during extended use.

- When renting a gravel tamper, consider project size, material type, access and maneuverability, rental duration, and local availability.

- Effective operation involves preparation, equipment checks, using safety gear, proper positioning, and layering during compaction.

- Common issues include starting problems, inadequate compaction, excessive vibration, maneuverability difficulties, and uneven surfaces; these can often be resolved through simple checks and adjustments.

Introduction

In the construction and landscaping sectors, establishing a solid foundation is crucial, and gravel tampers are integral to this process. These versatile tools, commonly known as compactors, are engineered to compress and level loose materials such as gravel, soil, and sand, thereby ensuring a stable surface for a variety of projects. With a range of features—including weight, plate design, and vibration mechanisms—understanding the capabilities of gravel tampers is vital for selecting the appropriate tool for the task at hand.

As urbanization and infrastructure development continue to escalate, the demand for efficient tamping solutions has reached unprecedented levels. This article explores the essential features of gravel tampers, provides guidance for selecting the ideal rental for specific projects, and offers step-by-step instructions for effective operation, while also addressing common troubleshooting issues to enhance user experience.

Whether you are undertaking a small backyard project or managing a large construction site, mastering the use of gravel tampers can significantly influence the outcome of your endeavors.

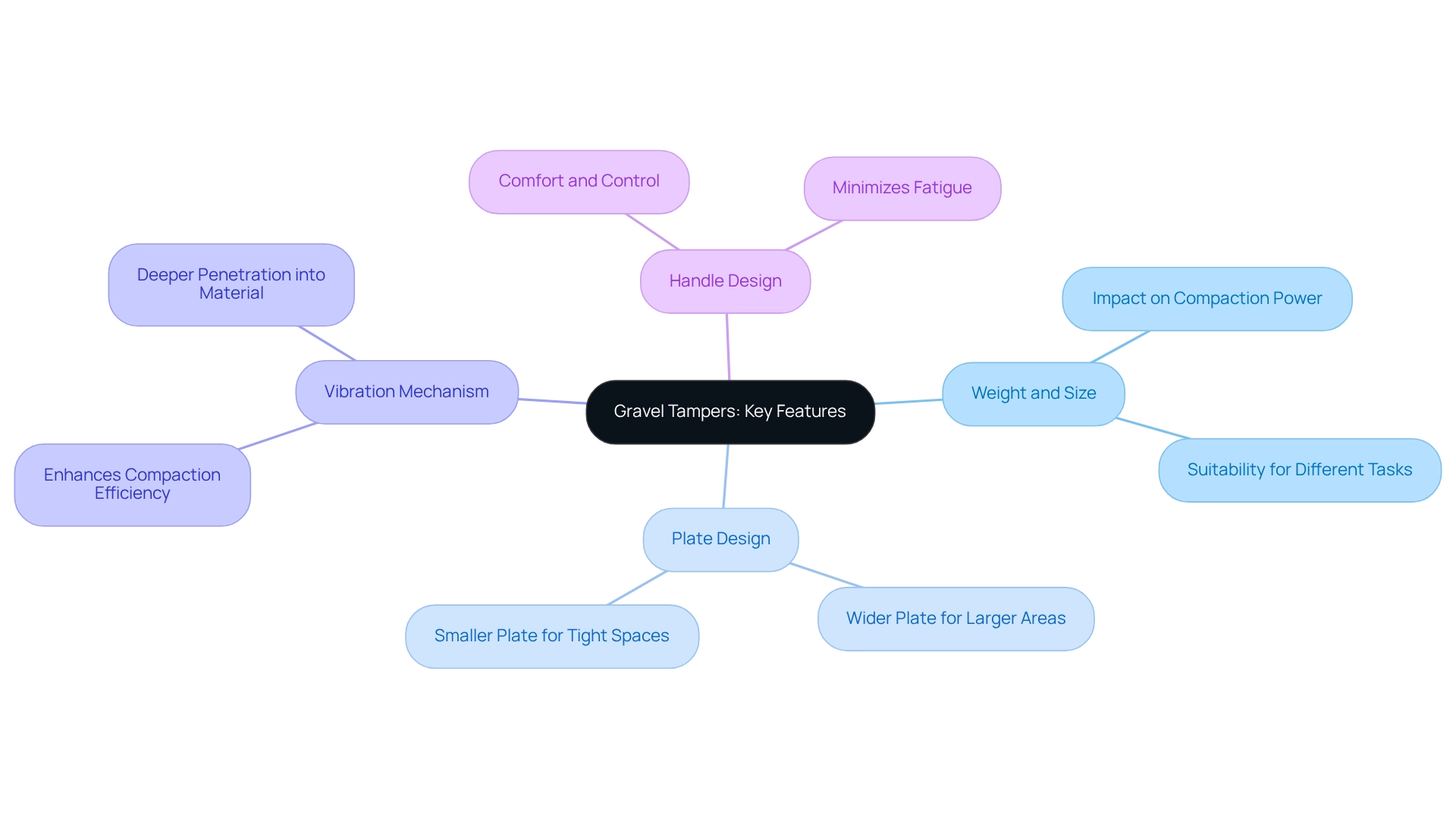

Understand Gravel Tampers: Key Features and Functions

Gravel compactors, often referred to as compressing devices, are essential instruments for compressing and leveling loose materials like gravel, soil, and sand. Understanding their key features is crucial for selecting the right tool for your project.

- Weight and Size: These tampers vary in weight and size, which directly impacts their compaction power and suitability for different tasks. Heavier tools generate greater force, making them ideal for larger areas, while lighter options excel in smaller, detailed work.

- Plate Design: The base plate's design plays a significant role in compaction efficiency. A wider plate can cover more ground, while a smaller plate is advantageous for tight spaces, allowing for precise compaction in confined areas.

- Vibration Mechanism: Many compactors incorporate a vibration mechanism that enhances compaction efficiency. This feature enables deeper penetration into the material, resulting in a more solid and stable surface. Familiarity with this mechanism can greatly improve tool operation.

- Handle Design: Ergonomically designed handles are vital for user comfort and control, particularly during extended use. A well-designed handle minimizes fatigue and enhances maneuverability, which is essential for maintaining productivity on the job site.

Familiarizing yourself with these features will empower you to choose the appropriate tool, including a gravel tamper rental, for your specific needs, ensuring effective operation and optimal results in your construction projects. Recent trends indicate that ongoing infrastructure development and urbanization are driving demand for advanced tamping technology. Staying informed about the latest innovations in this field is crucial. As Frank Gehry aptly stated, "Architecture should reflect its era and location, yet aspire for eternity," underscoring the importance of adapting tools like compactors to meet modern building requirements.

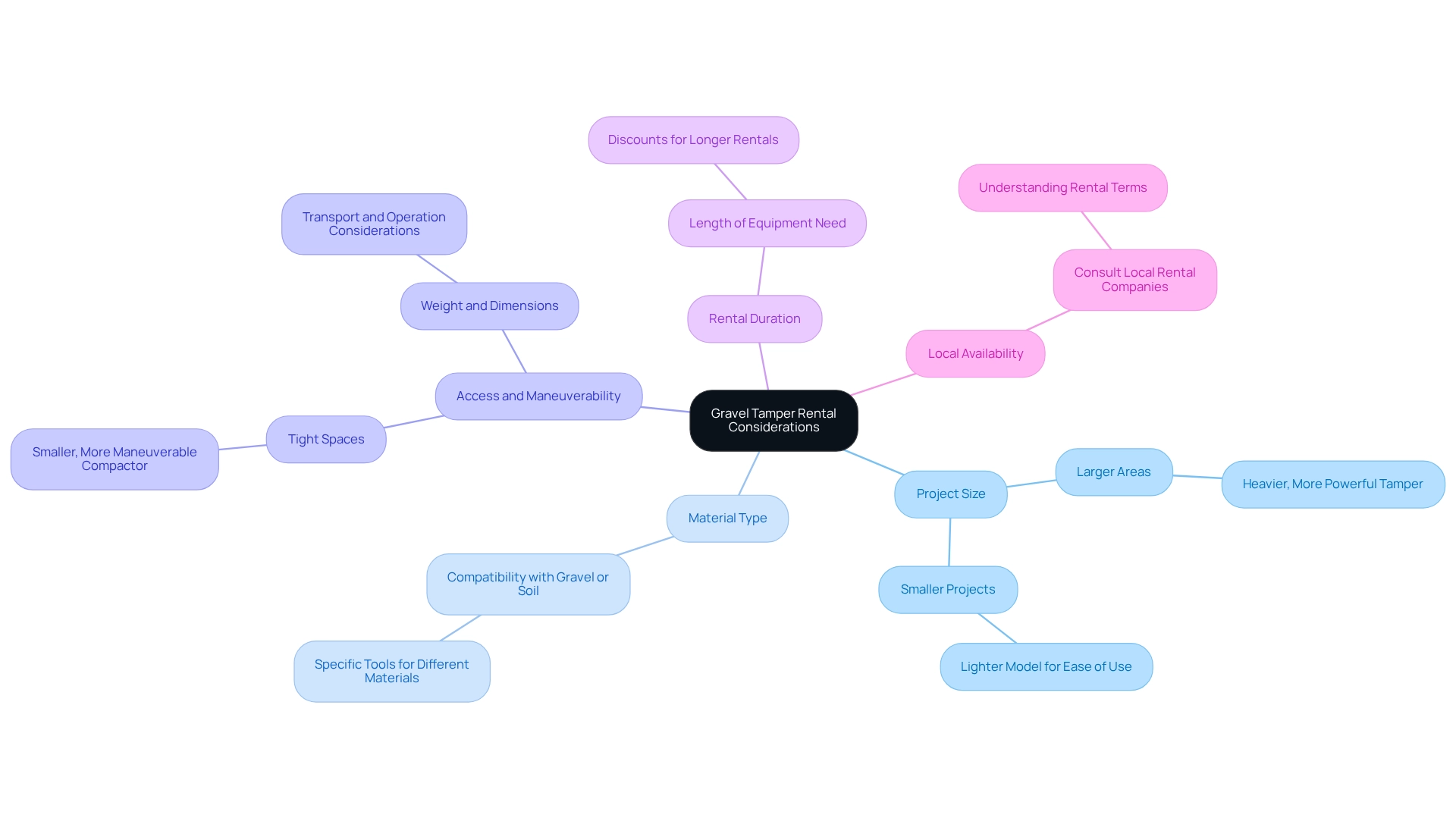

Select the Right Gravel Tamper Rental for Your Project

When considering a gravel tamper rental, it is essential to evaluate several key factors to ensure you make the right choice for your project, with project size being a primary consideration. For larger areas, a heavier, more powerful tamper may be necessary. Conversely, smaller projects can often be effectively managed with a lighter model, allowing for ease of use without compromising on efficiency.

Next, evaluate the Material Type you will be working with. Different tools are specifically designed for various materials. It is crucial to ensure that the device you select is appropriate for the kind of gravel or soil you will be compacting, as this will significantly impact the effectiveness of your work.

Access and Maneuverability also play a vital role in your selection process. If your project site has tight spaces, it is advisable to opt for a smaller, more maneuverable compactor. Consider the weight and dimensions of the equipment to ensure it can be easily transported and operated within your work area.

Additionally, determine your Rental Duration. Knowing how long you will need the equipment can influence your choice. Some rental companies offer discounts for longer rental periods, which can be a great way to save money while ensuring you have the right tools at your disposal.

Finally, check for Local Availability. It is beneficial to consult with local rental companies, such as EZ Equipment Rental, to see what models are available and understand their rental terms. By thoughtfully evaluating these elements, you can choose the most suitable compaction tool for your project, such as a gravel tamper rental, ensuring efficient and effective compression.

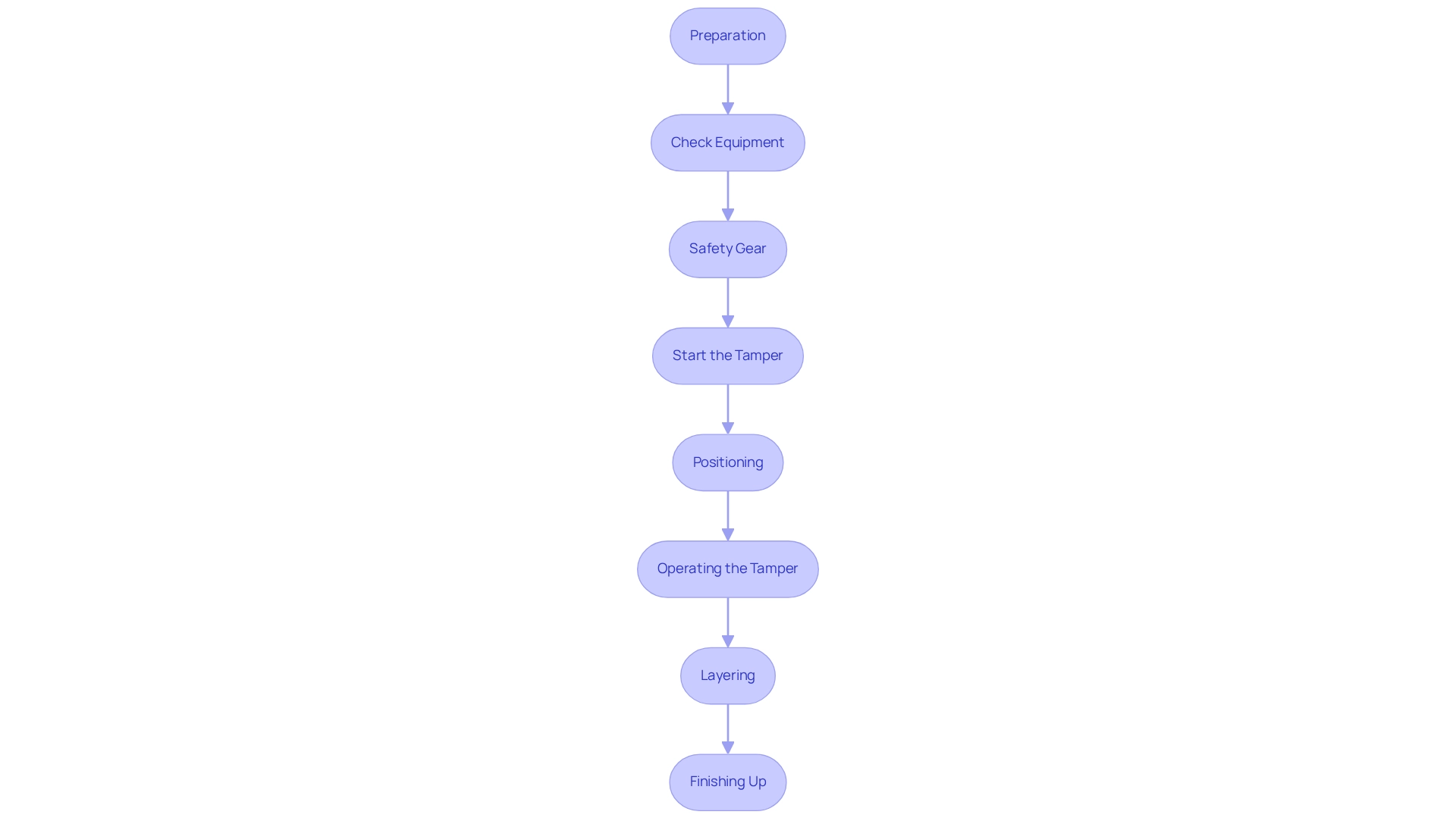

Operate the Gravel Tamper: Step-by-Step Instructions

To operate a gravel compactor effectively, it is essential to follow these comprehensive step-by-step instructions:

Preparation: Before you begin, ensure the space is clear of debris, rocks, and any obstacles that could disrupt the machine's operation.

Check Equipment: Inspect the device for any visible damage or issues. Confirm that all parts are functioning correctly, including the engine and vibration mechanism.

Safety Gear: Equip yourself with appropriate safety gear, including gloves, safety glasses, and ear protection, to safeguard against noise and debris. Remember, neglecting safety can lead to significant financial, emotional, and physical costs.

Start the Tamper: Adhere to the manufacturer's instructions to start the engine. Typically, this involves turning on the fuel valve, engaging the choke, and pulling the starter cord.

Positioning: Place the tool on the area to be compacted. Ensure it is level and stable before beginning. Utilizing a laser level can help ensure the surface is flat and level during tamping.

Operating the Tamper: Gradually lower the tamper onto the aggregate or soil. Move it in a slow, steady motion, allowing the vibration to compact the material effectively. Avoid rushing, as this can lead to uneven compaction.

Layering: If you are compacting a thick layer of stones, work in layers of 2-4 inches. Compact each layer thoroughly before adding more material.

Finishing Up: Once the area is compacted, turn off the machine and clean it according to the manufacturer's guidelines to maintain its condition for future use.

By adhering to these steps, you can ensure effective operation of the compactor, resulting in a well-compacted surface. Furthermore, if you are transporting the tool to a job site, be mindful of the commercial driver's license requirements that may apply to your operation.

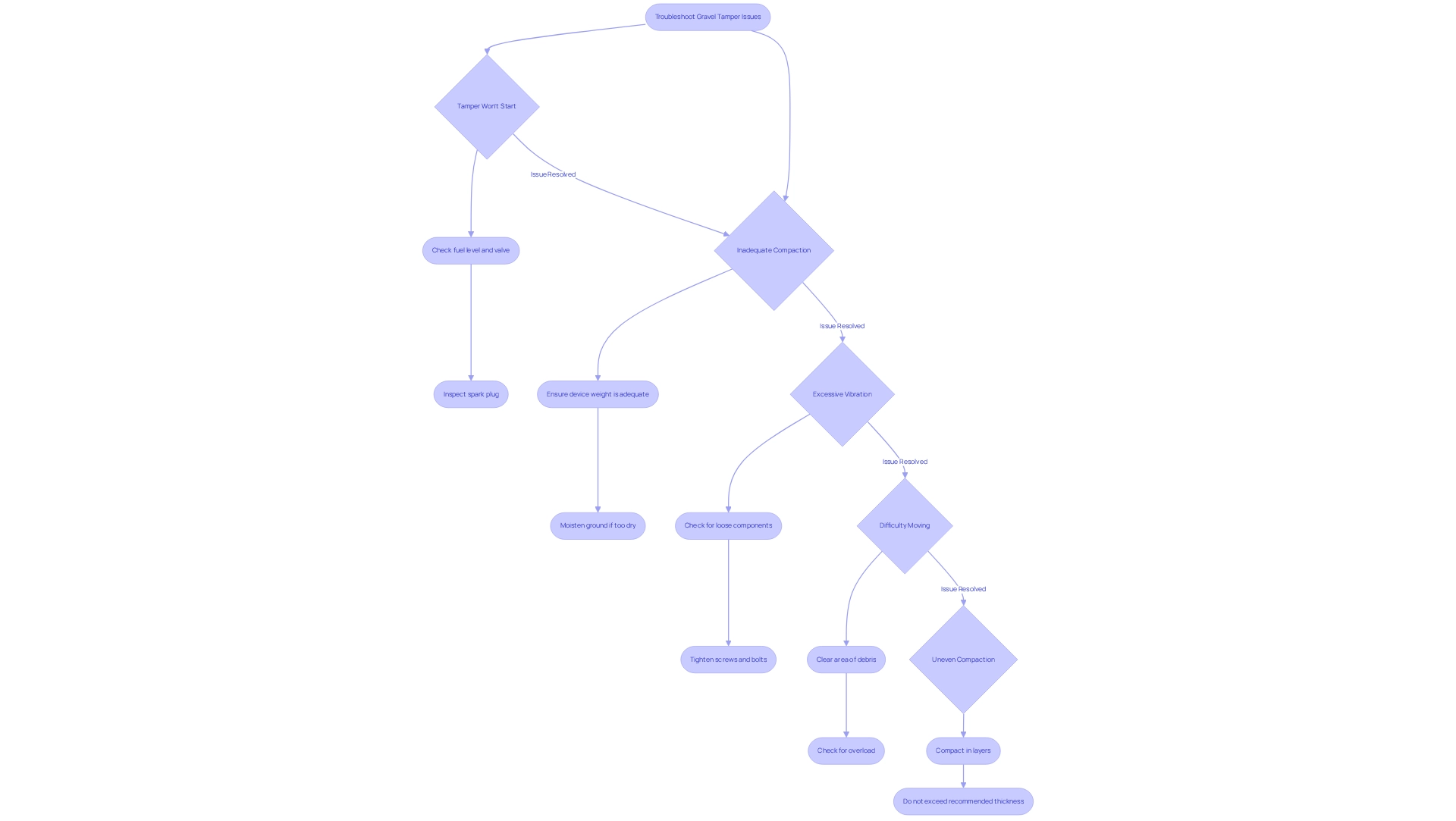

Troubleshoot Common Issues with Gravel Tamper Rentals

If you encounter issues while using a gravel tamper, consider the following troubleshooting tips to enhance your experience:

- Tamper Won't Start: First, check the fuel level and ensure the fuel valve is open. Inspect the spark plug for any damage or wear, and replace it if necessary. This simple step can save you time and frustration.

- Inadequate Compaction: Next, ensure that the device is heavy enough for the substance being compressed. If the ground is too dry, lightly moisten it to improve compaction effectiveness. Proper moisture levels can significantly enhance the results.

- Excessive Vibration: If the machine vibrates excessively, check for loose components or damage to the base plate. Tightening any loose screws or bolts can help stabilize the tamper, leading to better performance.

- Difficulty Moving: If you find the compactor hard to maneuver, ensure that the area is clear of debris and that it is not overloaded with material. A clear workspace is essential for effective operation.

- Uneven Compaction: Lastly, if you notice uneven surfaces, it may be due to improper layering. Ensure you are compacting in layers and not exceeding the recommended thickness for optimal results.

By proactively addressing these common issues, you can ensure a smoother and more efficient gravel tamper rental experience. As emphasized by Phil Bahler, Partner in Bahler Brothers Construction, "Do your homework. Compaction is everything in this business." Proper compaction is crucial for ensuring that construction projects are built on a solid foundation, underscoring the importance of maintaining your equipment. Furthermore, as demonstrated in the practices of Bahler Brothers, using the right equipment, such as Weber compactors, can significantly enhance the effectiveness of your compaction efforts.

Conclusion

Gravel tampers are essential tools in the construction and landscaping industries, providing the necessary compaction and leveling of loose materials. Their effectiveness hinges on key features such as weight, plate design, vibration mechanisms, and ergonomic handles. By understanding these characteristics, users can select the right tool for their specific projects, ensuring optimal performance and results.

When considering a gravel tamper rental, it is crucial to evaluate factors such as project size, material type, maneuverability, and rental duration. Careful consideration of these elements enables users to make informed decisions that enhance efficiency and effectiveness in their compaction tasks.

Successful operation with gravel tampers requires a systematic approach, encompassing preparation, equipment checks, safety protocols, and proper layering techniques. Additionally, troubleshooting common issues is vital, as it maintains equipment functionality and ensures a smooth working experience. The importance of proper compaction cannot be overstated; utilizing the right tools and techniques is essential for achieving a solid foundation in any project.

In conclusion, mastering the use of gravel tampers significantly enhances the quality of construction and landscaping projects, underscoring the importance of meticulous preparation and equipment management. As urbanization continues to rise, the demand for proficient tamping solutions will only increase. It is imperative for professionals and DIY enthusiasts alike to remain informed and skilled in utilizing these indispensable tools.

Frequently Asked Questions

What are gravel compactors used for?

Gravel compactors, also known as compressing devices, are essential for compressing and leveling loose materials like gravel, soil, and sand.

How do weight and size affect the performance of gravel compactors?

The weight and size of gravel compactors directly impact their compaction power and suitability for different tasks. Heavier tools generate greater force, making them ideal for larger areas, while lighter options are better for smaller, detailed work.

What is the significance of the plate design in gravel compactors?

The design of the base plate is crucial for compaction efficiency. A wider plate can cover more ground, while a smaller plate is better for tight spaces, allowing for precise compaction in confined areas.

How does the vibration mechanism enhance the performance of gravel compactors?

Many compactors feature a vibration mechanism that improves compaction efficiency by enabling deeper penetration into the material, resulting in a more solid and stable surface.

Why is handle design important in gravel compactors?

Ergonomically designed handles are vital for user comfort and control, especially during extended use. A well-designed handle reduces fatigue and enhances maneuverability, which is essential for maintaining productivity on the job site.

What should I consider when selecting a gravel tamper for my project?

Familiarizing yourself with the key features of gravel compactors, such as weight, plate design, vibration mechanism, and handle design, will help you choose the appropriate tool for your specific needs.

What trends are influencing the demand for gravel compactors?

Ongoing infrastructure development and urbanization are driving demand for advanced tamping technology, making it important to stay informed about the latest innovations in this field.