Overview

Horizontal boring rental is vital for efficient construction projects, enabling trenchless installation of underground utilities. This method significantly minimizes surface disruption and enhances project timelines, making it an indispensable choice for modern urban development. As the demand for this approach grows, the directional drilling market is projected to reach an impressive $24.41 billion by 2032, underscoring the increasing reliance on this technology.

Key equipment for horizontal boring includes:

- Advanced drilling rigs

- Specialized tooling

- Support systems designed for optimal performance

Preparation steps are critical; ensuring that all equipment is in peak condition not only boosts reliability but also streamlines operations. Common troubleshooting strategies are essential for maintaining efficiency on site, ensuring that any potential issues are swiftly addressed to keep projects on track.

With urban development on the rise, the advantages of horizontal boring cannot be overstated. This method not only preserves surface integrity but also accelerates project timelines, providing a competitive edge in the industry. By focusing on quality and reliability, construction teams can confidently choose horizontal boring as their go-to solution.

In conclusion, the growing trend towards trenchless technology highlights the need for reliable equipment rental services. Engaging with professional rental providers ensures access to top-tier equipment and expertise, paving the way for successful construction projects. Take action now to explore the benefits of horizontal boring rental and elevate your project outcomes.

Key Highlights:

- Horizontal drilling is a trenchless technique used for installing underground utilities with minimal surface disruption.

- Key applications include utility installation, environmental projects, and construction enhancements.

- The global directional drilling market is projected to reach $24.41 billion by 2032, indicating growing demand for efficient installation methods.

- Essential equipment for horizontal boring includes a horizontal boring machine, drill bits, locating equipment, and support equipment.

- Preparation steps for a successful project include site assessment, securing permits, team coordination, gear checks, and establishing safety protocols.

- The horizontal boring process involves setting up equipment, monitoring progress, tracking location, managing spoil removal, and completing the bore.

- Common issues during horizontal boring include equipment malfunction, bore misalignment, soil complications, and spoil blockage, each requiring specific troubleshooting strategies.

- Regular maintenance and documentation are crucial for preventing issues and ensuring the longevity of equipment.

Introduction

Horizontal boring has emerged as a transformative technique in the construction industry, providing a trenchless solution for the installation of vital underground utilities while significantly reducing surface disruption. This article explores the diverse applications and advantages of horizontal boring, demonstrating how it can enhance project efficiency and lower costs, especially in urban environments. As the demand for this innovative method increases, so too do the challenges linked to its execution. What are the essential steps and best practices to ensure a successful horizontal boring project?

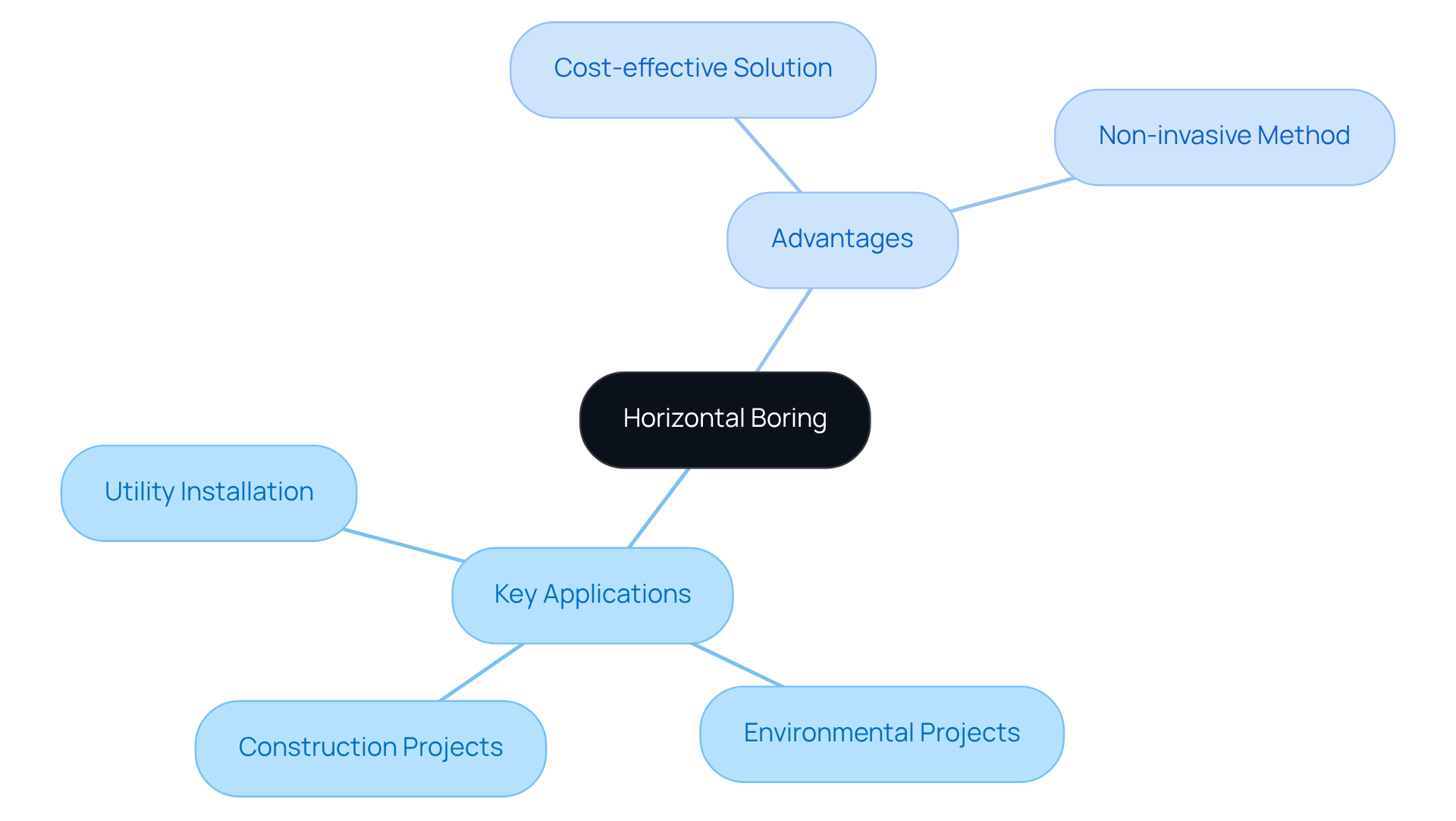

Understand Horizontal Boring and Its Applications

Horizontal drilling is a trenchless technique that facilitates the installation of underground utilities, including water, gas, and telecommunications lines, while significantly reducing the need for extensive excavation. This method minimizes surface disruption, making it particularly advantageous in urban environments where space is at a premium. Key applications of horizontal boring include:

- Utility Installation: This method allows for the efficient laying of pipes and cables beneath roads and buildings, ensuring minimal disruption to surface activities.

- Environmental Projects: Horizontal drilling is instrumental in installing monitoring wells or remediation systems in ecologically sensitive areas, supporting environmental restoration initiatives.

- Construction Projects: It aids in the installation of drainage systems or foundation supports, enhancing the overall efficiency of construction operations.

The advantages of lateral drilling extend beyond mere convenience. It provides a cost-effective solution for utility installation, particularly in densely populated areas where traditional excavation methods would be impractical, thanks to horizontal boring rental options. As urban development continues to rise, the demand for non-invasive, efficient utility installation techniques such as directional drilling is expected to grow. In fact, the global directional drilling market is projected to reach approximately $24.41 billion by 2032, reflecting a compound annual growth rate (CAGR) of 13.91% from 2024 to 2032.

Understanding these applications and advantages empowers you to make informed choices regarding the use of lateral drilling in your projects, ensuring optimal results throughout the rental process.

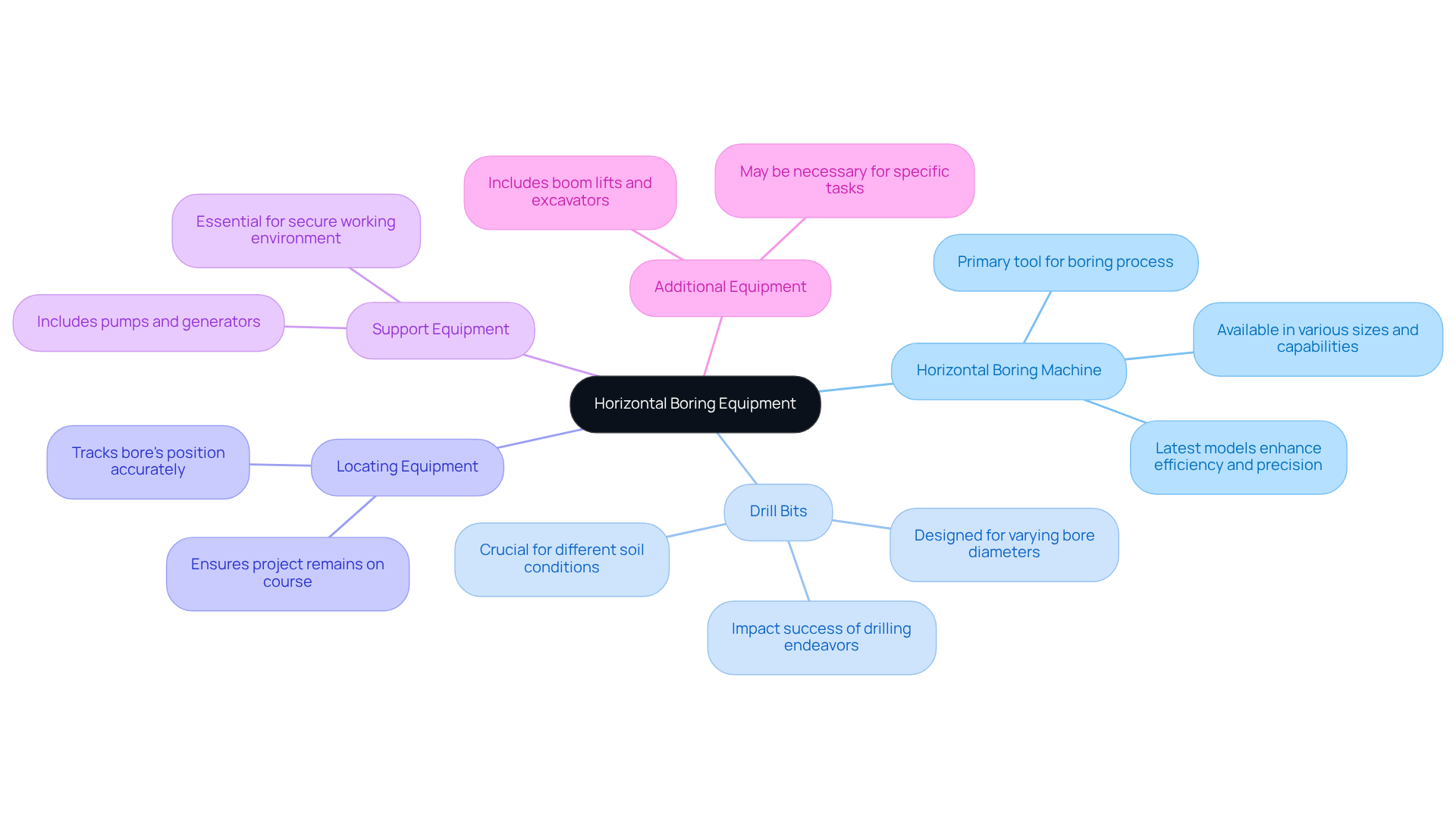

Identify Required Horizontal Boring Equipment

To efficiently execute a horizontal drilling task, determining the appropriate tools tailored to your specific requirements is paramount. The key components are as follows:

- Horizontal Boring Machine: This is the primary tool for the boring process, available in various sizes and capabilities to meet different project needs. The latest models come equipped with advanced features that enhance efficiency and precision.

- Drill Bits: Selecting the right drill bits is crucial, as various types are designed for differing soil conditions and bore diameters. Using the correct bit can significantly impact the success of your endeavor.

- Locating Equipment: Accurate tracking of the bore's position is vital for ensuring the project remains on course. Locating equipment aids in maintaining precision during the drilling process.

- Support Equipment: This category includes pumps, generators, and safety gear, all essential for facilitating the drilling operation while ensuring a secure working environment.

- Additional Equipment: Consider other machinery, such as boom lifts and excavators, which may be necessary for your undertaking.

For optimal results, consult with your tool rental provider, such as EZ Tool Rental, to explore the best options for horizontal boring rental based on your task requirements and to ensure you have all the essential instruments for a successful lateral drilling operation. Moreover, average rental expenses for flat drilling machinery in Texas typically range from $1,500 to $3,000 daily, depending on the equipment category and scope of work.

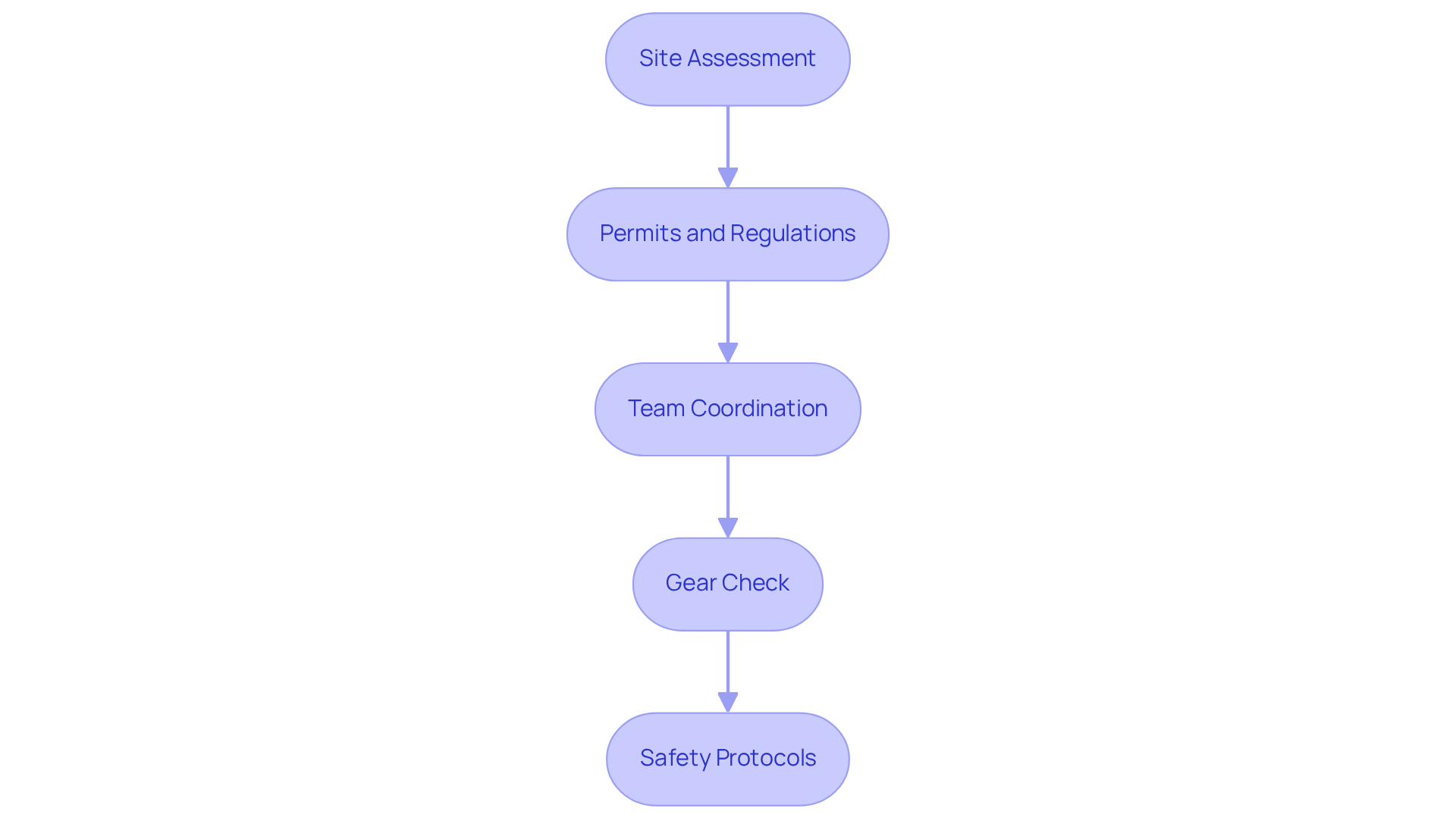

Prepare for Your Horizontal Boring Project

To ensure a successful horizontal boring project, it is crucial to adhere to the following preparation steps:

-

Site Assessment: Conduct a thorough evaluation of the site to identify potential obstacles, including existing utilities and geological challenges. This evaluation is vital, as it informs the feasibility of the drilling operation and helps reduce risks associated with unexpected underground conditions.

-

Permits and Regulations: Confirm that all required permits are secured and that your undertaking adheres to local regulations governing underground work. In Texas, this may involve submitting applications and construction plans to local authorities, as well as understanding specific requirements for horizontal boring operations.

-

Team Coordination: Gather your work team early and clearly outline roles and responsibilities. Effective communication among team members is essential to ensure that everyone is aligned and aware of their tasks throughout the project.

-

Gear Check: Before starting work, examine all rented tools for functionality and safety. Verify that each item is in optimal working condition to prevent delays and ensure a smooth operation. EZ Equipment Rental provides expert assistance and a broad selection of affordable tools suitable for horizontal boring rental projects, ensuring you have the right instruments for the task. Furthermore, consult user manuals for detailed guidance on utilizing tools to maximize efficiency.

-

Safety Protocols: Establish comprehensive safety measures and ensure that all team members are trained in equipment use and emergency procedures. This proactive approach not only enhances safety on-site but also fosters a culture of responsibility among the crew.

By following these steps, you will establish a solid base for your lateral drilling project, reducing possible problems and improving overall efficiency.

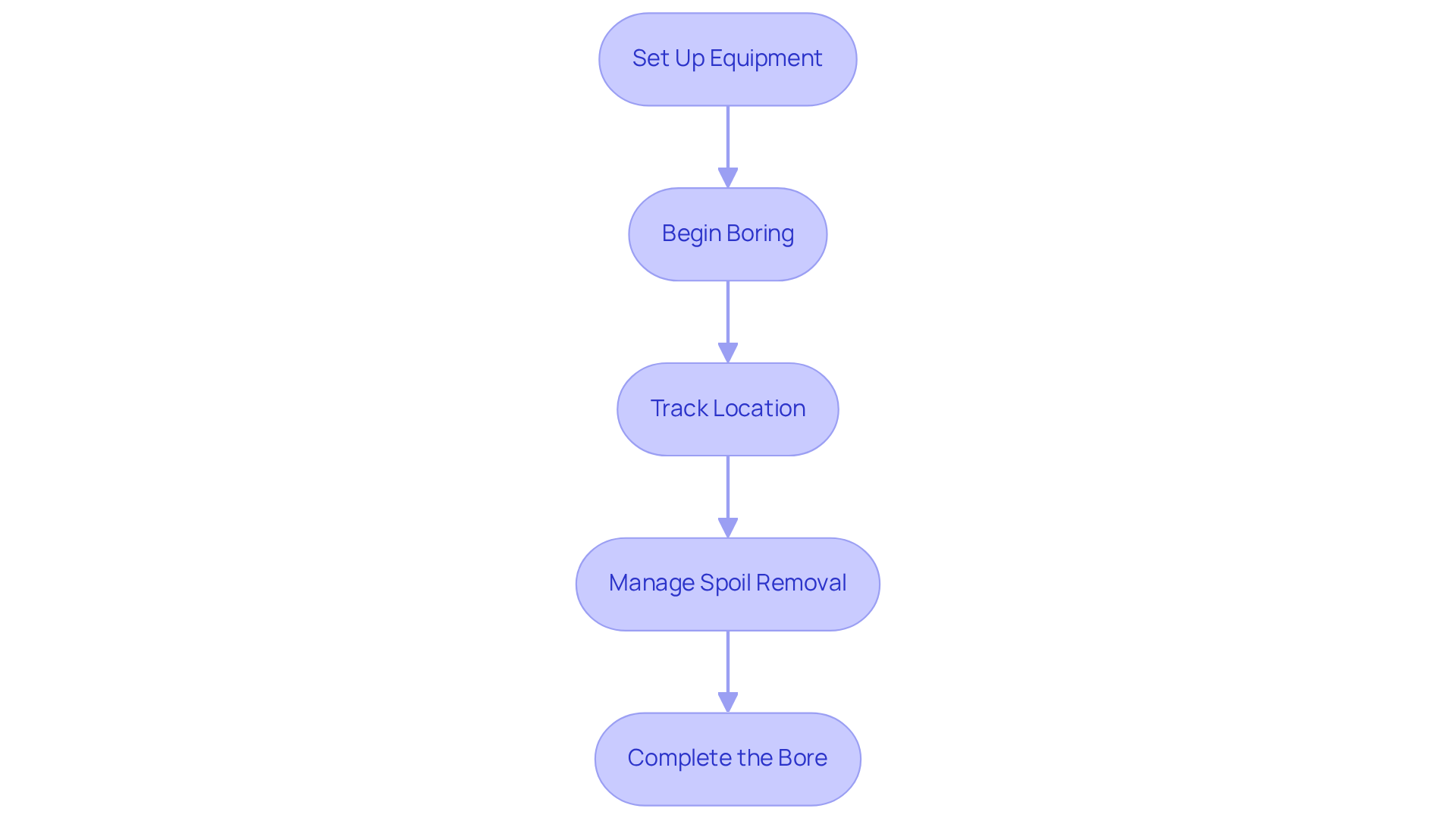

Execute the Horizontal Boring Process

To execute the horizontal boring process effectively, follow these essential steps:

- Set Up Equipment: Position the horizontal boring rental machine at the designated entry point, ensuring it is securely anchored to prevent movement during operation.

- Begin Boring: Start the machine and closely monitor the progress. Modify the speed and pressure as needed, especially in reaction to changing soil conditions. High clay content can pose difficulties that necessitate specialized tools. The typical installation expense for HDD endeavors varies from $5 to $7 per inch diameter per linear foot, making effective resource management crucial.

- Track Location: Utilize locating equipment to ensure the bore remains on the correct path and at the desired depth. Accurate tracking is crucial, with wire-line systems offering higher precision for navigation.

- Manage Spoil Removal: Regularly remove spoil material to maintain operational efficiency and prevent blockages, which can significantly hinder progress.

- Complete the Bore: Once the desired length is achieved, carefully retract the drill bit and prepare for the installation of utilities, ensuring that all safety protocols are followed.

Executing these steps will promote a seamless and effective horizontal boring rental operation, which will reduce risks and improve overall task efficiency. As Mary Johnson, a marketing coordinator in the industry, emphasizes, "Understanding ground conditions is critical for the success of HDD projects," highlighting the need for adaptability throughout the process. Furthermore, referencing case studies, such as the sewer siphon installation under State Route 60, can provide practical insights into the challenges and solutions encountered during HDD operations.

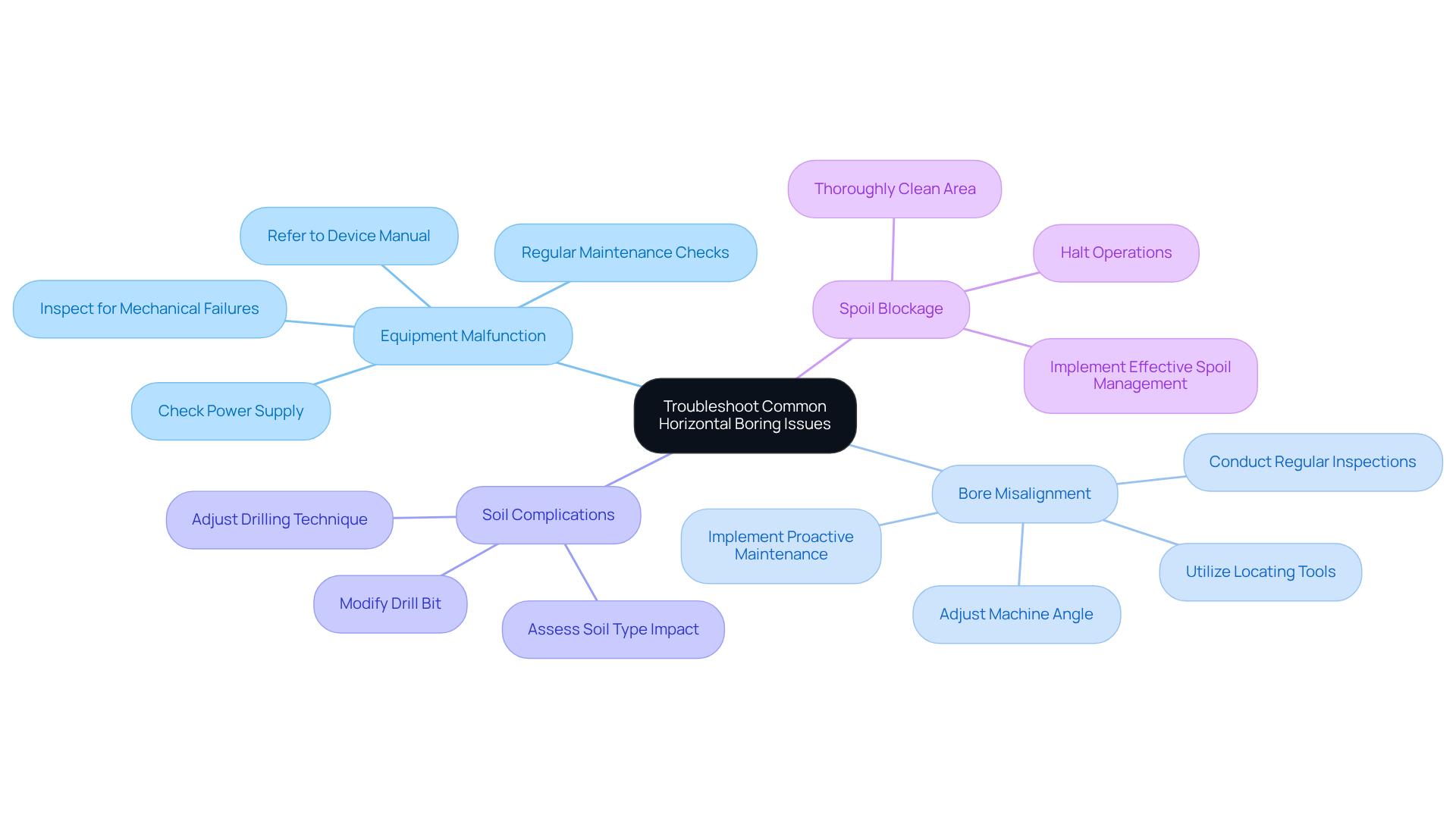

Troubleshoot Common Horizontal Boring Issues

During the horizontal boring rental process, several common issues may arise, each necessitating specific troubleshooting strategies.

-

Equipment Malfunction: When the boring machine ceases operation, it is critical to first check for power supply issues or mechanical failures. Referring to the device manual can provide essential troubleshooting steps to accurately identify and resolve the issue. Notably, data shows that 83.8 percent of all reported failures occurred when rigs were not operational, underscoring the necessity of regular maintenance checks.

-

Bore Misalignment: Misalignment can result in significant operational inefficiencies. If the bore deviates from its intended path, it is imperative to adjust the machine's angle and utilize locating tools for precise realignment. Regular inspections can help detect early signs of misalignment, thus preventing costly repairs and ensuring smooth operation. As highlighted in various case studies, proactive maintenance, including line machining, can greatly reduce downtime and enhance equipment reliability.

-

Soil Complications: Unexpected soil conditions, such as encountering rock or excessive moisture, can complicate the drilling process. In these scenarios, consider modifying the drill bit or adjusting the drilling technique to accommodate the new conditions. Data indicates that soil type significantly influences bore performance, making adaptability essential.

-

Spoil Blockage: Blockages caused by spoil material can impede progress. In such cases, it is crucial to halt operations and thoroughly clean the area before resuming drilling. Effective spoil management is vital for maintaining operational flow and preventing downtime.

By proactively addressing these challenges and incorporating routine inspections and preventive maintenance, such as horizontal boring rental, you can maintain control over your project and ensure successful outcomes. Expert insights emphasize that regular documentation of maintenance schedules is key to preventing issues and enhancing machinery longevity.

Conclusion

Mastering horizontal boring rental for construction projects is essential for achieving efficiency and minimizing disruption. This trenchless technique not only facilitates the installation of utilities but also supports various environmental and construction initiatives. By understanding the applications and advantages of horizontal boring, project managers can make informed decisions that enhance the overall effectiveness of their operations.

The article delves into crucial aspects such as:

- Identifying the necessary equipment

- Preparing for projects

- Executing the boring process

- Troubleshooting common issues

It emphasizes the importance of proper site assessment, securing permits, coordinating with the team, and adhering to safety protocols. Furthermore, it highlights the significance of effective resource management and adaptability to overcome challenges that may arise during the drilling process.

In conclusion, embracing horizontal boring as a rental service can lead to significant cost savings and operational efficiency. As urban development continues to evolve, the demand for innovative, non-invasive utility installation methods will only grow. By implementing best practices and maintaining equipment diligently, construction professionals can ensure successful outcomes in their projects, paving the way for a more sustainable and efficient future in the industry.

Frequently Asked Questions

What is horizontal boring and its main applications?

Horizontal boring is a trenchless technique used for the installation of underground utilities, such as water, gas, and telecommunications lines, with minimal surface disruption. Key applications include utility installation, environmental projects, and construction projects.

How does horizontal boring benefit urban environments?

It minimizes surface disruption, making it particularly advantageous in urban areas where space is limited, allowing for efficient installation of utilities without extensive excavation.

What are the advantages of using horizontal boring?

Horizontal boring provides a cost-effective solution for utility installation, especially in densely populated areas, and is expected to see increased demand as urban development rises.

What is the projected growth of the directional drilling market?

The global directional drilling market is projected to reach approximately $24.41 billion by 2032, with a compound annual growth rate (CAGR) of 13.91% from 2024 to 2032.

What equipment is required for horizontal boring?

Key equipment includes a horizontal boring machine, drill bits suitable for various soil conditions, locating equipment for tracking the bore's position, support equipment (such as pumps and generators), and additional machinery like boom lifts and excavators.

How can I choose the right tools for my horizontal boring project?

It is important to determine the specific requirements of your project and consult with a tool rental provider, such as EZ Tool Rental, to explore the best options for horizontal boring rental.

What are the average rental costs for horizontal boring equipment in Texas?

Average rental expenses for flat drilling machinery in Texas typically range from $1,500 to $3,000 daily, depending on the equipment category and scope of work.