Introduction

In the ever-evolving landscape of construction and maintenance, jib boom lifts have emerged as indispensable tools, bridging the gap between safety and efficiency. With their unique design that allows for enhanced reach and maneuverability, these aerial work platforms are tailored to tackle the challenges of accessing difficult-to-reach areas. As industries increasingly prioritize safety and productivity, understanding the features, applications, and maintenance needs of jib boom lifts becomes crucial.

From their pivotal role in construction projects to their importance in telecommunications and maintenance tasks, jib boom lifts are redefining how professionals approach elevated work. This article delves into the functionality, applications, and safety considerations surrounding jib boom lifts, providing insights that can help industry stakeholders optimize their operations and reduce risks on job sites.

Defining the Jib Boom Lift: Function and Features

A jib boom lift is an essential aerial work platform, characterized by its unique design featuring a horizontal arm, or jib, extending from a sturdy vertical mast. This innovative design significantly enhances the ability of operators to access elevated work areas that may present challenges with traditional equipment. Equipped with a secure platform at the end of the jib, workers can safely perform essential tasks such as maintenance, installation, or construction activities at various heights and angles.

The main purpose of jib boom lifts centers on offering exceptional reach and maneuverability, which is essential for productivity on construction sites.

Recent developments in jib crane technology have resulted in improved operational features, such as:

- Adjustable arms that enable accurate positioning

- Rotating platforms for greater versatility

- A broad array of lifting capacities designed to accommodate various project needs

According to the IMARC Group, vehicle-mounted lifts hold the largest market share among product types, primarily due to their exceptional mobility and operational efficiency. Statistics suggest that the utilization of jib boom lifts in the construction industry is projected to increase notably, corresponding with a compound annual growth rate of 5.7% until 2024.

Practical uses of jib boom lifts can be seen in numerous construction projects, where they excel in providing access to hard-to-reach locations. Their ability to adapt to different operational needs makes them a preferred choice in the industry. Furthermore, insights from Table 79: Linamar Corporation Financial Performance could offer additional context regarding the market dynamics surrounding jib cranes.

As construction managers persist in searching for solutions that enhance safety and productivity, understanding the functionality and key characteristics of the jib boom lift becomes crucial for optimizing project results. Additionally, while the Autonomous Mining Equipment Global Market Report 2024 concentrates on autonomous technologies, it mirrors wider market trends that could affect the adoption of jib cranes in different sectors.

Applications of Jib Boom Lifts in Various Industries

Jib boom lift hoists are pivotal in various sectors, particularly in construction, maintenance, and telecommunications. In the construction sector, the jib boom lift and other apparatuses excel in tasks such as:

- Roofing installations

- Exterior work on tall structures

- Performing inspections at significant heights

Their unique capability to extend and navigate around obstacles makes them essential for precision-driven tasks where safety is paramount.

In maintenance tasks, technicians depend on the jib boom lift to reach high locations for repairs or installations, including:

- Lighting fixtures

- HVAC systems

The telecommunications sector also heavily utilizes jib boom lifts for the installation and upkeep of communication towers, where reaching elevated locations is critical. In 2024, industry statistics suggest that jib cranes are anticipated to experience a 15% rise in usage within the construction sector, highlighting their increasing significance.

For example, a recent case study showcased the effective use of jib cranes by Galmon (S) Pte Ltd in a significant telecommunications project, greatly enhancing efficiency and security during tower installations. According to industry experts, strike the perfect balance in your warehouse operations with strategies that prioritize both efficiency and security. Keep your team well-trained and use the right equipment.

This guidance showcases the increasing focus on security and efficiency in 2024, with the jib boom lift being a favored option for experts assigned to tasks at elevation. Their versatility and effectiveness ensure the jib boom lift remains a fundamental tool for overcoming the challenges of elevated work.

Safety Considerations When Using Jib Boom Lifts

Safety is paramount when operating jib boom lifts, and comprehensive training is essential for operators to fully understand the capabilities and limitations of the jib boom lift. Current regulations emphasize that employers must ensure crane operators are qualified, as outlined in 1926.1427. This underscores the necessity of robust training programs designed to equip operators with the knowledge needed to navigate potential hazards effectively.

A thorough pre-operation inspection checklist should be utilized to detect any mechanical issues that could jeopardize security during use. Furthermore, operators must assess the work area for hazards, such as overhead power lines and unstable ground conditions, to mitigate risks. Additionally, using wheel chocks on sloped surfaces when safe is crucial to prevent unintended movement of the equipment.

Personal protective equipment (PPE)—including hard hats, harnesses, and protective footwear—must be worn at all times to safeguard against injuries. Insights from recent discussions emphasize that proper training is crucial to prevent accidents involving jib boom lifts, highlighting the necessity for ongoing education and compliance with protocols. Following manufacturer guidelines and local regulations not only improves protection but also significantly decreases the risk of accidents.

As Michael McCann, Ph.D., CIH, from the CPWR – Center for Construction Research and Training points out, ongoing research into the safe operation of aerial devices is crucial to improving these practices. By promoting a culture of security, as highlighted at the National Highways 'Driving Change' conference, and ensuring that operators are well-trained, the construction sector can effectively reduce the risks connected with the use of jib boom lifts.

Maintenance and Care for Jib Boom Lifts

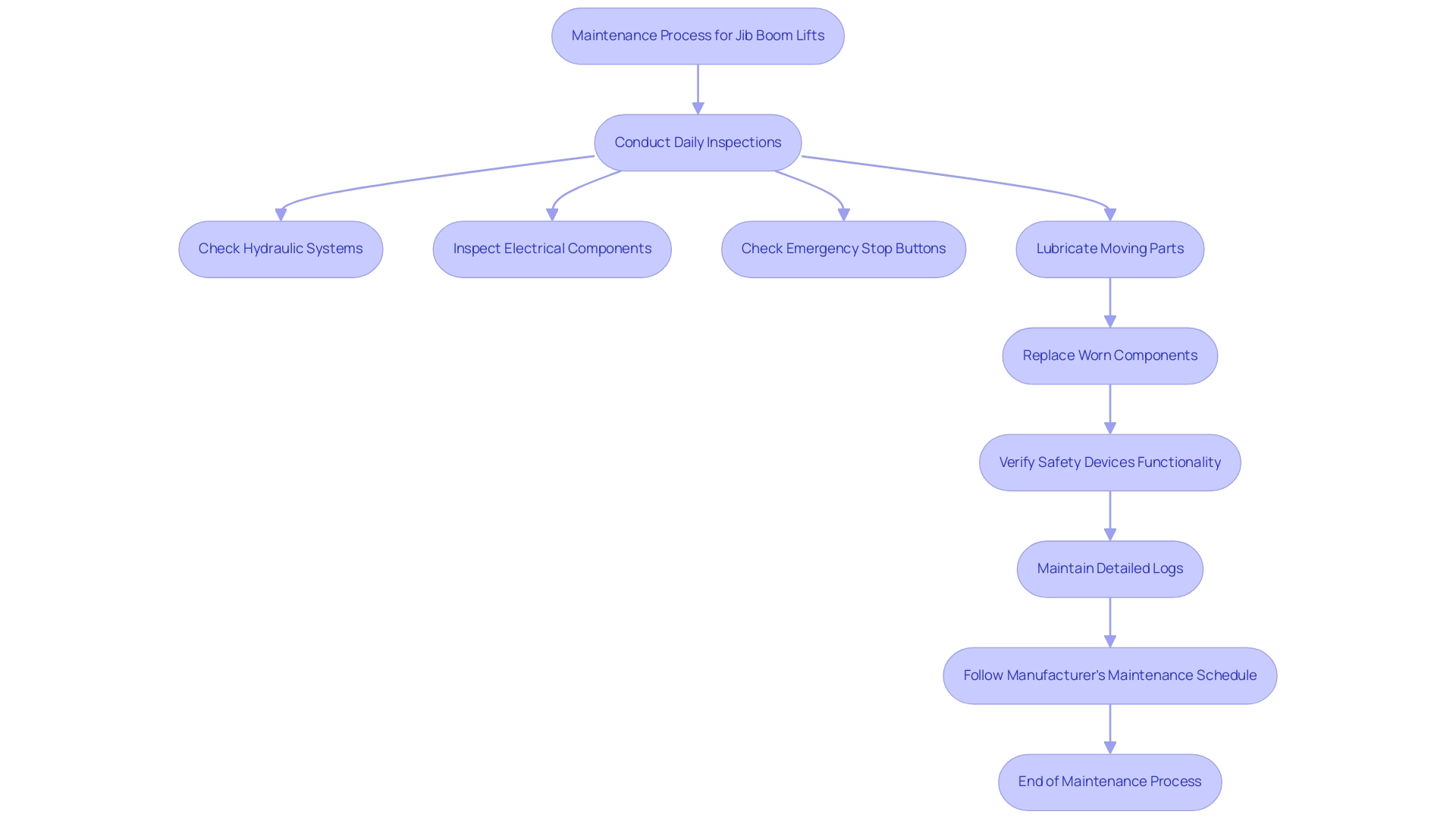

Regular upkeep of jib boom lifts is essential for ensuring security and operational efficiency on construction sites. Operators should conduct daily inspections prior to use, meticulously checking for any signs of wear or damage in crucial components. Key areas to emphasize encompass:

- Hydraulic systems

- Electrical components

- Essential features such as emergency stop buttons

According to industry experts, routine inspections can prevent up to 75% of mechanical failures. Maintenance tasks often involve:

- Lubricating moving parts

- Replacing worn components

- Verifying that safety devices are functioning properly

A comprehensive daily maintenance checklist for a jib boom lift should include these inspections, as well as a review of the equipment’s overall condition.

Following the manufacturer's maintenance schedule and maintaining detailed logs of inspections and repairs can significantly mitigate the risk of unexpected breakdowns, ultimately prolonging the equipment's lifespan. Furthermore, case studies indicate that companies implementing strict maintenance practices not only reduce downtime but also enhance productivity, making it a worthwhile investment for construction managers. For instance, the case study titled 'Cost Considerations: Boom Lifts vs. Traditional Methods' emphasizes that although the initial expense of aerial platforms may be greater, they considerably decrease workplace accident hazards and enhance productivity.

This long-term value underscores the importance of regular maintenance. Furthermore, with the rental segment dominating the market by end use, ensuring that jib boom lifts are well-maintained is essential for maximizing their operational efficiency and safety on construction sites. On a regional level, the market has been categorized into:

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

Where North America currently leads the global market, further highlighting the importance of sustaining these advantages in a competitive environment.

Comparing Jib Boom Lifts to Other Aerial Work Platforms

Jib boom lifts, along with scissor platforms and telescopic machinery, represent different types of aerial work platforms, each designed for specific operational requirements. Jib boom lifts excel in maneuvering around barriers and reaching confined areas, making them especially advantageous for construction and maintenance activities that require a high level of accuracy. Their flexibility allows operators to maneuver effectively in complex environments, enhancing overall job site efficiency.

For example, studies have demonstrated that jib cranes can enhance operational efficiency by as much as 20% in comparison to telescopic cranes because of their superior maneuverability in tight areas. In contrast, scissor platforms primarily offer vertical elevation but are limited in lateral reach, which can be a drawback in situations where space is constrained. While telescopic boom platforms are designed to achieve impressive heights, they often lack the agility required for confined areas, potentially impacting productivity.

As highlighted in a recent case study on autonomous mining equipment, the effectiveness of equipment selection can significantly influence operational success, paralleling the importance of choosing the right lift type for specific tasks. Moreover, addressing workplace negativity through effective equipment use, as emphasized in the quote, 'Address workplace negativity effectively with open dialogue, positive reinforcement, and support,' is crucial for fostering a productive environment on job sites. By understanding these critical differences, construction project managers can make informed decisions about equipment selection, ultimately improving safety protocols and operational efficiency on site.

Conclusion

Jib boom lifts play a crucial role in enhancing safety and productivity across various industries, particularly in construction, maintenance, and telecommunications. Their unique design and advanced features enable operators to access hard-to-reach areas with precision and ease, making them indispensable tools for modern work environments. As the demand for these lifts continues to rise, understanding their functionality, applications, and maintenance needs becomes essential for industry professionals looking to optimize their operations.

Safety considerations are paramount when operating jib boom lifts. Comprehensive training and adherence to safety protocols not only protect operators but also contribute to a culture of safety that minimizes risks on job sites. Regular maintenance is equally important, ensuring that equipment remains in optimal condition and reducing the likelihood of mechanical failures. By prioritizing both safety and maintenance, organizations can enhance overall operational efficiency.

In summary, the effectiveness of jib boom lifts in navigating complex work environments underscores their value in today's construction landscape. By making informed choices regarding equipment selection and emphasizing ongoing training and maintenance, industry stakeholders can significantly improve safety outcomes and productivity. Embracing these practices will ultimately lead to a more efficient and secure work environment, empowering professionals to tackle the challenges of elevated work with confidence.

Frequently Asked Questions

What is a jib boom lift?

A jib boom lift is an aerial work platform featuring a horizontal arm, or jib, that extends from a vertical mast, allowing operators to access elevated work areas that may be difficult to reach with traditional equipment.

What are the main purposes of jib boom lifts?

The main purposes of jib boom lifts are to provide exceptional reach and maneuverability, which enhances productivity on construction sites by allowing workers to safely perform tasks at various heights and angles.

What recent developments have been made in jib crane technology?

Recent developments in jib crane technology include adjustable arms for accurate positioning, rotating platforms for greater versatility, and a range of lifting capacities to accommodate different project needs.

What is the market trend for jib boom lifts in the construction industry?

The utilization of jib boom lifts in the construction industry is projected to increase significantly, with a compound annual growth rate of 5.7% expected until 2024.

In what sectors are jib boom lifts commonly used?

Jib boom lifts are commonly used in construction, maintenance, and telecommunications sectors.

What specific tasks do jib boom lifts excel in within the construction sector?

In the construction sector, jib boom lifts excel in tasks such as roofing installations, exterior work on tall structures, and performing inspections at significant heights.

How are jib boom lifts used in maintenance tasks?

Technicians use jib boom lifts to reach high locations for repairs or installations, such as lighting fixtures and HVAC systems.

Why are jib boom lifts important in the telecommunications sector?

Jib boom lifts are crucial in the telecommunications sector for the installation and maintenance of communication towers, where accessing elevated locations is essential.

What is the anticipated increase in the usage of jib cranes within the construction sector by 2024?

Jib cranes are anticipated to experience a 15% rise in usage within the construction sector by 2024.

What case study highlights the effectiveness of jib cranes in telecommunications projects?

A case study on Galmon (S) Pte Ltd showcased the effective use of jib cranes in a significant telecommunications project, enhancing efficiency and security during tower installations.