Introduction

In the fast-evolving landscape of material handling, pallet stackers have emerged as indispensable tools for businesses aiming to enhance efficiency and safety in their operations. These machines, designed to lift and stack pallets with precision, play a critical role in warehouses, distribution centers, and manufacturing facilities.

As organizations grapple with the challenges of managing heavy loads and optimizing space, understanding the functionality and benefits of pallet stackers becomes essential.

With options ranging from manual to electric variants, businesses can tailor their equipment choices to meet specific operational demands. Moreover, the rising trend of renting pallet stackers offers a flexible, cost-effective solution for companies navigating fluctuating workloads.

This article delves into the key aspects of pallet stackers, from selecting the right model to maintaining safety standards, providing insights that empower businesses to streamline their material handling processes and improve overall productivity.

Understanding Pallet Stackers: Definition and Functionality

Pallet movers constitute an essential type of material transport apparatus, specifically designed to elevate and arrange platforms with efficiency and accuracy. These machines are indispensable in environments such as warehouses, distribution centers, and manufacturing facilities, where they streamline the handling of heavy loads. Offered in both manual and electric versions, material handlers are created to improve operational efficiency by enabling vertical stacking of loads, thereby maximizing available space.

Equipped with hydraulic systems or electric motors, these devices can raise loads to various heights, making them essential not just for inventory organization, but also for improving overall workflow and safety standards. According to industry specialists, the efficient utilization of load lifters can result in substantial productivity improvements, especially in high-intensity operations. With the worldwide market for forklift trucks anticipated to reach USD 129.4 billion by 2030, increasing at a compound annual growth rate of 7.45%, the need for sophisticated load lifters is expected to grow.

Recent innovations, including the introduction of the next generation of powered transport and lifting vehicles by Toyota Material Handling Europe, indicate a commitment to improving load management capabilities. Furthermore, Hyster-Yale's purchase of Maximal Forklift for $400 million in mid-2023 reflects shifting market dynamics and the increasing competitiveness in the material transport sector. Insights from significant import values of USD 214.1 million from China and USD 213.9 million from Malaysia emphasize the global demand for storage systems, further underscoring their importance in modern operations.

As companies strive to enhance their material handling processes, understanding the features and uses of pallet stacker rental equipment becomes vital for tackling operational challenges and ensuring safety in the workplace.

The Benefits of Renting Pallet Stackers for Your Business

Renting a pallet stacker rental provides substantial benefits for companies, particularly those dealing with fluctuating demands or limited budgets. One of the foremost benefits is cost-effectiveness; with the purchase of a new forklift often ranging from $20,000 to $100,000, renting mitigates the need for a hefty upfront investment. Additionally, NISHIO provides flexible pallet stacker rental terms, including options for short-term rentals and immediate delivery, which enhances adaptability for businesses.

Rental agreements typically encompass maintenance and servicing, alleviating the responsibility of equipment upkeep from the business. Furthermore, the flexibility of rental choices enables companies to select stackers tailored to specific project requirements, whether needed for short-term use during busy seasons or for particular project phases. For example, when selecting between a jack and a forklift, construction project managers must take into account their project requirements, budget, and jobsite conditions.

- Pallet trucks are ideal for moving loads in narrow spaces, while forklifts are suitable for hauling large items over long distances.

- This adaptability not only facilitates scalable operations but also enhances efficiency and productivity in material management tasks, ultimately supporting businesses in optimizing their resources through pallet stacker rental without the long-term commitment associated with ownership.

As NISHIO states, 'If you want to explore pallet stacker rental options or rent a Reach truck (even other equipment), please contact NISHIO,' emphasizing the availability of tailored rental solutions.

Choosing the Right Pallet Stacker for Your Needs

Selecting the appropriate pallet mover is essential for optimizing material handling efficiency and involves a thorough assessment of several key factors.

- Load capacity is a primary consideration; it defines the maximum weight the equipment can lift and transport, which is vital for maintaining safety and operational effectiveness.

- The average lift height differs by type of equipment, making it essential to choose a model that satisfies the specific height needs of your storage systems.

- Electric lifting devices are especially appropriate for indoor tasks, offering a quieter and more effective solution, while manual alternatives are frequently more adaptable for outdoor uses.

- Notably, Crown Equipment Corporation holds a significant market share of 7.67%, with other prominent suppliers including:

- Hyster-Yale at 5.67%

- Anhui-Heli at 3.91%

- Kalmar Cargotec at 3.7%, emphasizing the competitive landscape in the forklift market.

Additionally, understanding the frequency of use can guide the decision between renting and purchasing equipment; high-frequency operations may benefit from ownership, while sporadic needs might be best served through pallet stacker rental.

By evaluating these factors—load capacity, lift height, operational environment, and usage frequency—construction project managers can make informed choices that significantly enhance material handling processes.

As indicated in the latest market trends, the electric vehicle technology surge is driving expansion in the transport truck market, highlighting the significance of electric freight lifters in today’s changing operational environment. Additionally, the 'Specialized Warehousing And Storage Global Market Report 2025' offers insights into specialized warehousing solutions, demonstrating how the appropriate loading equipment can enhance operations across different sectors.

Maintaining Safety Standards While Using Pallet Stackers

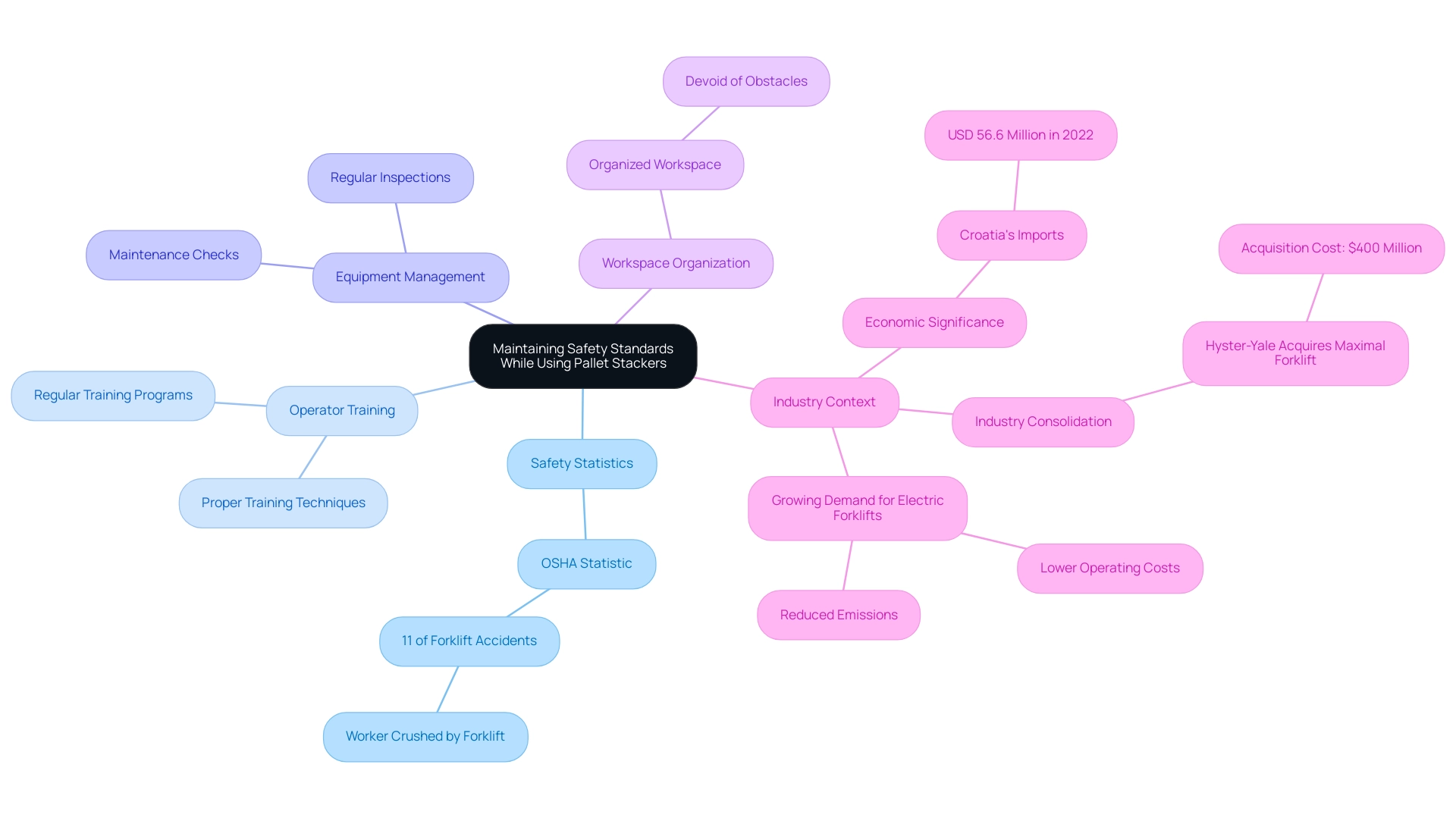

Ensuring strict safety standards during load handling operations is vital for minimizing workplace accidents and injuries. According to OSHA, approximately 11% of all forklift accidents involve a worker being crushed by a forklift, underscoring the necessity for proper operator training. This is particularly relevant in the context of Croatia's growing import market, which stood at USD 56.6 million in 2022, highlighting an economic environment where efficient and safe pallet stacker rental operations are essential.

Operators must be well-versed in equipment management, load handling, and maneuvering techniques. Regular inspections and maintenance checks can preemptively address potential issues, significantly reducing the risk of accidents. Moreover, maintaining an organized workspace devoid of obstacles is essential for safe operation.

Employers should cultivate an atmosphere where concerns regarding well-being can be openly discussed and supply personal protective equipment (PPE) to operators as needed. The recent purchase of Maximal Forklift by Hyster-Yale for $400 million demonstrates industry consolidation, which can influence standards and training practices across the sector. Furthermore, the growing use of electric forklifts, propelled by their reduced operating expenses and ecological advantages, corresponds with improved standards and signifies the increasing demand for such equipment.

By prioritizing safety training—supported by rigorous training programs and expert insights—businesses can cultivate a secure work environment that not only protects employees but also boosts productivity and overall well-being.

Conclusion

Pallet stackers are pivotal in modern material handling, offering businesses an efficient means to lift and stack pallets while optimizing space and enhancing safety. Understanding their functionality is essential for organizations aiming to navigate the complexities of heavy load management. With options ranging from manual to electric variants, businesses can choose equipment that aligns with their specific operational needs, ensuring both productivity and safety in fast-paced environments.

Renting pallet stackers presents a cost-effective solution, particularly for companies facing fluctuating demands. This flexibility allows businesses to adapt to their immediate requirements without the burden of substantial upfront costs associated with purchasing equipment. Furthermore, rental agreements often include maintenance, relieving organizations of ongoing upkeep responsibilities and enabling them to focus on core operations.

Selecting the appropriate pallet stacker demands careful consideration of factors such as load capacity, lift height, and operational environment. By conducting a thorough assessment, businesses can make informed decisions that enhance their material handling processes. Additionally, maintaining safety standards is critical; proper training and regular inspections can significantly mitigate the risk of accidents, fostering a safer workplace.

In conclusion, the strategic use of pallet stackers not only streamlines operations but also contributes to a culture of safety and efficiency. As businesses adapt to evolving market demands, prioritizing the right equipment and safety protocols will be essential in achieving sustained productivity and operational success. Investing in pallet stackers—whether through purchase or rental—can empower organizations to meet their material handling challenges head-on, ensuring they remain competitive in a fast-paced industry.

Frequently Asked Questions

What are pallet movers and their primary function?

Pallet movers are material transport apparatus designed to elevate and arrange platforms efficiently and accurately, primarily used in warehouses, distribution centers, and manufacturing facilities to handle heavy loads.

What types of pallet movers are available?

Pallet movers are available in both manual and electric versions, designed to improve operational efficiency by enabling vertical stacking of loads.

How do pallet movers contribute to operational efficiency?

They allow for vertical stacking of loads, maximizing available space, improving workflow, and enhancing safety standards in material handling operations.

What mechanisms do pallet movers use to lift loads?

Pallet movers are equipped with hydraulic systems or electric motors that enable them to raise loads to various heights.

What impact can efficient load lifters have on productivity?

The efficient utilization of load lifters can lead to substantial productivity improvements, particularly in high-intensity operations.

What is the projected market growth for forklift trucks?

The worldwide market for forklift trucks is anticipated to reach USD 129.4 billion by 2030, growing at a compound annual growth rate of 7.45%.

What recent innovations have occurred in the pallet mover industry?

Innovations include the introduction of the next generation of powered transport and lifting vehicles by Toyota Material Handling Europe, reflecting advancements in load management capabilities.

What significant market activity occurred in 2023 related to pallet movers?

Hyster-Yale's purchase of Maximal Forklift for $400 million in mid-2023 highlights shifting market dynamics and increased competitiveness in the material transport sector.

Why is understanding pallet stacker rental equipment important for companies?

Understanding the features and uses of pallet stacker rental equipment is vital for addressing operational challenges and ensuring safety in the workplace.