Overview

To achieve success in roller equipment rental, four key strategies must be prioritized:

- Understanding the various types of rollers and their specific applications

- Evaluating rental providers based on quality and reliability

- Implementing cost-effective strategies

- Comprehending rental terms and conditions

Selecting the appropriate roller type is crucial as it significantly enhances project efficiency. Furthermore, the condition of the equipment and the level of customer support provided by rental companies are essential factors in evaluating potential providers.

In addition, negotiating rental terms and planning strategically can lead to substantial cost reductions. It is vital to outline critical rental terms to ensure compliance and avoid potential financial pitfalls. By focusing on these strategies, rental businesses can position themselves for success and foster strong partnerships with their clients, ultimately leading to improved operational outcomes.

Engaging with reliable providers who prioritize quality and customer satisfaction not only enhances project efficiency but also builds long-term relationships. As you consider your options, remember that the right equipment and a trustworthy rental partner can make all the difference in your project's success.

Key Highlights:

- Cylindrical rollers are lightweight and ideal for small compaction tasks in asphalt and soil.

- Pneumatic rollers provide even pressure distribution and are effective in asphalt compaction, crucial for road development.

- Sheepsfoot rollers are designed for compacting cohesive soils like clay, essential for foundational work.

- Vibratory rollers enhance compaction efficiency for granular soils and asphalt, preventing structural issues.

- Tandem rollers are used for laying asphalt on roads and runways, ensuring a smooth finish.

- Key evaluation criteria for rental providers include equipment condition, customer reviews, service support, and clear lease terms.

- Maintaining equipment condition can lead to 43% higher utilisation rates, emphasising its importance.

- Understanding project needs can prevent over-renting and lead to significant savings.

- Negotiating rental terms and planning durations can reduce leasing costs by up to 20%.

- Dynamic pricing models can help secure lower rates during off-peak rental times.

- Critical rental terms include rental duration, liability and insurance, maintenance responsibilities, and cancellation policies.

Introduction

The construction industry thrives on efficiency and precision, making the choice of equipment rental critical to project success. Roller equipment, essential for tasks ranging from soil compaction to asphalt paving, offers a variety of options tailored to specific needs. However, navigating the complexities of roller equipment rental can pose challenges. How does one ensure they are selecting the right equipment, negotiating favorable terms, and comprehending the rental agreements? This article delves into four key strategies that can empower construction managers to maximize their roller equipment rental experience, driving both performance and cost-effectiveness.

Identify Types of Roller Equipment and Their Applications

Roller equipment rental plays a pivotal role in building and landscaping, with various types tailored for specific applications. The most prevalent types include:

-

Cylindrical Rollers: These lightweight, walk-behind rollers are ideal for smaller compaction tasks, particularly in asphalt and soil compaction. Their compact design allows for maneuverability in tight spaces, ensuring effective performance in landscaping and minor building jobs.

-

Pneumatic Rollers: Equipped with multiple rows of rubber tires, pneumatic rollers distribute pressure evenly across an 80% coverage area. They excel in asphalt compaction, delivering a smooth finish and proving especially efficient in road development and overlay tasks, where uniformity is crucial. Their adaptability to various surfaces enhances their versatility in building applications.

-

Sheepsfoot Rollers: Featuring protruding feet, sheepsfoot rollers are specifically designed for compacting cohesive soils, such as clay. Experts highlight their effectiveness in densifying silty clay and wet clay, making them indispensable for foundational work. They are particularly advantageous in road construction and landfill operations, where deep penetration and consolidation are necessary.

-

Vibratory Rollers: By utilizing vibration to boost compaction efficiency, vibratory rollers are well-suited for granular soils and asphalt. Their vibrating mechanism achieves high compaction levels, preventing structural issues caused by voids. This type of roller is frequently employed in extensive projects, ensuring optimal performance and durability.

-

Tandem Rollers: Featuring two smooth drums, tandem rollers are commonly used for laying asphalt on roads and airport runways, guaranteeing a smooth finish. Their design facilitates efficient paving and compaction, making them a favored choice across various building applications.

Understanding the unique features and applications of these roller types empowers managers to select the most appropriate roller equipment rental, thereby enhancing performance and cost-efficiency in their construction projects.

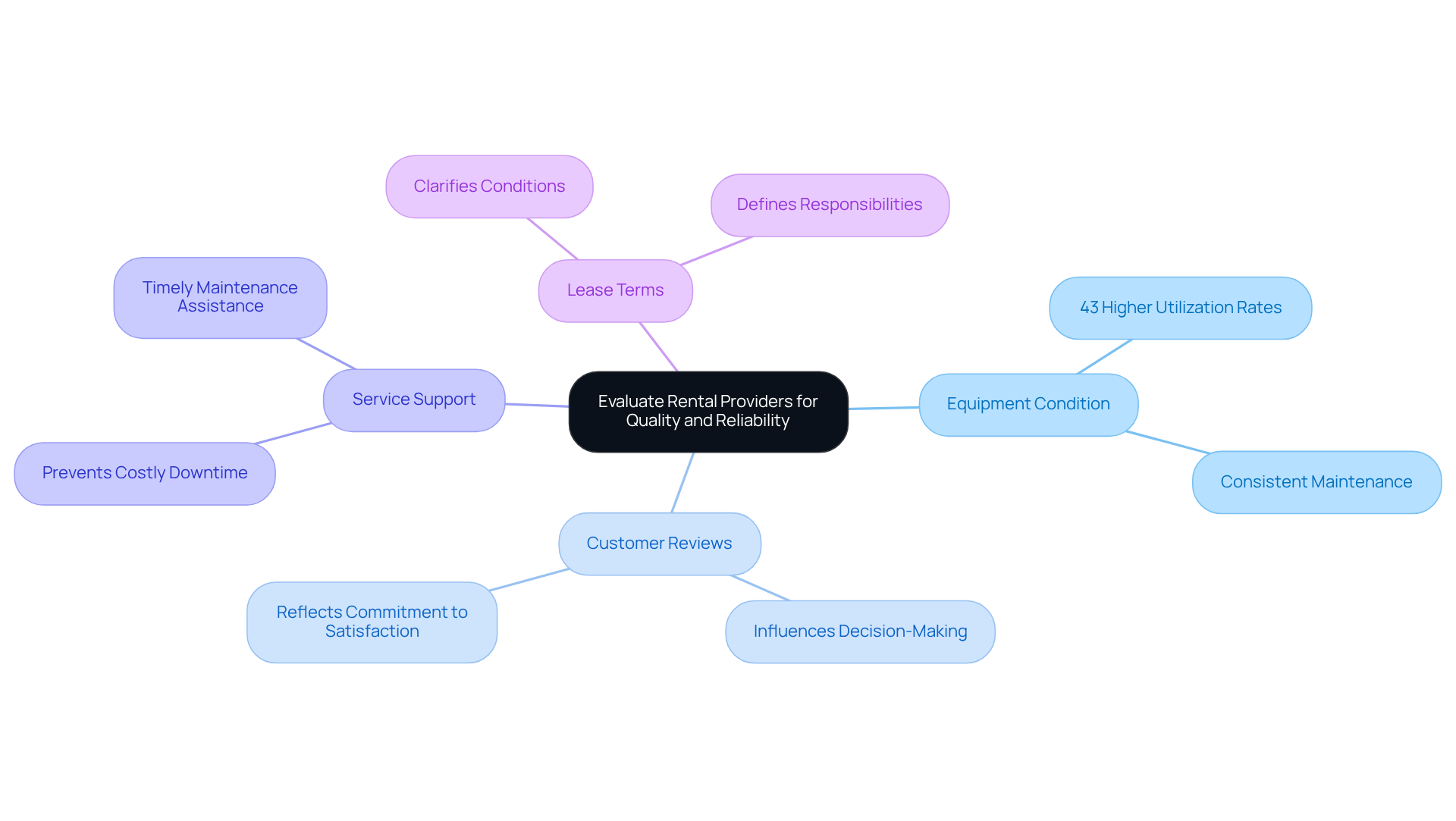

Evaluate Rental Providers for Quality and Reliability

When assessing rental providers, it is essential to consider several critical criteria.

-

Equipment Condition: Examine the equipment for any signs of wear and tear. A reliable supplier guarantees that their tools are consistently serviced and in peak functioning order, which is essential for operational efficiency. Research indicates that companies prioritizing equipment condition experience 43% higher utilization rates, underscoring the importance of this factor.

-

Customer Reviews: Seek out feedback from previous customers to evaluate the provider's reliability and service quality. Positive reviews often reflect a provider's commitment to customer satisfaction and operational excellence. According to industry insights, customer feedback significantly influences decision-making for construction managers, making it a vital consideration.

-

Service Support: Confirm that the provider offers robust support throughout the rental period, including maintenance and troubleshooting assistance. Access to timely support can prevent costly downtime and ensure the smooth execution of tasks. As noted by Glorek, comprehensive customer service is crucial for navigating project complexities, reinforcing the need for reliable support.

-

Lease Terms: Carefully review the lease agreement for clarity on conditions, including insurance, liability, and maintenance responsibilities. Understanding these details aids in preventing misunderstandings and guarantees a smooth leasing experience.

By meticulously assessing potential service providers according to these standards, you can secure high-quality tools that align with your operational needs, ultimately enhancing your success. Incorporating these factors can lead to 57% fewer missed bookings and a more efficient leasing experience.

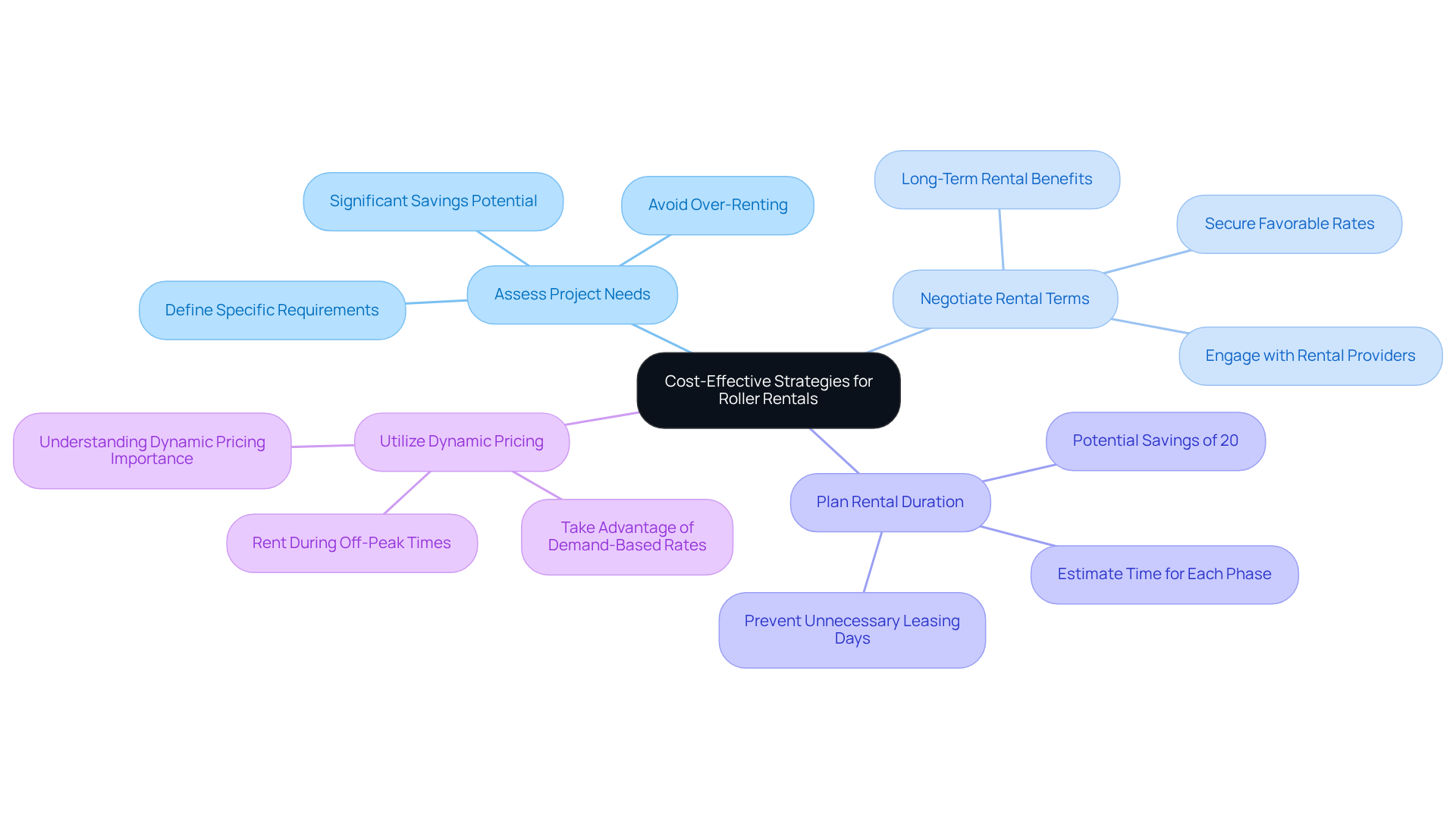

Implement Cost-Effective Strategies for Roller Rentals

To implement cost-effective strategies for roller rentals, consider these key approaches:

-

Assess Project Needs: Clearly define the specific requirements of your project to avoid over-renting equipment. Understanding the exact type and quantity of rollers needed from roller equipment rental can lead to significant savings. As industry specialist Abhishek Kataria highlights, roller equipment rental has become essential for construction firms of all scales, allowing them to complete projects on schedule and within budget.

-

Negotiate rental terms for roller equipment rental by engaging in discussions with rental providers to secure favorable rates and terms, especially for long-term rentals. Many companies are open to adjusting prices, especially for roller equipment rental, when they foresee potential for ongoing business. Josh Nickell emphasizes the importance of planning and analytics in managing equipment needs, particularly roller equipment rental, moving away from guesswork.

-

Plan the roller equipment rental duration by carefully estimating the time required for each phase of your project. This foresight helps prevent unnecessary leasing days in roller equipment rental, which can inflate costs. Precise planning can result in savings of up to 20% on leasing costs, which is an important factor in the roller equipment rental industry expected to expand by $48.6 billion between 2022 and 2029.

-

Utilize Dynamic Pricing: Take advantage of dynamic pricing models offered by some leasing companies, which adjust rates based on demand. Renting during off-peak times can yield lower rates, further reducing overall costs. The growing need for roller equipment rental, driven by rapid urban development and construction initiatives, makes understanding dynamic pricing even more crucial.

By implementing these methods, you can greatly reduce expenses while ensuring you possess the essential tools to complete your task effectively.

Understand Rental Terms and Conditions for Better Compliance

Before entering into a rental agreement, it is crucial to grasp the following key terms:

-

Rental Duration: Clearly define the start and end dates of the rental period to prevent incurring additional charges. The typical duration for leasing machinery usually varies from a few days to several months, based on requirements. Notably, 70% of building initiatives utilize machinery leases for periods shorter than three months. This statistic underscores the necessity for transparency in lease contracts.

-

Liability and Insurance: Understand your responsibilities concerning damage to tools and the insurance coverage provided by the rental company. Liability can significantly impact your budget; studies indicate that unforeseen equipment damage can lead to cost overruns of up to 15%. Legal expert Tony Mariotti emphasizes, "Understanding your liability and insurance options is essential to avoid financial pitfalls during your project."

-

Maintenance Responsibilities: Familiarize yourself with the maintenance tasks you are expected to perform during the rental period. Knowing these responsibilities can help you avoid penalties and ensure the equipment remains in good working condition. A recent case study revealed that neglecting routine maintenance resulted in a 20% increase in repair costs, highlighting the importance of adhering to maintenance guidelines.

-

Cancellation Policies: Review the provider's cancellation policies to avoid unexpected fees. Understanding these terms can save you from financial surprises should your project timeline change. According to TransUnion, "Clear communication regarding cancellation policies can prevent misunderstandings and protect your budget."

By thoroughly understanding these terms, you can ensure compliance and protect your interests throughout the leasing process. Legal experts emphasize that clear communication regarding liability and maintenance responsibilities is essential for a successful rental experience, as it helps mitigate risks and fosters a positive relationship with the rental provider.

Conclusion

Understanding the intricacies of roller equipment rental is essential for achieving success in construction and landscaping projects. Recognizing the specific types of roller equipment available and their unique applications enables managers to make informed choices that enhance project efficiency and cost-effectiveness. Selecting the right equipment is just the beginning; evaluating rental providers based on quality, reliability, and customer service is equally critical to ensuring operational success.

Key strategies such as:

- Assessing project needs

- Negotiating favorable rental terms

- Comprehensively understanding rental agreements

can significantly impact the overall cost and effectiveness of roller equipment rentals. The condition of the equipment, customer feedback, and service support are vital in minimizing downtime and maximizing productivity. Furthermore, implementing cost-effective strategies and being aware of rental terms can lead to substantial savings and a smoother leasing experience.

Ultimately, the significance of these practices extends beyond individual projects. As the demand for roller equipment rental continues to grow, adopting these best practices not only enhances immediate project outcomes but also positions businesses for long-term success in a competitive market. Embracing these strategies empowers construction and landscaping professionals to navigate the complexities of equipment rental with confidence, ensuring that every project is completed on time and within budget.

Frequently Asked Questions

What are the main types of roller equipment used in construction and landscaping?

The main types of roller equipment include cylindrical rollers, pneumatic rollers, sheepsfoot rollers, vibratory rollers, and tandem rollers, each tailored for specific applications.

What is the purpose of cylindrical rollers?

Cylindrical rollers are lightweight, walk-behind rollers ideal for smaller compaction tasks, particularly in asphalt and soil compaction, and are designed for maneuverability in tight spaces.

How do pneumatic rollers operate and what are their applications?

Pneumatic rollers are equipped with multiple rows of rubber tires that distribute pressure evenly across an 80% coverage area. They excel in asphalt compaction, delivering a smooth finish and are especially efficient in road development and overlay tasks.

What are sheepsfoot rollers used for?

Sheepsfoot rollers are designed for compacting cohesive soils, such as clay, and are effective in densifying silty clay and wet clay. They are particularly advantageous in road construction and landfill operations.

What makes vibratory rollers effective?

Vibratory rollers use vibration to enhance compaction efficiency, making them well-suited for granular soils and asphalt. Their mechanism achieves high compaction levels, preventing structural issues caused by voids.

In what scenarios are tandem rollers typically used?

Tandem rollers, featuring two smooth drums, are commonly used for laying asphalt on roads and airport runways, ensuring a smooth finish and facilitating efficient paving and compaction.

How can understanding roller types benefit construction managers?

Understanding the unique features and applications of different roller types empowers managers to select the most appropriate roller equipment rental, enhancing performance and cost-efficiency in construction projects.