Overview

The essential guide to 40 ft extension ladder rental serves as a crucial resource for construction project managers aiming to enhance safety, productivity, and efficiency on job sites. This guide outlines best practices that are vital for mitigating risks and optimizing equipment use in construction projects. Key steps include conducting thorough inspections, maintaining effective communication with rental companies, and strictly adhering to safety protocols. Collectively, these measures not only bolster safety but also streamline operations, ensuring that projects are executed smoothly and efficiently.

Key Highlights:

- Extension ladders are essential for safe access to heights on construction sites, facilitating work on elevated structures without scaffolding.

- A 40 ft extension ladder rental can enhance productivity and safety, particularly for tasks like painting and roof repairs.

- Forklifts play a critical role in transporting heavy materials, improving workflow and reducing labor costs.

- Effective training on ladder use is vital, with 98% of organizations providing ladder training to reduce accident risks.

- Best practices include inspecting ladders before use, ensuring stable placement, and maintaining a 75-degree setup angle.

- Project managers should conduct thorough research on rental companies and inspect equipment before leasing to avoid safety issues.

- Clear communication with leasing companies helps manage expectations and mitigate challenges like equipment availability and unexpected costs.

- Regular maintenance of rented ladders, including inspections and cleaning, is crucial for safety and longevity of the equipment.

- Training resources can enhance safety knowledge and ensure compliance with OSHA guidelines for ladder use.

Introduction

In the dynamic world of construction, safety and efficiency are paramount—especially when it comes to reaching new heights. Extension ladders have become indispensable tools on job sites, enabling workers to access elevated areas safely while maximizing productivity. Selecting the right ladder, such as a robust 40 ft extension ladder, is crucial; it not only facilitates various tasks but also plays an essential role in maintaining a secure work environment.

As project managers navigate the complexities of ladder rentals, safety protocols, and equipment maintenance, understanding best practices is vital in fostering a culture of safety and efficiency. This article explores the multifaceted role of extension ladders in construction, providing insights into their selection, rental processes, and best practices that ensure both worker safety and project success.

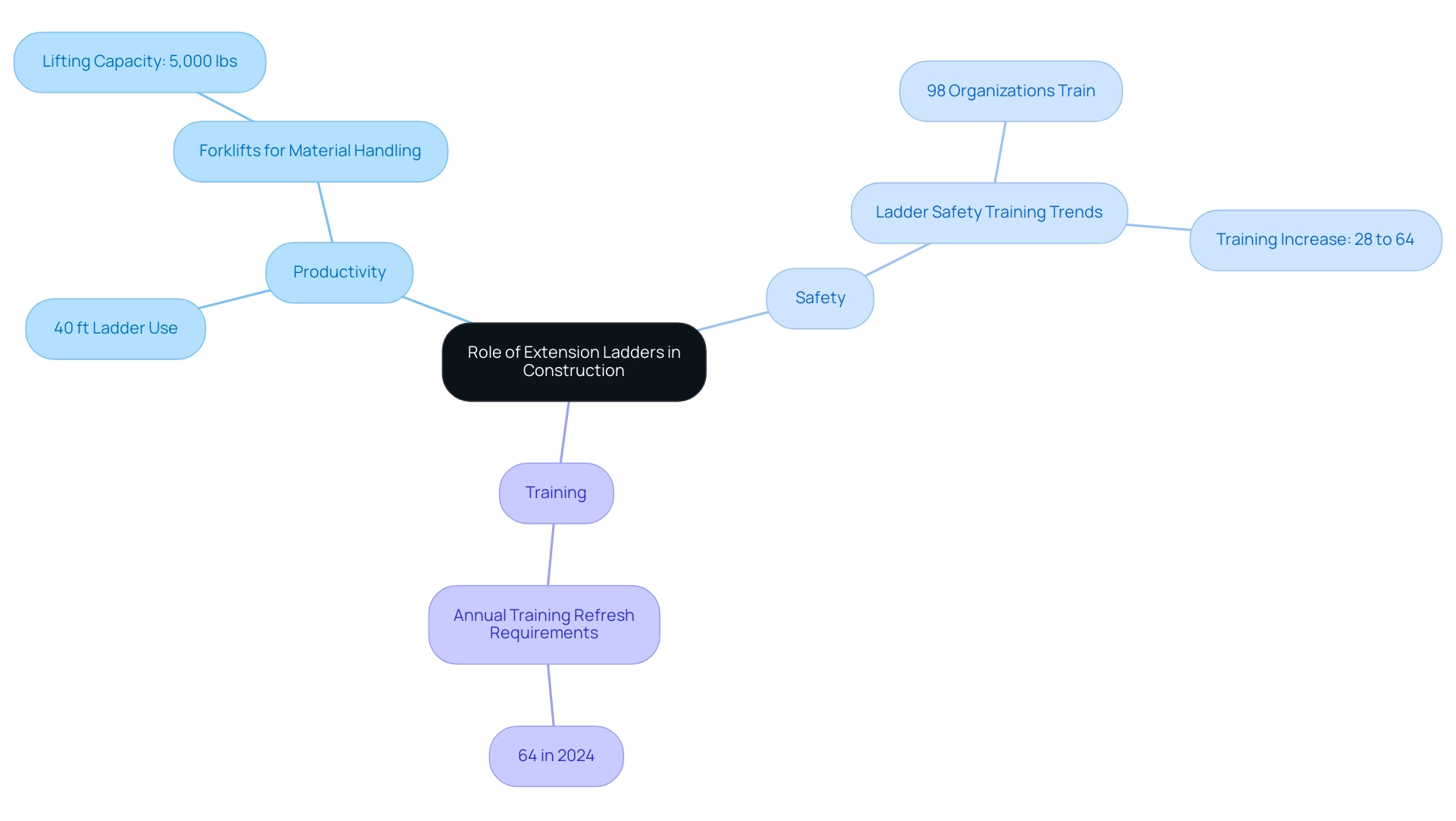

The Role of Extension Ladders in Construction Projects

Extension tools are essential access devices on construction sites, enabling workers to reach significant heights safely and efficiently. Utilizing a 40 ft extension ladder rental allows managers to assist work on two-story buildings or elevated structures without the necessity for scaffolding. A recent commercial project exemplifies this; the painting crew utilized a 40 ft scaffold, enabling them to finish their tasks ahead of schedule.

This not only emphasizes how proper equipment boosts productivity but also highlights the essential role extension tools play in construction efficiency. Moreover, forklifts are crucial for transporting heavy materials, with models capable of lifting loads up to 5,000 lbs, significantly reducing the time and manpower required for material handling. This integration streamlines workflow and improves security on site.

Crucially, the use of ladders and forklifts, when paired with effective training—evidenced by a recent survey showing that 98% of organizations utilize some form of ladder training and a significant increase in those paying for such instruction from 28% in 2020 to 64% in 2024—greatly reduces the risk of accidents and injuries. The case study titled 'Ladder Safety Training Trends' illustrates this evolution in commitment to safety education. As Jonny Finity from Procore aptly states, 'In construction, teams are highly focused on successfully delivering each task on time and within budget, placing priority on productivity, efficiency, and delivery.'

Therefore, incorporating extension equipment and forklifts into construction practices not only enhances productivity but also serves as a key component of maintaining a safe work environment.

Why Choose a 40 Ft Extension Ladder for Your Projects?

Choosing a 40 ft extension ladder rental is essential for construction projects that demand access to elevated areas, with a strong emphasis on security and stability. These extension devices can reach heights of up to 40 feet or more, making them particularly effective for a variety of residential and commercial tasks, such as gutter cleaning and roof repairs. Many contemporary 40 ft extension ladders are designed with protective features, including slip-resistant rungs and durable materials like aluminum or fiberglass, which significantly enhance user safety.

For example, a project manager overseeing a residential renovation reported that using a 40 ft extension ladder rental not only met the height requirements but also provided crucial safety benefits when working near electrical installations, considering that fiberglass is non-conductive. Furthermore, utilizing personal protective equipment (PPE) is vital when working with climbing tools; gloves, for instance, serve as PPE to shield your hands from hazardous chemicals, cuts, and scrapes. Additionally, proper setup techniques for extension apparatus are critical to prevent accidents.

Key steps include:

- Selecting a stable surface

- Positioning the ladder at a 75-degree angle

- Securing it with stabilizing devices

Adhering to these setup techniques helps prevent the device from slipping or tipping over. These considerations underscore the importance of choosing the right equipment for specific tasks, particularly in 2024, where safety features continue to evolve, enabling construction professionals to work confidently at significant heights.

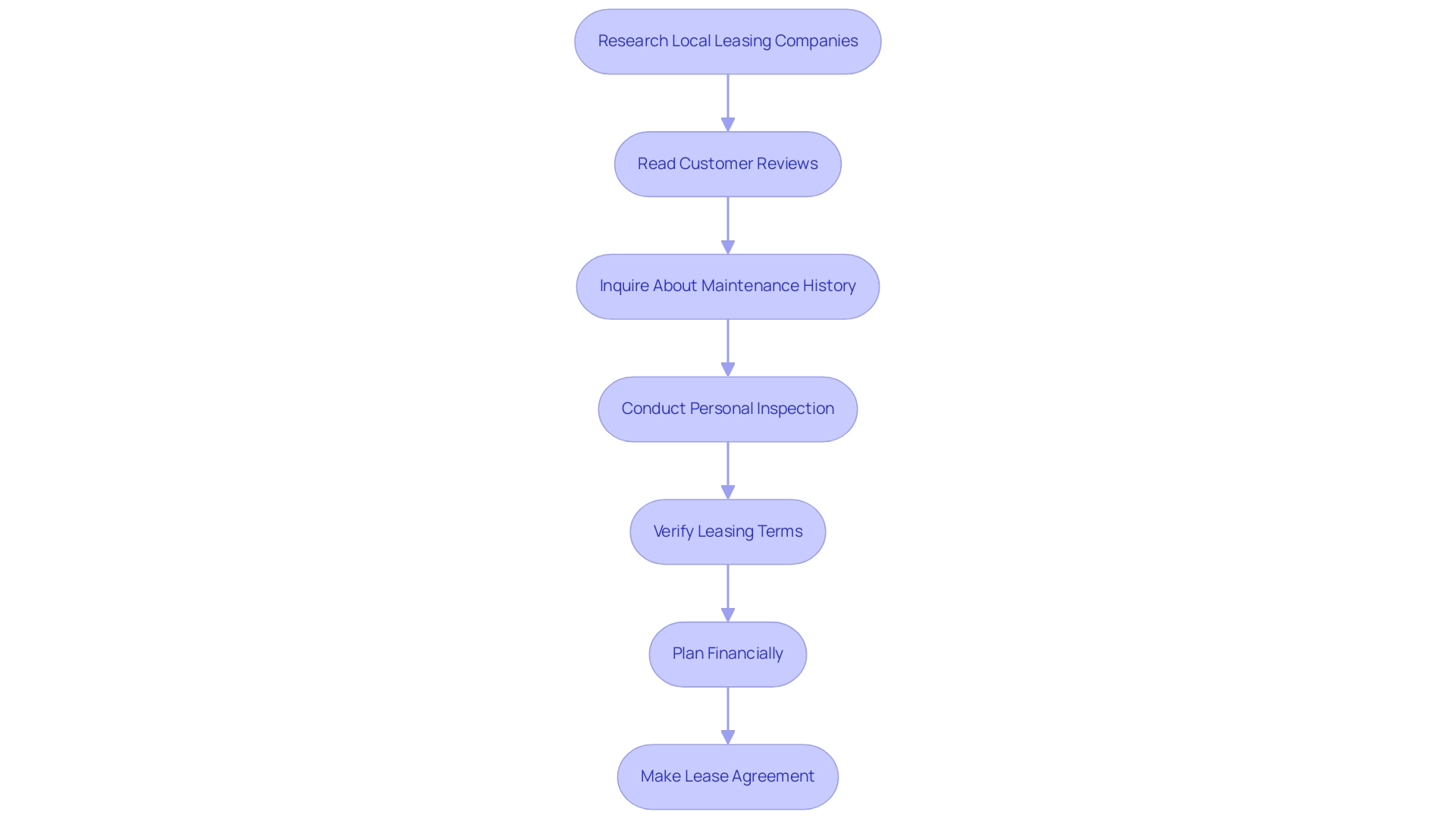

Navigating the Ladder Rental Process: Tips for Project Managers

When leasing a 40 ft extension ladder rental, project managers must navigate several critical factors to facilitate a seamless borrowing experience. It begins with thorough research on local leasing companies. Reading customer reviews can help identify reputable providers known for their quality service.

Before concluding any lease agreement, it's vital to inquire about the ladder's maintenance history and conduct a personal inspection to detect any signs of wear or damage. This precaution not only enhances safety but also guarantees that the equipment meets specifications. Moreover, clarity regarding leasing terms is crucial; managers should verify the pricing framework, length of the lease, and any possible late return charges to prevent unforeseen costs.

Significantly, average leasing expenses for extension tools can approach approximately $1,249 each month in regions such as Mississippi, making it essential for managers to plan their finances accordingly. For example, one manager who diligently followed these steps successfully secured a high-quality ladder at a competitive rate, ultimately saving their budget while ensuring both safety and efficiency. As occupancy rates stabilize and start to increase in 2024, as pointed out by Jamie Lane, RevPAR growth is anticipated to speed up, which may affect leasing decisions and market trends.

Furthermore, considering the financial consequences of leasing equipment is crucial; similar to the elevated mortgage rates linked to investment property loans because of their risks, choosing high-quality leased equipment is important to reduce possible setbacks. As the equipment rental market develops, remaining aware of current best practices will be essential for success in 2024 and beyond.

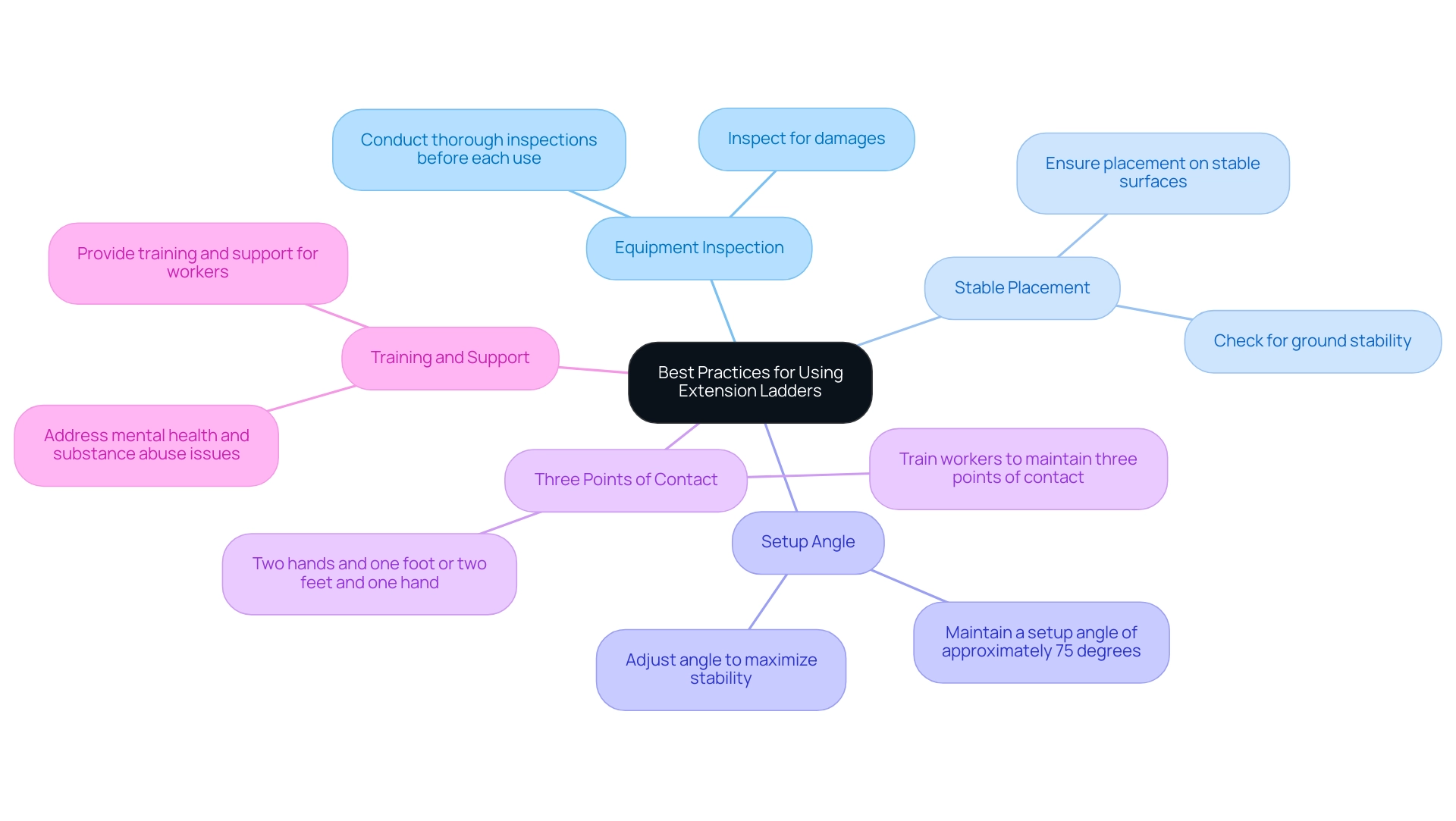

Safety First: Best Practices for Using Extension Ladders

To promote the safe usage of extension equipment, project managers must adopt best practices that align with the latest OSHA guidelines for 2024. Critical safety measures include:

- Conducting thorough inspections of climbing equipment before each use.

- Ensuring they are placed on stable surfaces.

- Maintaining a setup angle of approximately 75 degrees to maximize stability.

It is essential that workers are trained to maintain three points of contact while climbing—this means having either two hands and one foot or two feet and one hand securely on the climbing structure.

Notably, statistics indicate that approximately 40% of injuries related to these tools occur due to sliding at the base from an incorrect setup angle, underscoring the importance of proper setup. Recent observations during a site inspection highlighted the significance of these protocols; a project manager remarked that a crew adhering to these precautionary measures significantly reduced the risk of falls and injuries. This reinforces the critical role of training and vigilance in achieving compliance with OSHA ladder regulations and emphasizes the potential to reduce accident rates associated with improper ladder use.

Furthermore, organizations like USF SafetyFlorida Services provide valuable assistance in identifying potential hazards and improving safety programs, which can enhance workplace safety and potentially qualify companies for exemptions from routine OSHA inspections. As Jonny Finity, Content Manager, points out, the stigma surrounding mental health and substance abuse issues in the construction industry can hinder workers from seeking help. Addressing these issues through training and support is vital for fostering a safe working environment.

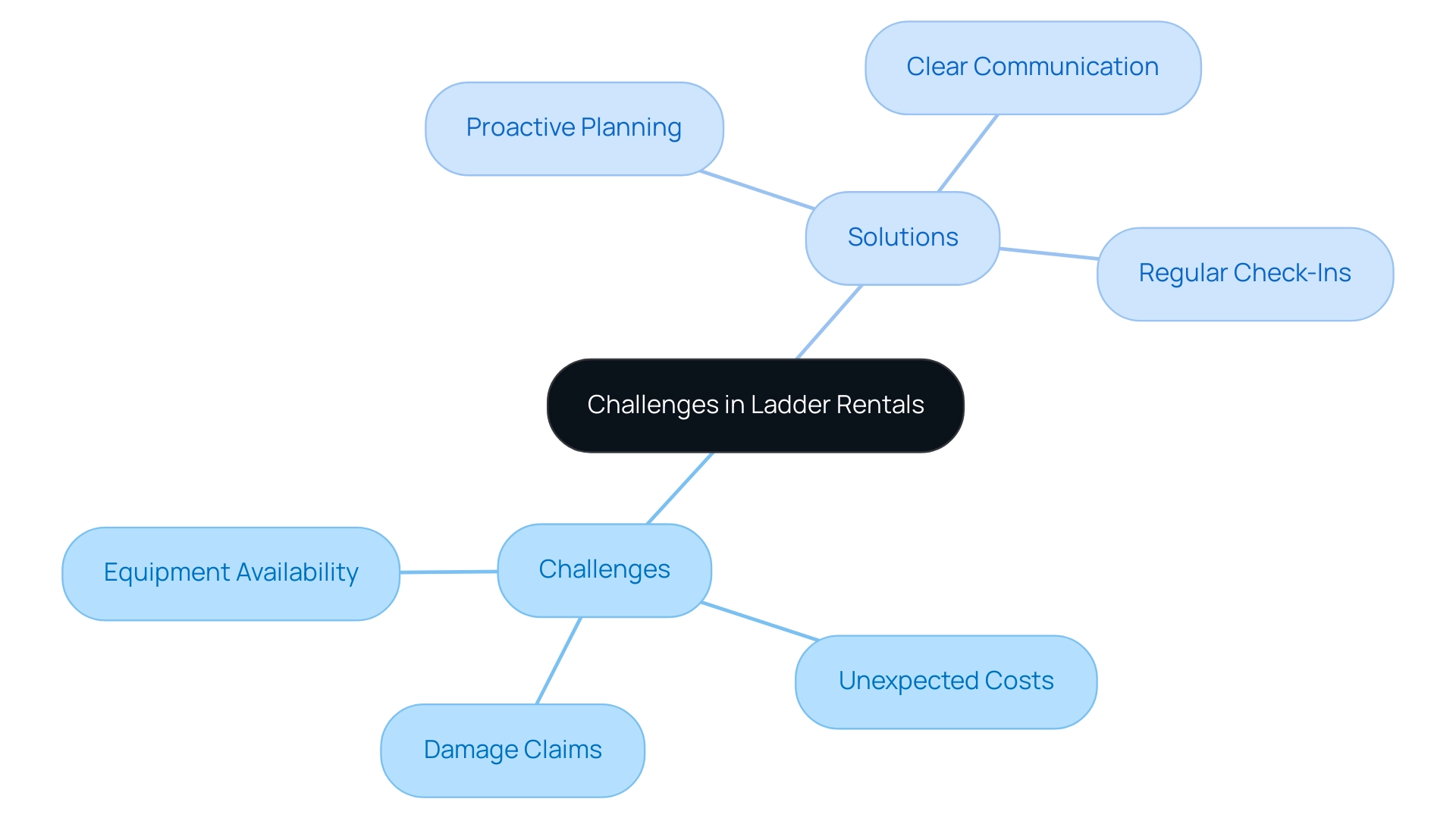

Overcoming Common Challenges in Ladder Rentals

Ladder hires often present significant challenges, including equipment availability, unexpected costs, and disputes over damage claims. With the global aerial work platforms market projected to grow at a CAGR of 8.9% from 2024 to 2033, the demand for dependable ladder leases is expected to rise. This trend underscores the necessity for effective communication with leasing companies, making it more critical than ever. To navigate these challenges, managers are encouraged to plan proactively by reserving equipment well in advance, particularly during peak construction seasons when demand surges.

Establishing clear communication with leasing companies is essential; discussing usage expectations and potential damages upfront can significantly mitigate misunderstandings. For instance, one supervisor who proactively outlined their timeline and specific requirements with their leasing service successfully secured the necessary ladders without delays. This strategic approach not only ensured timely completion of their assignment but also emphasized the importance of effective communication in managing leasing agreements.

As articulated by a project supervisor, 'Clear communication with leasing firms ensures that everyone is on the same page, which is vital for the success of the initiative.' By understanding and addressing these common challenges, managers can enhance their operational efficiency and minimize unforeseen costs associated with equipment leasing. Furthermore, a case study on overcoming challenges in equipment rentals illustrates how a construction team improved their rental experience by implementing regular check-ins with their rental provider, fostering a collaborative relationship that led to timely equipment delivery.

Maintaining Equipment: Ensuring Ladder Longevity

To maximize the lifespan of rented extension tools, managers must establish a comprehensive maintenance routine. This involves:

- Performing regular inspections to identify wear and tear.

- Cleaning the equipment after each use to eliminate debris.

- Ensuring that all moving parts function properly.

For example, a manager who adhered to a strict inspection timetable effectively identified and addressed minor issues before they could escalate, significantly prolonging the lifespan of the rented equipment while safeguarding their team’s well-being.

Moreover, it is critical to ensure that each part of a multi-section apparatus overlaps by at least 3 feet for structures up to 36 feet, and 4 feet for those 40 feet or longer, as this practice is essential for stability and security. By fostering a culture of care and responsibility regarding equipment use, project managers can enhance safety and operational efficiency on their job sites. Additionally, the case study titled 'Choosing the Right Equipment' underscores the importance of selecting appropriate materials for specific tasks; for instance, fiberglass structures are recommended for electrical work due to their non-conductive properties.

Furthermore, training resources like EasyLlama’s interactive Ladder Safety course, which incorporates real-life scenarios and quizzes, can complement maintenance routines by empowering employees with essential knowledge and skills for safe ladder use in various construction environments.

Conclusion

Extension ladders are essential for enhancing safety and efficiency on construction sites. By selecting the appropriate ladder, such as a 40 ft extension ladder, project managers can ensure access to elevated areas, streamlining workflows and boosting productivity. The implementation of effective safety training further minimizes accident risks, highlighting the critical nature of rigorous protocols in maintaining a secure work environment.

Navigating the ladder rental process necessitates careful consideration and proactive planning. By thoroughly researching rental companies, inspecting equipment, and clearly communicating expectations, project managers can circumvent unexpected costs and guarantee timely access to essential tools. Furthermore, adopting best practices for ladder use—including proper setup and maintenance routines—is vital for maximizing equipment longevity and safeguarding worker safety.

Ultimately, cultivating a culture of safety and efficiency in construction relies on the informed selection and use of extension ladders. As the industry progresses, remaining informed about best practices and safety standards will be crucial for project success. Prioritizing these elements not only enhances project outcomes but also fosters a safer working environment for all involved.

Frequently Asked Questions

What are extension tools used for in construction?

Extension tools are essential access devices that enable workers to reach significant heights safely and efficiently on construction sites.

How does renting a 40 ft extension ladder benefit construction projects?

Renting a 40 ft extension ladder allows managers to assist with work on two-story buildings or elevated structures without the need for scaffolding, enhancing productivity and safety.

Can you provide an example of the benefits of using a 40 ft extension ladder?

In a recent commercial project, a painting crew utilized a 40 ft scaffold, which allowed them to complete their tasks ahead of schedule, demonstrating how proper equipment boosts productivity.

What role do forklifts play in construction?

Forklifts are crucial for transporting heavy materials, with some models capable of lifting loads up to 5,000 lbs, significantly reducing the time and manpower required for material handling.

How does training impact the safety of using ladders and forklifts?

Effective training greatly reduces the risk of accidents and injuries. A recent survey showed that 98% of organizations utilize some form of ladder training, with the percentage of those paying for such instruction increasing from 28% in 2020 to 64% in 2024.

What safety features are found in contemporary 40 ft extension ladders?

Many contemporary 40 ft extension ladders are designed with protective features, including slip-resistant rungs and durable materials like aluminum or fiberglass, which enhance user safety.

Why is fiberglass considered a safe material for extension ladders?

Fiberglass is non-conductive, making it a safer choice when working near electrical installations.

What personal protective equipment (PPE) is recommended when using climbing tools?

Using gloves as PPE is vital to shield hands from hazardous chemicals, cuts, and scrapes while working with climbing tools.

What are the key steps for properly setting up an extension ladder?

Key steps include selecting a stable surface, positioning the ladder at a 75-degree angle, and securing it with stabilizing devices to prevent slipping or tipping over.

How does the evolution of safety features impact construction practices in 2024?

Evolving safety features enable construction professionals to work confidently at significant heights, emphasizing the importance of choosing the right equipment for specific tasks.