Overview

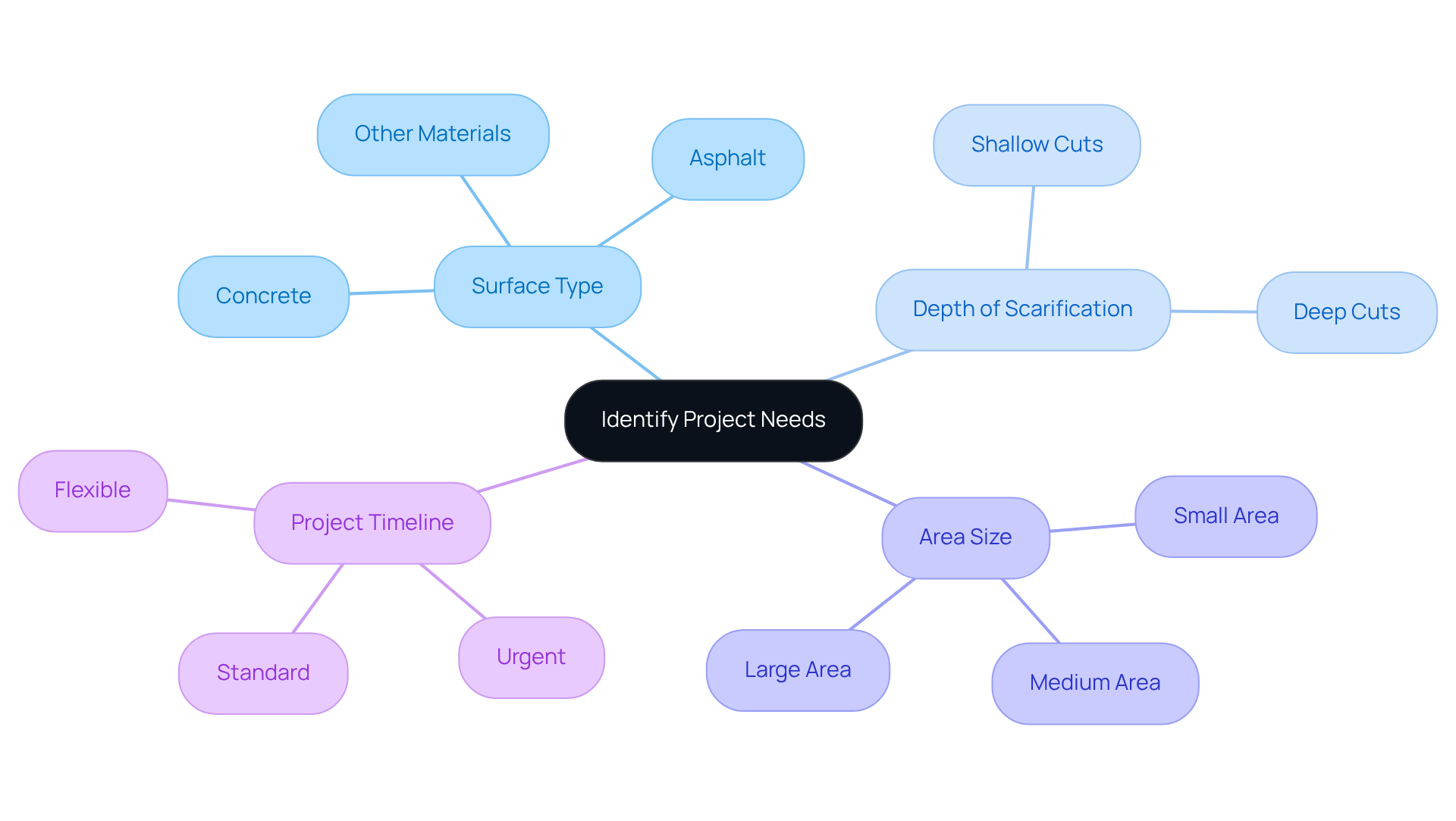

To rent a scarifier effectively, construction project managers must first assess their specific project needs. Considerations such as surface type, depth of scarification, area size, and project timeline are crucial in selecting the appropriate equipment. Evaluating these factors not only ensures optimal performance but also helps in avoiding unexpected costs during the rental process.

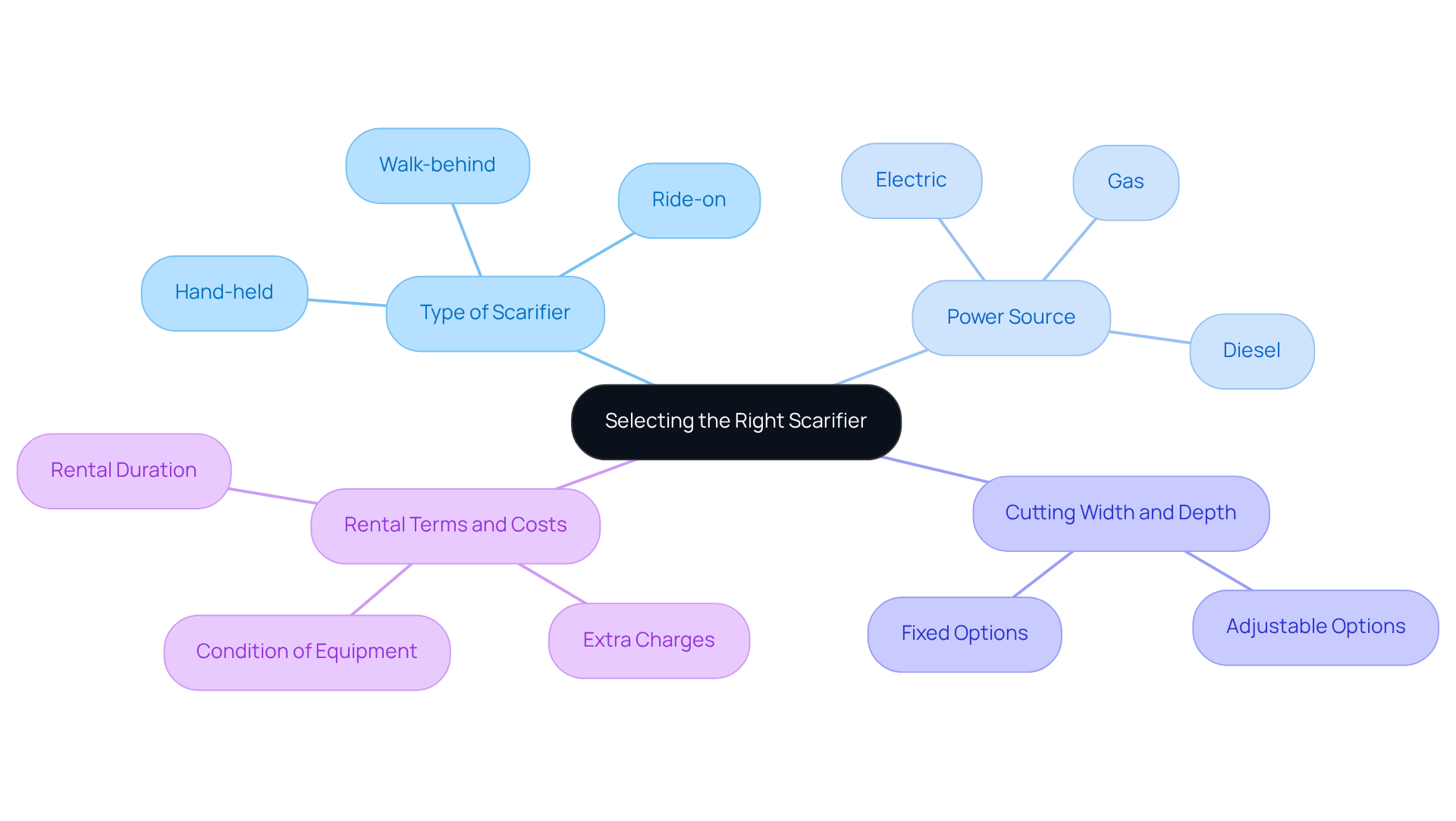

Furthermore, it is essential to examine the type of scarifier, power source, and rental terms to make an informed decision. This careful evaluation supports the overall success of the project and enhances the reliability of the equipment used.

Key Highlights:

- Assess specific project needs before renting a scarifier, including surface type, depth of scarification, area size, and project timeline.

- Choose the appropriate type of scarifier (walk-behind, hand-held, or ride-on) based on the project's size and nature.

- Consider the power source: gas for mobility and power, electric for quiet operation, and diesel for heavy-duty tasks.

- Look for scarifiers with adjustable cutting widths and depths for versatility across different tasks.

- Compare rental terms and costs from suppliers like EZ Equipment Rental to avoid unexpected expenses.

- Conduct pre-operation checks on the scarifier to ensure it's in good condition before use.

- Wear appropriate personal protective equipment (PPE) to safeguard against debris and noise.

- Set up the scarifier correctly, adjusting cutting depth to meet project requirements.

- Operate the scarifier in straight lines, overlapping passes for even coverage, and monitor performance continuously.

- Clean the scarifier post-operation and store it according to rental guidelines to maintain its condition.

Introduction

Navigating the complexities of construction projects often requires specialized equipment. Renting a scarifier can be a game-changer for project managers, offering significant advantages. This guide delves into the essential steps for:

- Selecting a scarifier

- Renting a scarifier

- Operating a scarifier effectively

By ensuring that projects run smoothly and efficiently, you can avoid costly mistakes. With various types of scarifiers available and differing project requirements, determining the best fit for specific needs is crucial. By following this guide, you can make informed decisions that enhance your project's success.

Identify Your Project Needs and Requirements

Begin by evaluating the specific tasks that require you to rent a scarifier. This initial assessment is crucial for selecting the right equipment. Consider the following key factors:

- Surface Type: Identify whether you are working on concrete, asphalt, or another material. Different surfaces necessitate distinct kinds of scarifiers to achieve optimal results.

- Depth of Scarification: Determine how deep you need to scarify the surface. This depth will influence your choice of soil cultivator, as certain models are designed for deeper cuts than others.

- Area Size: Measure the total area that needs scarification. Larger areas may require more powerful or larger machines to complete the job efficiently.

- Project Timeline: Assess how quickly you need the work completed. Understanding your timeline will assist in determining the size and strength of the equipment required to meet your deadlines.

By clearly defining these parameters, you can streamline the rental process and ensure you choose the most appropriate equipment for your task. This strategic approach not only enhances efficiency but also guarantees the reliability and quality of your project outcomes.

Evaluate and Select the Right Scarifier for Your Project

To effectively meet your project needs, it is essential to evaluate the various options to rent a scarifier available at EZ Equipment Rental in Irving, TX. Begin by considering the Type of Scarifier: You can choose among walk-behind, hand-held, or ride-on models based on your project's size and nature. Walk-behind models are ideal for smaller areas, while ride-on models excel in larger spaces, providing efficiency and comfort during extended use.

Next, assess the Power Source that best suits your requirements. Gas models offer robust power and mobility, making them suitable for extensive projects. In contrast, electric options are quieter and more environmentally friendly, ideal for residential areas. Diesel models deliver high performance for heavy-duty tasks but may incur higher operational costs.

When selecting a scarifier, consider the Cutting Width and Depth. Opt for machines with adjustable cutting widths and depths, allowing you to customize performance for various tasks and enhancing versatility across different surfaces and conditions.

Finally, compare rental terms and costs from various suppliers, including EZ Equipment Rental, to rent a scarifier. Pay close attention to rental duration, any extra charges, and the condition of the items. Understanding these factors will empower you to make an informed decision and avoid unexpected costs.

By thoughtfully evaluating these factors, you can select a tool that aligns with your project needs, ensuring optimal performance and efficiency while taking advantage of the comprehensive rental services available in the DFW Metroplex.

Set Up and Operate the Scarifier Safely and Effectively

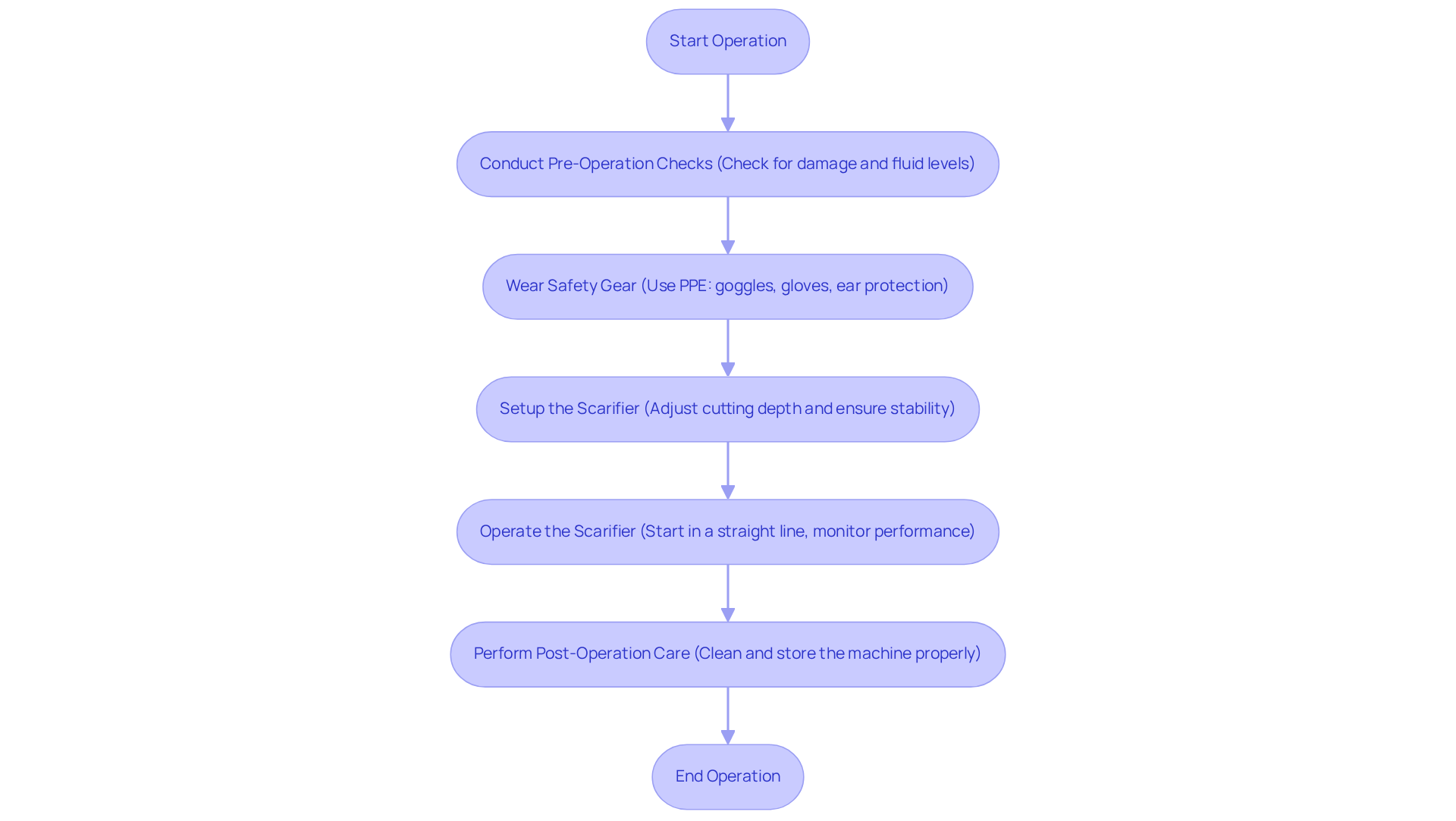

To ensure the safe and effective operation of the scarifier, follow these essential steps:

Pre-Operation Checks: Before starting, conduct a thorough inspection of the scarifier for any visible damage or wear. Check fluid levels, belts, and blades to confirm that everything is functioning properly. Regular pre-operation checks are crucial; neglecting them can lead to operational inefficiencies and increased wear on the machine. As emphasized by industry specialists, 'thorough pre-operation checks are fundamental to preventing accidents and ensuring the durability of tools.'

Safety Gear: Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and ear protection. These measures are vital for safeguarding against debris and noise. Current statistics indicate that compliance with safety protocols is essential, with PPE usage rates among construction workers showing a significant impact on reducing workplace injuries.

Setup: Place the scarifier in a stable, level area if you need to rent a scarifier. Adjust the cutting depth according to project requirements, ensuring it is set correctly before starting. Proper setup is critical; if you rent a scarifier and use incorrect depth settings, it can result in uneven surface preparation and excessive wear on the cutter heads. Common setup mistakes include failing to double-check depth settings, which can lead to ineffective preparation.

To properly operate the machine, you may need to rent a scarifier and follow the manufacturer's instructions. Begin scarifying in a straight line, overlapping each pass slightly to ensure even coverage. Continuously monitor the machine's performance and make adjustments as necessary to maintain efficiency.

Post-Operation Care: After finishing the task, clean the machine thoroughly to remove debris and dust. Store it according to the rental company's guidelines to preserve its condition for future use. Regular maintenance and care are essential to prevent breakdowns and ensure optimal performance.

By adhering to these operational guidelines, you can maximize the efficiency of the scarifier when you rent a scarifier, while ensuring a safe working environment. Remember, as emphasized by industry experts, thorough pre-operation checks are fundamental to preventing accidents and ensuring equipment longevity.

Conclusion

Understanding the process of renting a scarifier is crucial for construction project managers who strive for optimal results in their projects. By thoroughly assessing project requirements, selecting the appropriate equipment, and adhering to safe operational practices, managers can ensure that their projects are executed smoothly and efficiently.

This article outlines a comprehensive approach to renting a scarifier, beginning with the identification of specific project needs such as surface type, depth of scarification, and area size. It emphasizes the importance of evaluating various scarifier types and power sources to select the most suitable option for the task at hand. Furthermore, it highlights the necessity of conducting pre-operation checks, utilizing appropriate safety gear, and following established setup and operation procedures to maximize both efficiency and safety.

In conclusion, the insights provided serve as a valuable guide for project managers navigating the scarifier rental process. By emphasizing thorough preparation and careful selection of equipment, managers not only enhance project outcomes but also foster a culture of safety on the job site. By applying these principles, project managers can confidently tackle their construction projects, ensuring both quality and efficiency in their work.

Frequently Asked Questions

What should I evaluate before renting a scarifier?

You should evaluate the specific tasks that require a scarifier, including the surface type, depth of scarification, area size, and project timeline.

How does the surface type affect the choice of scarifier?

Different surfaces, such as concrete or asphalt, require distinct kinds of scarifiers to achieve optimal results.

Why is the depth of scarification important?

The depth of scarification influences your choice of soil cultivator, as certain models are designed for deeper cuts than others.

How does the size of the area impact the scarifier selection?

Larger areas may require more powerful or larger machines to complete the job efficiently.

What role does the project timeline play in selecting a scarifier?

Understanding your timeline helps determine the size and strength of the equipment needed to meet your deadlines.

How can defining project parameters streamline the rental process?

Clearly defining parameters helps ensure you choose the most appropriate equipment for your task, enhancing efficiency and guaranteeing the reliability and quality of project outcomes.