Overview

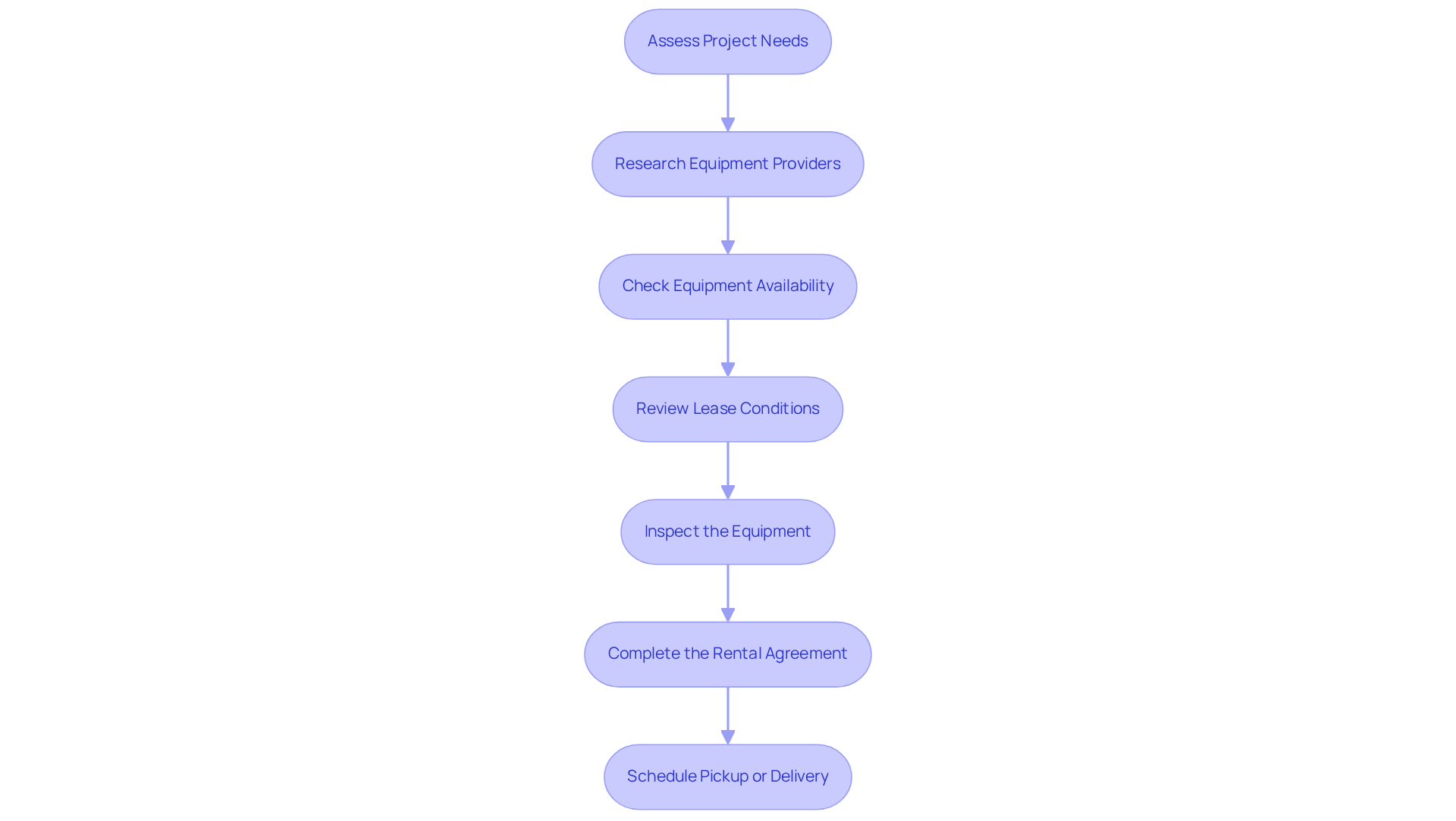

To rent an abrasive blaster, managers are advised to adhere to a systematic process. This process includes:

- Assessing project needs

- Researching providers

- Meticulously reviewing lease conditions

It is crucial to select reputable rental companies, as this ensures equipment quality and compliance with safety regulations. Ultimately, such careful selection enhances operational efficiency and contributes significantly to project success.

Key Highlights:

- Abrasive blasters, also known as sand cleaners, are used for surface cleaning and preparation across various industries, including construction and automotive.

- Different types of abrasive blasters include pressure units for heavy-duty tasks and wet systems for dust suppression.

- The global sandblasting machines market is projected to grow from USD 500.86 million in 2024 to USD 764.53 million by 2034, driven by demand in construction.

- Choosing the right blasting equipment is crucial for efficiency and compliance with safety regulations.

- To rent an abrasive blaster, assess project needs, research providers, cheque equipment availability, review lease conditions, inspect equipment, complete the rental agreement, and schedule delivery.

- Factors to consider when selecting a rental provider include reputation, equipment quality, customer service, lease conditions, and equipment availability.

- Common rental issues include equipment malfunction, insufficient training, delivery delays, unexpected expenses, and safety concerns, each with suggested solutions.

Introduction

Understanding the intricacies of abrasive blasters is crucial for managers navigating the complexities of surface preparation across various industries. The projected market growth underscores the increasing demand for these powerful cleaning machines, making it essential to know how to effectively rent an abrasive blaster. This knowledge can significantly impact project efficiency and cost management.

However, challenges may arise during the rental process, prompting the need for managers to ensure they select the right equipment tailored to their specific needs. This guide offers a comprehensive step-by-step approach to renting abrasive blasters, equipping managers with the necessary insights to make informed decisions and troubleshoot common issues.

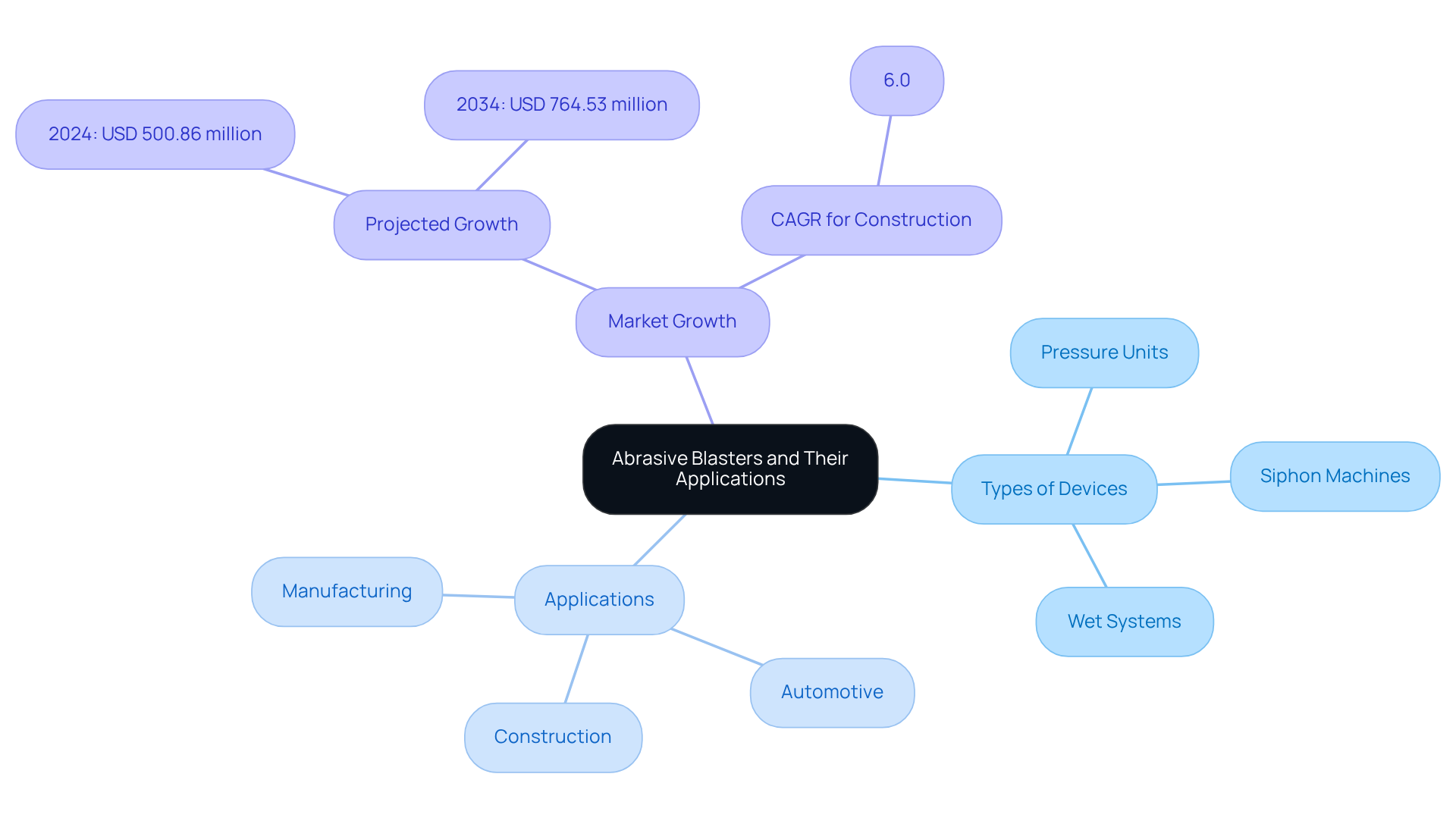

Understand Abrasive Blasters and Their Applications

Rough cleaning machines, commonly known as sand cleaners, are powerful devices designed to clean, smooth, or prepare surfaces by projecting gritty substances at high velocities. These machines find extensive application in various industries, including construction, automotive, and manufacturing. Understanding the different types of abrasive devices—such as pressure units, siphon machines, and wet systems—enables managers to determine when to rent an abrasive blaster for their specific tasks. For instance, pressure devices excel in heavy-duty cleaning, while wet systems effectively minimize dust and are ideal for sensitive surfaces. Familiarity with these applications ensures the selection of the right tools tailored to project requirements.

The global sandblasting machines market is poised for significant growth, projected to rise from USD 500.86 million in 2024 to USD 764.53 million by 2034. This trend underscores the increasing demand for effective surface preparation solutions across diverse sectors. Notably, the construction segment is anticipated to expand at a compound annual growth rate (CAGR) of 6.0%, propelled by ongoing infrastructure development activities. Such growth highlights the critical importance of choosing the right blasting equipment, especially when you rent an abrasive blaster for various applications, as inappropriate tools can lead to inefficiencies and elevated costs. Industry leaders, including Clemco Industries Corporation, emphasize that selecting the appropriate blasting equipment, like a rent abrasive blaster, not only enhances productivity but also ensures compliance with safety regulations, particularly in environments where dust suppression is vital.

Real-world examples illustrate the automotive sector's reliance on surface cleaning for preparation, especially in the manufacturing of electric vehicles, where effective corrosion prevention is paramount. As the demand for high-quality surface finishes continues to escalate, understanding the intricacies of blasting technology becomes increasingly essential for project managers aiming to optimize their operations. Furthermore, the growing trend towards recyclable materials and environmentally friendly substances significantly influences contemporary equipment rental services.

Follow the Step-by-Step Rental Process

To rent an abrasive blaster effectively, follow these essential steps:

-

Assess Your Project Needs: Begin by evaluating the scope of your project. Identify the specific requirements for blasting, including the type of surface to be treated and the desired finish quality. Understanding these needs is crucial for selecting the right equipment.

-

Research Equipment Providers: Seek out reputable machinery leasing companies in your area, such as EZ Equipment Rental, recognized for their extensive selection of blasting tools. A reliable provider will ensure you can rent an abrasive blaster that meets your specifications and provides quality equipment.

-

Check Equipment Availability: Contact the leasing firm to confirm the availability of the particular grinding device needed for your project. Ensuring the equipment is ready when you need it can prevent costly delays.

-

Review Lease Conditions: Carefully examine the lease agreement, paying attention to the duration, fees, and any additional costs associated with delivery or insurance. Understanding these terms is vital to avoid unexpected expenses.

-

Inspect the equipment: Before completing the lease, perform a comprehensive examination of the rent abrasive blaster to verify any damage or wear, ensuring it meets your project standards. A thorough inspection helps guarantee that the equipment will perform as expected.

-

Complete the Rental Agreement: Fill out the necessary paperwork and provide any required documentation, such as a credit card for security purposes. This step finalizes your commitment and prepares you for the rental.

-

Schedule Pickup or Delivery: Arrange for the items to be either collected or brought to your job site, ensuring you have the appropriate transportation if you choose to collect them yourself. Timely logistics are essential for keeping your project on track.

Choose a Reliable Equipment Rental Provider

When selecting an equipment rental provider, several key factors must be considered to ensure a successful rental experience:

-

Reputation: Investigate the company's reputation by examining online reviews and testimonials from past customers. Providers with high ratings and positive feedback are more likely to supply dependable tools and exceptional service.

-

Device Quality: Prioritize companies that uphold their machinery rigorously. Inquire about their maintenance practices and the frequency of inspections. High-quality equipment is essential for project success; construction project managers emphasize that well-maintained tools can significantly impact productivity and safety on site.

-

Customer Service: Assess the level of customer support offered. A responsive and knowledgeable team can address any questions or issues that may arise during the leasing process, enhancing your overall experience.

-

Lease Conditions: Carefully review the lease terms and conditions. Transparency in pricing is crucial; be on the lookout for any hidden fees or charges that could affect your budget.

-

Availability of Equipment: Ensure that the provider has the specific rent abrasive blaster you require in stock and ready for your project timeline. Businesses such as EZ Equipment Rental are acknowledged for their vast inventory and adaptable leasing conditions, establishing them as a dependable option in the DFW region.

By concentrating on these factors, you can make a well-informed choice that matches your project requirements and guarantees a seamless leasing experience.

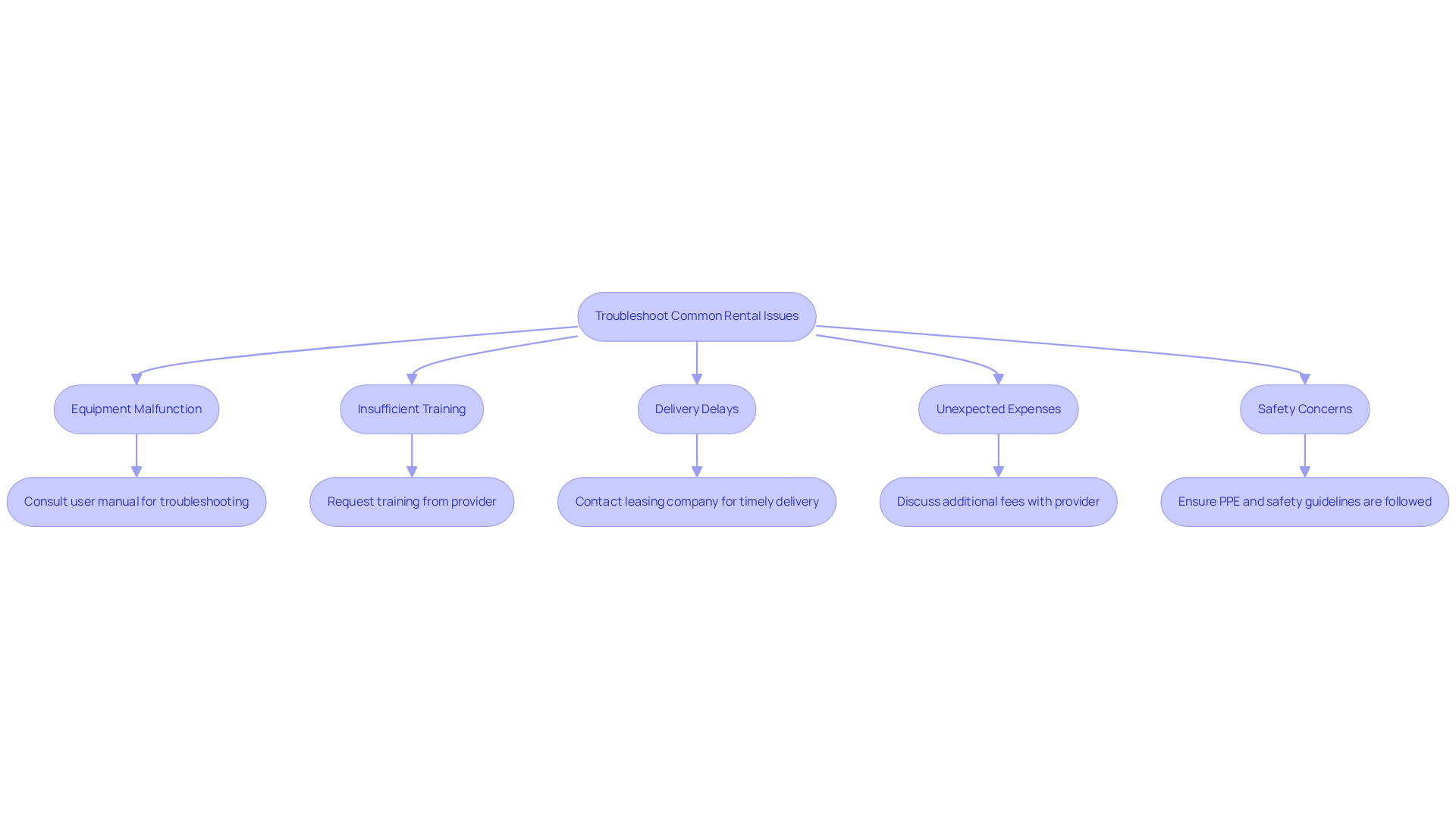

Troubleshoot Common Rental Issues

Common issues that may arise during the rental of abrasive blasters include:

-

Equipment Malfunction: If the sanding device is not operating properly, typical problems may involve blocked hoses or incorrect pressure settings. It is crucial to consult the user manual for troubleshooting advice, as approximately 15% of reported issues in grinding devices stem from these problems, which might be resolved if you rent an abrasive blaster. Addressing these concerns promptly can ensure the smooth operation and efficiency of the project when using a rent abrasive blaster.

-

Insufficient training on how to use a rent abrasive blaster can compromise the safe and effective operation of the machinery. Training programs specifically designed for rent abrasive blaster operators can significantly lower the risk of accidents and misuse of tools. If necessary, request training from the provider to enhance operator competency and confidence in handling the rent abrasive blaster equipment.

-

To avoid delivery delays, it is vital to ensure timely delivery when you rent an abrasive blaster for your project schedules. If the equipment does not arrive on time, promptly contact the leasing company to rent an abrasive blaster and resolve the issue. Having a backup plan can mitigate potential project delays, especially when you rent an abrasive blaster, which can be costly and disruptive to your workflow.

-

To prevent unexpected expenses, carefully examine the lease agreement before finalizing the arrangement to rent an abrasive blaster. If additional fees arise when you rent an abrasive blaster, be sure to discuss them with the rental provider to gain clarity on the charges and ensure they align with your budget. To effectively plan finances, it is key to maintain transparency in costs, especially when you rent abrasive blaster.

-

Safety concerns dictate that prioritizing safety is paramount when using a rent abrasive blaster. Ensure that all operators wear suitable personal protective gear (PPE) and adhere to established safety guidelines when they rent an abrasive blaster. Quotes from safety experts emphasize that effective training and compliance in the operation of equipment, such as when you rent abrasive blaster, can significantly reduce workplace accidents and reinforce the need for a strong safety culture. By fostering a commitment to safety, you enhance not only the well-being of your team but also the overall efficiency of your operations when you rent abrasive blaster equipment.

Conclusion

Renting an abrasive blaster necessitates a strategic approach that includes a thorough understanding of the equipment's applications, careful selection of the right provider, and adherence to a structured rental process. By comprehending the intricacies of abrasive blasting technology and its significance across diverse industries, managers can make informed decisions that enhance operational efficiency and improve project outcomes.

This article outlines essential steps for a successful rental experience, such as:

- Assessing project needs

- Researching equipment providers

- Reviewing lease conditions

It underscores the importance of equipment quality and exceptional customer service in facilitating a seamless rental process. Furthermore, addressing common rental issues like equipment malfunction and delivery delays is crucial for maintaining project timelines and safety standards.

Ultimately, managers must prioritize meticulous planning and informed decision-making when renting abrasive blasters. By recognizing the importance of selecting the right equipment and provider, along with proactively tackling potential challenges, businesses can optimize their operations and achieve outstanding results. Embracing these guidelines ensures that the rental process positively contributes to project success and operational excellence.

Frequently Asked Questions

What are abrasive blasters and their primary function?

Abrasive blasters, commonly known as sand cleaners, are powerful machines designed to clean, smooth, or prepare surfaces by projecting gritty substances at high velocities.

In which industries are abrasive blasters commonly used?

Abrasive blasters find extensive application in various industries, including construction, automotive, and manufacturing.

What are the different types of abrasive blasting devices?

The different types of abrasive blasting devices include pressure units, siphon machines, and wet systems.

When should one use pressure devices versus wet systems?

Pressure devices excel in heavy-duty cleaning, while wet systems are ideal for minimizing dust and are suitable for sensitive surfaces.

What is the projected growth of the global sandblasting machines market?

The global sandblasting machines market is projected to rise from USD 500.86 million in 2024 to USD 764.53 million by 2034.

What is driving the growth in the construction segment of the sandblasting market?

The construction segment is anticipated to expand at a compound annual growth rate (CAGR) of 6.0%, driven by ongoing infrastructure development activities.

Why is it important to select the right blasting equipment?

Choosing the right blasting equipment is critical to enhance productivity, ensure compliance with safety regulations, and avoid inefficiencies and elevated costs.

How does the automotive sector utilize abrasive blasting?

The automotive sector relies on surface cleaning for preparation, especially in the manufacturing of electric vehicles, where effective corrosion prevention is essential.

What trends are influencing contemporary equipment rental services in abrasive blasting?

The growing trend towards recyclable materials and environmentally friendly substances significantly influences contemporary equipment rental services.