Overview

This article provides a comprehensive overview of best practices for project managers engaged in boring under driveway rental projects. It emphasizes the effective use of techniques, equipment, and safety protocols essential for successful project execution. Among the various methods discussed are:

- Horizontal Directional Drilling

- Auger Drilling

These methods are critical for ensuring efficiency and minimizing risks.

Thorough assessments of equipment, along with regular inspections, are paramount in maintaining operational integrity. Adherence to established safety measures not only enhances project efficiency but also significantly reduces potential hazards. By prioritizing these practices, project managers can ensure a seamless workflow and a safer working environment.

In addition to discussing techniques, this article highlights the importance of reliability and quality in equipment rental. By utilizing proven methods and adhering to safety protocols, project managers can achieve optimal results. Engaging with these best practices will undoubtedly lead to improved project outcomes, making it imperative for professionals in the field to stay informed and proactive.

For those looking to elevate their project management strategies, this article serves as a vital resource. We encourage you to explore these best practices further and implement them in your upcoming projects to ensure success and safety.

Key Highlights:

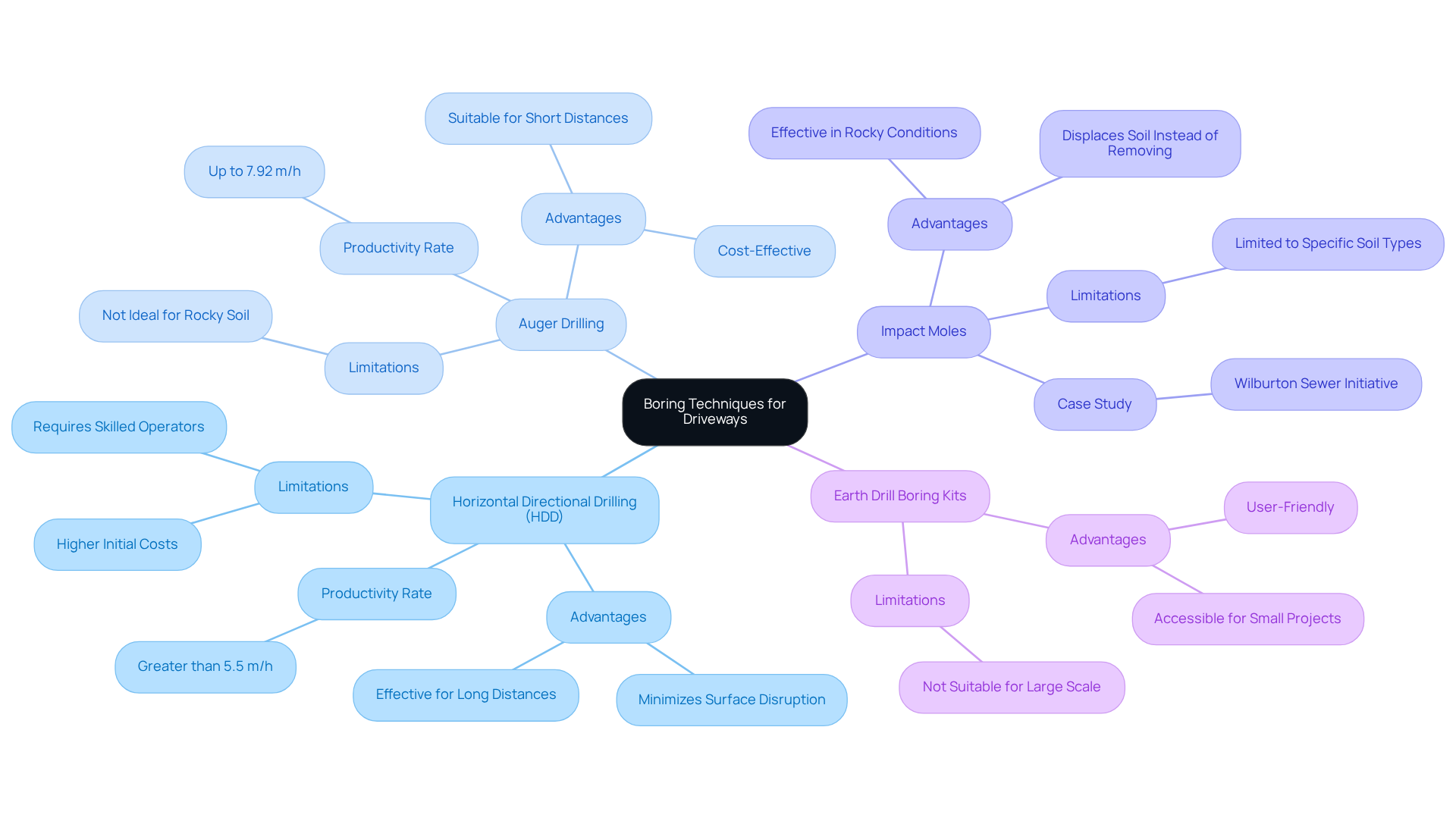

- Horizontal Directional Drilling (HDD) is effective for long distances with minimal surface disruption, achieving higher productivity than conventional methods.

- Auger Drilling is cost-efficient for shorter distances, with comparable installation speeds to traditional techniques.

- Impact Moles are advantageous in rocky or compact soils, displacing rather than removing soil.

- Earth Drill Boring Kits are suitable for small-scale tasks, accessible for contractors and DIY enthusiasts.

- Conducting thorough equipment assessments is crucial for selecting appropriate tools based on project requirements.

- Regular inspections of rental tools prevent breakdowns and enhance productivity.

- Training operators on equipment use reduces accident risks and improves efficiency.

- Adhering to manufacturer guidelines ensures safe and effective tool operation.

- Understanding soil conditions is vital for selecting the right boring technique and ensuring project efficiency.

- Utility conflicts can lead to costly damages, necessitating comprehensive site evaluations before work begins.

- Weather conditions can disrupt project timelines, requiring contingency planning.

- Regular maintenance checks and having backup equipment mitigate risks of device malfunctions.

- Compliance with local regulations and securing necessary permits is essential to avoid delays and fines.

- Implementing safety protocols, including PPE and site safety briefings, significantly reduces workplace injuries.

Introduction

Boring under driveways is a critical yet often overlooked aspect of construction and project management, where the choice of technique can significantly impact efficiency and safety. Various methods are available—from Horizontal Directional Drilling to Auger Drilling—each offering unique benefits tailored to specific site conditions and project requirements. Project managers face the challenge of selecting the most suitable approach, ensuring that their decisions align with both safety protocols and project goals.

To navigate the complexities of equipment rental, it is essential to employ strategies that manage potential risks effectively. Understanding the nuances of each method not only enhances project outcomes but also reinforces safety measures. In addition, utilizing case studies and testimonials can provide valuable insights into the reliability and quality of equipment options, fostering confidence in decision-making.

This article delves into best practices and insights that empower managers to tackle these challenges effectively. By emphasizing the importance of informed choices and strategic planning, we aim to equip project managers with the knowledge necessary to drive successful project execution. Take action now—explore the available methods and ensure your next project is executed with precision and safety.

Explore Boring Techniques for Driveways

When considering boring under driveway rental, several techniques stand out, each offering unique advantages and limitations.

-

Horizontal Directional Drilling (HDD) excels for longer distances and significantly minimizes surface disruption. This method involves drilling a pilot hole, which is then enlarged to accommodate the necessary pipe or conduit. HDD is particularly effective in urban settings where maintaining surface integrity is crucial. Based on industry insights, the typical productivity for conventional open-cut techniques is around 5.5 meters per hour, whereas HDD can achieve greater efficiency, making it a favored option for numerous undertakings.

-

Auger Drilling is ideal for shorter distances and utilizes a rotating helical screw to excavate soil and create a borehole. This technique is not only effective for smaller projects but also tends to be more cost-efficient, making it a popular choice among contractors. Statistics indicate that auger boring can achieve productivity rates comparable to traditional methods, with average installation speeds reaching up to 7.92 meters per hour. As Robert Carpenter, Editor-in-Chief, noted, "Not all machines are created equal," emphasizing the importance of selecting quality equipment for optimal results.

-

Impact Moles utilize a pneumatic tool to create a borehole by displacing soil rather than removing it. This technique is particularly advantageous in rocky or compacted soil conditions, where traditional methods may struggle. The Wilburton Sewer initiative serves as a case study, demonstrating the effectiveness of impact moles in challenging terrains.

-

Earth Drill Boring Kits enable manual boring and are best suited for small-scale tasks. Their ease of use makes them accessible for contractors and DIY enthusiasts alike, and they can be conveniently rented from equipment rental companies such as EZ Equipment Rental. By utilizing the right tools, managers can improve their operational efficiency.

By thoroughly evaluating the scale, soil conditions, and necessary depth, managers can choose the most appropriate method for boring under driveway rental, ensuring successful results while maximizing efficiency and cost-effectiveness. Furthermore, being mindful of typical mistakes, such as incorrect tool choice or insufficient site evaluation, can further improve the success of the endeavor.

Implement Best Practices for Rental Equipment Use

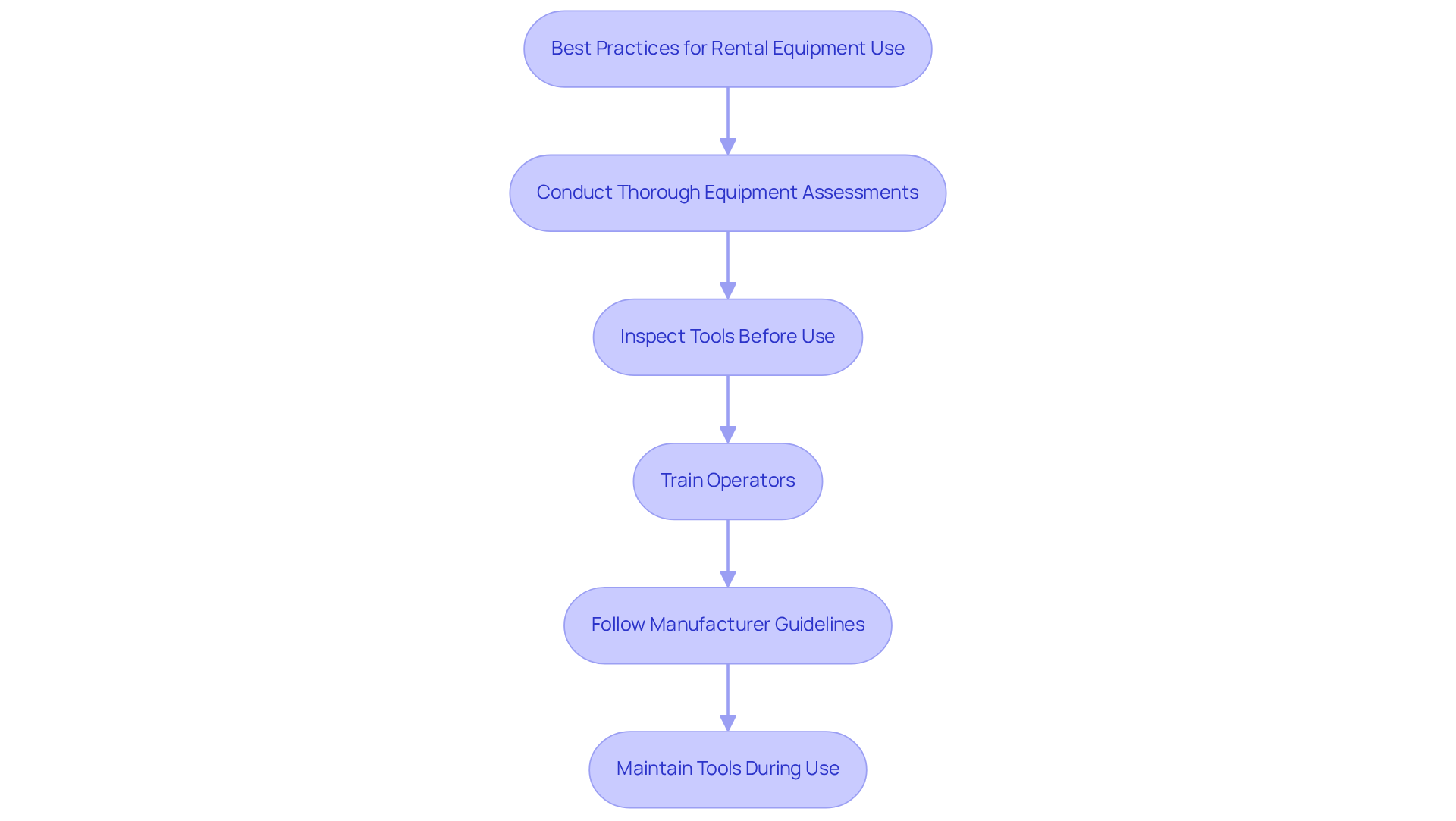

To ensure optimal use of rental equipment for boring under driveway rental, project managers must adhere to best practices that guarantee efficiency and reliability.

-

Conduct Thorough Equipment Assessments: Before renting, it is critical to evaluate the specific requirements of the task, including soil type, bore distance, and the size of the pipe or conduit. This thorough evaluation is essential for selecting the appropriate tools, ensuring a smooth operation.

-

Inspect Tools Before Use: Always conduct a comprehensive examination of rental tools for signs of wear or damage prior to commencing work. Routine evaluations can prevent unforeseen machinery breakdowns, which are often costly and can lead to project delays. In fact, statistics show that regular inspections can save both time and money by averting breakdowns and downtime, significantly enhancing overall productivity.

-

Train Operators: It is imperative that all operators receive adequate training on the equipment being used. Familiarity with machinery not only reduces the risk of accidents but also enhances operational efficiency. A well-trained operator can swiftly identify potential issues during use, further safeguarding the project and ensuring a successful outcome.

-

Follow Manufacturer Guidelines: Adhering strictly to the manufacturer's operating instructions and safety guidelines is non-negotiable. This practice ensures safe and effective tool utilization, minimizing the risk of accidents and enhancing performance throughout the project.

-

Maintain Tools During Use: Regularly checking fluid levels, listening for unusual noises, and monitoring the tools' performance throughout the rental period is essential. Proactive maintenance during operation helps identify minor issues before they escalate into major problems, thereby extending the lifespan and reliability of the machinery.

By implementing these optimal methods, managers can significantly enhance the dependability and efficiency of leased tools, leading to successful project outcomes. Engaging with experienced suppliers can also provide valuable insights into equipment care, further ensuring safety and efficiency on the job site.

Address Challenges in Driveway Boring Projects

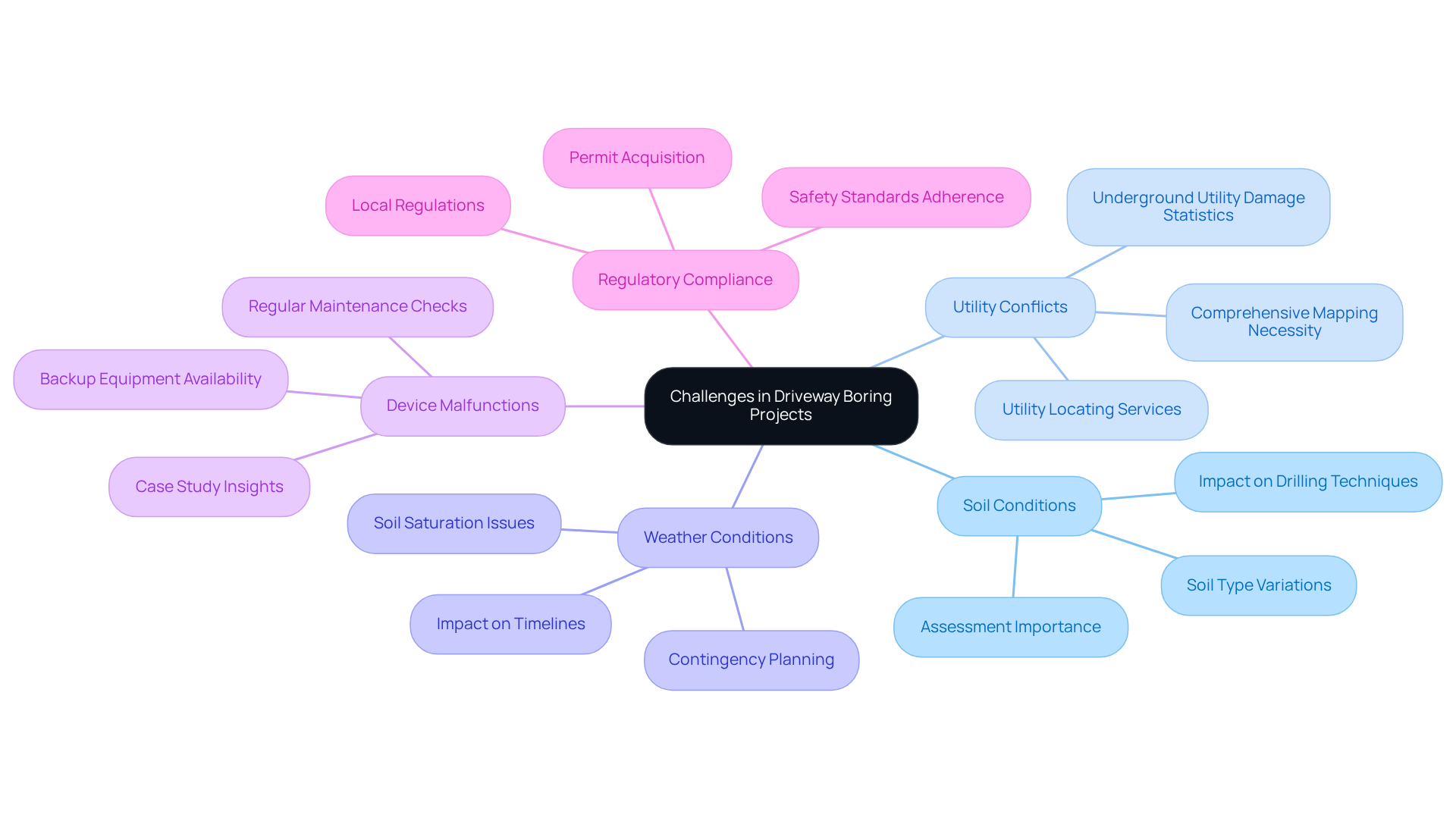

Boring under driveway rental projects present several challenges that project managers must navigate effectively.

-

Soil Conditions play a crucial role in determining the appropriate drilling technique. Variations in soil type, such as rocky or compact soil, may necessitate the use of more robust equipment or alternative methods like impact moles. Understanding the soil composition is essential, as it directly affects the efficiency and safety of the drilling process. For instance, clay soils can lead to longer drilling times due to their density, making it imperative to assess soil conditions thoroughly before commencing work.

-

Utility Conflicts pose significant risks during boring operations. Statistics reveal that over 400,000 incidents of underground utility damage occur annually in the U.S., highlighting the necessity for comprehensive site evaluations. By employing utility locating services prior to starting work, project managers can avoid damaging existing infrastructure, ensuring smoother execution. As one manager noted, "Comprehensive utility mapping is not merely a precaution; it's crucial for preventing expensive delays and repairs."

-

Weather Conditions can also disrupt timelines and impact equipment performance. It is essential for project managers to develop contingency plans to address potential delays caused by inclement weather, thereby keeping projects on track. For example, heavy rains can lead to soil saturation, complicating the boring process and necessitating adaptive strategies.

-

Device Malfunctions represent another challenge that can halt progress and incur costly delays. Regular maintenance checks and having backup equipment readily available are key strategies to mitigate this risk, allowing for swift recovery in the event of malfunctions. A case study from a recent project underscored the effectiveness of this approach, revealing that having a backup drill on-site significantly reduced downtime when the primary drill failed.

-

Regulatory Compliance is essential before initiating any boring work. Adhering to local regulations and securing necessary permits ensures compliance with safety standards and environmental guidelines, which can vary by location. Failure to obtain the proper permits can result in project delays and potential fines.

By proactively addressing these challenges, project managers can significantly enhance their chances of success, reduce disruptions, and ultimately achieve more efficient and dependable outcomes.

Ensure Safety Protocols Are Followed

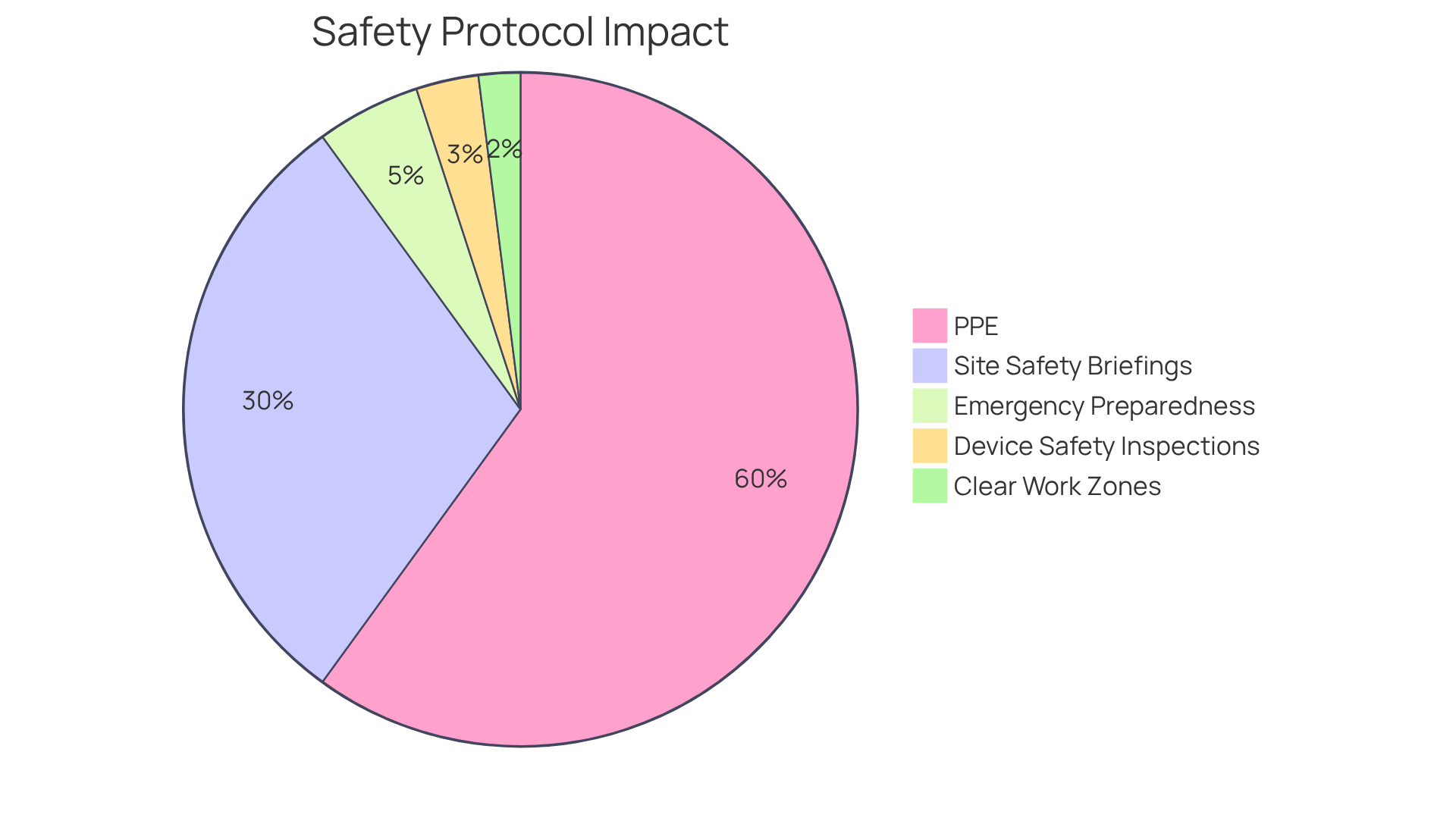

To ensure a safe working environment during driveway boring projects, project managers must implement essential safety protocols.

-

Personal Protective Equipment (PPE) is paramount; all team members must wear suitable PPE, including hard hats, gloves, protective glasses, and steel-toed boots. Proper use of PPE can reduce workplace injuries by up to 60%, significantly decreasing incidents of eye injuries, respiratory conditions, and hand injuries. Notably, around 60% of employees utilize PPE while working, underscoring the necessity of adherence in enhancing protection.

-

Site Safety Briefings are crucial for keeping all team members informed about potential dangers and protective measures. Research indicates that organized training programs focused on protection can lead to a 30% decrease in injury rates. Furthermore, businesses conducting regular training sessions have noticed a 25% decline in workplace injuries, highlighting the effectiveness of these briefings in fostering a culture that prioritizes well-being.

-

Emergency Preparedness involves creating and conveying a thorough emergency response strategy detailing procedures for addressing device failures, accidents, or unfavorable weather conditions. This proactive approach is essential for minimizing risks and ensuring swift action when incidents occur.

-

Device Safety Inspections require performing comprehensive pre-operation inspections on all machinery to ensure it is in secure working order prior to use. This practice not only enhances security but also boosts worker confidence in the equipment being utilized.

-

Clear Work Zones must be established, utilizing barriers or signage to restrict unauthorized personnel from entering the work area. This measure is critical for preventing accidents and maintaining focus on the tasks at hand.

By prioritizing these protective protocols, project managers can safeguard their teams and ensure that boring under driveway rental projects are completed efficiently and without incident. Advocates for protection assert, 'Protection should never be a priority. It should be a precondition.' This mindset fosters a culture of safety that benefits everyone involved.

Conclusion

Boring under driveways is a multifaceted endeavor that demands meticulous planning and execution. Selecting the right boring technique, such as Horizontal Directional Drilling or Auger Drilling, is essential to meet specific project needs. Furthermore, the effective use of rental equipment, thorough site evaluations, and proactive safety measures are crucial for ensuring successful project outcomes while minimizing risks.

Key insights highlight the necessity of understanding soil conditions, addressing potential utility conflicts, and maintaining equipment to avoid costly delays. Implementing robust safety protocols not only safeguards workers but also enhances operational efficiency. By focusing on these critical aspects, project managers can navigate the complexities of driveway boring projects with confidence.

Ultimately, the success of boring under driveway rental projects hinges on meticulous preparation and execution. Embracing these best practices streamlines operations and fosters a culture of safety and reliability. Project managers are encouraged to prioritize thorough assessments, staff training, and proactive maintenance to overcome challenges and achieve seamless project execution. Taking these steps will enhance project efficiency and contribute to a safer working environment for all involved.

Frequently Asked Questions

What are the main techniques for boring under driveways?

The main techniques include Horizontal Directional Drilling (HDD), Auger Drilling, Impact Moles, and Earth Drill Boring Kits.

What is Horizontal Directional Drilling (HDD) and its advantages?

HDD is a technique that excels for longer distances and minimizes surface disruption. It involves drilling a pilot hole that is then enlarged for the necessary pipe or conduit. HDD is particularly effective in urban settings where maintaining surface integrity is crucial.

How does the productivity of HDD compare to conventional methods?

HDD can achieve greater efficiency, with conventional open-cut techniques typically producing around 5.5 meters per hour, while HDD can exceed this rate.

What is Auger Drilling and when is it most effective?

Auger Drilling utilizes a rotating helical screw to excavate soil and create a borehole. It is ideal for shorter distances and is more cost-efficient, making it popular among contractors.

What are the productivity rates for Auger Drilling?

Auger boring can achieve installation speeds of up to 7.92 meters per hour, comparable to traditional methods.

What are Impact Moles and their benefits?

Impact Moles use a pneumatic tool to create a borehole by displacing soil, making them advantageous in rocky or compacted soil conditions where traditional methods may struggle.

Can you provide an example of where Impact Moles have been effective?

The Wilburton Sewer initiative serves as a case study demonstrating the effectiveness of impact moles in challenging terrains.

What are Earth Drill Boring Kits and who can use them?

Earth Drill Boring Kits enable manual boring and are best suited for small-scale tasks. They are accessible for both contractors and DIY enthusiasts and can be rented from equipment rental companies.

How can managers choose the appropriate boring method?

Managers should evaluate the scale, soil conditions, and necessary depth to select the most appropriate method for boring under driveways, ensuring successful results while maximizing efficiency and cost-effectiveness.

What common mistakes should be avoided in boring under driveways?

Common mistakes include incorrect tool choice and insufficient site evaluation, which can hinder the success of the boring endeavor.